Patents

Literature

41results about How to "Avoid big swings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

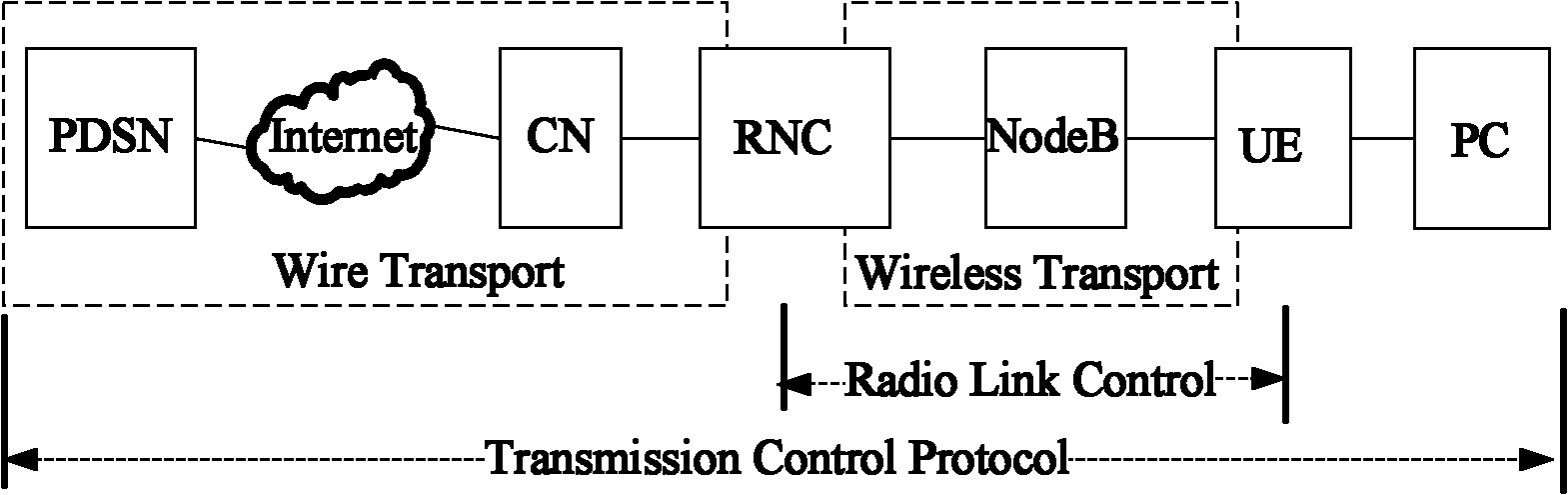

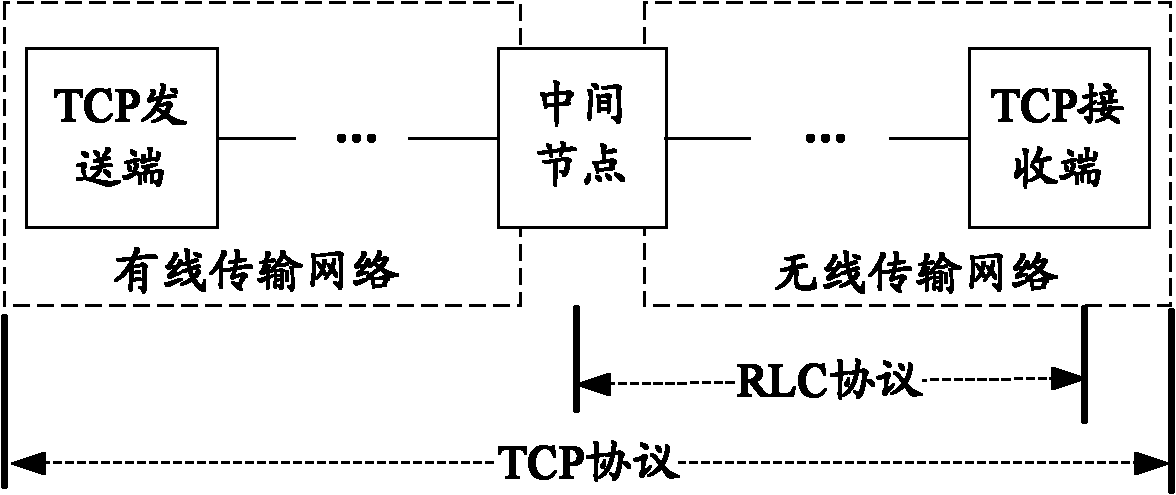

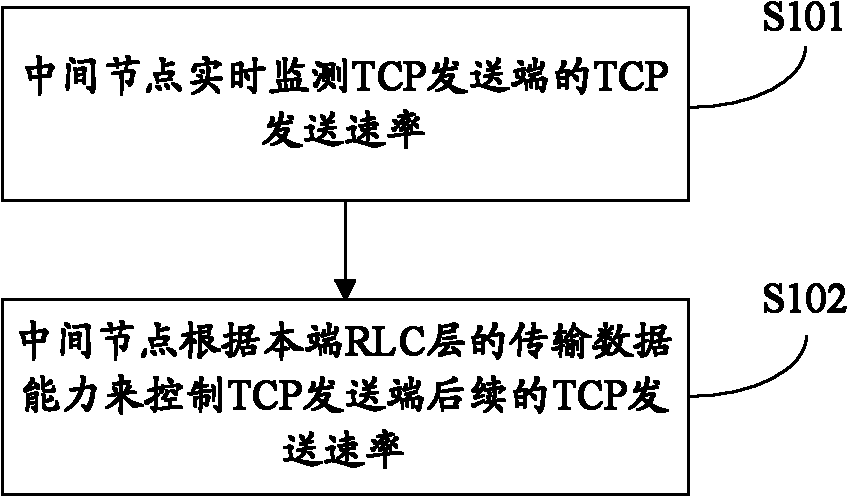

Method and system for controlling data transmission of radio network

InactiveCN103001727ASmooth connectionAvoid big swingsError preventionRadio networksRadio Network Controller

The invention discloses a method and a system for controlling data transmission of a radio network. The method includes the steps of controlling TCP (transmission control protocol) data transmission on an intermediate node of a transmission network, enabling actual TCP data transmission capability of a TCP transmitter to be close to radio network bandwidth so as to realize good link between an RLC (radio link control) level and a TCP level, and simultaneously avoiding substantial fluctuation of transmission loopback delay. Up-level TCP data transmission can be controlled according to low-level transmission capability of a radio resource, cache data size on an RNC (radio network controller) can be kept within a reasonable range, and waste of bandwidth of a radio network level is avoided.

Owner:ZTE CORP

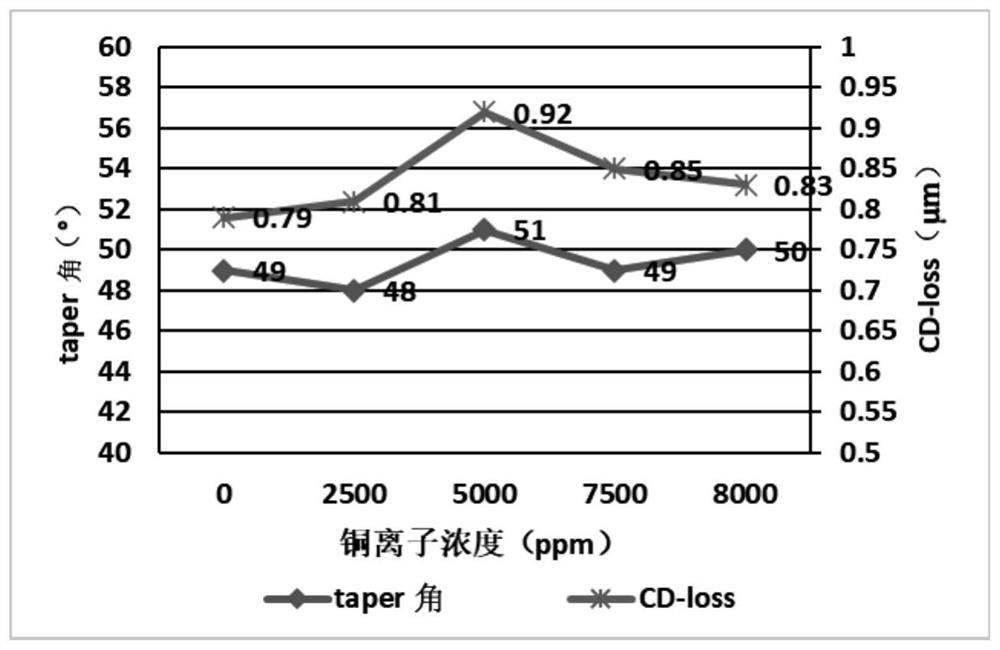

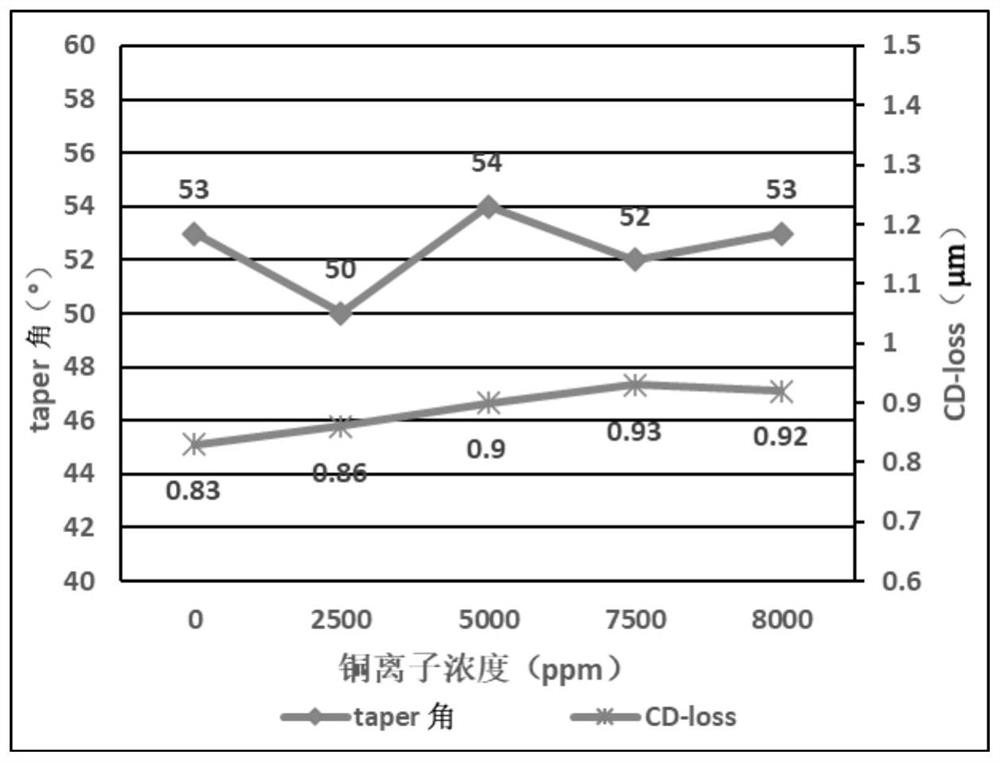

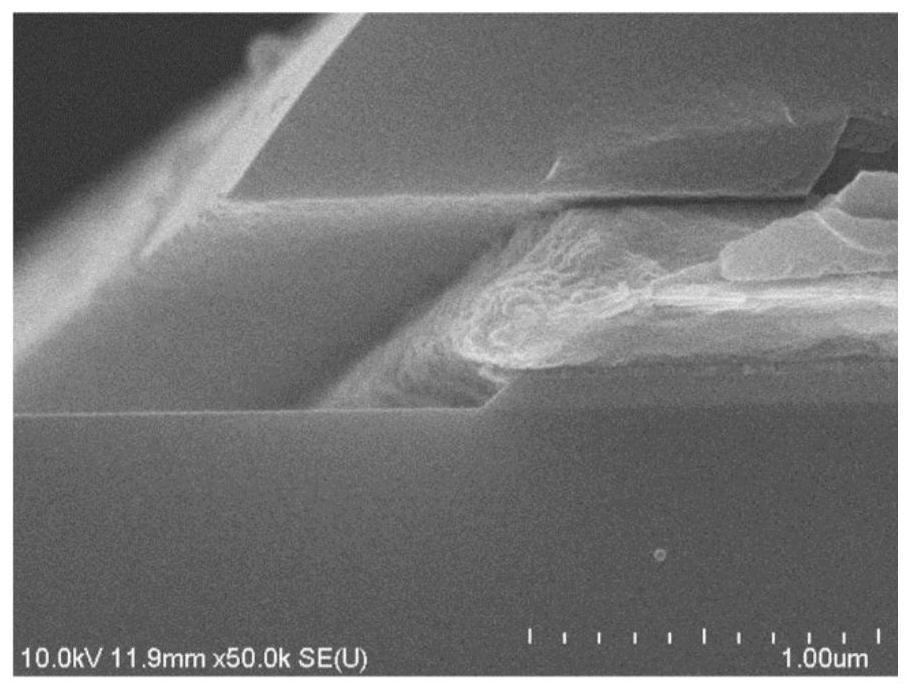

Etching solution and etching replenishing solution for copper/molybdenum (niobium)/IGZO film layer, and preparation methods and application of etching solution and etching replenishing solution

PendingCN111808612ASimultaneous etchEtching stabilitySolid-state devicesSemiconductor/solid-state device manufacturingHydrogen SulfateOrganic base

The invention provides an etching solution and an etching replenishing solution for a copper / molybdenum (niobium) / IGZO film layer, and preparation methods and application of the etching solution and the etching replenishing solution. The etching solution comprises the following components of: 5-15% of hydrogen peroxide, 0.1-10% of nitric acid and / or sulfuric acid, 0.1-2% of hydrofluoric acid and / or ammonium fluoride, 1-10% of an organic acid, 1-10% of organic base, 0.08-1% of an azole metal corrosion inhibitor, 0.1-1% of phenyl urea, and the balance of water. The etching replenishing solutioncomprises the following components: 5-30% of nitric acid and / or sulfuric acid, 0.1-5% of hydrofluoric acid and / or ammonium fluoride, 5-30% of an organic acid, 5-30% of an organic base, 0.1%-2% of an azole metal corrosion inhibitor, and the balance of water. With the etching solution and the etching replenishing solution adopted, an SD / IGZO film layer has a good slope angle after being etched twice, the serioustrailing of the IGZO film layer is prevented, the number of applied photomasks is reduced, the copper loading capacity is high, and the production cost is low.

Owner:江苏和达电子科技有限公司 +1

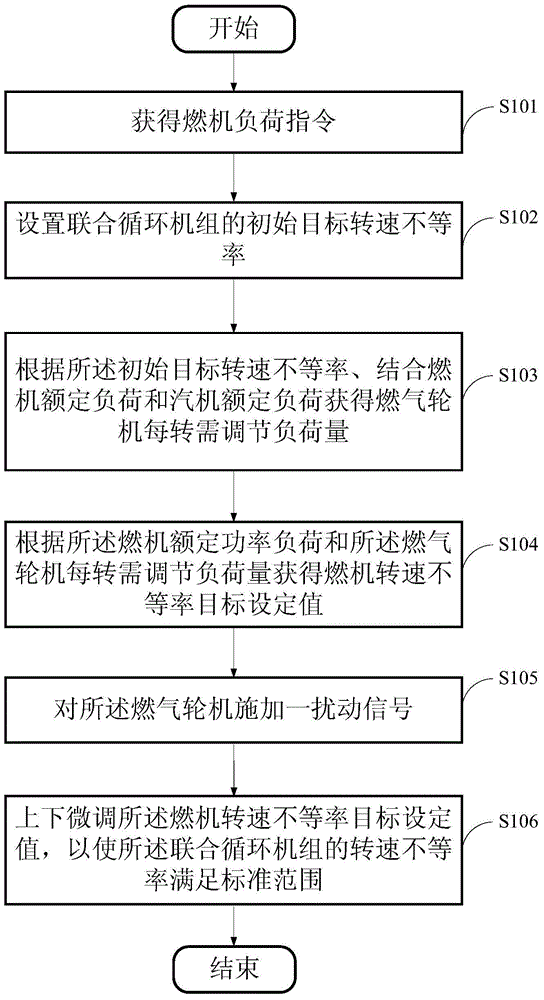

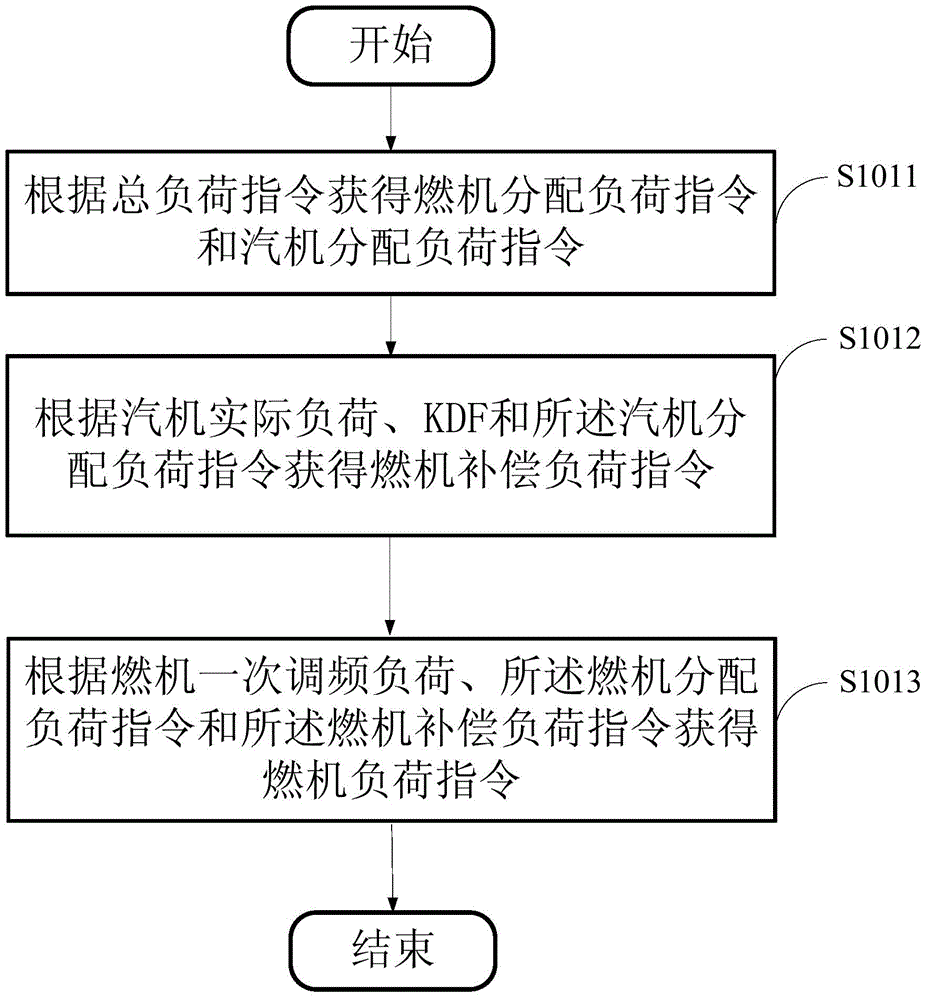

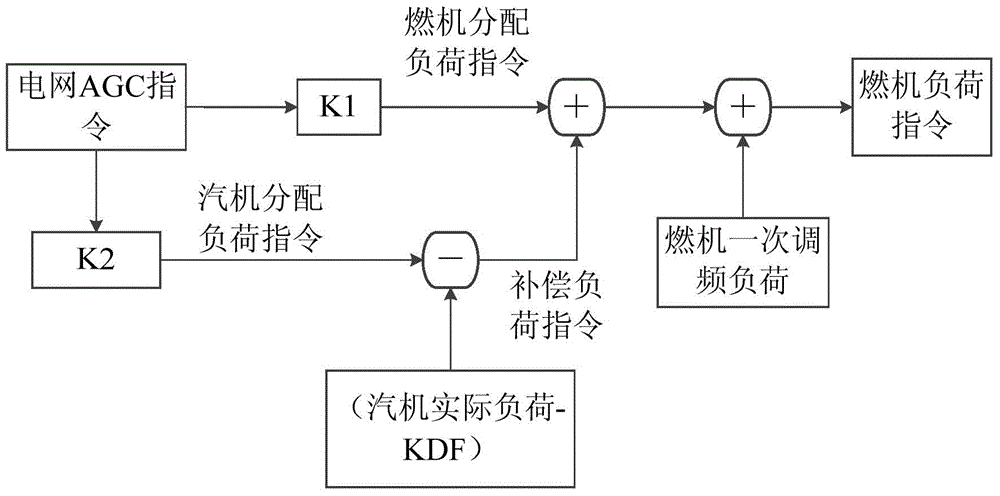

Primary frequency modulation testing method, device and system of gas and steam combined cycle unit

ActiveCN104950254AEasy to monitorAvoid big swingsDynamo-electric machine testingSystem stabilityTarget setting

The invention provides a primary frequency modulation testing method, device and system of a gas and steam combined cycle unit. The method includes acquiring load commands of a gas turbine, setting diversity factor of an initial target revolving speed of the combined cycle unit; acquiring load to be adjusted in each turn of the gas turbine according to the diversity factor of the initial target revolving speed, the rated loads of the gas turbine and a steam engine; acquiring target setting values of diversity factor of the revolving speed according to the rated load of the gas turbine and the load to be adjusted in each turn of the gas turbine; applying a disturbance signal to the gas turbine; finely adjusting the target setting value of the diversity factor of the revolving speed of the gas turbine up and down so as to enable the diversity factor of the revolving speed of the combined cycle unit to meet the standard range. Expected load response loop of the steam engine is added to a frequency modulation load command loop of the gas turbine, so that reverse action of the load of the gas turbine is prevented. The primary frequency modulation testing method can optimize and adjust control parameters in real time, reverse action of the load of the gas turbine is avoided, and system is more stable and safer.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

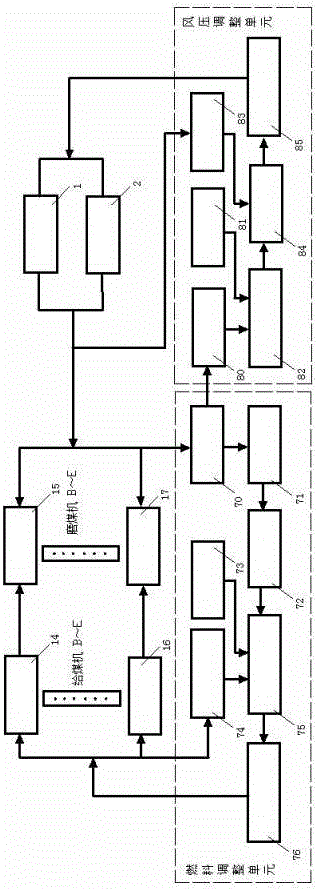

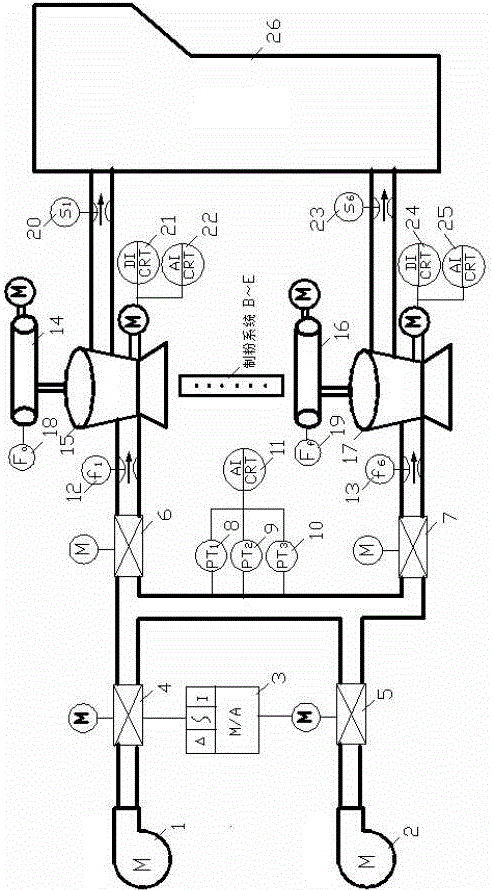

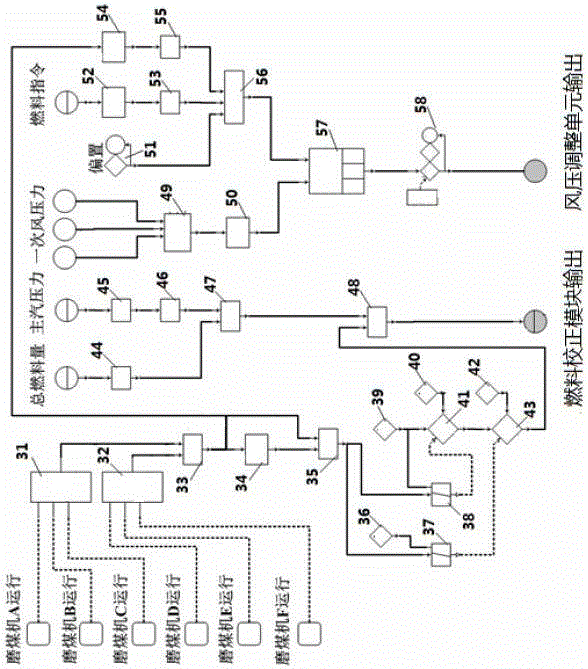

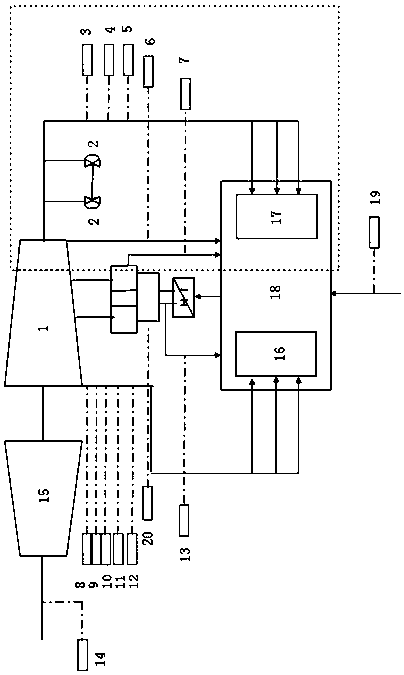

Anti-interference and energy-saving type thermal power generating unit powder making control system

PendingCN106801887AAnti-cloggingImprove anti-interference abilityFuel supply regulationFuel feeding arrangementsSteam pressureControl system

The invention provides an anti-interference and energy-saving type thermal power generating unit powder making control system. The anti-interference and energy-saving type thermal power generating unit powder making control system comprises a plurality of coal feeders, a plurality of coal mills, two primary air fans, a fuel adjusting unit and an air pressure adjusting unit. A counting module and a judgment module in the fuel adjusting unit are used for monitoring the running state of the coal mills, and once start or stop signals of the coal mills are monitored, the control system is immediately started. A fuel measuring module, a main steam pressure and fuel correcting module and a fuel output module conduct operation, then a fuel instruction is rapidly adjusted, and the stability of the fuel amount of a hearth is maintained. Meanwhile, the primary air pressure is rapidly adjusted through an air pressure correcting module, an instruction module and an adjusting module in the air pressure adjusting unit, and the dynamic matching relation between the average output of the coal mills and the primary air pressure is kept. The anti-interference and energy-saving type thermal power generating unit powder making control system solves the technical problem that in the coal mill start and stop processes, main parameters of the unit greatly fluctuate; the energy consumption of the primary air fans is reduced, blockage of the powder making control system can be prevented, and the safety performance, the stability performance and energy saving indexes of the unit are comprehensively improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

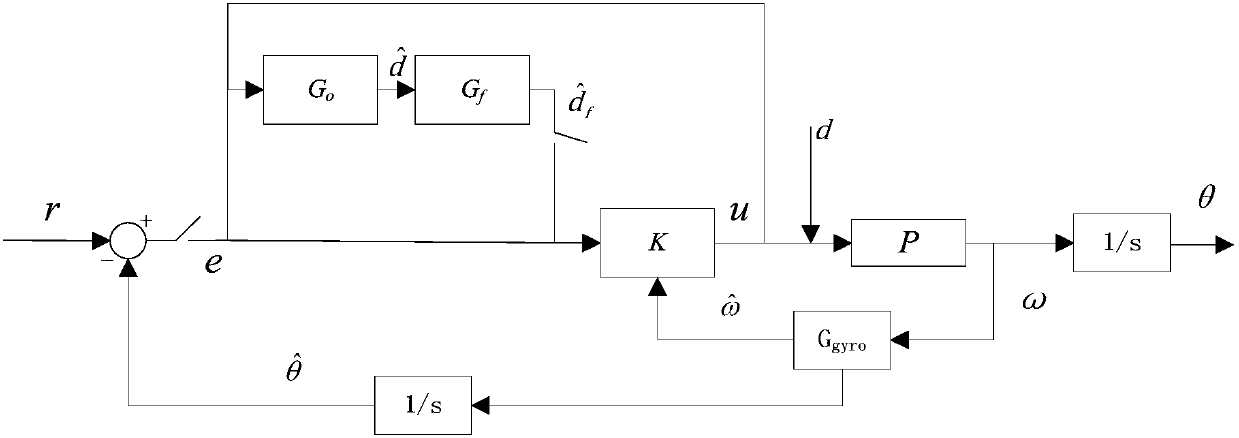

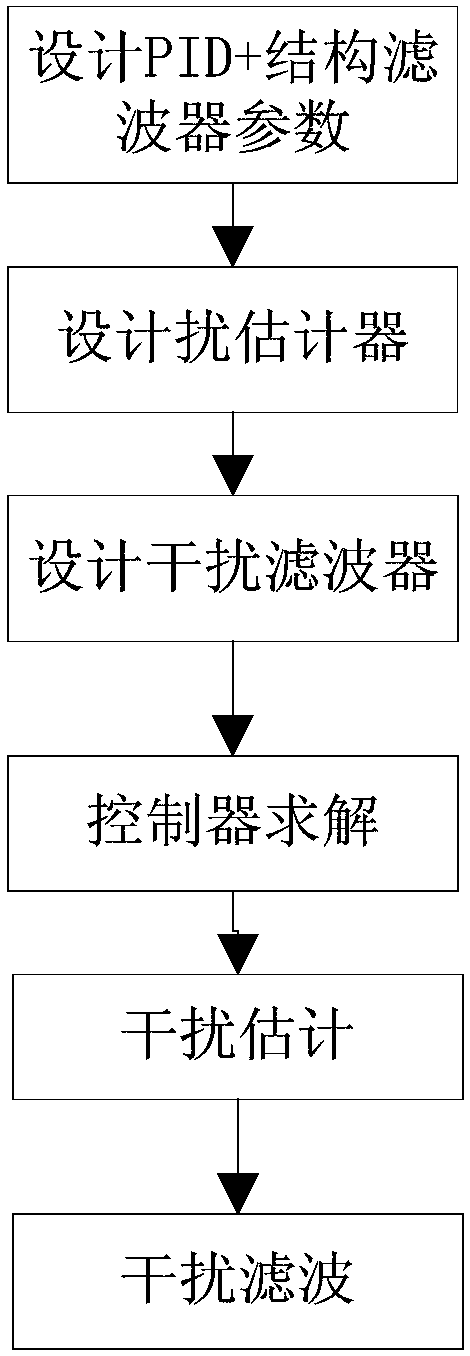

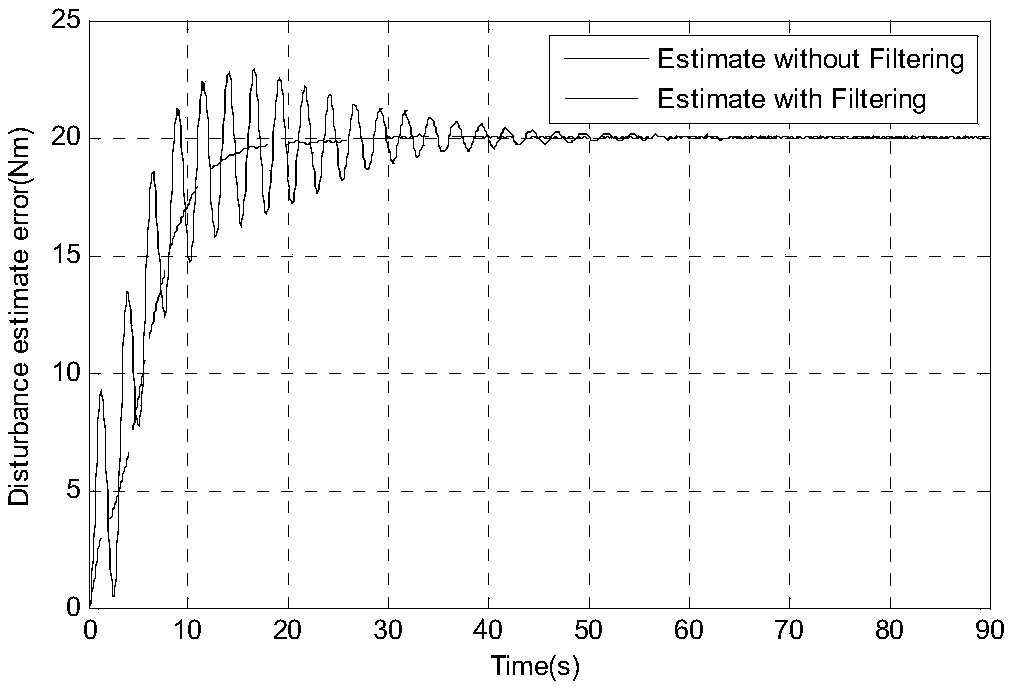

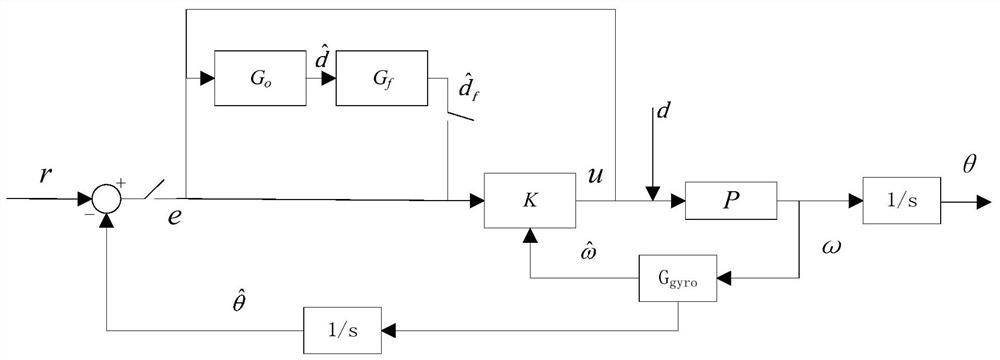

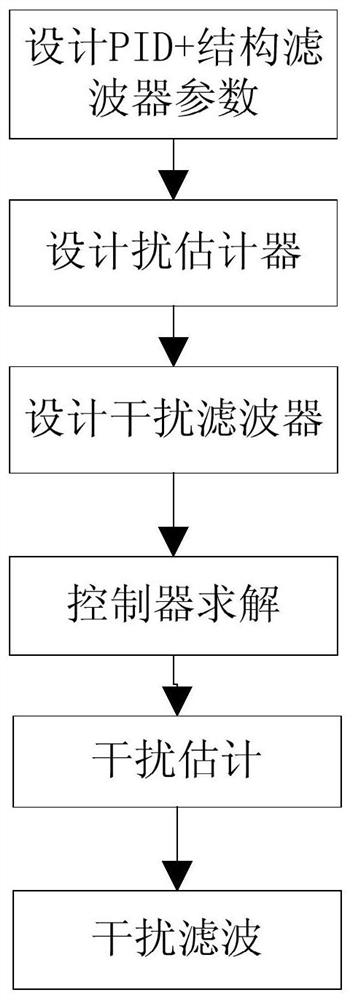

Rapid spacecraft disturbance torque on-orbit closed-loop identification method, system and medium

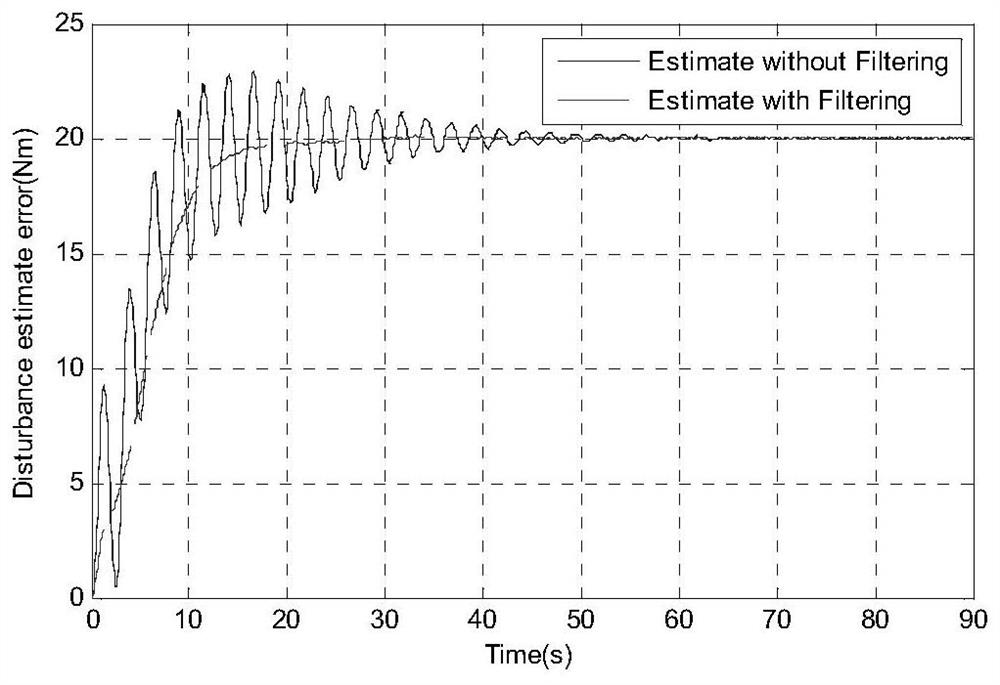

ActiveCN108279695AAdjust the convergence rateFast convergenceCosmonautic vehiclesCosmonautic partsGyroscopeAttitude control

The invention discloses a rapid spacecraft disturbance torque on-orbit closed-loop identification method, system and medium, and provides a rapid orbital transfer disturbance torque closed-loop identification method to solve the attitude control problem of a spacecraft with flexural vibration and liquid sloshing in orbital transfer during ignition of a main engine. The method includes the steps: (1) integrating angular speed measured by a gyroscope to obtain an attitude angle and calculating needed control quantity by a controller; (2) inputting data to a disturbance estimation equation according to attitude angle input and the calculated control quantity to obtain a preliminary estimation value of disturbance torque; (3) further inputting the preliminary estimation value of the disturbance torque to a filter, and filtering low-frequency flexural and liquid sloshing information to obtain final disturbance estimation values. By the method, when flexural vibration and liquid sloshing arepresent, the disturbance torque can be rapidly and accurately identified. Disturbance identification results can be directly fed forward to an integral term, so that attitude overshoot caused by start of the main engine can be decreased.

Owner:BEIJING INST OF CONTROL ENG

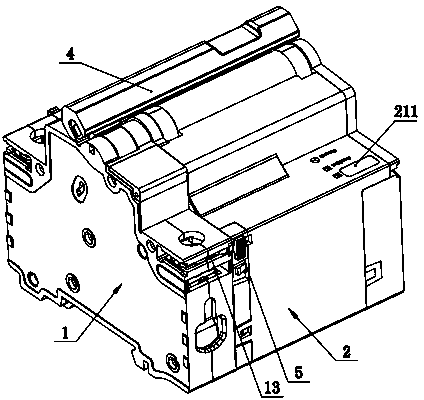

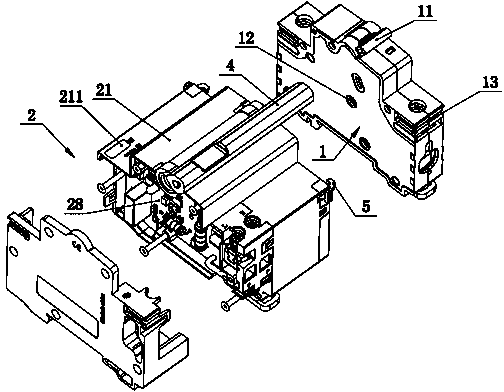

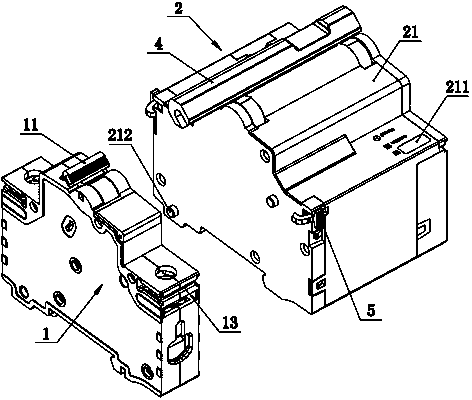

Circuit breaker controlled by remote wireless signal

InactiveCN103400726AEasy to controlImprove securityProtective switch operating/release mechanismsOvervoltageElectricity

The invention discloses a circuit breaker controlled by a remote wireless signal, which comprises a circuit breaker body equipped with a manual control handle, an automatic reclosing mechanism, and a remote signal controller, wherein the automatic reclosing mechanism comprises an outer casing, an automatic control handle, a linkage rod, a reset torsion spring, a coil, a coil bracket, an electromagnet, and an integrated circuit board; the electromagnet is electrically connected with and controlled by the integrated circuit board; an electric leakage time delay protection module, an overvoltage and undervoltage protection module, a rectifying transformation module, and a communication module kept in communication with the remote signal controller are further arranged on the integrated circuit board. Through the structure, a user can remotely control the open and close of the circuit breaker body through a wireless signal, so that the user can control the circuit more conveniently, and the safety and the reliability of electricity using are increased.

Owner:YUEQING GUOLONG ELECTRIC

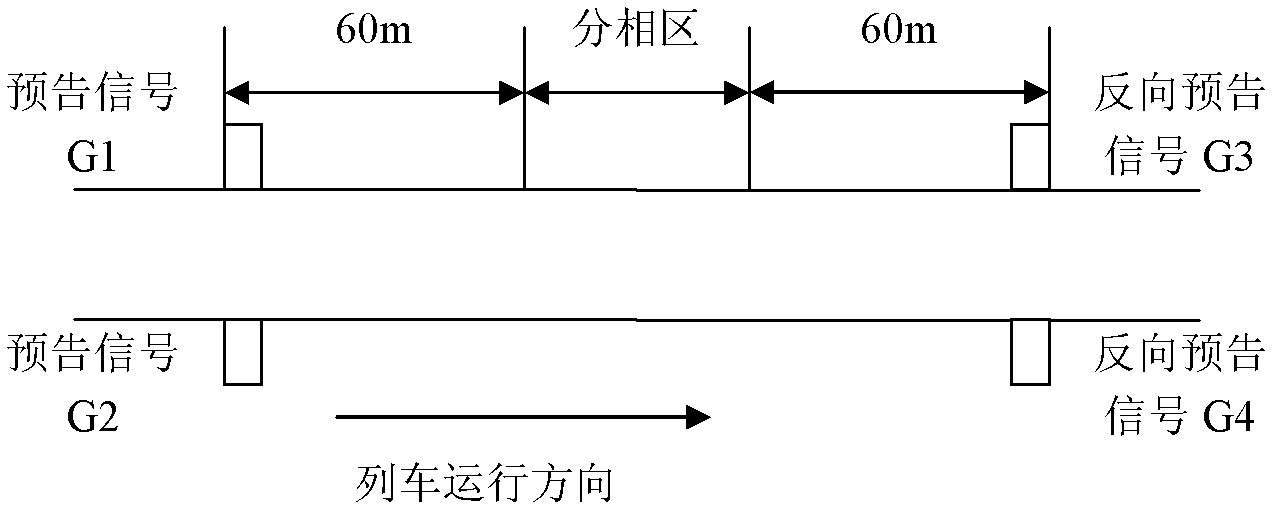

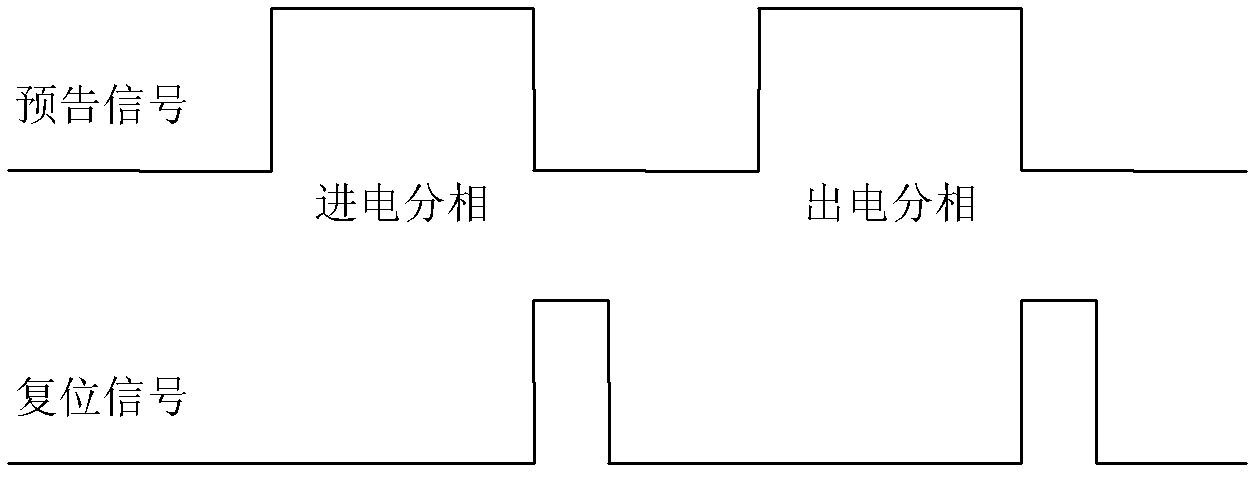

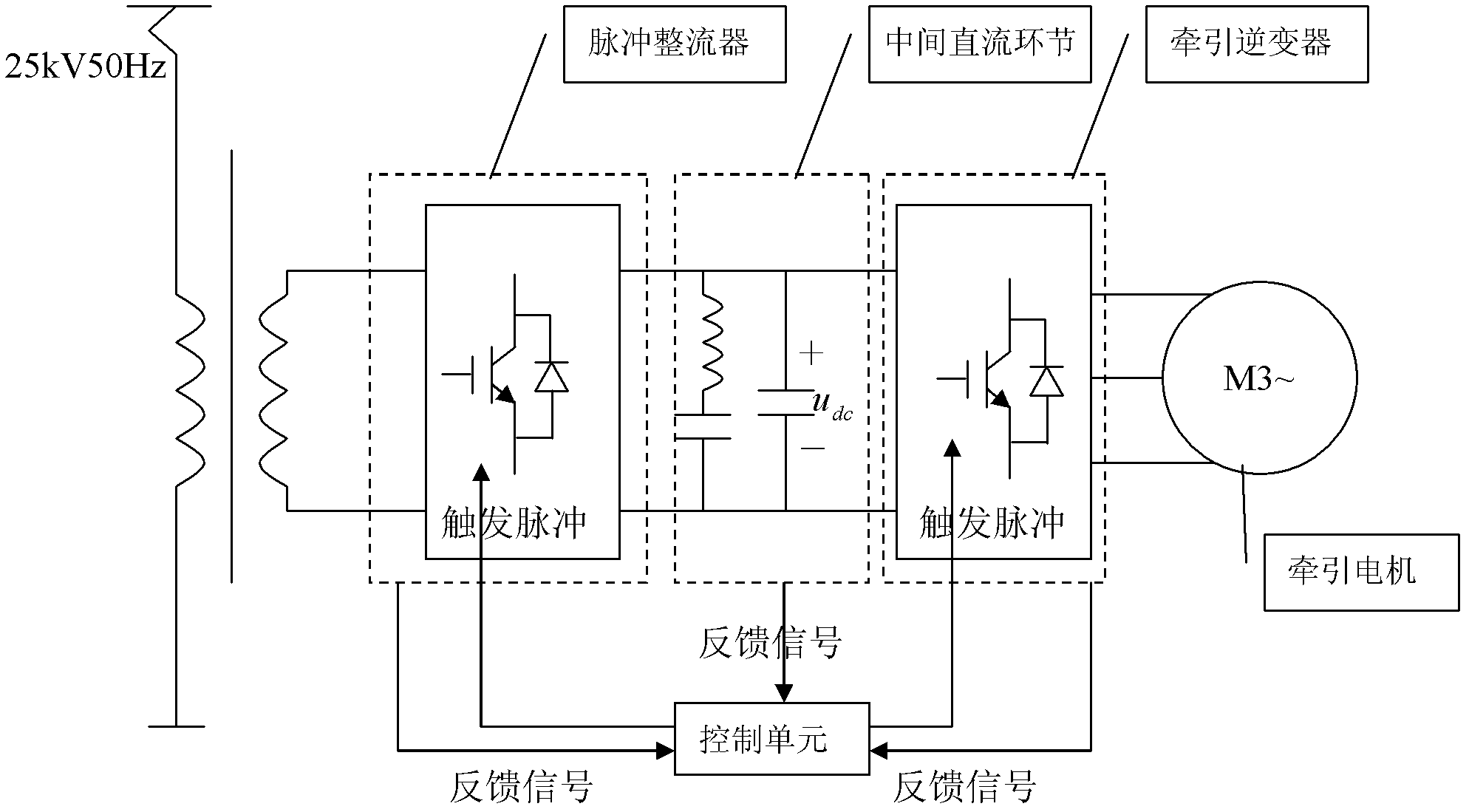

Coasting over-voltage split-phase pulse blocking and pulse unblocking method for alternating-current transmission system

The invention discloses a coasting over-voltage split-phase pulse blocking and pulse unblocking method for an alternating-current transmission system. After the alternating-current transmission system receives electric split-phase entry signals and confirms the signals, a control system controls torque instruction voltage or reference torque of a traction converter to drop to zero according to a certain slope, and then blocking pulse instructions are sent out to block the traction converter. After pulse blocking is relieved by a train through electric phase splitting, the control system controls the torque instruction voltage or reference torque of the traction converter to rise to a calculation value of the control system, and then turns to normal operating conditions. Using the method can avoid defective impulses generated during blocking of the converter by the blocking pulses, avoid high fluctuation of intermediate direct-current voltage of the traction converter in pulse unblocking, and improve performance of a traction transmission system.

Owner:SOUTHWEST JIAOTONG UNIV

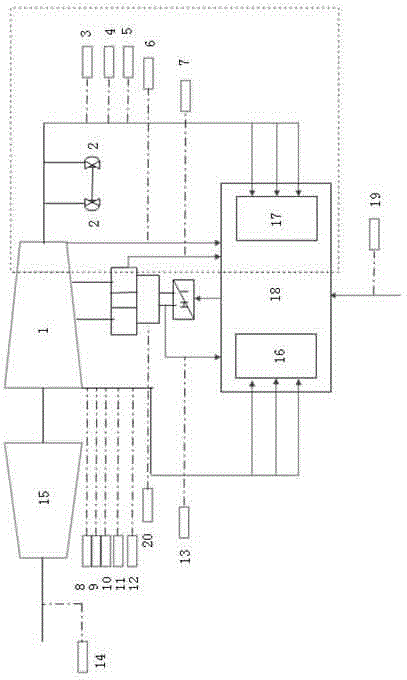

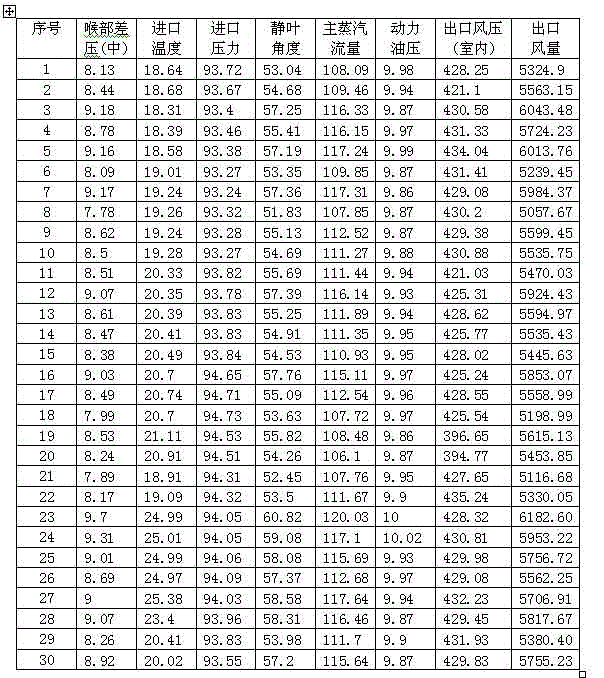

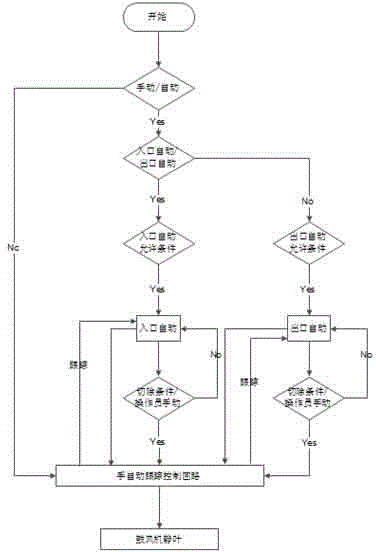

Method for controlling air volume of air blower

ActiveCN105441609AStable working conditionMonitor and judge abnormal conditions in timeBlast furnace detailsThermodynamicsAir volume

The invention relates to a method for controlling the air volume of an air blower. According to the method, the idea that automatic control over a stationary blade is conducted by means of the inlet air volume of the air blower is provided for the first time. A calculation method for the inlet air volume is provided. Measurement signals obtained through indoor measurement devices and slightly restrained by environment factors can be accurately used for calculating the inlet air volume. The measurement effect that the inlet air volume is consistent with the outlet air volume is achieved. The stability and the automatic input rate of an automatic air volume control loop are increased.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

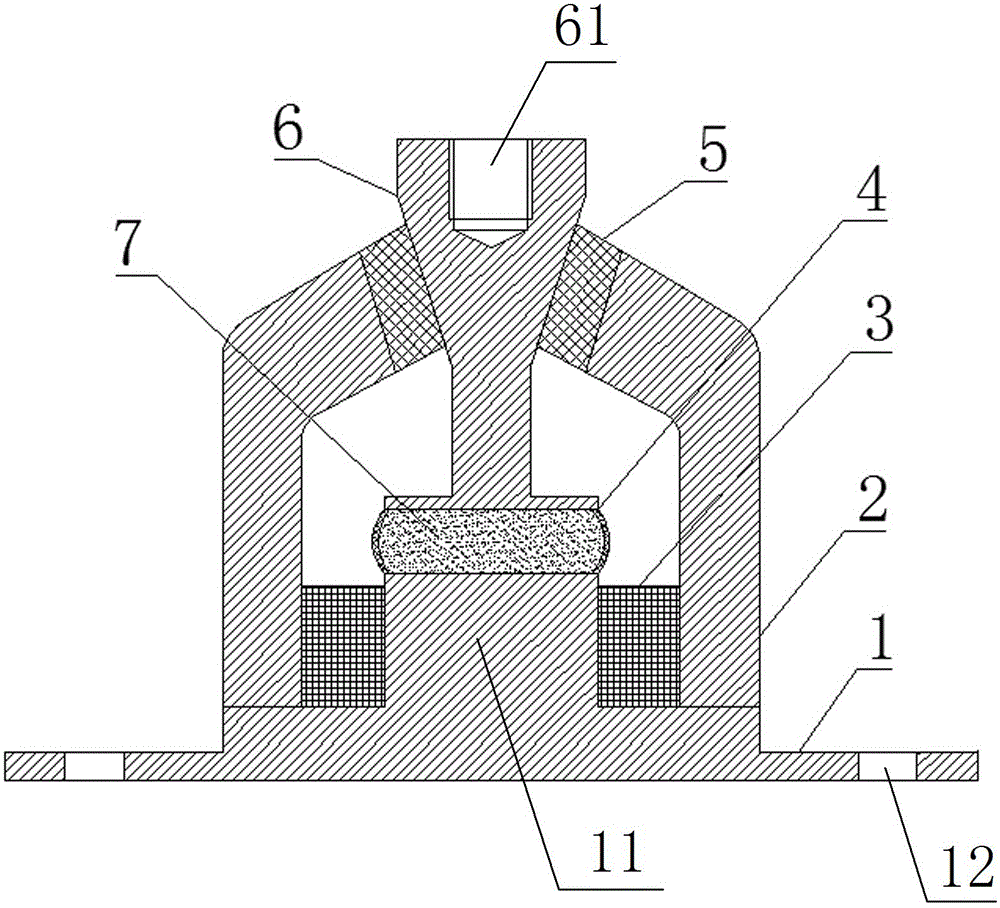

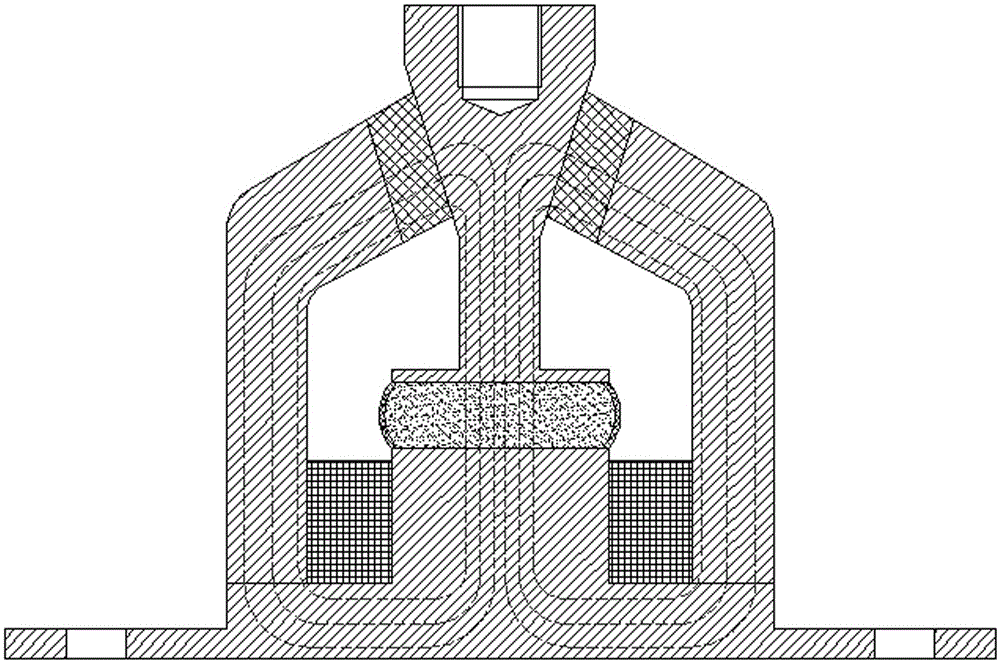

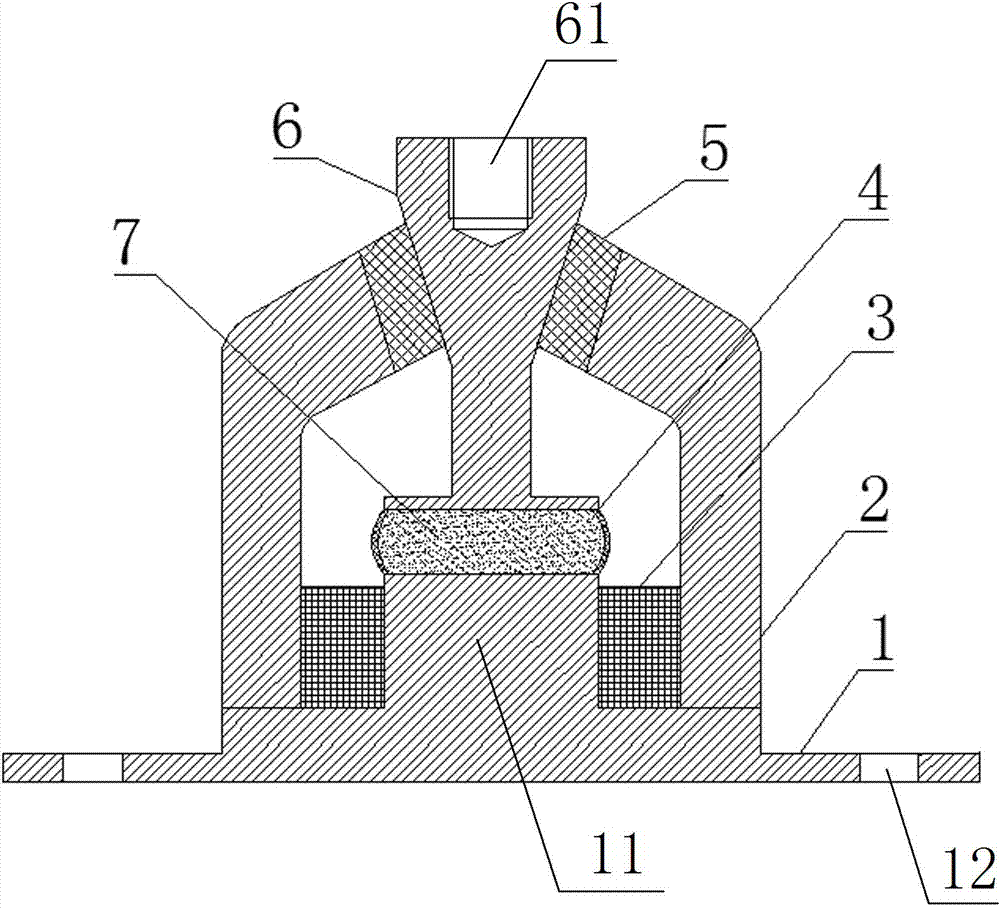

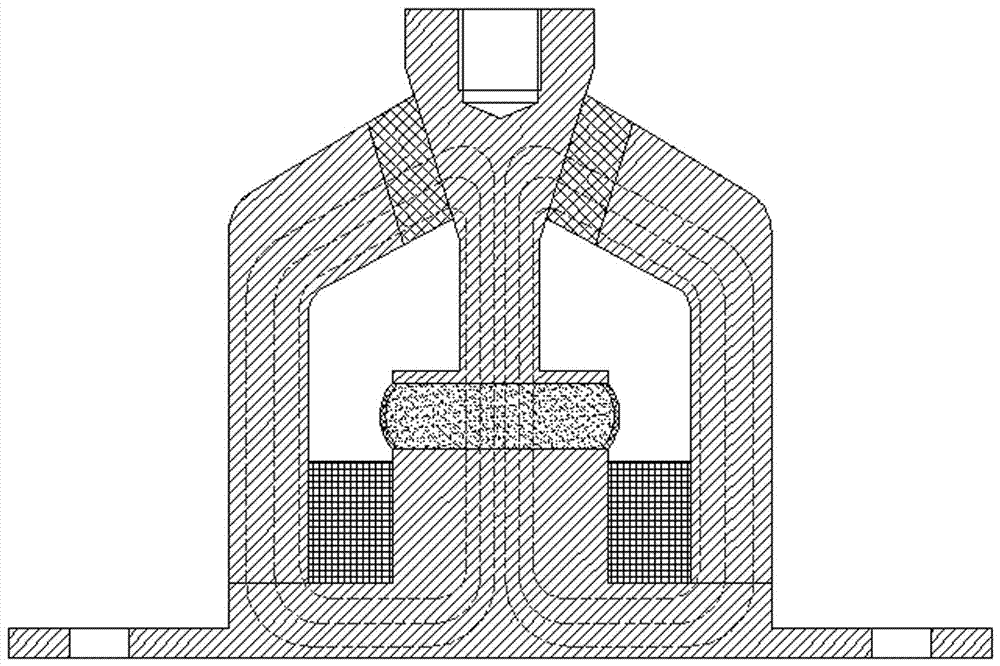

Magneto-rheological vibration isolation support based on mixed mode

ActiveCN105020328AReal-time adjustment of mechanical propertiesAchieve isolationSpringsShock absorbersElastomerEngineering

The invention relates to a magneto-rheological vibration isolation support based on a mixed mode. The support comprises a supporting rod, a base and an exciting coil, wherein the supporting rod is connected with a device subjected to vibration isolation, the base is connected with a vibration source, and the exciting coil is used for generating a magnetic field. Magneto-rheological cement gum are arranged between the supporting rod and the base and sealed in an elastic bag sleeve. The upper end and the lower end of the elastic bag sleeve are fixedly connected to the supporting rod and the base respectively. The base is fixedly provided with an outer sleeve. The supporting rod is located in an inner cavity of the outer sleeve. The upper end of the supporting rod extends out of the outer sleeve. The magneto-rheological elastomers are fixedly disposed between the supporting rod and the outer sleeve. The magneto-rheological vibration isolation support can adjust the magnetic field intensity of the vibration isolation support in real time according to outside vibration interference, vibration excitation is effectively tracked and responded, and vibration interference is effectively isolated within the wide-frequency range.

Owner:CHONGQING MATERIALS RES INST

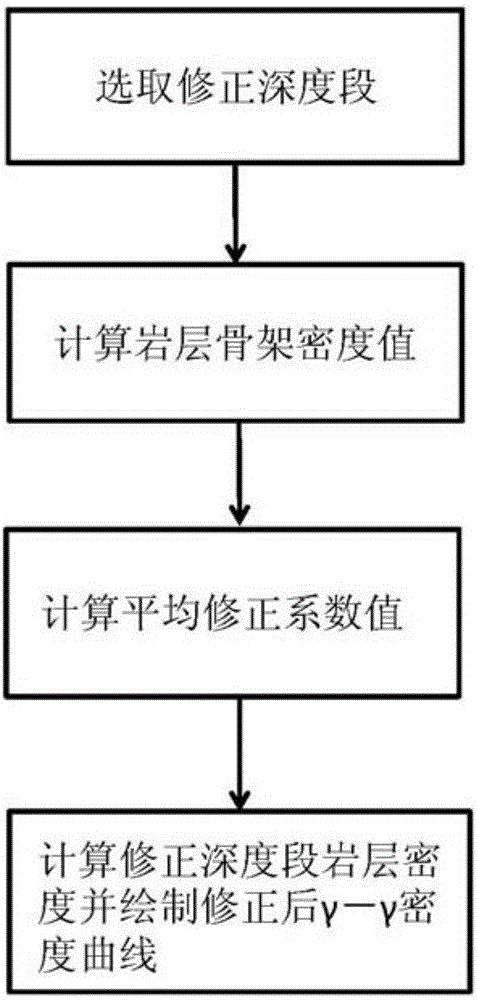

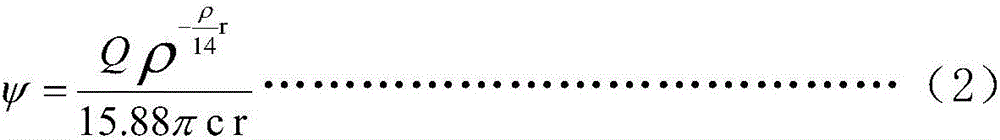

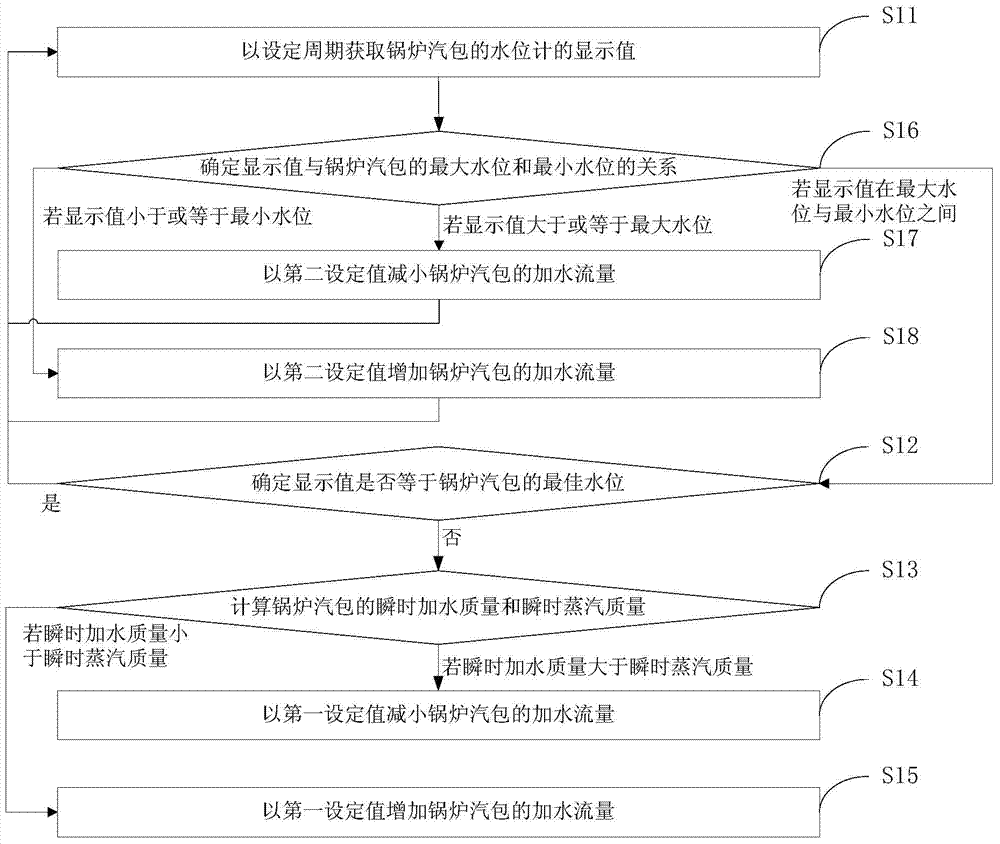

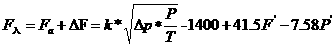

Gamma-gamma density logging distorted curve correction method

ActiveCN106094037AAvoid big swingsAccurate Acoustic Impedance DataSeismic signal processingSeismology for water-loggingData sortingCorrection method

The invention belongs to the field of nuclear physics research and application, and specifically relates to a gamma-gamma density logging distorted curve correction method. The invention provides a correction method for eliminating gamma-gamma density logging curve distortion produced due to rock radiation in the stage of gamma-gamma density logging data sorting. The method comprises the following steps: S1, selecting a correction depth section; S2, calculating the density value of a rock skeleton; S3, calculating the average correction coefficient value; and S4, calculating the rock density of the correction depth section and drawing a corrected gamma-gamma density curve. The problem that a curve fluctuates drastically in a uranium enrichment section before correction is solved. Accurate acoustic impedance data can be provided for seismic exploration, and the quality of gamma-gamma density logging can be monitored effectively. The correction method is also applicable to a gamma-gamma density logging distorted curve affected by a hole enlarge section and a hole collapse section.

Owner:核工业二〇八大队

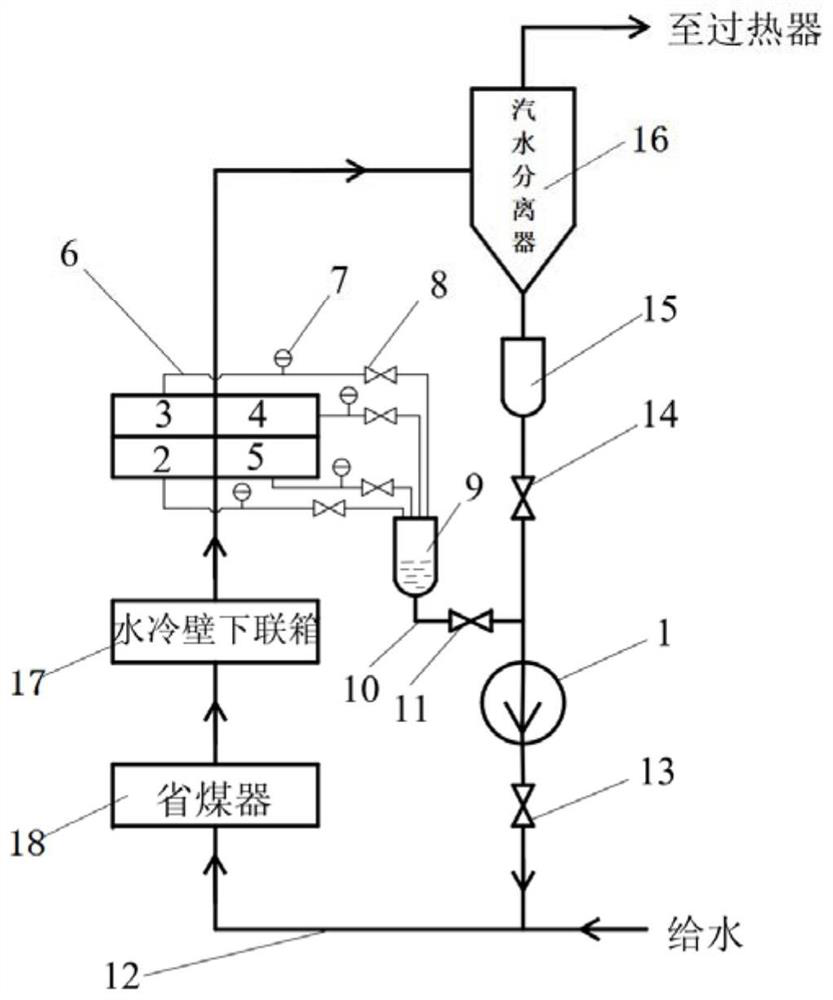

Boiler water recirculation system and method for preventing overtemperature of hearth water wall under low load

PendingCN112283690AIncrease water temperatureImprove economyBoiler water tubesSteam separation arrangementsWater storage tankOutfall

The invention discloses a boiler water recirculation system and method for preventing overtemperature of a hearth water wall under low load. The system comprises a boiler water circulating pump, a steam-water separator, a main water storage tank, a water wall middle mixing header, a water wall lower header and a coal economizer. The coal economizer, the water wall lower header, the water wall middle mixing header and the steam-water separator are sequentially connected through pipelines. A coal economizer inlet pipeline of the coal economizer is connected with a water supply pipe. A gas outletof the steam-water separator is connected to a superheater. A liquid outlet of the steam-water separator, the main water storage tank and the boiler water circulating pump are sequentially connectedand connected to the coal economizer inlet pipeline. The water wall middle mixing header is connected with a bypass water storage tank through a bypass water delivery branch pipe. A water outlet of the bypass water storage tank is connected with an inlet of the boiler water circulating pump. By means of the system, the problems that due to low flow of low-load working media, the water wall is overheated, and the wall temperature fluctuates substantially can be avoided, and transverse cracks are relieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

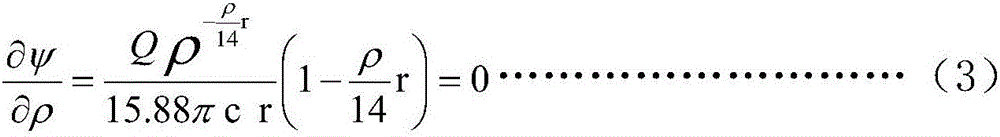

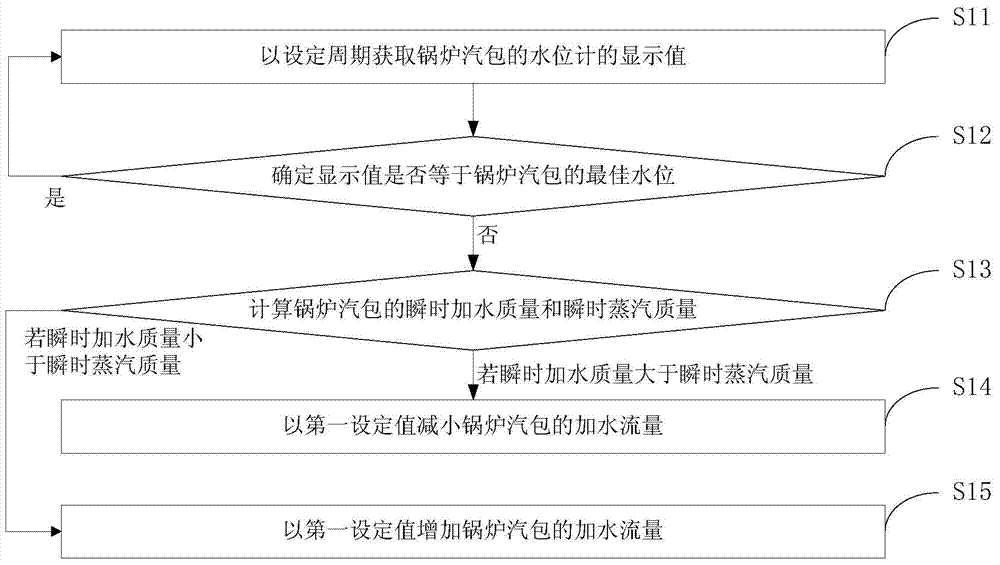

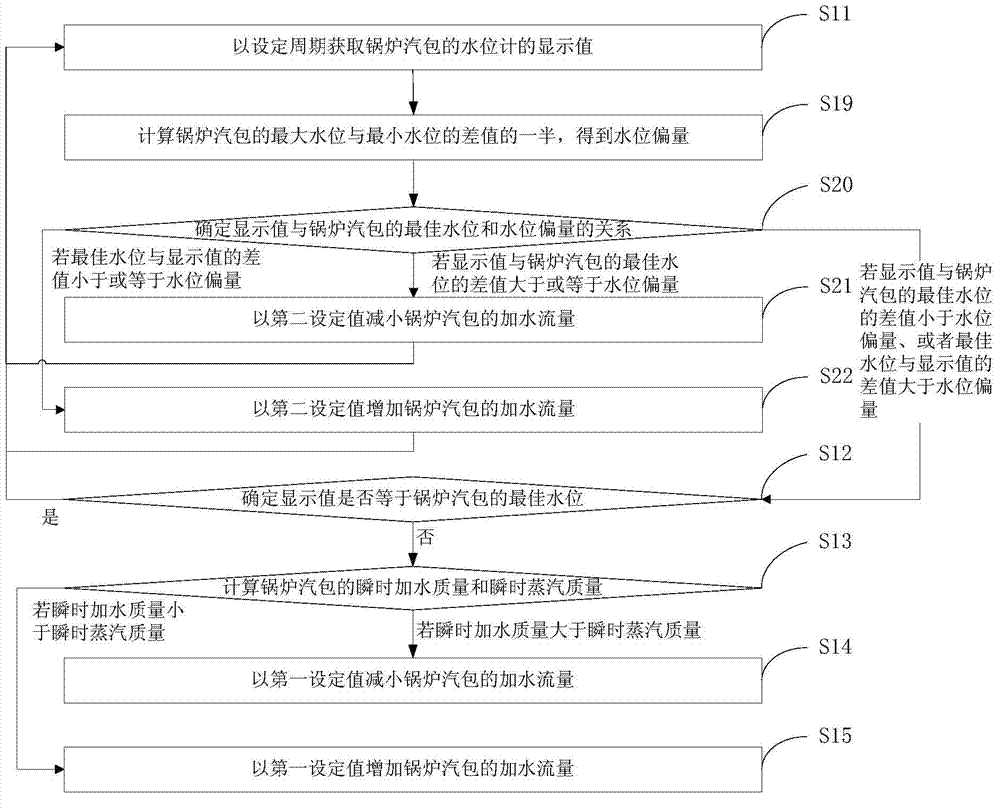

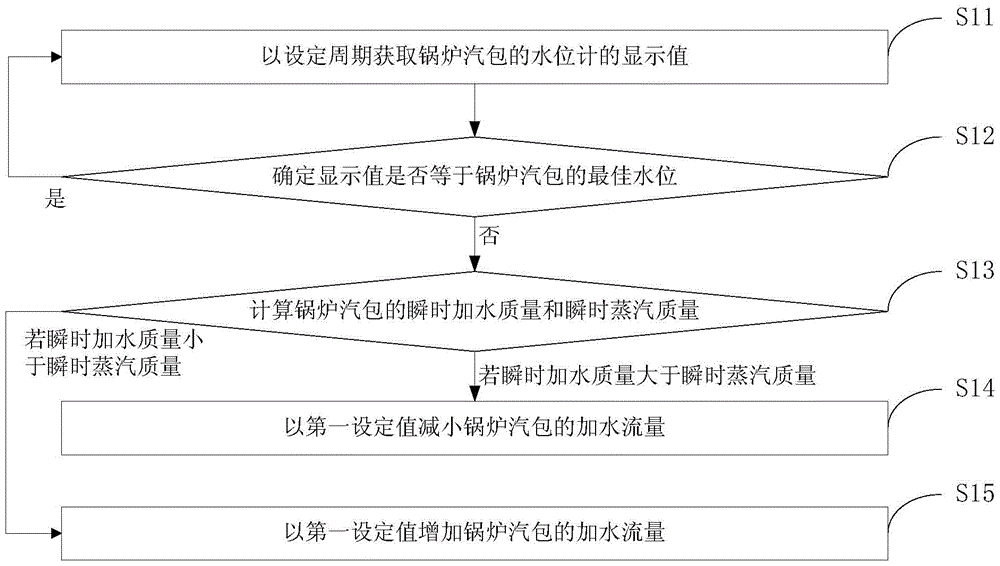

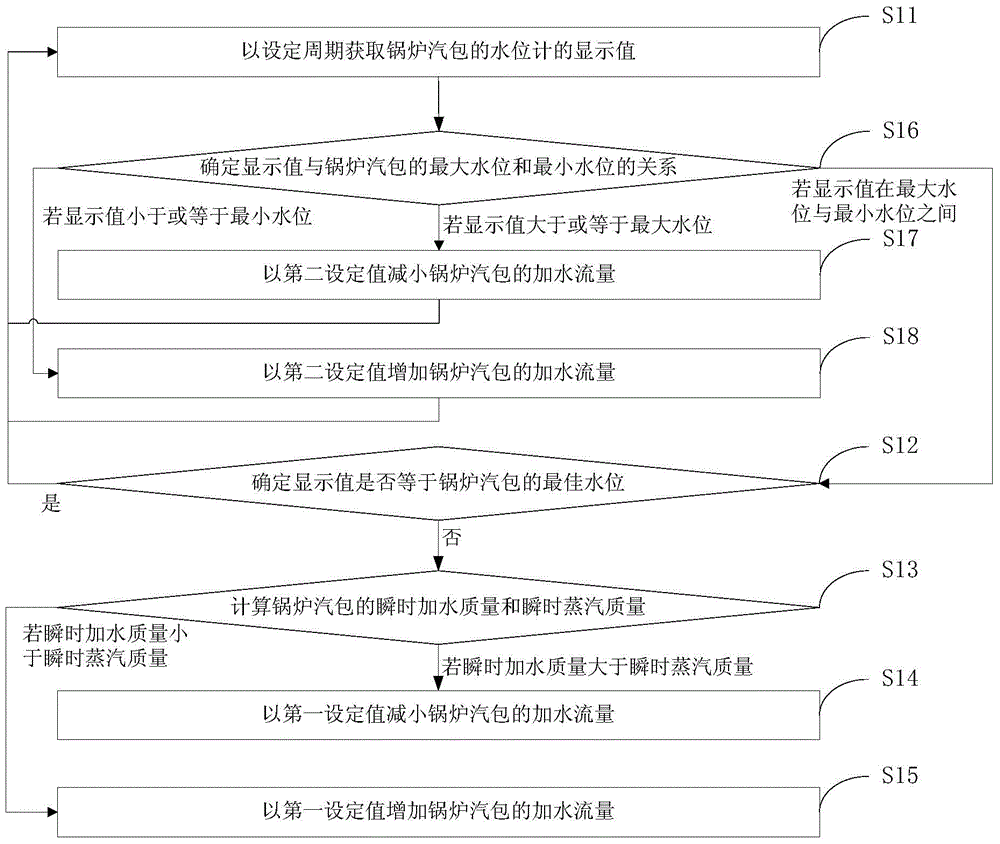

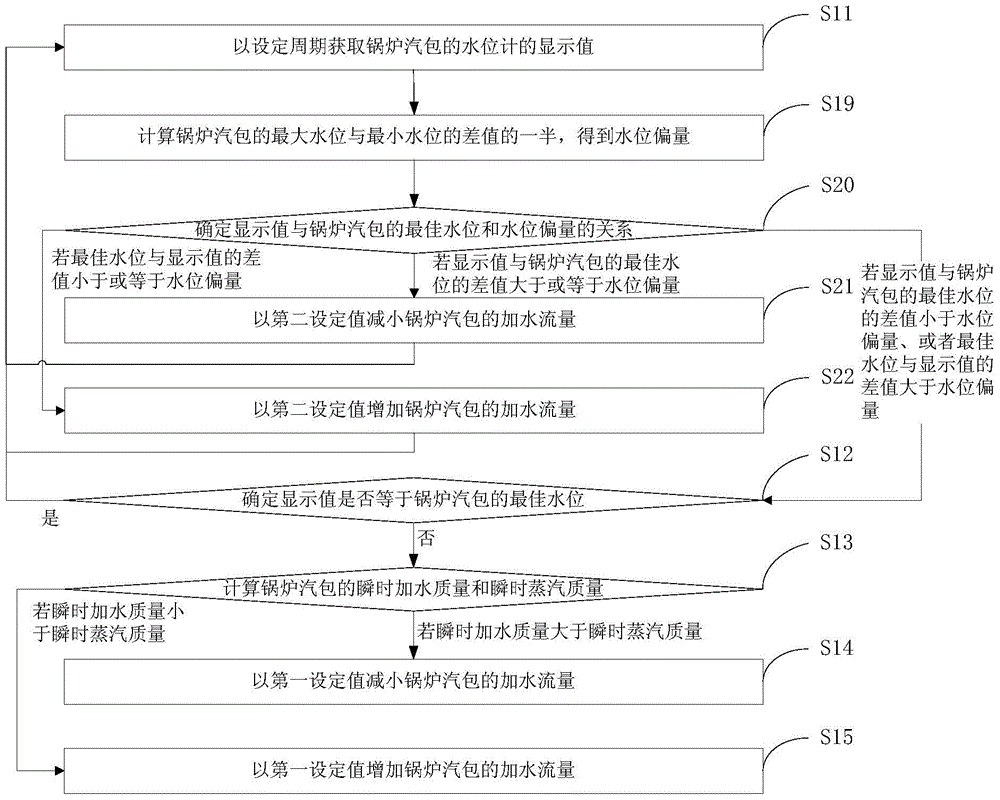

Boiler drum water level control method and boiler drum water level control device

ActiveCN104503519AGuaranteed Energy Efficiency RatioEasy to controlSimultaneous control of multiple variablesBusiness efficiencyWater flow

The embodiment of the invention discloses a boiler drum water level control method and a boiler drum water level control device. The method comprises the steps of acquiring the display value of a water level gauge of a boiler drum at an interval of set period, determining whether the display value is equal to the optimal water level of the boiler drum, calculating the transient added water mass and the transient steam mass of the boiler drum if the display value is not equal to the optimal water level of the boiler drum, reducing the added water flow by a first set value if the transient added water mass is greater than the transient steam mass, and increasing the added water flow by the first set value if the transient added water mass is smaller than the transient steam mass. Compared with the method of adjusting the added water flow according to the steam flow in the prior art, the water level of the boiler drum can be accurately controlled to the optimal water level, sharp fluctuation of the water level of the boiler drum is avoided, and the gas-liquid conversion and energy efficiency ratio of the boiler drum are ensured.

Owner:ELECTRON CO LTD

A screening method for drought-tolerant, wide-ranging, suitable and stable-yielding wheat varieties

ActiveCN105104180BImprove reliabilityEliminate the effects ofPlant genotype modificationHorticultureAgricultural scienceScreening method

Owner:WHEAT RES INST OF AGRI SCI

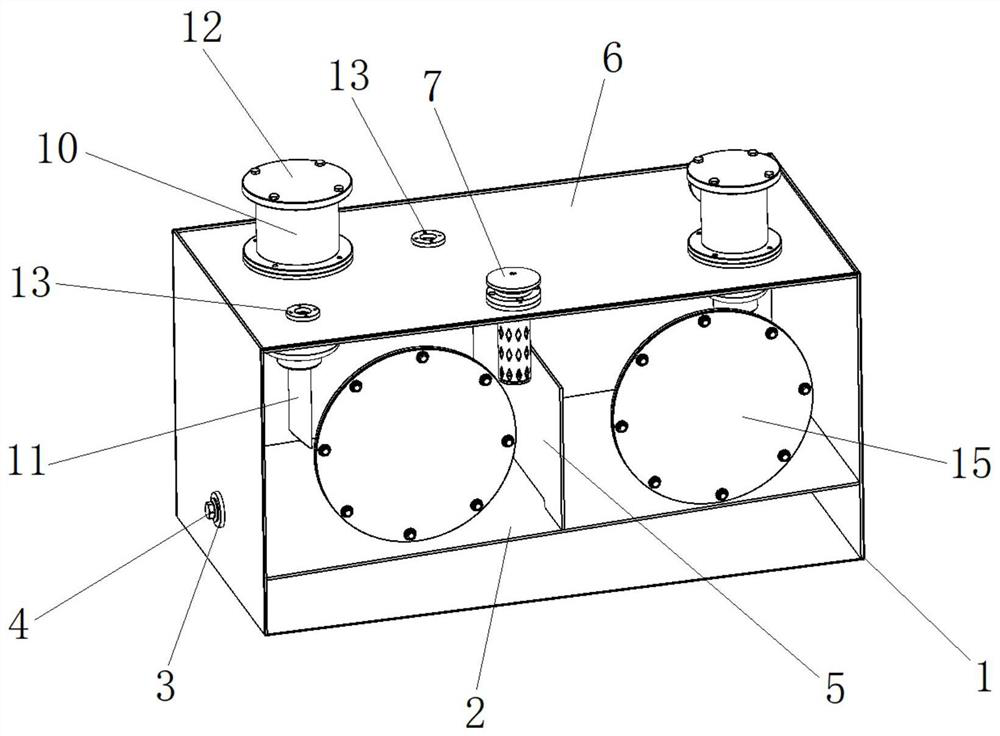

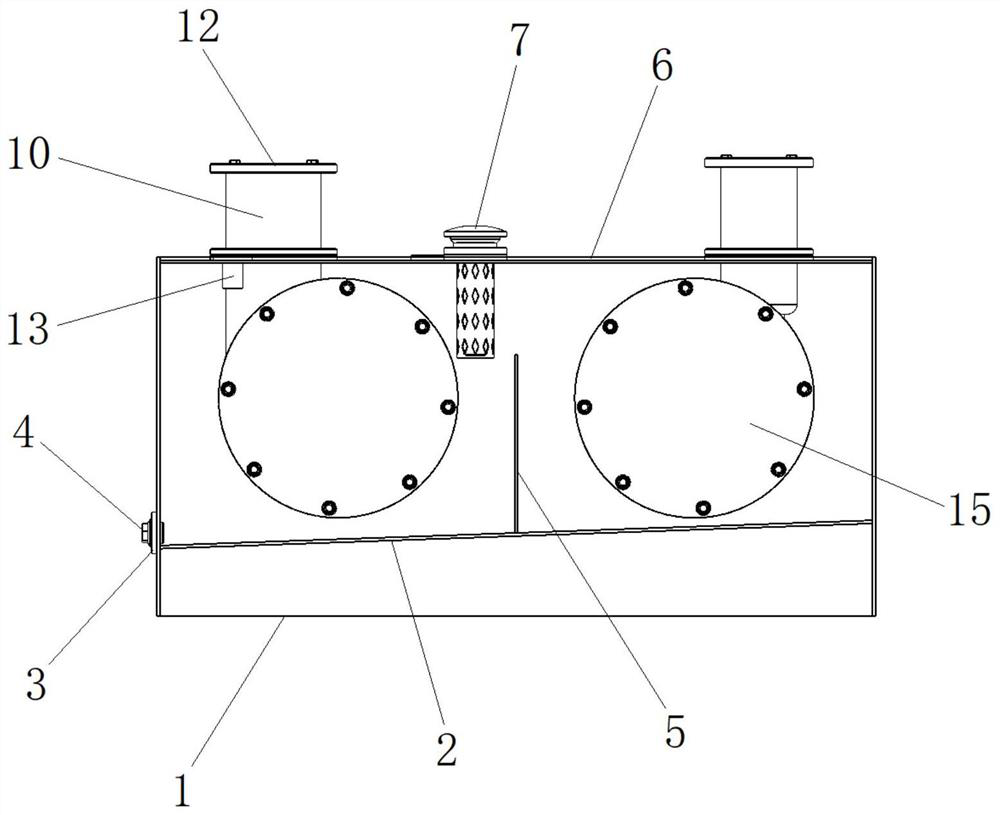

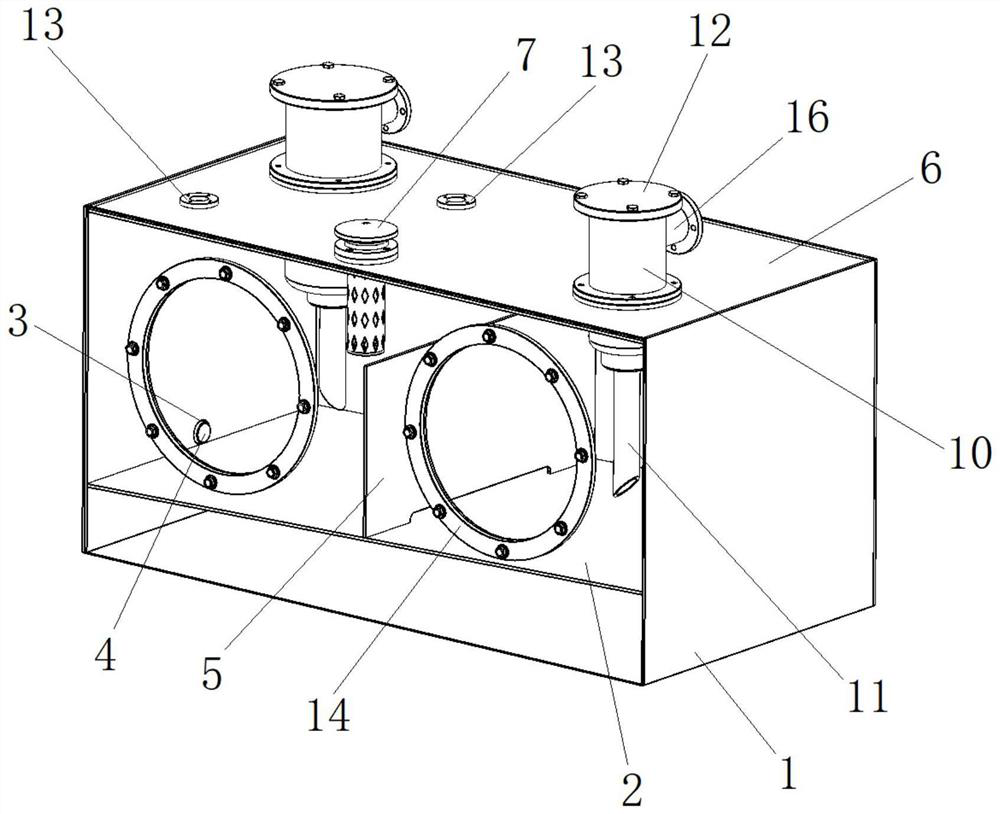

Signal remote transmission gas relay

PendingCN112435888AExternal structure improvementThe external structure ensuresHigh-tension/heavy-dress switchesAir-break switchesOil canControl theory

The invention provides a signal remote transmission gas relay. According to the technical scheme, the external structure of the gas relay is improved, and meanwhile, the image acquisition module is introduced. Specifically, the bottom face of the containing cavity is designed to be the inclined face so that one-way movement of oil can be guaranteed, and meanwhile the middle partition plate is additionally arranged so that large fluctuation can be avoided in the oil flowing process. On the basis, the camera is additionally arranged at the top of the device, a liquid level image can be transmitted to a background in real time and remotely monitored by a worker, and frequent on-site checking actions are omitted. In addition, the sleeve is used for protecting the binding post, and a circuit can enter and exit from the side end; and during maintenance, the flange cover at the upper end can be opened, so that the installation and maintenance of the equipment are not influenced. According tothe invention, the oil level monitoring efficiency of the gas relay is improved, and a more perfect protection structure is provided.

Owner:XIAN YA NENG ELECTRIC CO LTD

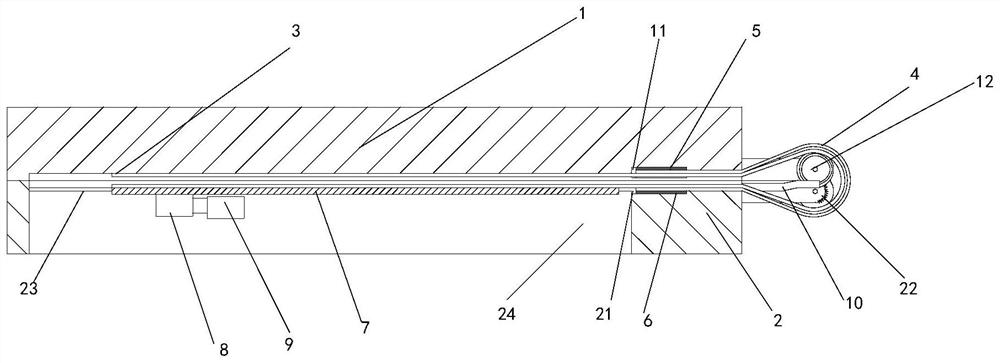

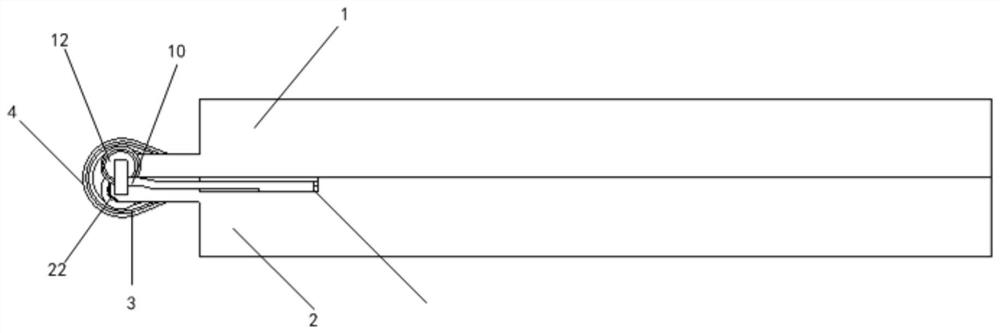

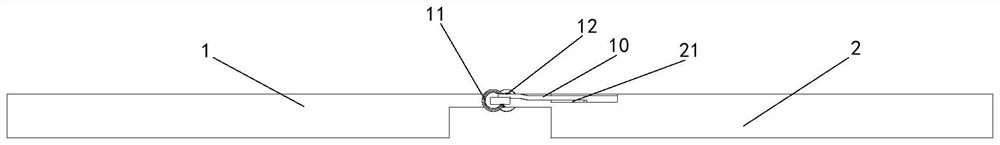

Foldable module and display device

ActiveCN113487972AAvoid big swingsDoes not affect bendabilityIdentification meansDisplay deviceEngineering

The invention discloses a foldable module and a display device.The foldable module comprises a first machine shell and a second machine shell, the first machine shell and the second machine shell are rotatably connected, a display module is installed on the first machine shell and the second machine shell, and the display module is fixedly connected with the first machine shell and is in sliding connection with the second machine shell; and a supporting plate is arranged at the bent position of the display module, and the supporting plate is arranged close to the display module. According to the technical scheme provided by the embodiment of the invention, the supporting plate is arranged at the bent position of the display module, the supporting plate and the display module abut against each other and are not pasted, the two sides of the supporting plate are slidably connected with the first machine shell and the second machine shell respectively, and the supporting plate supports the display module after the display module is unfolded; and the supporting plate is not in contact with the display module when being bent so that the generation of large displacement when the state of the display module is changed from unfolding to bending or from bending to unfolding is avoided, and the bending performance of the display module is not influenced.

Owner:BOE TECH GRP CO LTD +1

Magneto-rheological vibration isolation bearing based on hybrid mode

ActiveCN105020328BReal-time adjustment of mechanical propertiesAchieve isolationSpringsShock absorbersMagnetic currentElastomer

The invention relates to a magneto-rheological vibration isolation support based on a mixed mode. The support comprises a supporting rod, a base and an exciting coil, wherein the supporting rod is connected with a device subjected to vibration isolation, the base is connected with a vibration source, and the exciting coil is used for generating a magnetic field. Magneto-rheological cement gum are arranged between the supporting rod and the base and sealed in an elastic bag sleeve. The upper end and the lower end of the elastic bag sleeve are fixedly connected to the supporting rod and the base respectively. The base is fixedly provided with an outer sleeve. The supporting rod is located in an inner cavity of the outer sleeve. The upper end of the supporting rod extends out of the outer sleeve. The magneto-rheological elastomers are fixedly disposed between the supporting rod and the outer sleeve. The magneto-rheological vibration isolation support can adjust the magnetic field intensity of the vibration isolation support in real time according to outside vibration interference, vibration excitation is effectively tracked and responded, and vibration interference is effectively isolated within the wide-frequency range.

Owner:CHONGQING MATERIALS RES INST

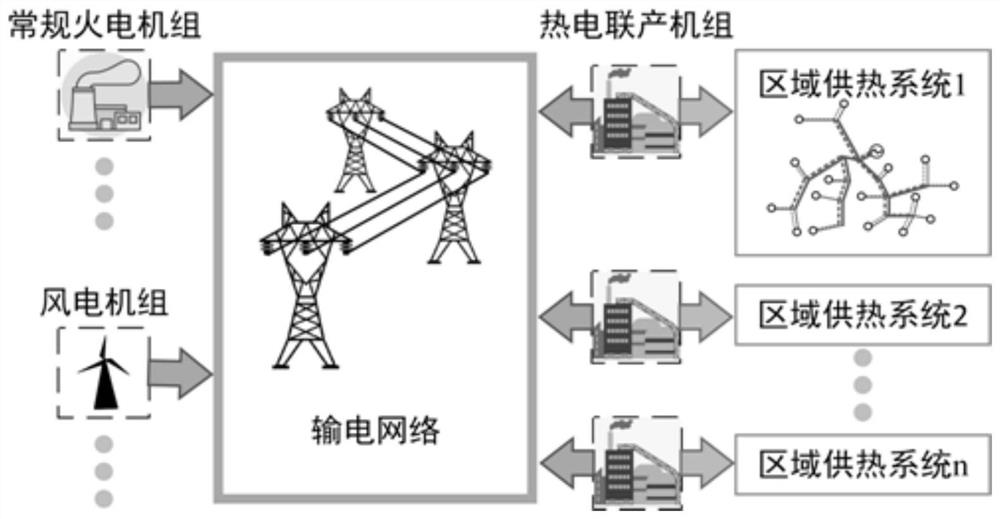

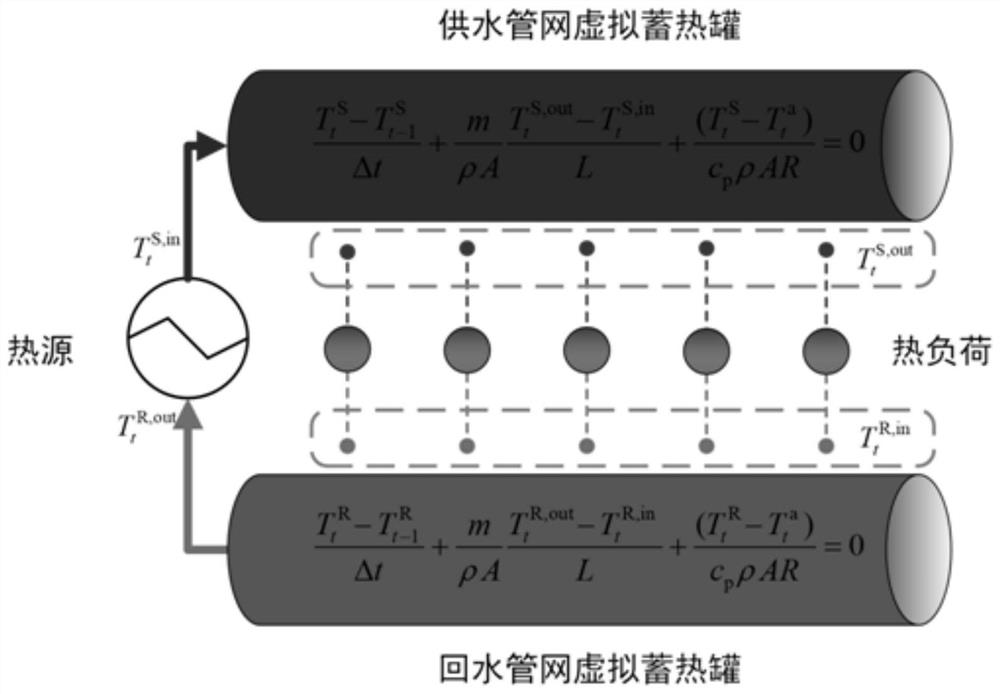

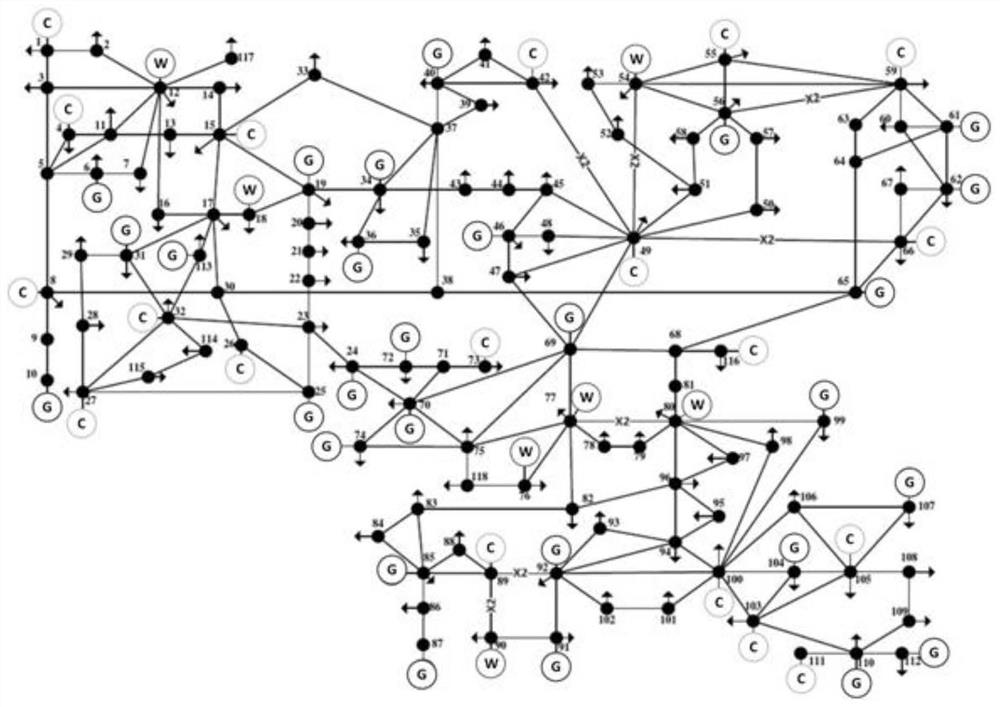

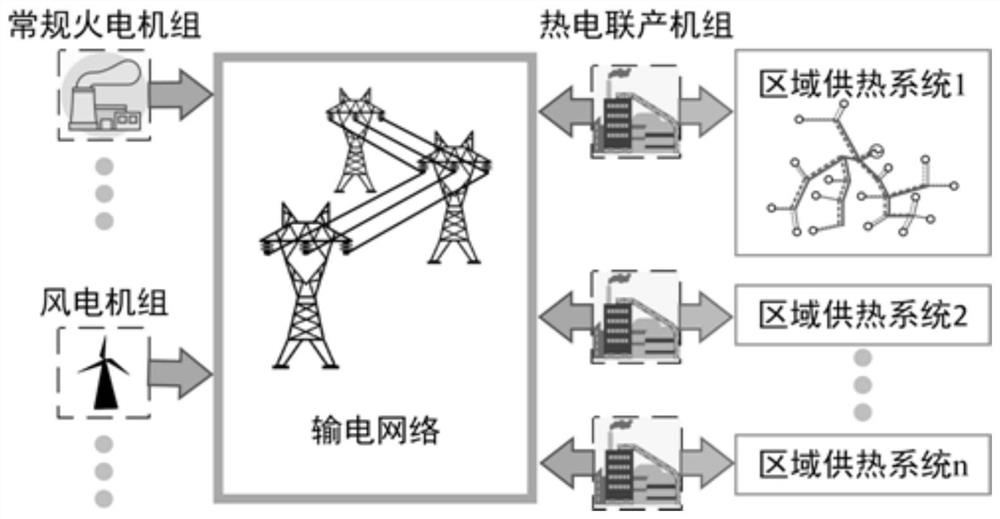

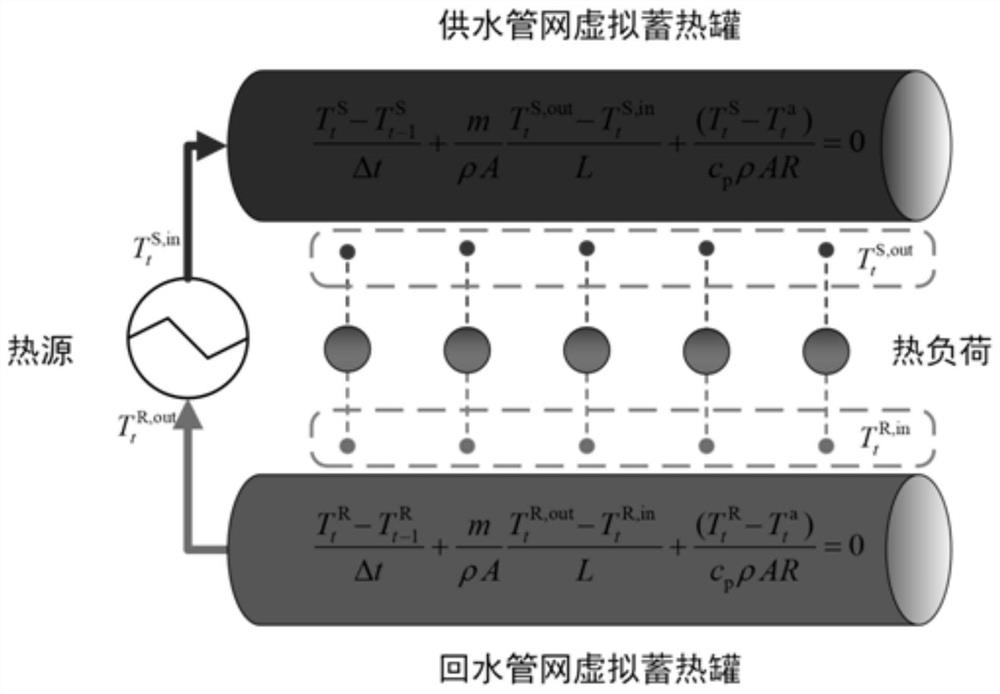

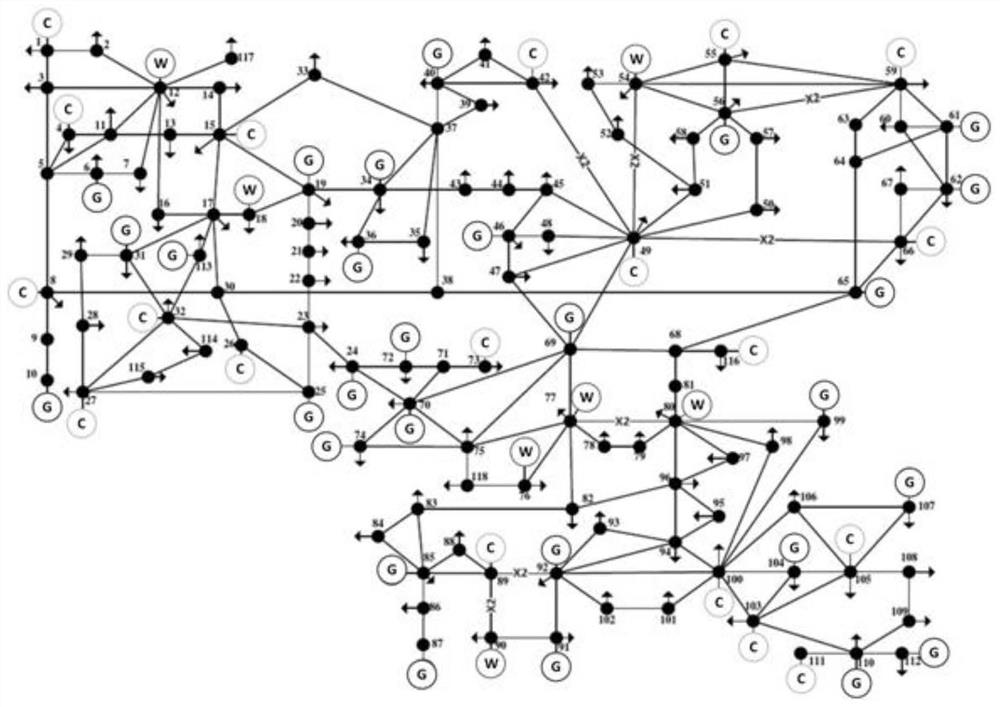

Multi-zone electricity-heat comprehensive energy system optimization control method considering quantitative heat storage

ActiveCN113537632AAvoid large fluctuations in heat storageLow costForecastingDesign optimisation/simulationIntegrated energy systemControl engineering

The invention discloses a multi-zone electricity-heat comprehensive energy system optimization control method considering quantitative heat storage, which comprises the following steps: considering the thermal dynamic characteristics of a heat supply pipe network and the computational efficiency demand of multi-zone scheduling, improving and simplifying a heat supply pipe network model based on first-order windward difference, and establishing a virtual heat storage tank model of the heat supply pipe network; establishing a heat storage quantitative index based on the virtual heat storage tank model for quantifying the heat storage level of the primary pipe network, and establishing a quantitative regulation and control index of pipe network heat storage; constructing a regulation and control target penalty term of the heat storage capacity of the pipe network by utilizing the quantitative regulation and control indexes; and constructing a multi-region IPHS optimization scheduling model in combination with the 1-bin unit commitment model, wherein a mixed integer quadratic programming solver is used for solving to obtain an optimization control result of IPHS day-ahead unit commitment and economic scheduling. According to the method, the calculation efficiency is improved, and collaborative optimization of the heat storage capacity of the heat supply pipe network in IPHS scheduling is realized.

Owner:TIANJIN UNIV

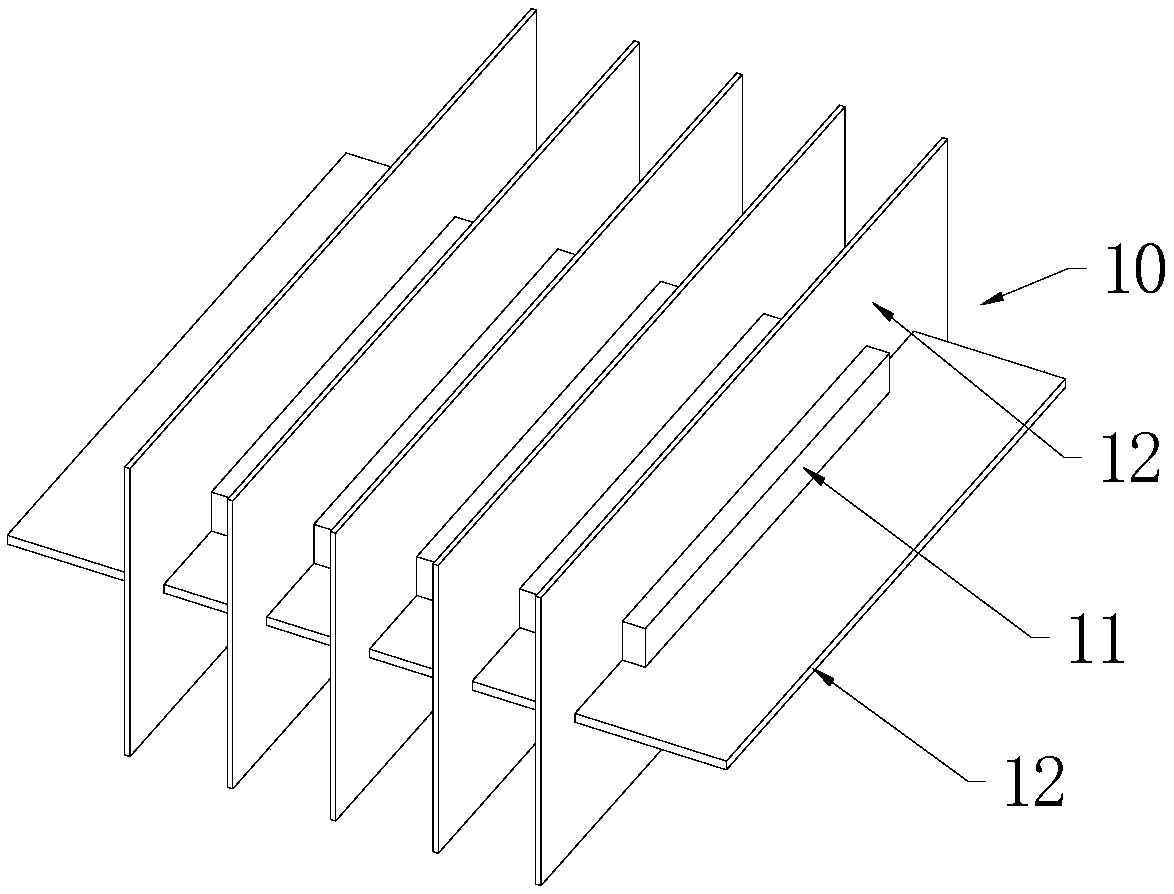

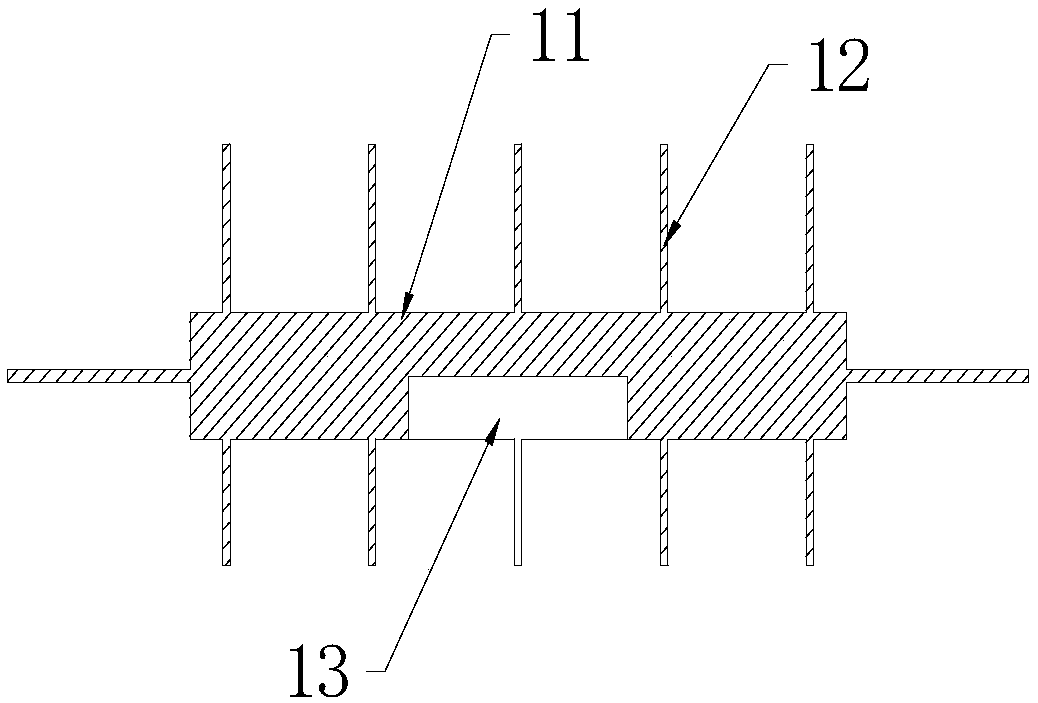

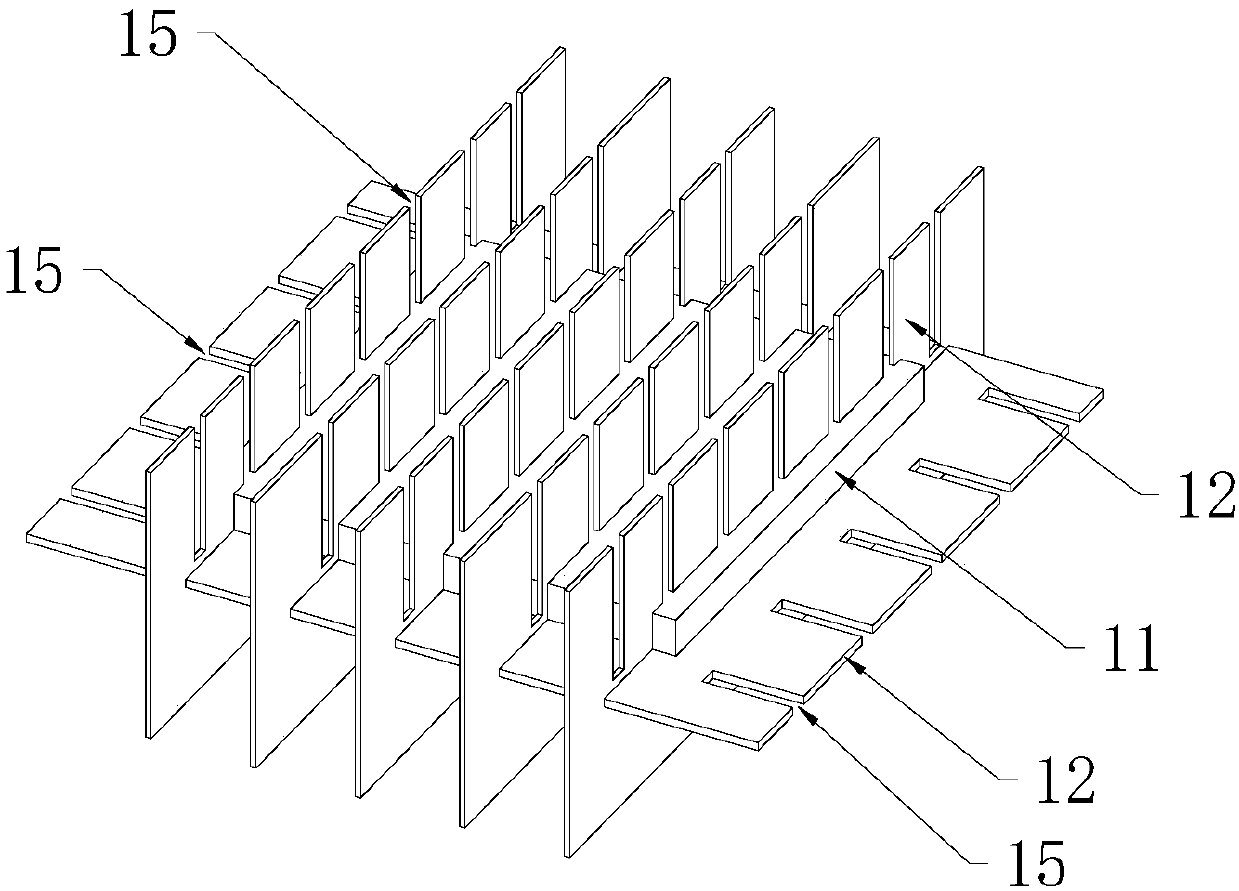

Mechanical filter

ActiveCN109839020AAccurate temperature detectionDisturbance interference signal filteringHeat storage plantsTemperature measurement of flowing materialsEngineeringRefrigeration

The invention discloses a mechanical filter. The mechanical filter comprises an energy storage part and a fin part, wherein the energy storage part and the fin part are fixed, and a temperature measuring part suitable for temperature measurement is arranged on the energy storage part. A fluid is subjected to heat application treatment such as heating and refrigeration, temperature distribution isnot uniform, a natural convection flow field is formed in the fluid under the action of gravity, the flowing of the fluid generates a disturbance signal to temperature detection, particularly to an ultralow-frequency disturbance signal with a period reaching the several-minute magnitude, the ultralow-frequency disturbance signal is difficult to filter out through an electronic filter, the mechanical filter can filter out the ultralow-frequency disturbance signal, a temperature sensor equipped with the filter can accurately detect fluid temperature, the interference influence of the disturbancesignal is avoided in the heat application treatment process, then fluctuation amplitude of the fluid temperature is extremely small, so that the fluid temperature is more easily stabilized at a set value, and temperature stabilization is shorter in required time.

Owner:河北鹏博通信设备有限公司

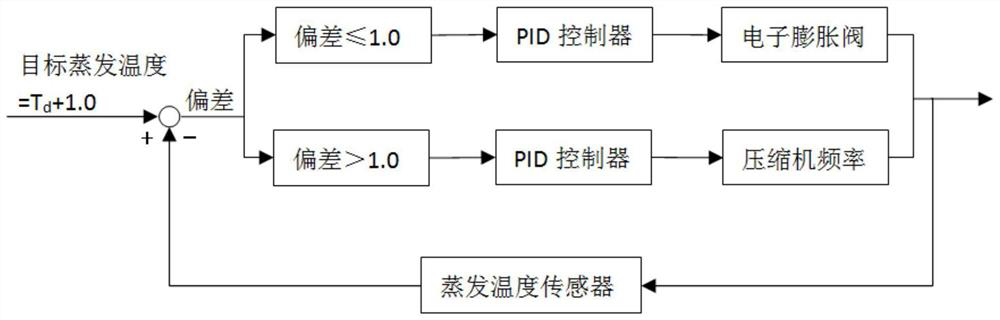

Condensation prevention method for air conditioner

InactiveCN113503626AImprove condensation phenomenonPrevent or reduce blowing waterMechanical apparatusSpace heating and ventilation safety systemsEngineeringMechanical engineering

The invention belongs to the technical field of air conditioner control, and particularly relates to a condensation prevention method for an air conditioner. The method comprises the steps that the dew point temperature Td and the target evaporation temperature Tr corresponding to the indoor air are calculated according to the indoor temperature t and the room humidity f, the difference between the actual evaporation temperature and the target evaporation temperature is obtained, and different control objects are selected to conduct control according to the absolute value of the deviation. According to the condensation prevention method for the air conditioner, the evaporation temperature is controlled to prevent or reduce condensate water generated by the air conditioner, the condensation phenomenon of the air conditioner is improved, and water blowing of the air conditioner is prevented; the control means can be selected correspondingly according to the deviation between the actual evaporation temperature and the target evaporation temperature; when the deviation is large, the frequency of a compressor is adjusted to control the evaporation temperature so as to achieve rapid adjustment; and when the deviation is very small, the opening degree of an electronic expansion valve is adjusted to control the evaporation temperature so as to achieve the accurate control.

Owner:WUHAN HANLI REFRIGERATION TECH CO LTD

Water level control method and device for boiler steam drum

ActiveCN104503519BGuaranteed Energy Efficiency RatioEasy to controlSimultaneous control of multiple variablesStream gaugeBusiness efficiency

The embodiment of the invention discloses a boiler drum water level control method and a boiler drum water level control device. The method comprises the steps of acquiring the display value of a water level gauge of a boiler drum at an interval of set period, determining whether the display value is equal to the optimal water level of the boiler drum, calculating the transient added water mass and the transient steam mass of the boiler drum if the display value is not equal to the optimal water level of the boiler drum, reducing the added water flow by a first set value if the transient added water mass is greater than the transient steam mass, and increasing the added water flow by the first set value if the transient added water mass is smaller than the transient steam mass. Compared with the method of adjusting the added water flow according to the steam flow in the prior art, the water level of the boiler drum can be accurately controlled to the optimal water level, sharp fluctuation of the water level of the boiler drum is avoided, and the gas-liquid conversion and energy efficiency ratio of the boiler drum are ensured.

Owner:ELECTRON CO LTD

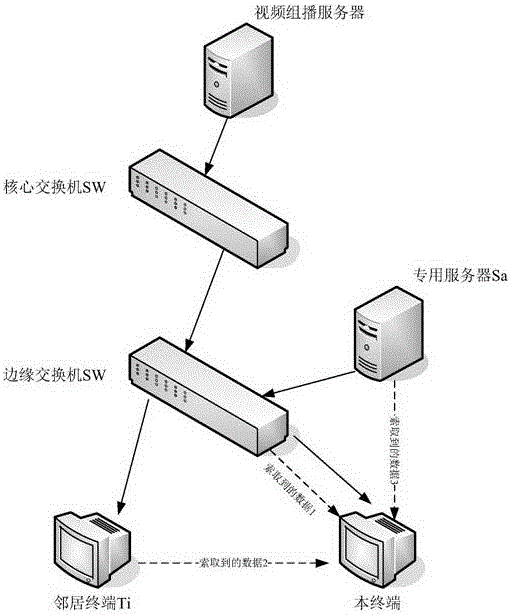

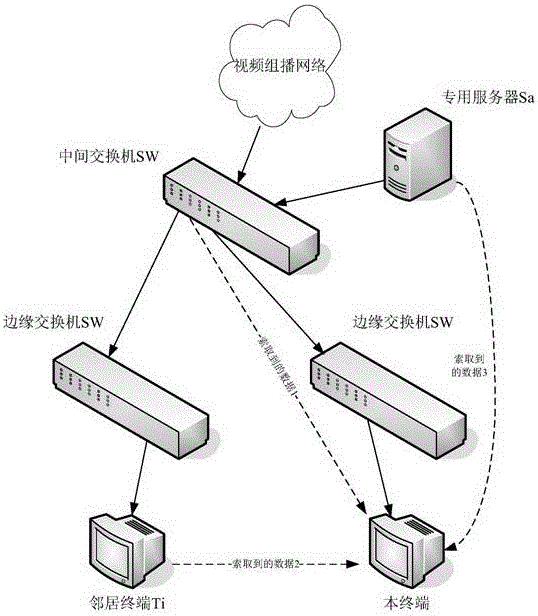

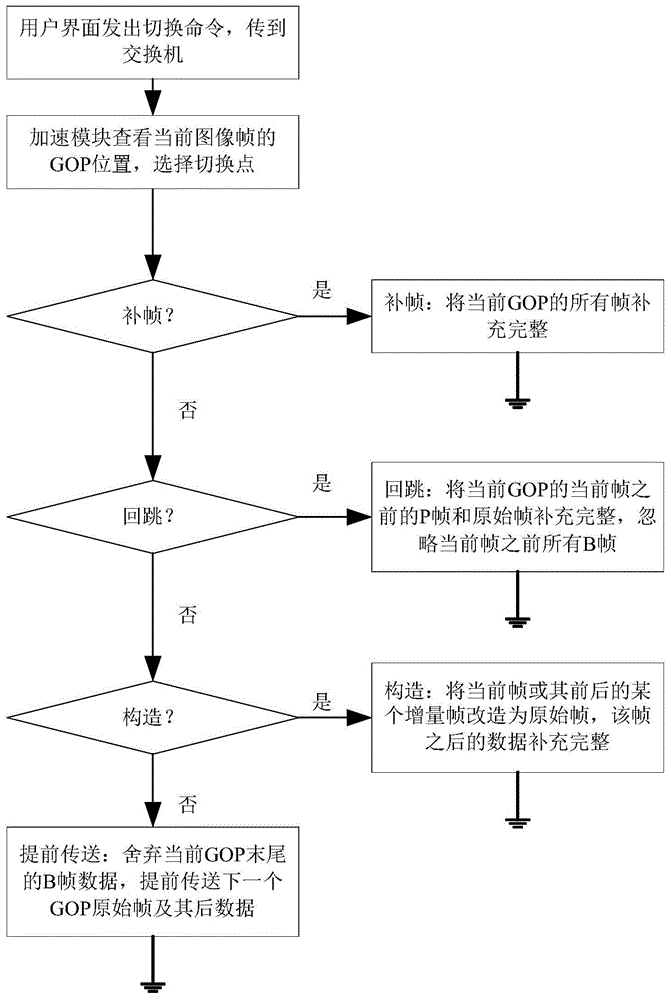

A method for accelerating channel switching in a video multicast network system and a channel group identification method

InactiveCN104093070BReduce latencyImprove experienceSelective content distributionTraffic capacityComputer module

The invention relates to a channel switching accelerating method and a channel ethnic group marking method in a video multicast network system. The channel switching accelerating method includes the steps of frame interpolation, rebound, construction and transmission in advance. A user sends out a switching request, and a terminal informs a switch of joining in a corresponding multicast group; an accelerating module executes corresponding actions according to the position or the operation stage, where a current image frame is located, of a group of video pictures (GOP); in the front part of the GOP, overdue frames are supplemented to be complete; in the front middle of the GOP, only reference frames are recalled; in the rear middle of the GOP, new I frames are constructed; in the tail of the COP, transmission is performed in advance. In addition, keys on a terminal control panel are not increased, one certain key or a certain group of keys are defined to have different functions under different states, and the operation functions of channel ethnic group marking and scanning type automatic switching in groups are achieved. Channel switching of video multicast can be accelerated, the possibility of jamming of the backbone network is lowered, and instant large fluctuations of network flow are avoided.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

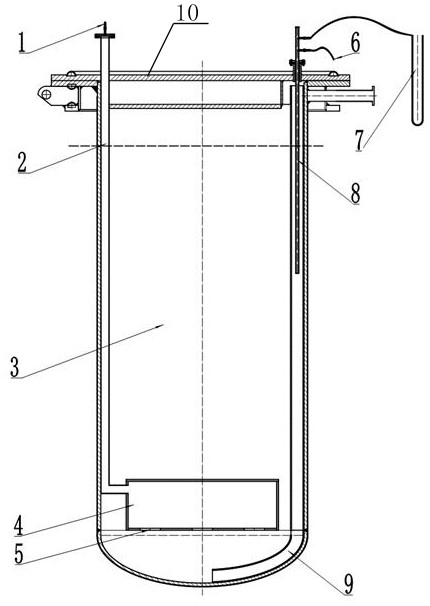

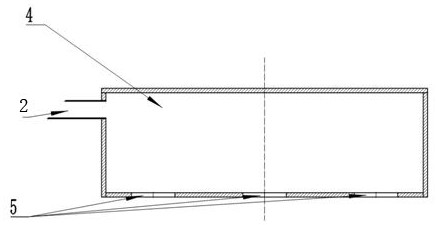

Liquid level control device and control method of reduction distillation reactor

PendingCN113204251AAvoid big swingsReduced creeping titanium generationLevel controlProcess efficiency improvementMagnesium chlorateEngineering

The invention relates to a liquid level control device and method for a reduction distillation reactor, the control device comprises a submerged device, an argon pipeline and a liquid level measuring device, the submerged device is located at the lower part of the reduction distillation reactor, and a cavity is formed in the submerged device; the bottom surface of the submerged device is positioned above a liquid inlet of a magnesium chloride discharge pipe in the reduction distillation reactor, a plurality of hole channels communicated with the inside and the outside of the cavity are formed in the bottom surface of the submerged device, the side surface of the submerged device is opened and is connected with the lower end of the argon pipeline, the upper end of the argon pipeline penetrates out of a large cover at the top of the reduction distillation reactor, and a valve is mounted at the upper end of the argon pipeline; and the liquid level measuring device is used for measuring the liquid level height of the reduction distillation reactor. According to the control method, the fluctuation amplitude of the liquid level can be counteracted and compensated through argon filling and pressure relief of the submerged device, and therefore the effect of stabilizing the height of the liquid level is achieved.

Owner:洛阳双瑞万基钛业有限公司

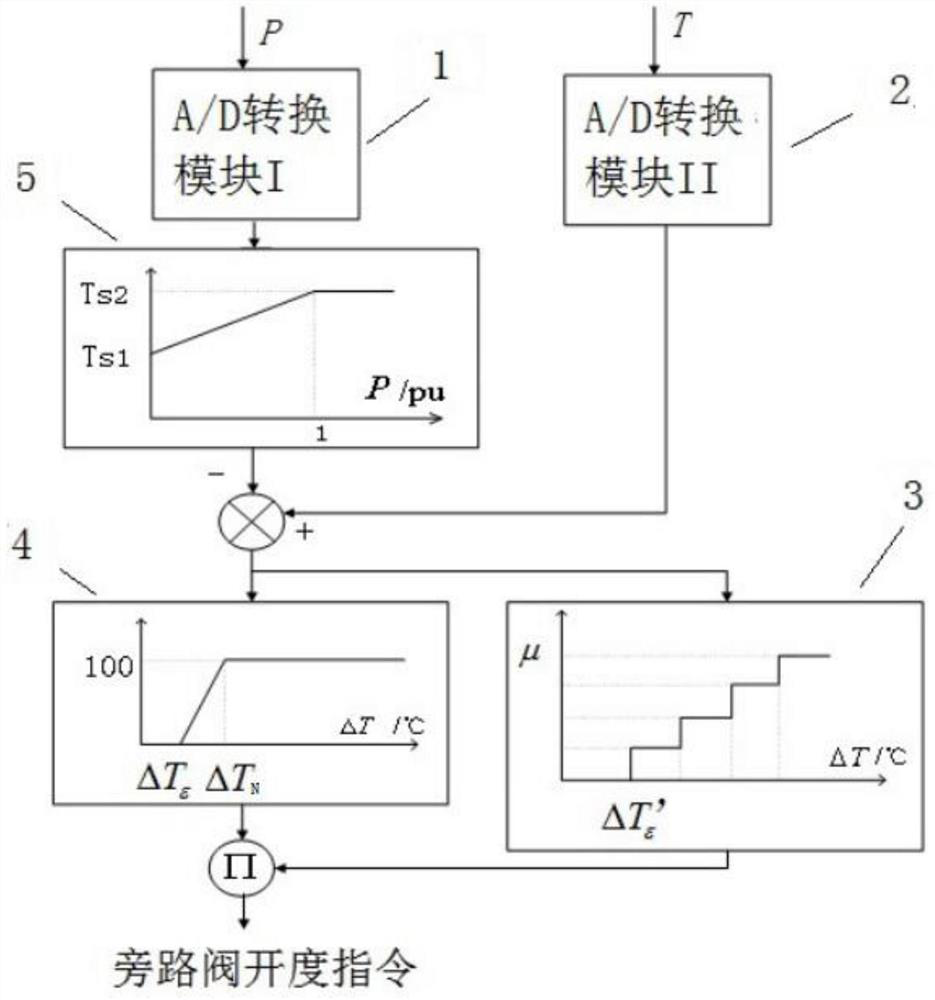

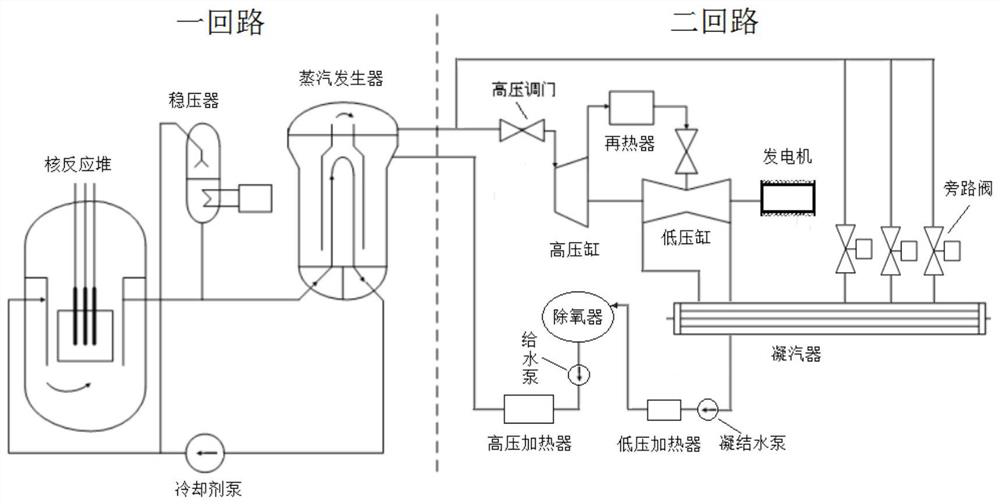

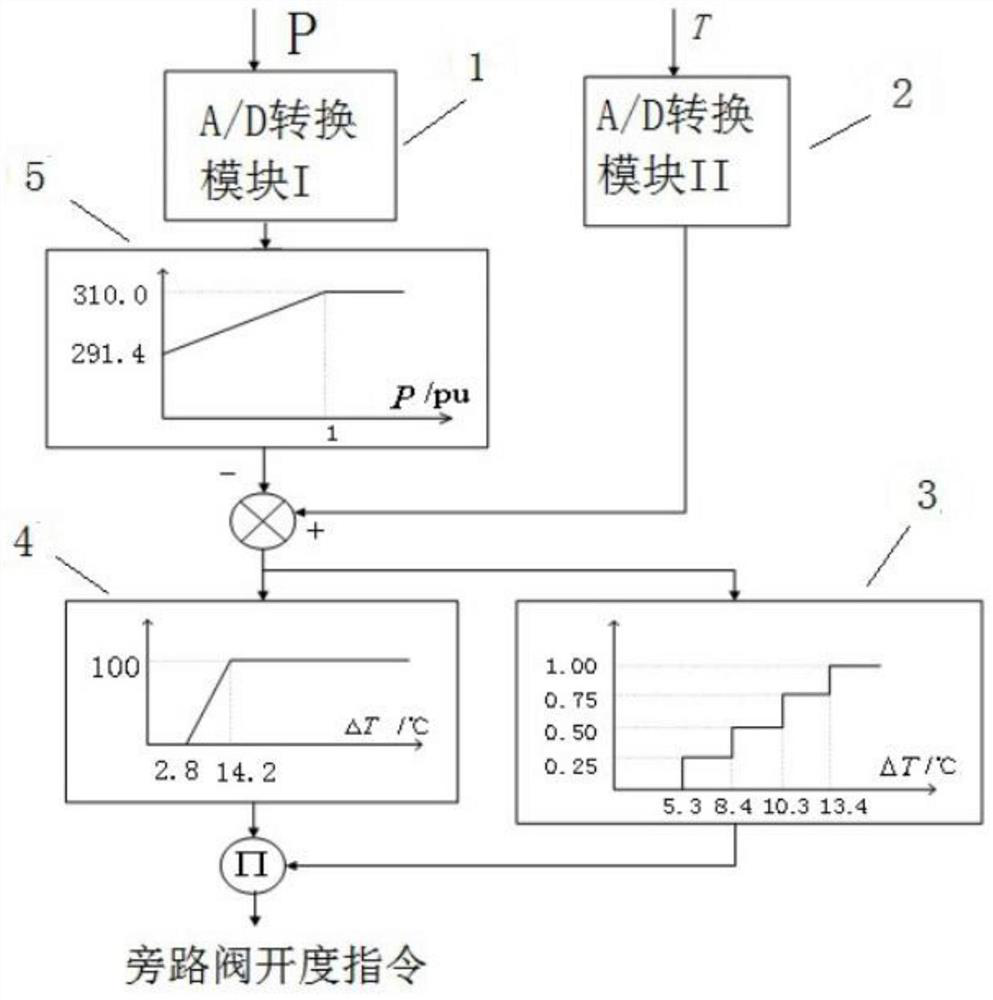

A control method for the main steam bypass system of a pressurized water reactor nuclear power unit

ActiveCN111400843BAvoid frequent opening and closingIncreased openingDesign optimisation/simulationLoad rejectionTemperature control

The invention relates to the technical field of nuclear power unit control, in particular to a control method for a main steam bypass system of a pressurized water reactor nuclear power unit. Aiming at the drastic changes in operating conditions such as load shedding and power consumption of the unit, or steam turbine idling after load shedding, a control method for the main steam bypass system of the pressurized water reactor nuclear power unit is proposed for the bypass system of the nuclear power unit. To make the unit fast and stable, to realize load shedding and island operation with factory power or smooth shutdown, the present invention uses the multiplication result of the output values of the threshold control module and the temperature control module as the opening instruction for controlling the bypass valve. The frequent opening and closing of the bypass valve is avoided. At the same time, when the output difference between the A / D conversion module II and the power control module is too large, the output value of the threshold control module increases in steps to improve the bypass valve. The opening range is conducive to the control of the main steam pressure of the secondary circuit and prevents large fluctuations.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

Optimal control method for multi-region electric-thermal integrated energy system considering quantitative heat storage

ActiveCN113537632BAvoid large fluctuations in heat storageLow costForecastingDesign optimisation/simulationIntegrated energy systemOptimal control

The invention discloses a multi-regional electric-thermal integrated energy system optimization control method considering quantitative heat storage. The heat supply pipe network model is used to establish a virtual heat storage tank model of the heat supply pipe network; based on the virtual heat storage tank model, a heat storage quantification index is established, which is used to quantify the heat storage level of the primary pipe network and establish the heat storage of the pipe network. Quantitative regulation index; use the quantitative regulation index to construct the regulation target penalty term for heat storage in the pipe network; build a multi-region IPHS optimal scheduling model combined with the 1-bin unit combination model, and use the mixed integer quadratic programming solver to solve, get the IPHS Optimal control results of unit combination and economic dispatch. The invention improves the calculation efficiency and realizes the coordinated optimization of the heat storage in the heating pipe network in the IPHS scheduling.

Owner:TIANJIN UNIV

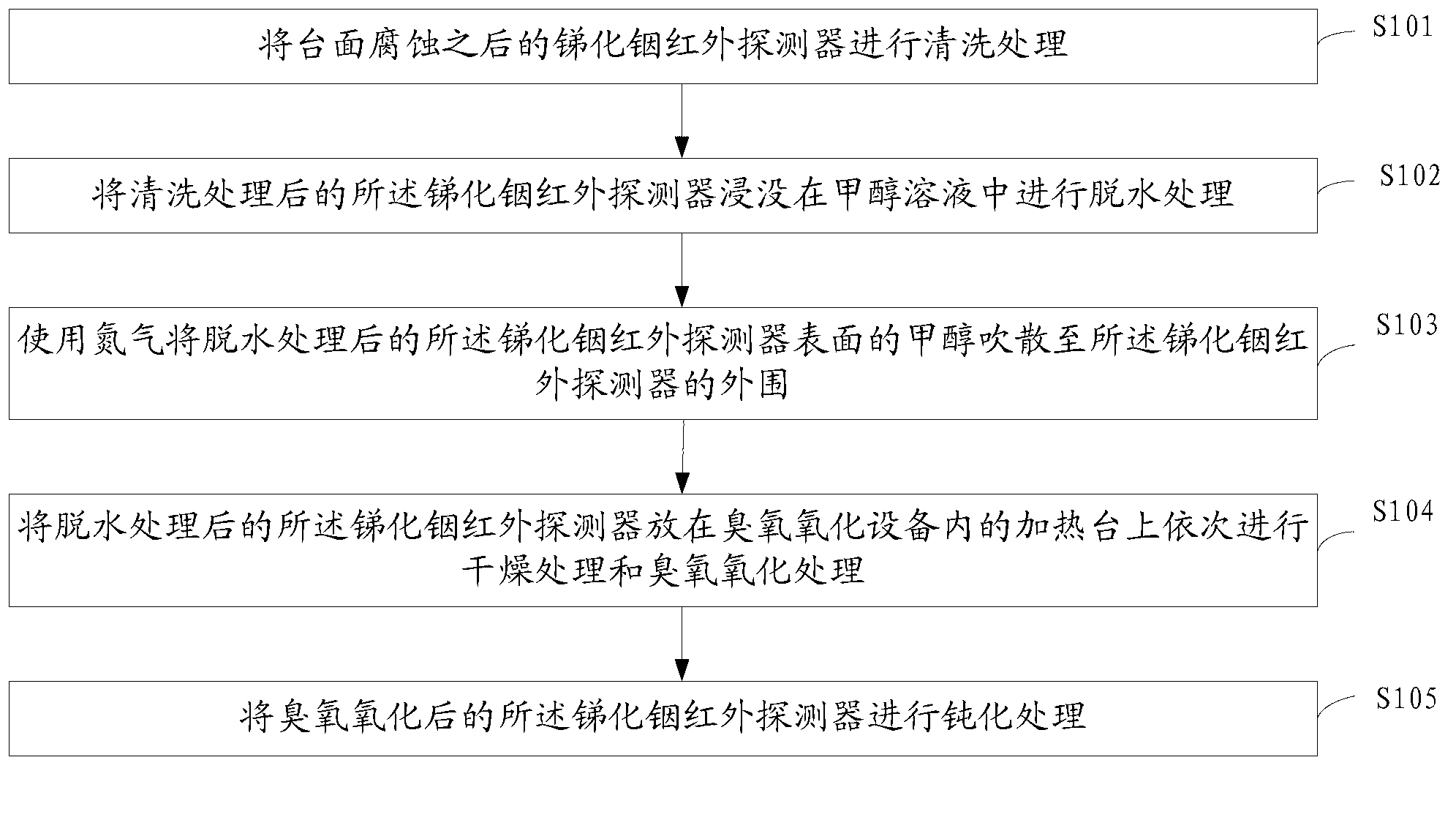

Dehydration treatment method for indium antimonide infrared detector

ActiveCN103219424AAvoid big swingsAvoid secondary pollutionFinal product manufactureSemiconductor devicesHigh humidityWater vapor

The invention discloses a dehydration treatment method for an indium antimonide infrared detector. The dehydration treatment method comprises the following steps of: pretreating the indium antimonide infrared detector of which the tabletop is corroded; placing the pretreated indium antimonide infrared detector into methanol for dehydration treatment; and placing the indium antimonide infrared detector subjected to dehydration treatment into ozonation equipment for sequentially carrying out drying treatment and ozonation treatment. Impurities and water resided on the indium antimonide infrared detector are thoroughly removed by sequentially cleaning and dehydrating the indium antimonide infrared detector, so the wild fluctuation of performances of the indium antimonide infrared detector along with the humidity change of a purifying room is avoided and the consistency of parts within batches and parts between batches of the performances of a chip is basically stabilized; and the dehydration treatment effect is maintained in the purifying room environment with high humidity by the drying treatment and the ozonation treatment, and thus secondary pollution to the chip due to water vapor is avoided.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

A method for controlling the air volume of a blower

ActiveCN105441609BStable working conditionMonitor and judge abnormal conditions in timeBlast furnace detailsAir volumeAutomatic control

The invention relates to a method for controlling the air volume of a blower, which proposes for the first time the idea of using the air volume at the inlet of the blower to automatically control the stator blades, and provides a calculation method for the air volume at the inlet, which can accurately use existing measuring devices that are all indoors , The measurement signal that is less restricted by environmental factors is used to calculate the inlet air volume, to achieve the same measurement effect as the outlet air volume, and to improve the stability and automatic input rate of the air volume automatic control loop.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

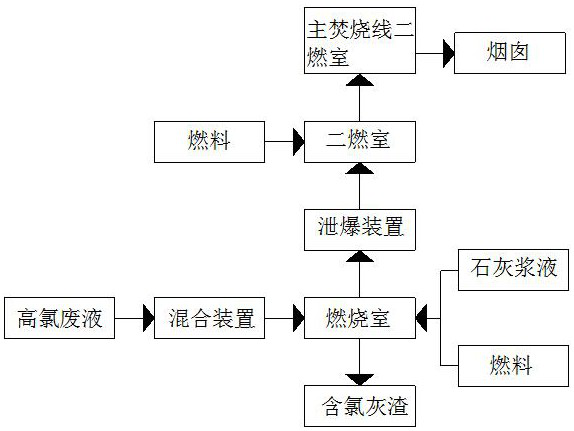

Incineration pretreatment process for high-chlorine waste liquid

PendingCN114165796APlay a buffer roleAct as a protective bufferIncinerator apparatusCombustion chamberFlue gas

The incineration pretreatment process comprises a mixing device, a combustion chamber, an explosion venting device and a secondary combustion chamber, the mixing device, the combustion chamber, the explosion venting device and the secondary combustion chamber are sequentially connected through pipelines according to the flowing path of flue gas generated after incineration, and the mode that the high-chlorine waste liquid enters the combustion chamber from the mixing device is atomized spraying. And the secondary combustion chamber is connected to a rotary kiln main incineration line secondary combustion chamber through a pipeline. The combustion chamber is mainly used for conducting primary combustion on the high-chlorine waste liquid, the secondary combustion chamber is used for conducting sufficient combustion on combustible smoke generated in the combustion chamber, a proper amount of lime slurry is sprayed in the combustion chamber in the incineration process, a large amount of chlorine-containing smoke is removed through an adsorption reaction, and combustible substances in the smoke are further combusted after further combustion in the secondary combustion chamber; flue gas enters a secondary combustion chamber of a main incineration line to be completely combusted after being treated and is discharged after reaching the hazardous waste incineration pollution control standard, and the buffering effect of protecting the rotary kiln is achieved.

Owner:广州雅居乐固体废物处理有限公司

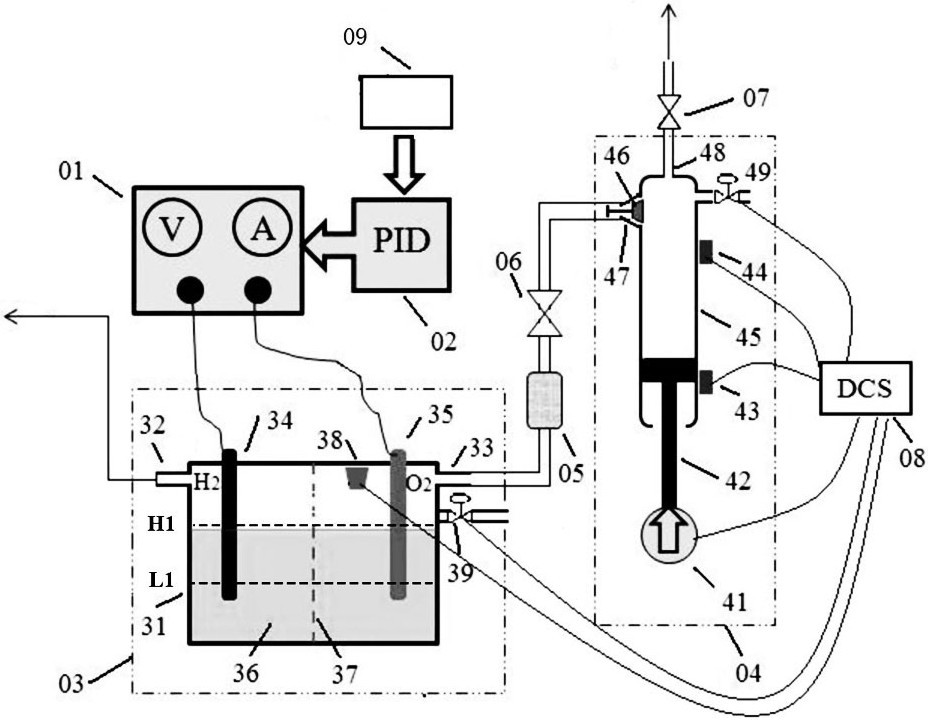

A system and method for automatically adding oxygen to water supply

ActiveCN108558030BOxygen automatic and preciseNo maintenanceWater treatment parameter controlScale removal and water softeningElectrolysed waterElectrolysis of water

The invention relates to an automatic oxygenation system for water supply, comprising an adjustable power supply, a PID control module, an oxygen generator, an oxygenation component and a unit dissolved oxygen detection part, the unit dissolved oxygen detection part is connected with the unit, and the PID control module is respectively connected with the adjustable oxygen generator The power supply and the dissolved oxygen detection part of the unit are connected, the adjustable power supply is connected with the oxygen generator, and the oxygen generator is connected with the oxygenation component. The invention also relates to a method for automatically adding oxygen to water. The PID control module controls the adjustable power supply to output the corresponding current value to the oxygen generator according to the dissolved oxygen concentration signal detected by the dissolved oxygen detector of the unit and the set target dissolved oxygen concentration signal. , the oxygen generator generates a matching amount of oxygen through electrolysis of water, and the generated oxygen is added to the feed water of the unit through the oxygenation component. The invention has the advantages of high degree of automation, precise control of oxygen addition, maintenance-free equipment, labor saving and the like.

Owner:湖南省湘电试验研究院有限公司

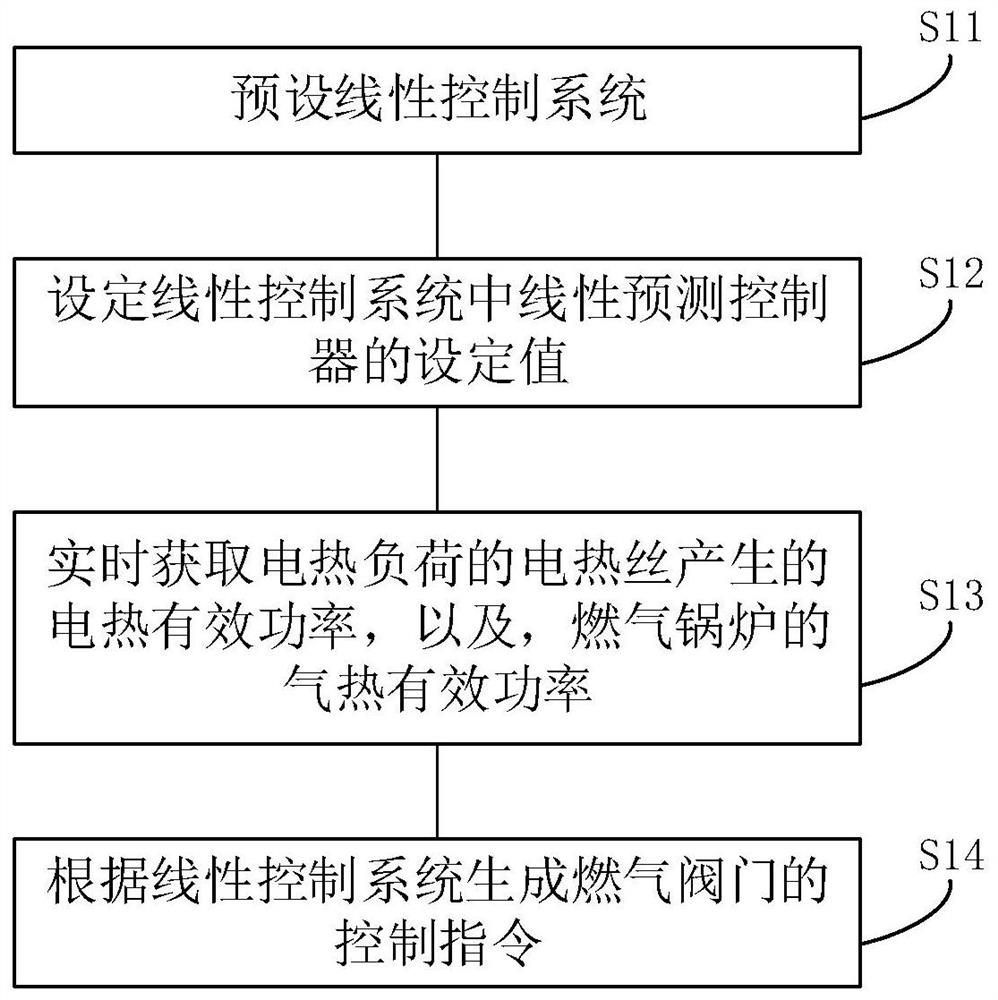

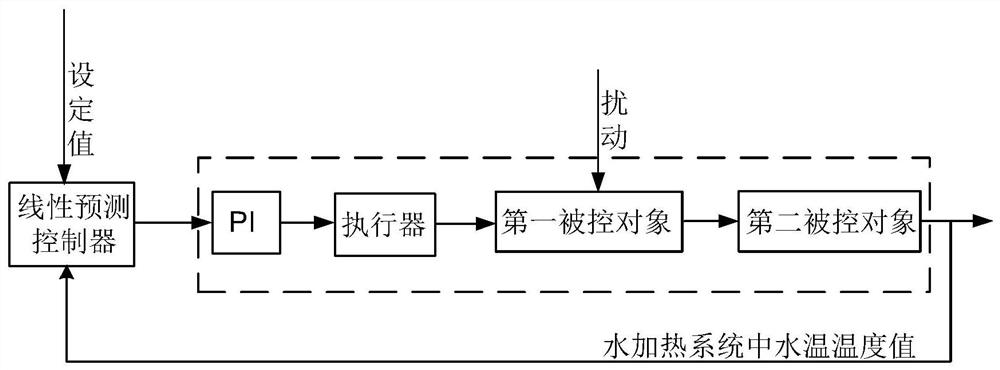

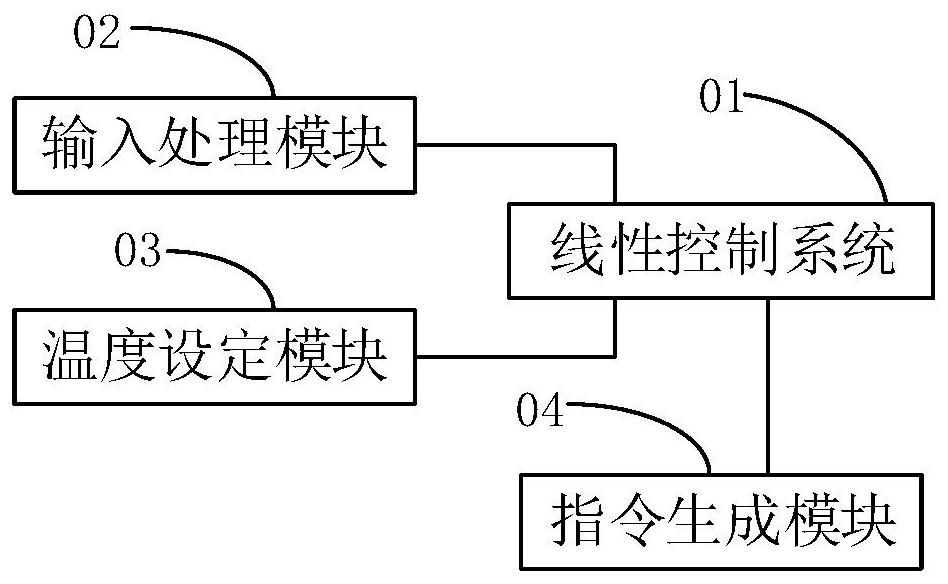

Memory, and electrical coordination control method, equipment and device for micro-grid

PendingCN113128822AAvoid big swingsGood thermostat controlGeometric CADDesign optimisation/simulationElectric heatingHeating system

The invention discloses an electrical coordination control method, equipment and device for a memory and a micro-grid. The method comprises the following steps: presetting a linear control system; setting a set value of a linear predictive controller in the linear control system; the set value comprises a reasonable interval of water temperature in the water heating system; the electric heating effective power generated by the electric heating wire of the electric heating load and the gas heat effective power of the gas-fired boiler are obtained in real time; and generating a control instruction of the gas valve according to the linear control system. When the electric heating load power changes, the linear control system solves the influence mode of the change value of the electric heating load power on the water temperature in the water heating system, and a control mode of a gas valve of the gas boiler for counteracting the influence can be generated; therefore, the gas valve of the gas-fired boiler does not need to be adjusted and coped after the water temperature is changed, large fluctuation of the water temperature in the water heating system can be avoided, and good constant-temperature control over the water temperature in the water heating system is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A fast on-orbit closed-loop identification method, system and medium for spacecraft disturbance torque

ActiveCN108279695BAdjust the convergence rateFast convergenceCosmonautic vehiclesCosmonautic partsGyroscopeAttitude control

The invention discloses a rapid spacecraft disturbance torque on-orbit closed-loop identification method, system and medium, and provides a rapid orbital transfer disturbance torque closed-loop identification method to solve the attitude control problem of a spacecraft with flexural vibration and liquid sloshing in orbital transfer during ignition of a main engine. The method includes the steps: (1) integrating angular speed measured by a gyroscope to obtain an attitude angle and calculating needed control quantity by a controller; (2) inputting data to a disturbance estimation equation according to attitude angle input and the calculated control quantity to obtain a preliminary estimation value of disturbance torque; (3) further inputting the preliminary estimation value of the disturbance torque to a filter, and filtering low-frequency flexural and liquid sloshing information to obtain final disturbance estimation values. By the method, when flexural vibration and liquid sloshing arepresent, the disturbance torque can be rapidly and accurately identified. Disturbance identification results can be directly fed forward to an integral term, so that attitude overshoot caused by start of the main engine can be decreased.

Owner:BEIJING INST OF CONTROL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com