Dehydration treatment method for indium antimonide infrared detector

A technology of an infrared detector and a processing method, which is applied in the field of communication, can solve the problems of poor consistency of indium antimonide infrared detectors, and achieves the effects of avoiding large fluctuations, avoiding secondary pollution, and stabilizing consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

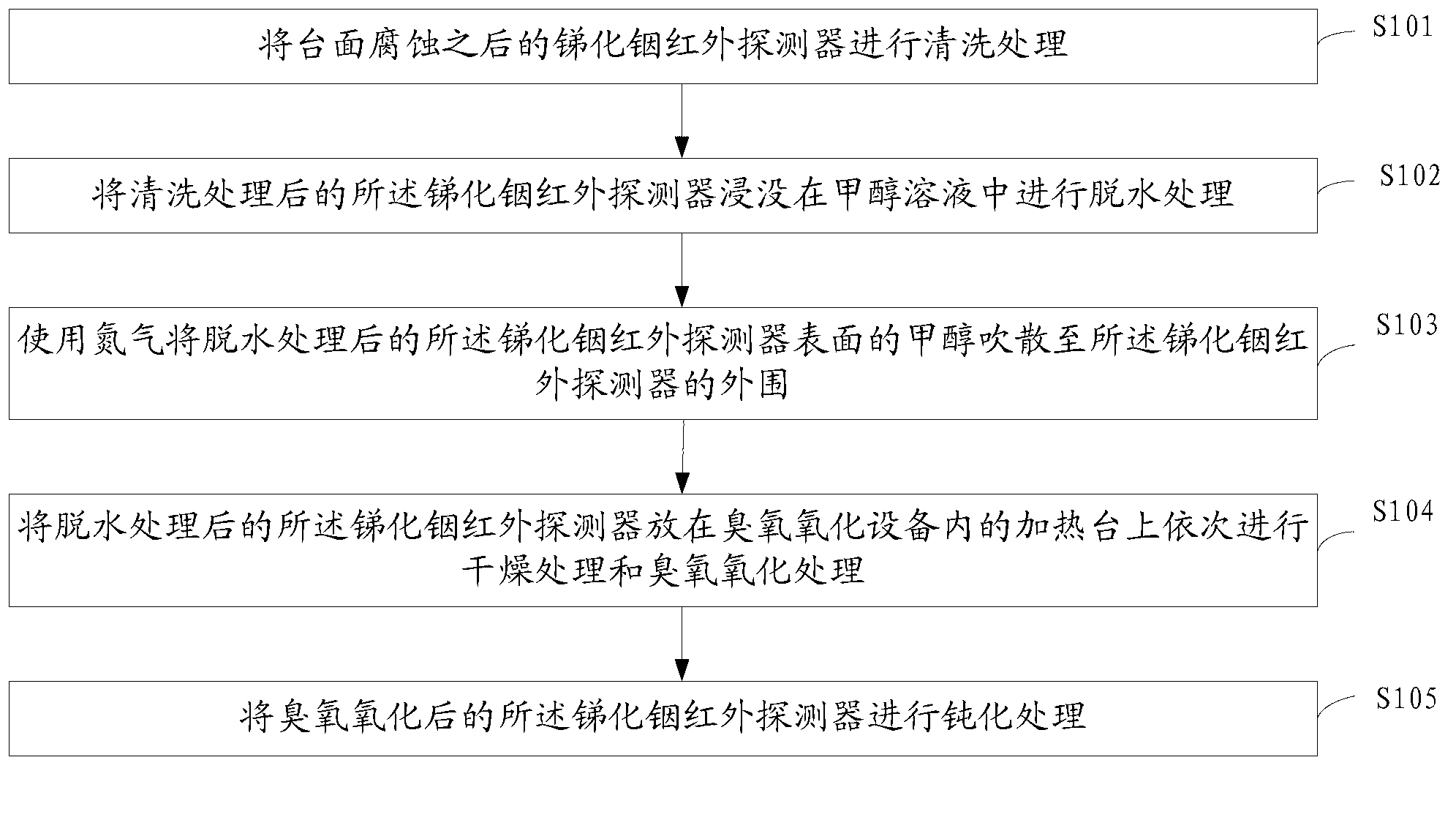

[0030] An embodiment of the present invention provides a method for dehydrating an indium antimonide infrared detector, see figure 1 , the method includes:

[0031] S101, cleaning the indium antimonide infrared detector after the table top is corroded;

[0032] Wherein, the cleaning treatment cleaning treatment specifically includes:

[0033] The indium antimonide infrared detector is cleaned with deionized water with a resistivity greater than 12 MΩ, and the flushing time is 30-60 minutes, so as to completely remove remaining impurities on the indium antimonide infrared detector.

[0034] S102. Submerge the cleaned indium antimonide infrared detector in a methanol solution for dehydration treatment for 1-3 minutes, and repeat this process three times to fully remove the remaining indium antimonide infrared detector The water is removed, thereby effectively controlling the large fluctuations in chip performance caused by changes in the humidity of the purification room, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com