Patents

Literature

79results about How to "Consistency and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

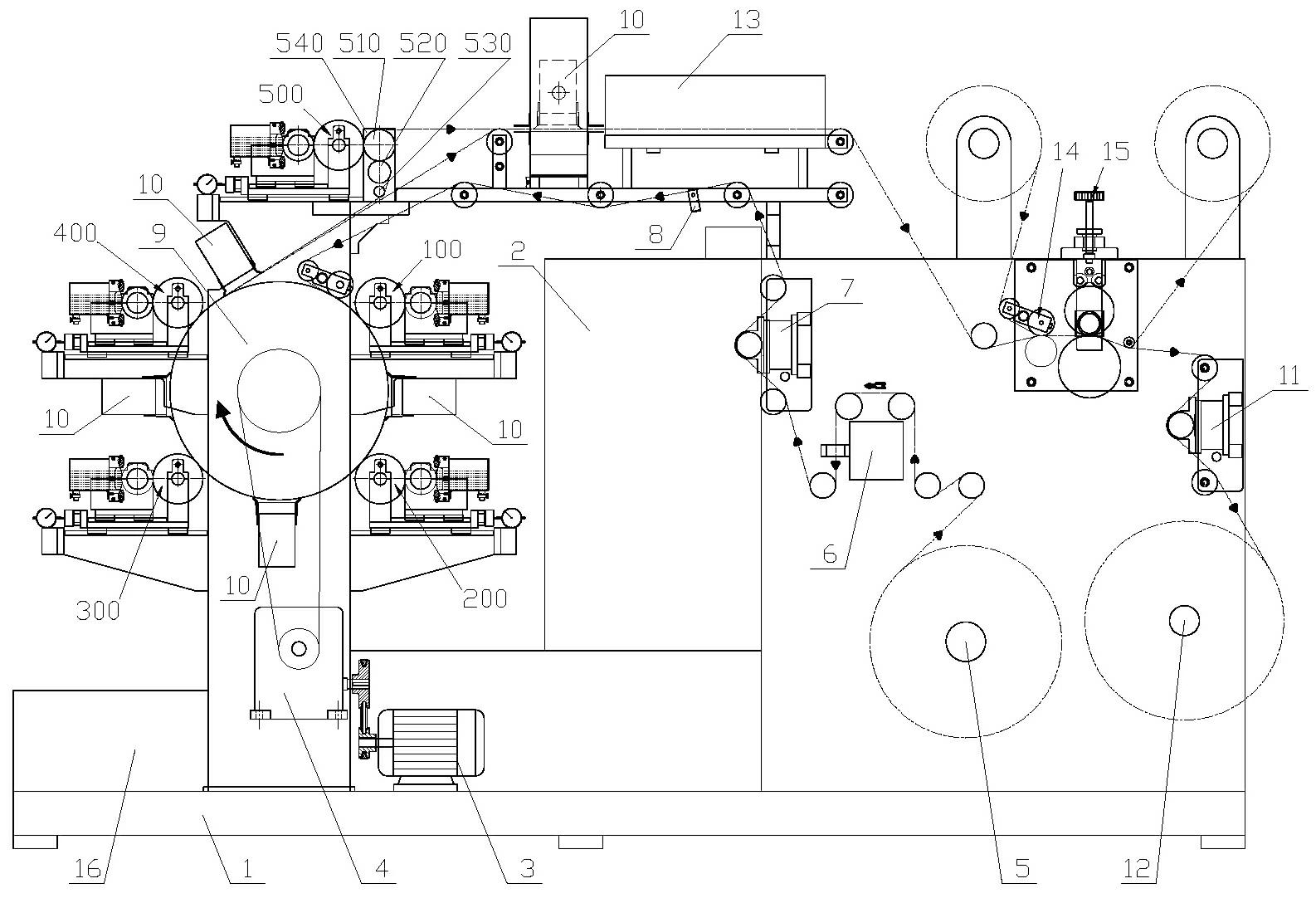

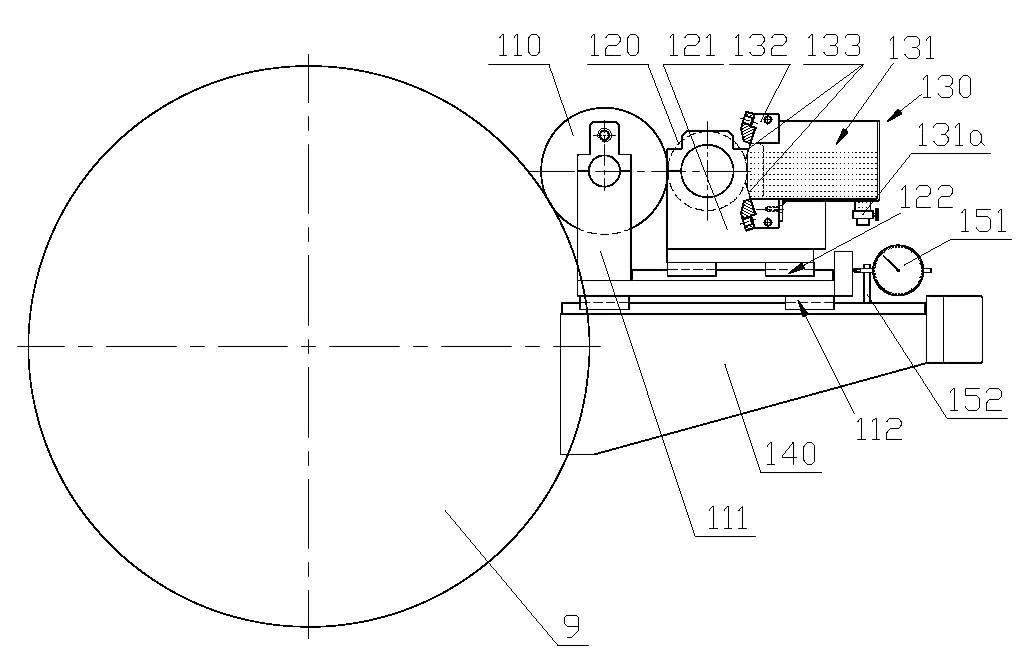

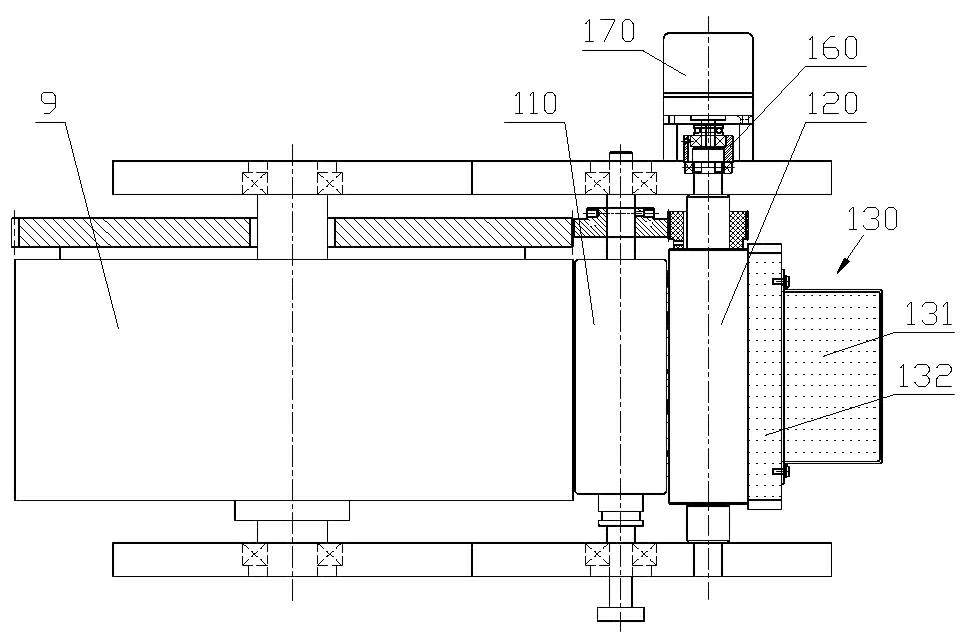

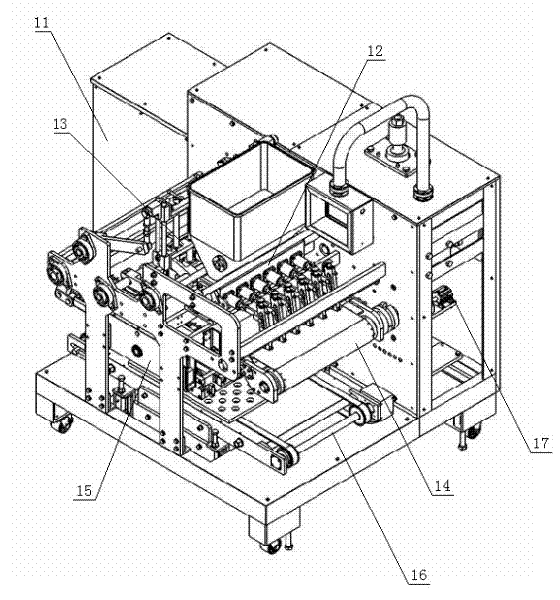

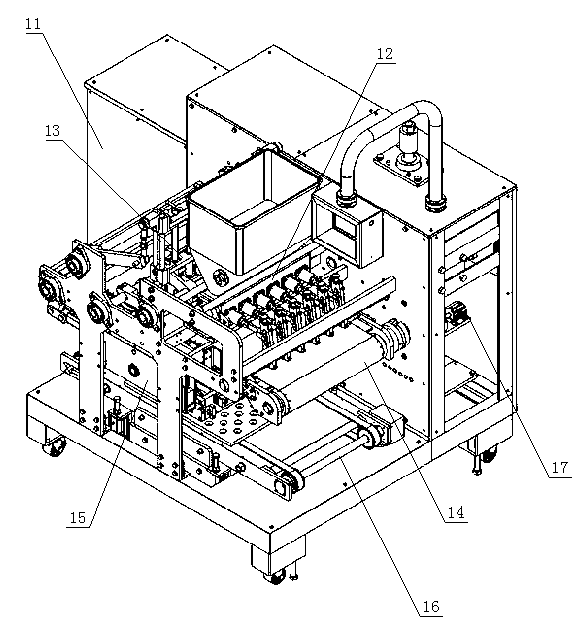

Narrow amplitude satellite type flexographic plate printing machine

InactiveCN102173184AEasy to operateConsistent contact pressureRotary letterpress machinesPrinting press partsInfraredWater based

The invention relates to a narrow amplitude satellite type flexographic plate printing machine which is characterized in that linear guide rails are adopted for ink transfer motion of an anilox roller and movement of a printing plate roller drum, the operation is lightweight and the printing precision is high; by setting an operation mechanism which can read data of a dial indicator for indicating the position of the printing plate roller drum, the technical difficulty in operation is reduced; the anilox roller is connected with a motor through a clutch, thereby avoiding the frequent cleaning problem in a workshop of the anilox roller; by using a back bucket type double-doctor ink supply device, the structure of an ink supply mechanism is greatly simplified, and the cost is greatly reduced; a central stamping roller drum is equipped with a water circulation cooling constant temperature system, thereby ensuring the printing quality; an ultraviolet drying device is provided with a power conversion energy-saving control circuit, thereby saving electrical energy; and an infrared drying device, a printing film covering device and a printing synchronous circular die-cutting device are arranged on the back side of the ultraviolet drying device after the last color of a printing group, thereby further saving the electrical energy, realizing synchronous multiple functions in one machine and reducing the cost. The narrow amplitude satellite type flexographic plate printing machine is applicable to water-based ink printing, and can avoid polluting commodities and causing harm to health of people, and is environment-friendly.

Owner:上海环野机械有限公司

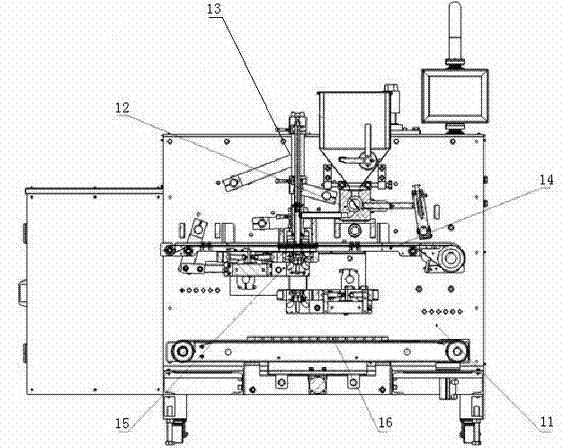

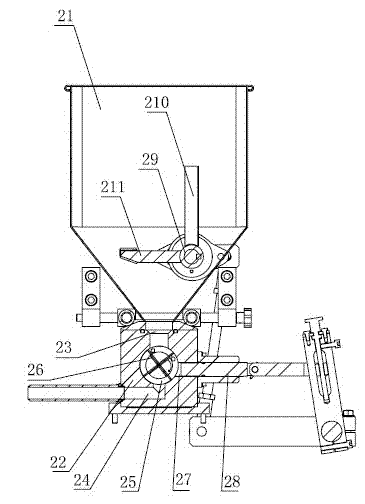

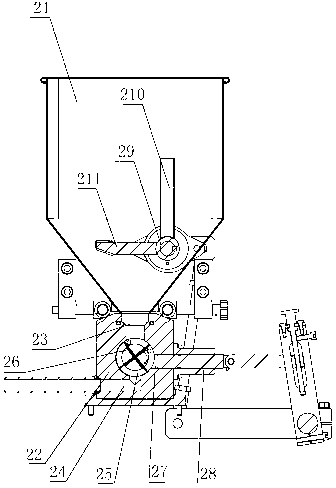

Food encrusting device

ActiveCN102177928AIncrease the number ofDoes not affect normal operationDough shaping and cutting apparatusDough dividingBiomedical engineeringFood products

The invention relates to the technical field of food machines, in particular to a food encrusting device, which comprises a food encrusting device machine frame, a food encrusting device stuffing injection component, food encrusting, stuffing pushing and wrapper cutting devices, a wrapper delivering component, a food encrusting device wrapper forming device, a food encrusting device conveying mechanism and a food encrusting device driving mechanism, wherein the food encrusting device stuffing injection component has a plurality of independent discharging channels and a plurality of food encrusting, stuffing pushing and wrapper cutting devices which are arranged in a way of corresponding to the discharging channels and complete stuffing pushing and wrapper cutting at the same station. The food encrusting device has the advantages that: the stuffing injection and wrapper cutting device are arranged in a linear mode, so a plurality of the stuffing injection and wrapper cutting devices can operate without interference, and even if one stuffing injection and wrapper cutting device has a fault, other stuffing injection and wrapper cutting devices can still work normally; and due to the linear arrangement mode, in a range matched with a driving mechanism, the stuffing injection and wrapper cutting devices can be increased randomly, so large-scale production can be realized, and the working efficiency is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

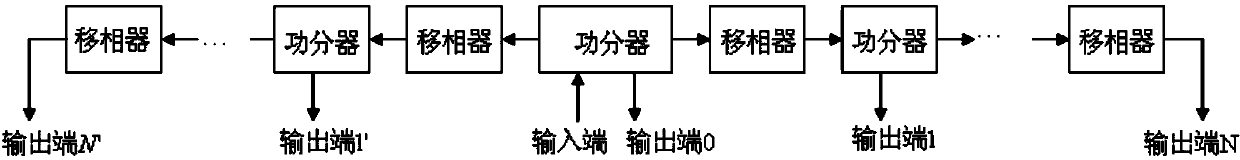

Base station antenna feed network

ActiveCN103975485ACompact structureSimple structureAntenna arraysAntenna supports/mountingsThree-phaseEngineering

The invention provides a base station antenna feed network which comprises at least two power dividers and at least three phase shifters. The output end of a front phase shifter is connected with the input end of a power divider. One output end of the power divider is used as one output end of the whole feed network, and the other output end is connected with the input end of a next phase shifter. Each phase shifter comprises a fixed transmission line and a slidable transmission line. The phase shifters and the power dividers are respectively arranged in an integrally formed metal chamber structure. Feed points are arranged along a long side direction. The base station antenna feed network according to the invention realizes flexible power dividing ratio design, stable performance and relatively low power loss. So that the feed network has advantages of compact structure, relatively small dimension, easy manufacture, low cost, easy realization for wide frequency band, more stable integral performance, higher consistency, and flexible combination for increasing number of output ends.

Owner:TONGYU COMM INC

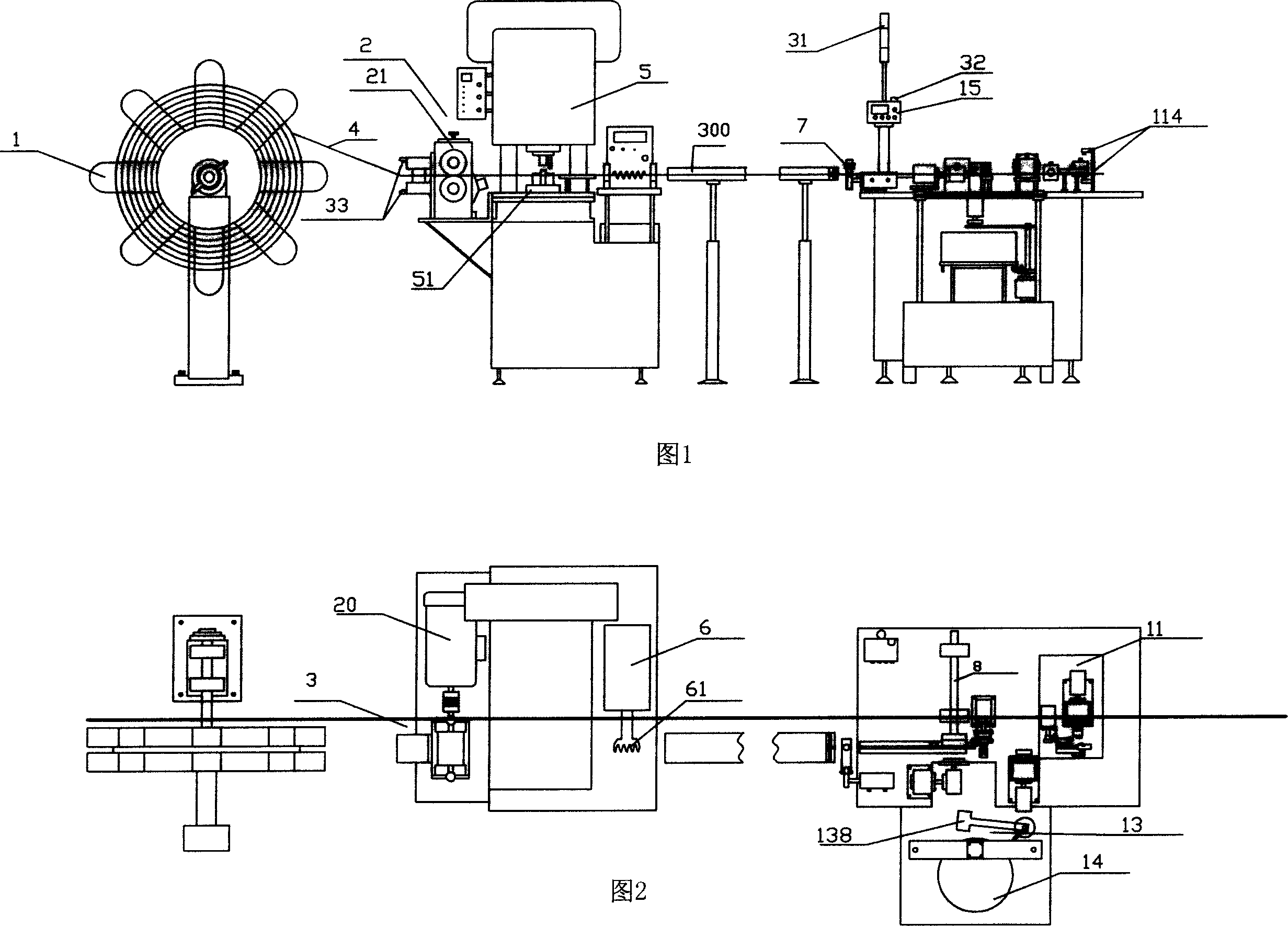

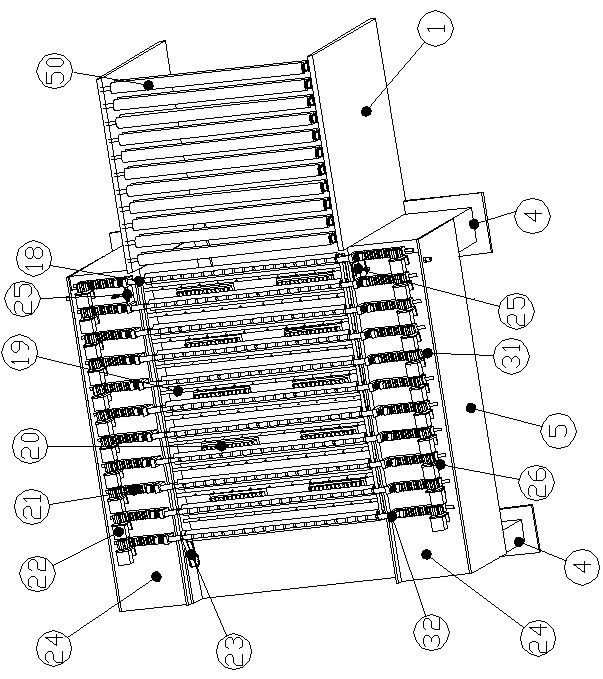

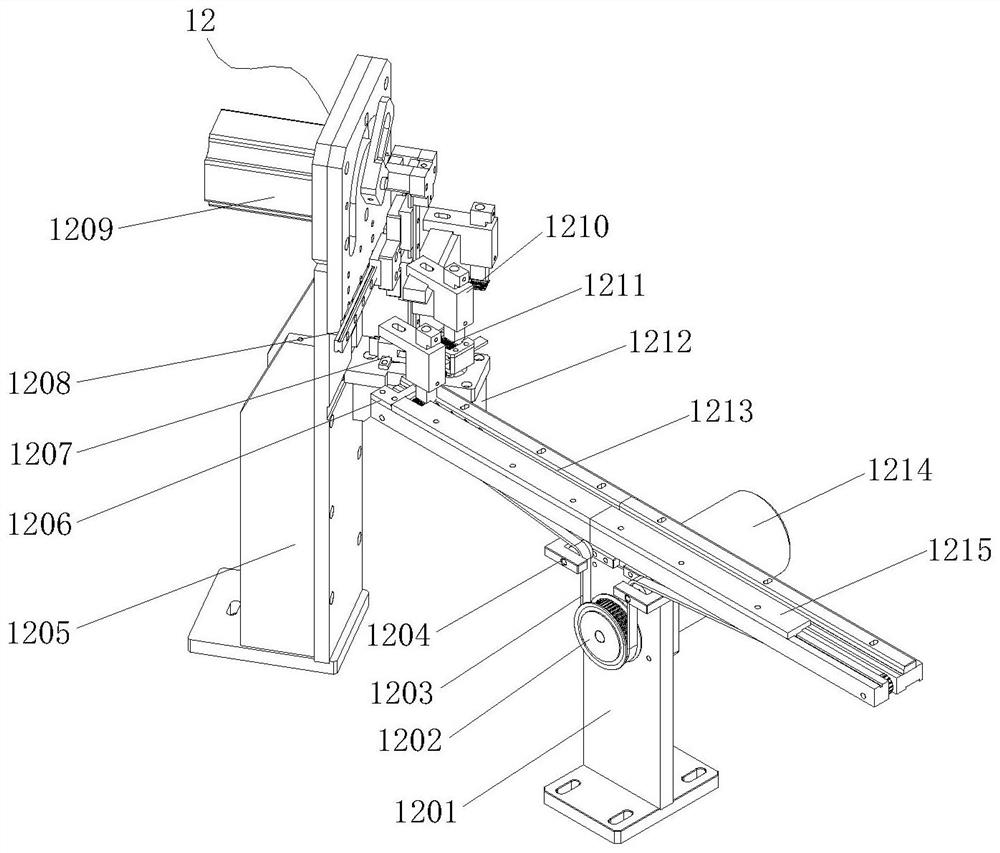

Automatic scroll spring forming apparatus

ActiveCN101020291ARealize automated productionIncrease productivityMetal-working feeding devicesOther manufacturing equipments/toolsProduction linePunch press

The automatic scroll spring forming apparatus includes a disc type feeder frame, a material failure optoelectronic controller, a length determining feeder, a punch with die, a high frequency annealer, an electromagnetic sucking head, a crimper, a former, a hook feeding device, a hook bender, an unloading device, an acceptor, a collector and controlling system. Under the control of the controlling system, the present invention completes the whole process including material feeding, cutting, high frequency annealing, bending hook, feeding hook, curling, unloading and collecting. The present invention has the advantages of integrated production line, low production cost, high product precision, etc.

Owner:宁波韵升弹性元件有限公司

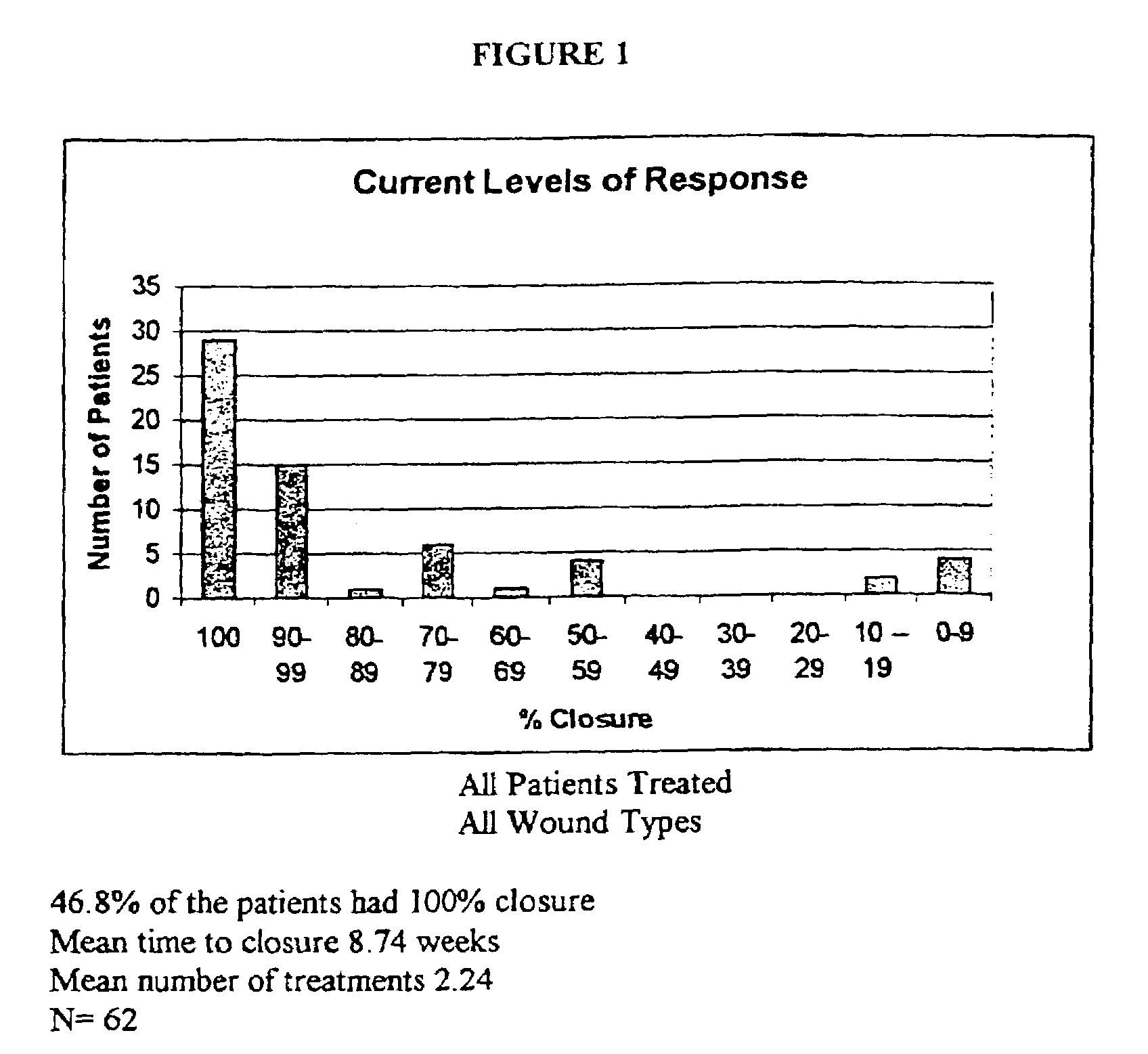

Enriched platelet wound healant

InactiveUS7112342B2Improved enriched platelet compositionDelay and prolong activated gelation periodBiocideHydroxy compound active ingredientsVitamin A AlcoholAntibiotic Y

An improved platelet gel wound healant, and methods of preparation and use thereof for healing wounds are disclosed. The improved wound healant comprises a therapeutically effective amount of activated growth factors and ascorbic acid with optional one or more additional anti-oxidant such as vitamin A and / or E, and optional one or more antibiotics.

Owner:NUO THERAPEUTICS

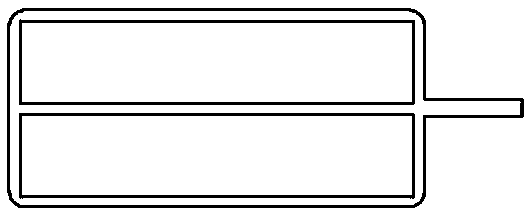

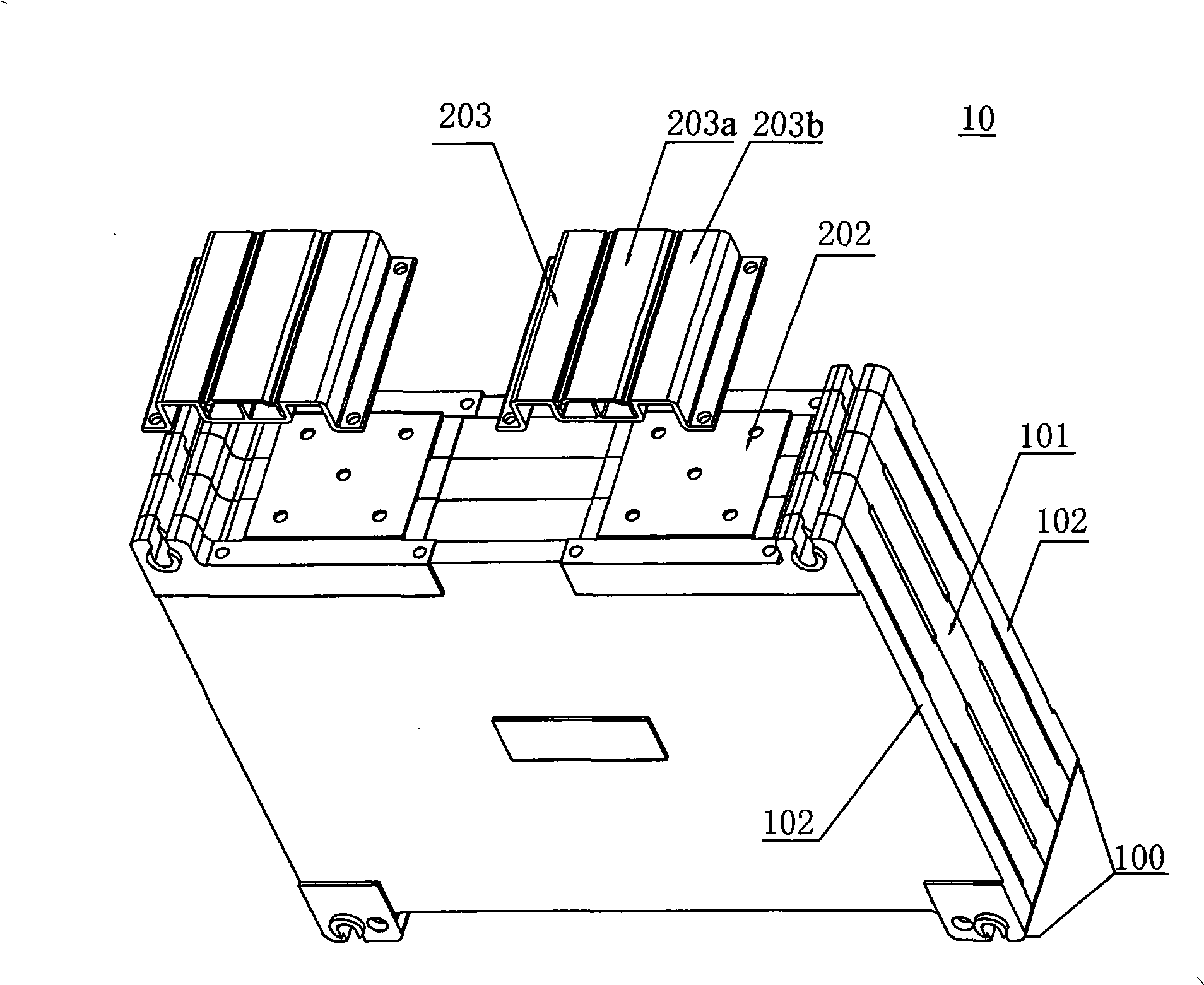

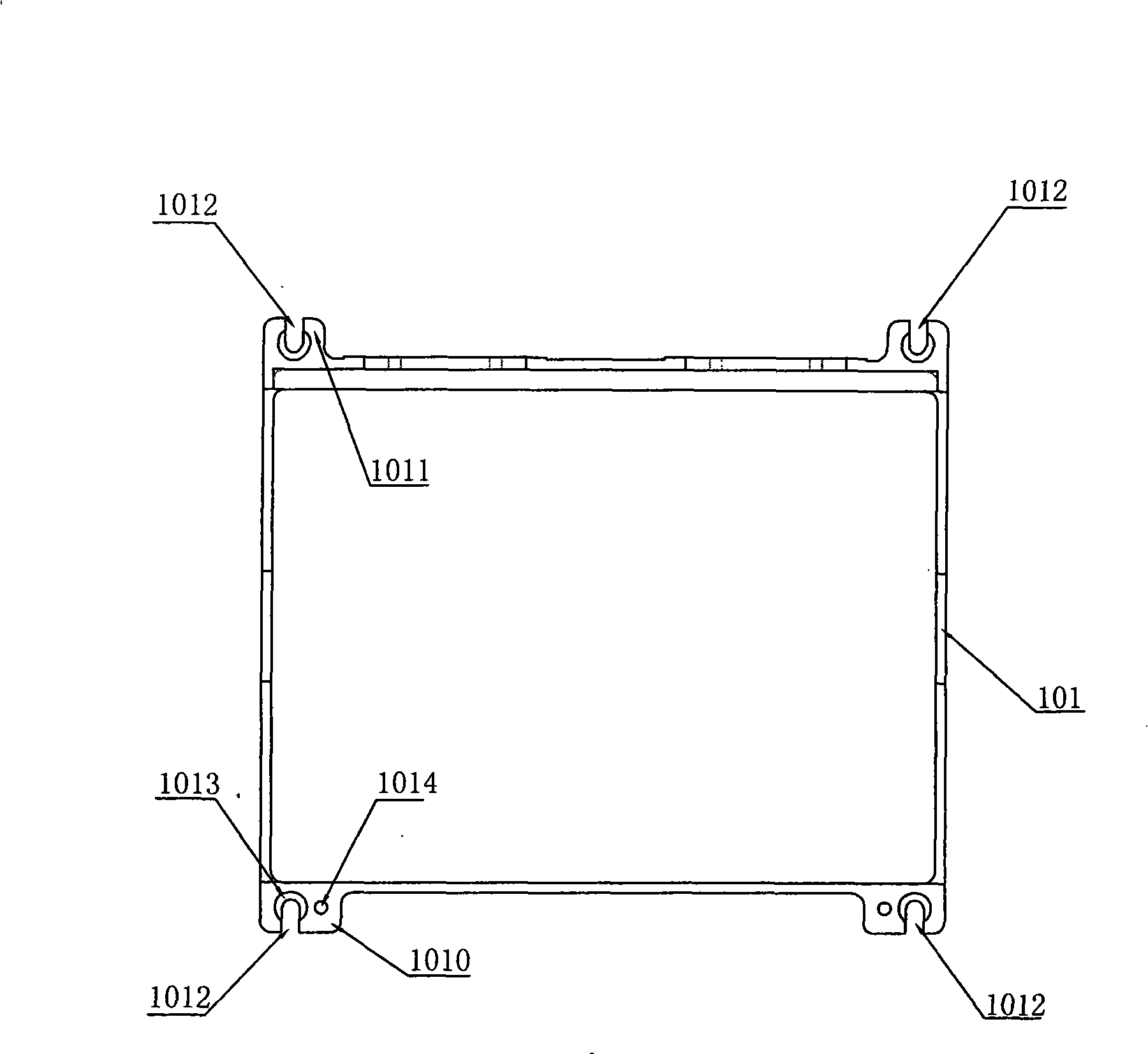

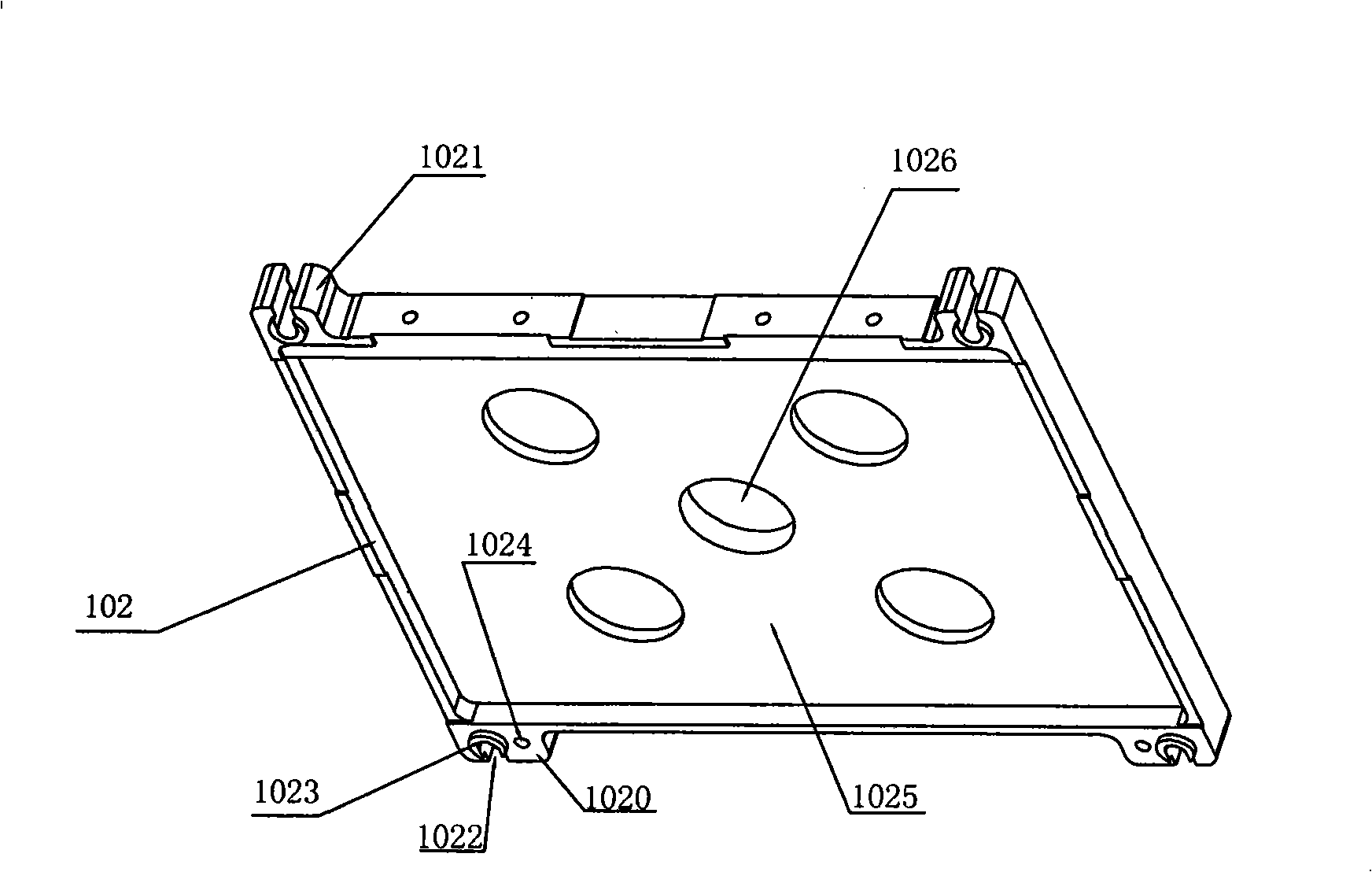

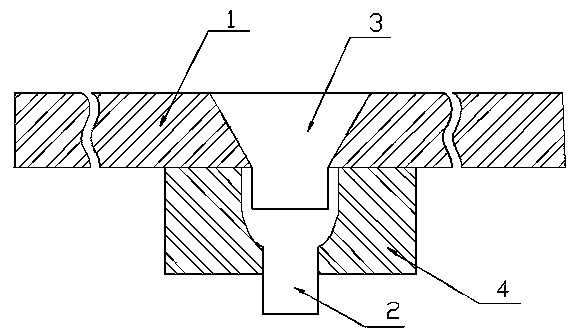

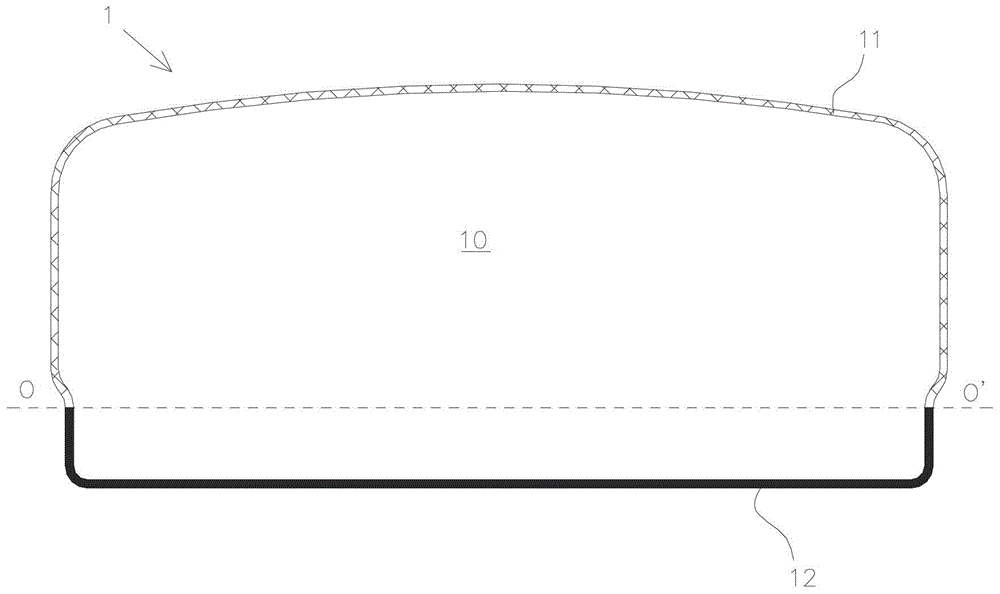

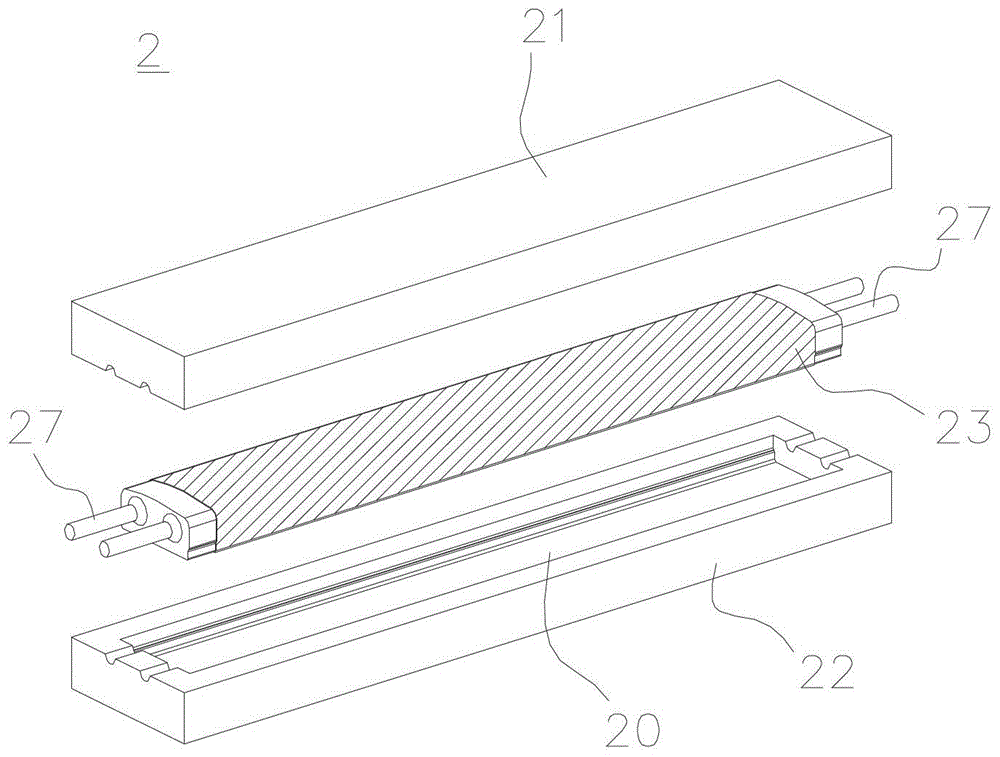

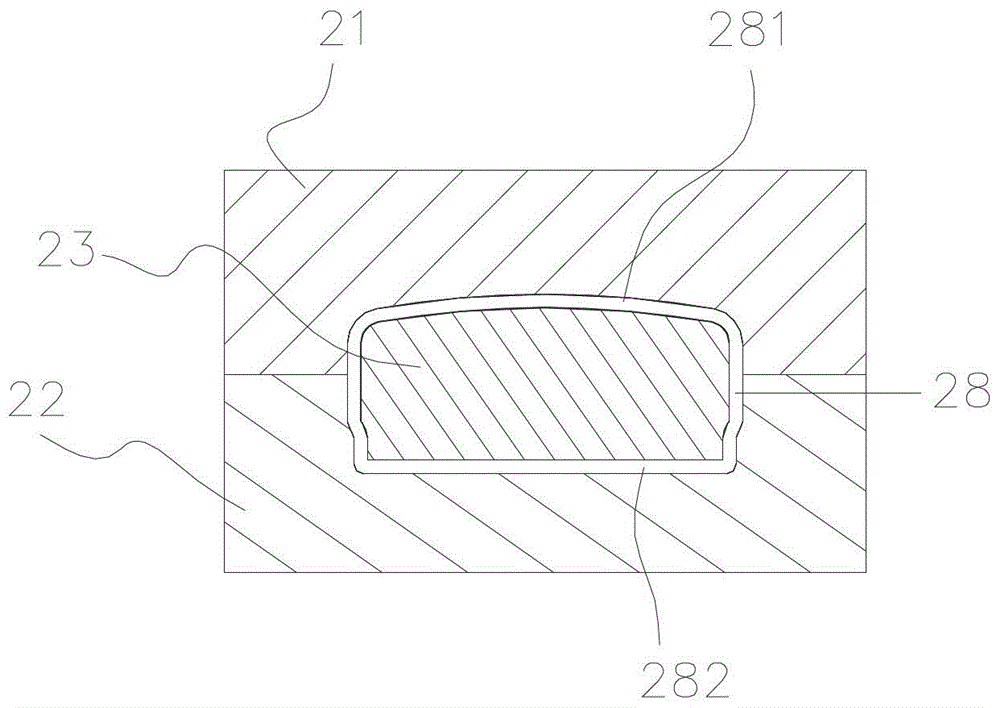

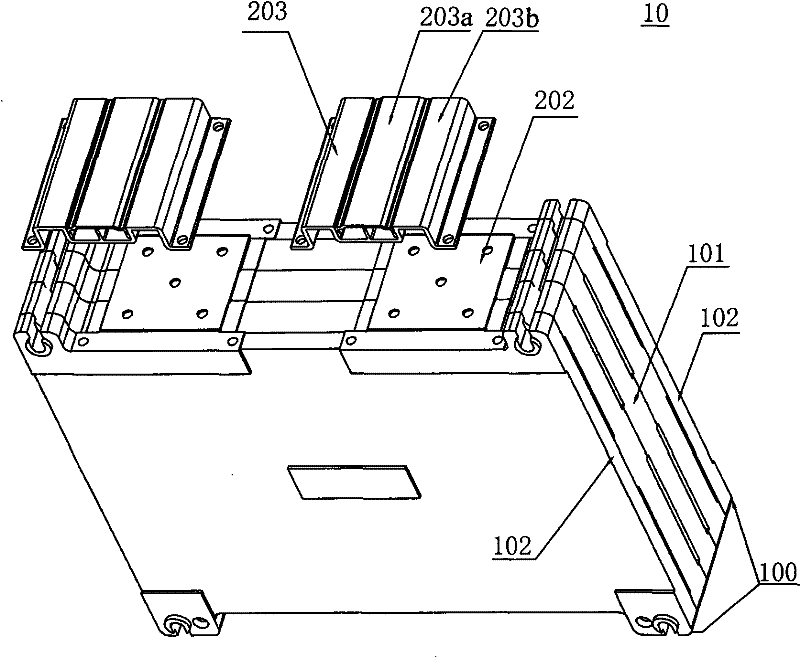

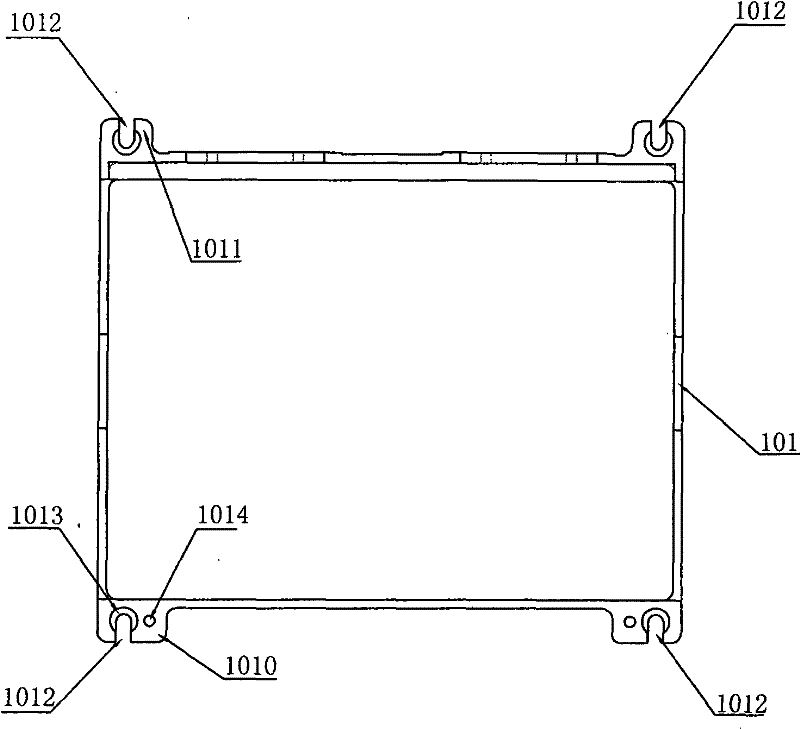

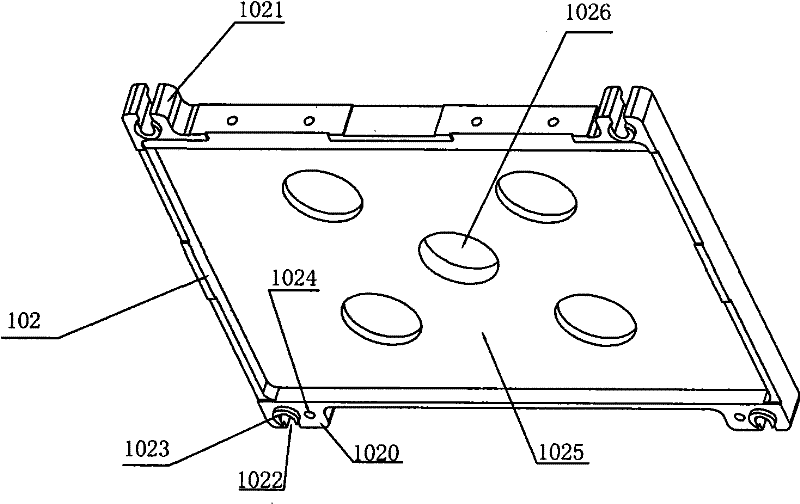

Housing of power cell with adjustable capacity and voltage

The invention provides a shell body capable of enveloping a plurality of power cells, which comprises: an upper end plate provided with an upper end plate groove with a shape corresponding to the outline of the end face of a power cell; at least one intermediate frame body, which is provided with a hollow structure corresponding to the outline of the power cell; and an lower end plate, which is provided with a lower end plate groove with a shape corresponding to the outline of the end face of the power cell. The shell body reasonably meets the requirements on shell body for power cells such as lithium batteries with soft batteries, and realizes the random adjustment of voltage and capacity. The single cells are clamped tightly to ensure the vacuity so as to reduce the vibration of aluminum-plastic film as well as scrapes and damages, to facilitate and ensure the reliability of the connection between a copper press plate and positive and negative plates and to ensure the stable performance and consistency of the cell.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for producing cast iron by adopting remelting furnace blowing smelting and purification, and apparatus thereof

InactiveCN104164529AEfficient removalEliminate generationProcess efficiency improvementSlagNon-metallic inclusions

The invention relates to a method for producing cast iron by adopting remelting furnace blowing smelting and purification, and an apparatus thereof. The method comprises the following steps: 1, adding an iron-containing raw material and auxiliary materials into a remelting furnace with a blowing function in a charging proportioning stage; 2, heating and slagging in a melting stage; 3, blowing a gas to the above obtained melt and making reducing slag in a blowing purification and reduction stage; and 4, carbonizing iron or graphitizing. The method aims to effectively remove impurities in the iron-containing raw material and the auxiliary materials through a blowing purification process, or / and an oxidation and reduction chemical reaction in high temperature blowing smelting, or / and a refining furnace blowing purification process and a vacuum process, substitutes physical remelting processes which cannot remove impurities through blowing smelting in traditional cast iron remelting induction furnaces in order to eliminate the harms of low melting point elements, high melting point elements, nonmetal inclusions and gases, stabilizes the product consistence, and matches with elements required by the production of various cast irons to produce the various cast irons through addition, generation and inoculation of iron carbide and various forms of basic structures of graphite required by the cast iron.

Owner:襄阳康捷飞龙机械制造有限公司

Antenna and its radome as well as the mold and molding process of the radome

ActiveCN103407018BQuality improvementConsistency and stabilityRadiating element housingsCompression moldingHigh volume manufacturing

The invention mainly relates to an antenna cover which is of a cylindrical structure which is integrally formed. The antenna cover comprises an upper cover with a hollow material structure and a lower cover with a compact material structure, wherein the upper cover and lower cover are divided by an invisible longitudinal section, and the upper cover and the lower cover are subjected to integrated compression molding. In addition, the invention relates to an antenna adopting the antenna cover, a mould for preparing the antenna cover as well as an antenna cover forming process for manufacturing the antenna cover. The process mainly adopts compression molding so as to obtain the antenna cover with a closed profiled bar structure. The invention provides the mould and the forming process and the like for improving the antenna cover based on the same idea, the antenna cover obtained by the idea has the closed profiled bar structure, excellent electromagnetism wave-transparent property and mechanical property can be achieved and are supported by measured data, and the antenna cover is simple in process, low in cost and is beneficial to volume production and popularization and application in the antenna.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

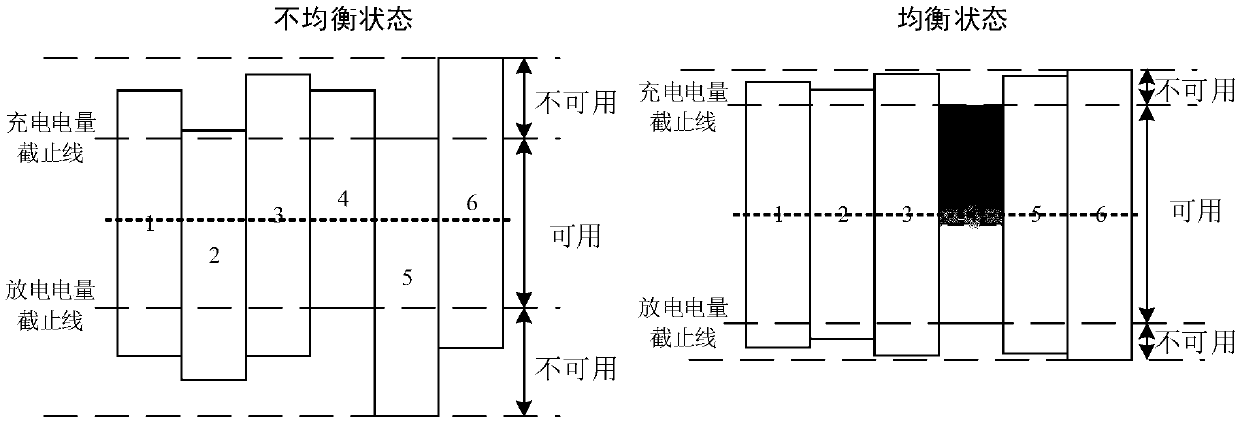

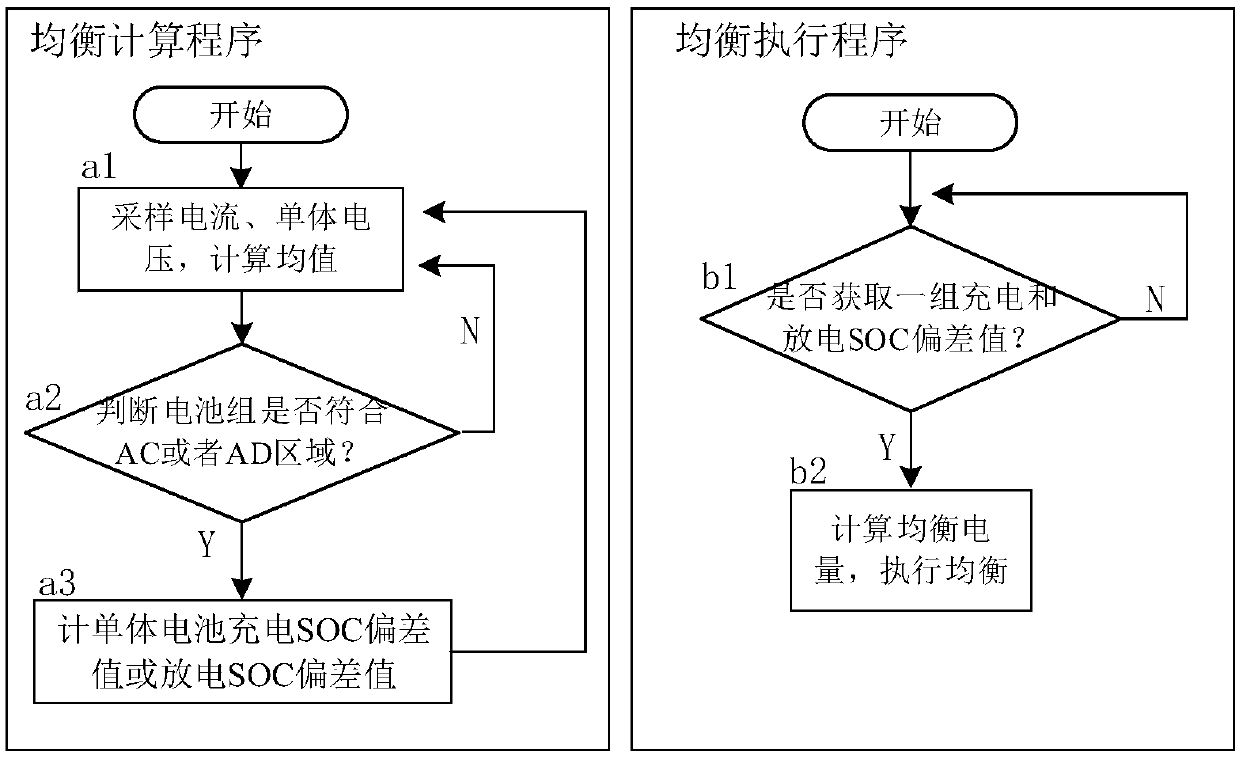

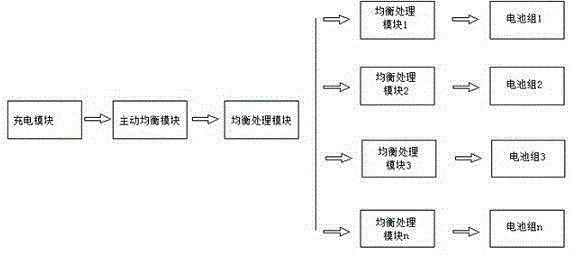

Equalization control method of lithium battery pack for hybrid power

ActiveCN109515251AReduce usable capacity lossEnsure battery consistencyVehicular energy storageBattery/fuel cell control arrangementState of chargeCharge and discharge

The invention discloses an equalization control method of a lithium battery pack for hybrid power. The target state of the equalization control is that: all battery cells simultaneously reach the median Sm of the state of charge (SOC) during charging and discharging, the median Sm can be set accord to application requirements, usually around 50%, the equalization control algorithm does not need toobtain the maximum available capacity value of each single cell, and only utilizes the voltage and current characteristics of a certain section in the charging and discharging process of the single cell to analyze the deviation between the SOC and the Sm of the single cell when the SOC of the battery pack reaches the Sm, so as to take the deviation as a criterion to enable the battery pack to reach the equalization target state. The equalization criterion is easy to obtain, the applicability is high, the battery pack can reach an ideal equilibrium target state by using the control method, theavailable capacity loss of the battery pack can be effectively reduced under the target state, and the long-term stability of the state is guaranteed.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

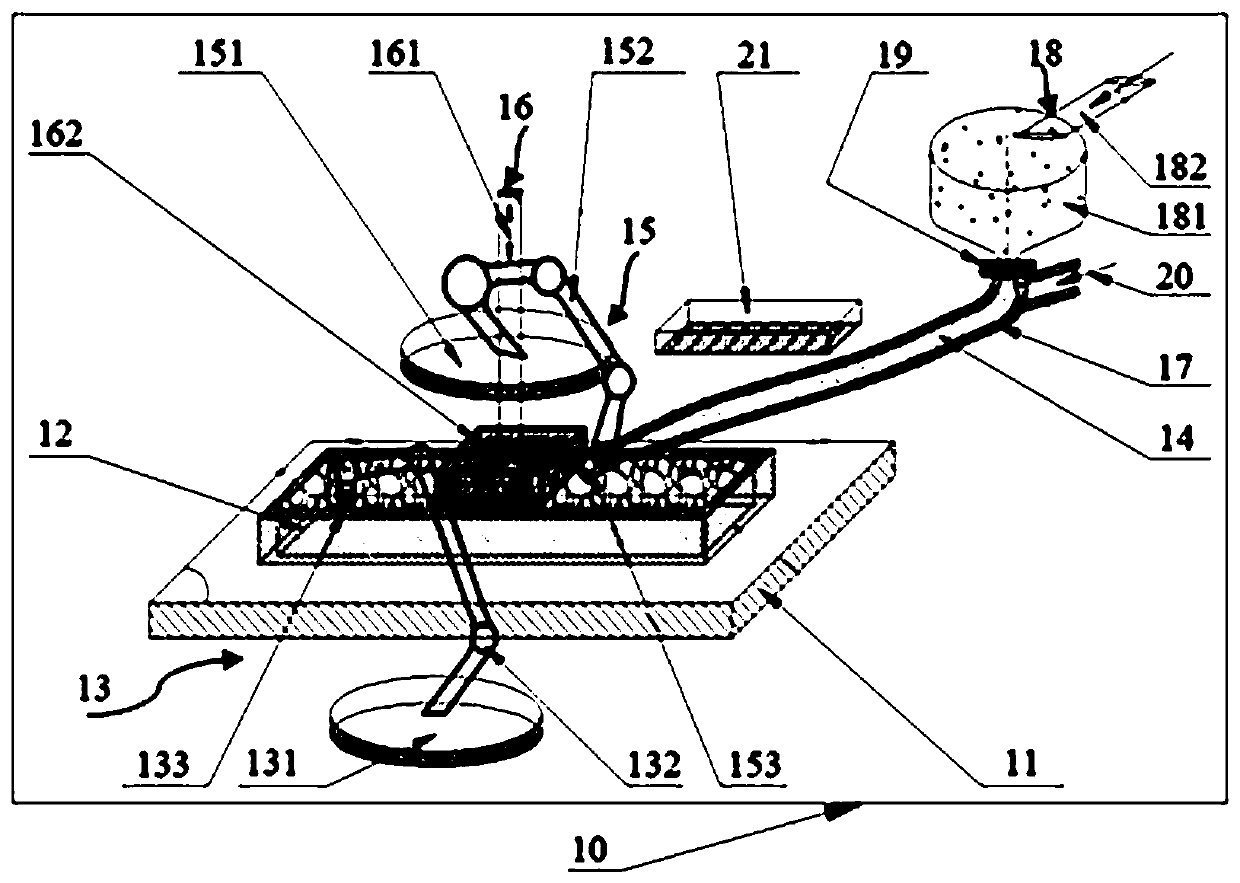

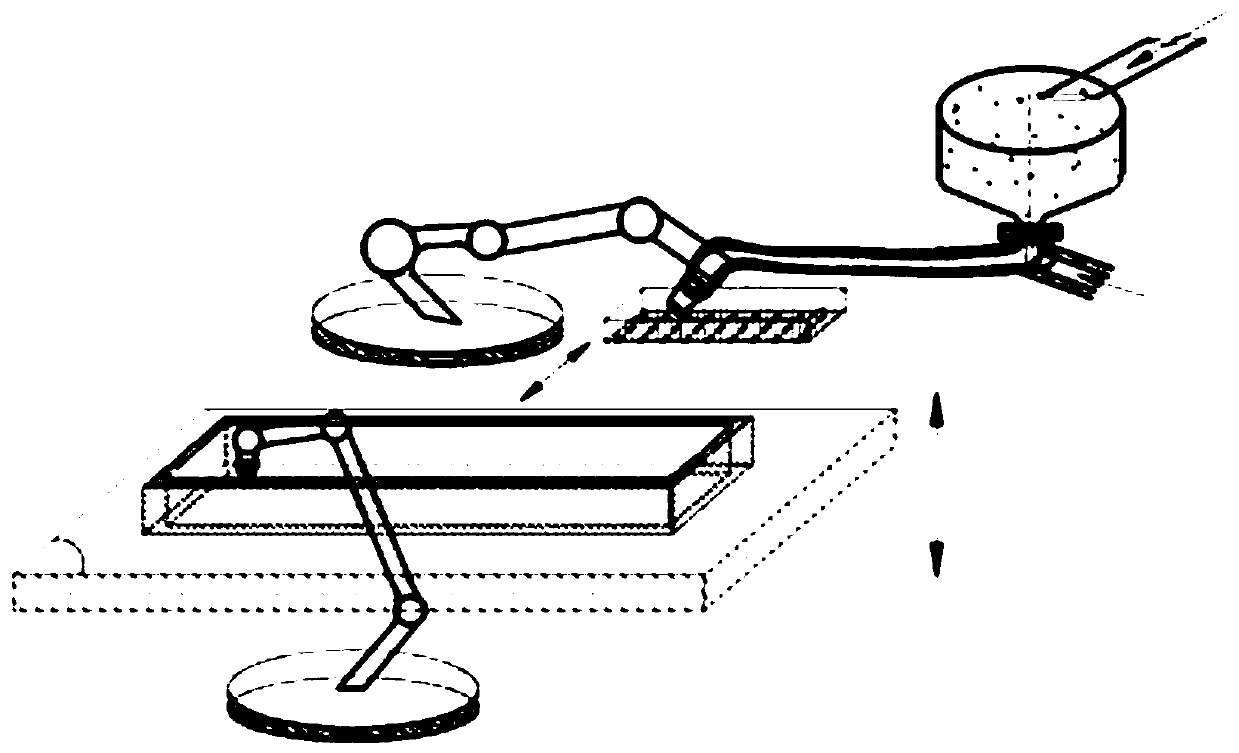

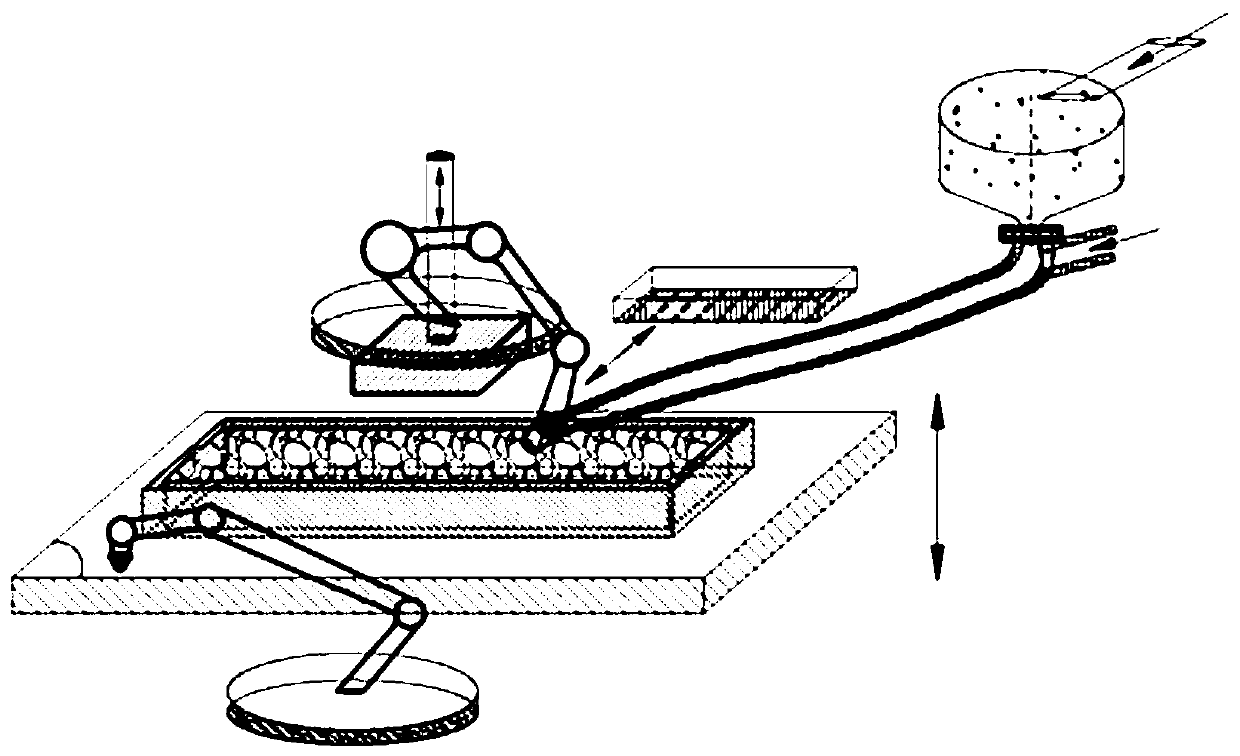

Jacket type composite additive manufacturing device

InactiveCN111468724AStrong connectionImprove sufficiencyAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing cost reductionPipe

The invention discloses a jacket type composite additive manufacturing device. The jacket type composite additive manufacturing device comprises a sealed forming cabin and a base arranged in the sealed forming cabin, wherein a jacket deposition forming device is arranged on one side of the base, a casting forming device is arranged on the other side of the base, an extruding / forging / rolling mechanical auxiliary device is arranged over the base, the casting forming device is connected with a metal smelting device through a flow guide pipe, the metal smelting device communicates with the flow guide pipe through a flow control element, and when metal liquid in a jacket is cooled to the proper pressure machining temperature, the metal liquid in the jacket is subjected to combined machining through the device. According to the jacket type composite additive manufacturing device, through the casting forming device, conventional wire and powder base metal is replaced with large-block base metal, the sufficiency of metal metallurgy is improved through the metal smelting device, a deposited blank is subjected to three-way extrusion stress, the action mode of an existing deposition and one-dimensional composite additive forming device is changed, the consistency and stability of a structure and performance of a formed component are greatly improved, the manufacturing efficiency is greatly improved, and the manufacturing cost is reduced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

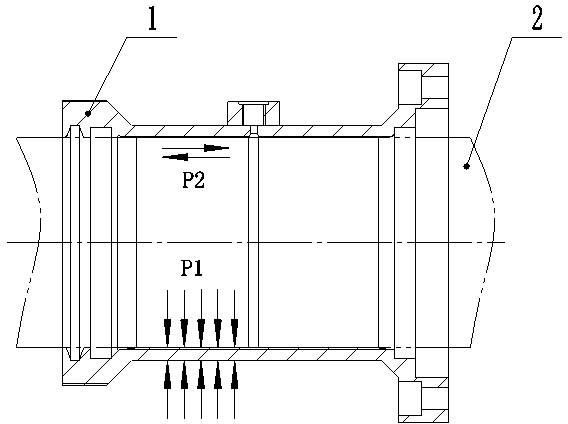

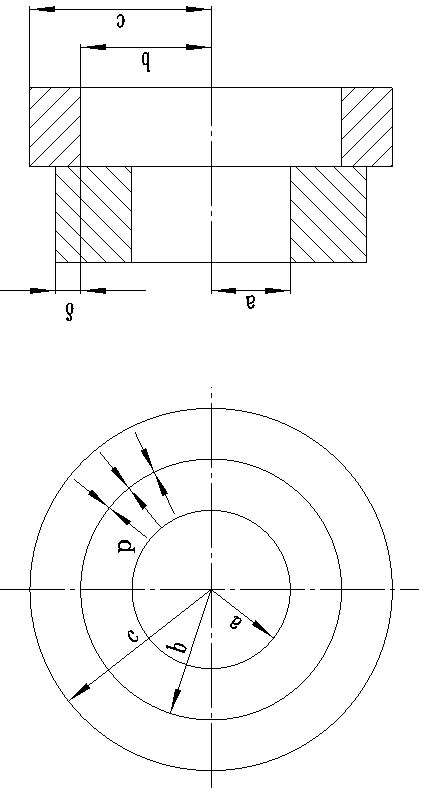

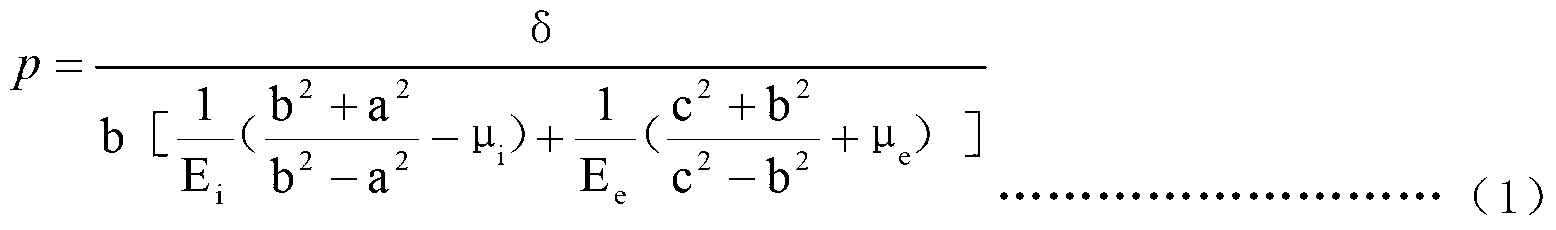

Method for matching mechanical external-extrusion lock sleeves

ActiveCN103268394AImprove accuracyConsistency and stabilitySpecial data processing applicationsPass rateEngineering

The invention relates to a method for matching mechanical external-extrusion lock sleeves and belongs to the field of mechanical lock of machinery and power and electrical engineering. The method for matching mechanical external-extrusion lock sleeves is provided for overcoming defects of the prior art so as to be capable of matching lock sleeves with qualified unlocking force and locking force in high pass rate. The technical scheme for solving the technical problem includes that the method includes: analyzing technical factors affecting matching of the lock sleeves according to locking principle of the mechanical external-extrusion lock sleeves and practical processing, and finding out a optimum interference magnitude matching method by determining reasonable interference magnitude between the lock sleeves and piston rods, determining interference magnitude and hardness of the lock sleeves, and explicating and measuring methods for matching and the like. By the method for matching the mechanical external-extrusion lock sleeves, matching success rate of the lock sleeves is increased.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

Method for producing cast iron by adopting electric furnace blowing smelting and purification

InactiveCN104164530AEliminate generationEliminate hazardsProcess efficiency improvementChemical reactionSlag

A method for producing cast iron by adopting electric furnace blowing smelting and purification comprises the following steps: 1, adding an iron-containing raw material and auxiliary materials into a furnace in a charging proportioning stage; 2, heating and making oxidizing slag in a preliminary melting stage; 3, blowing gas to the above obtained melt and making the oxidizing slag in an oxygen blowing heating oxidation stage; 4, blowing the gas to the melt and making reducing slag in a blowing purification and reduction stage; and 5, carbonizing iron or graphitizing. O2 is blown to provide oxidizing atmosphere and is used for oxidizing impurities, a large amount of impurities are carried by the upward floatation of a CO gas in the oxidation and reduction process, and N2, CO2 and Ar blown in the invention are used to eliminate harmful gases and the impurities carried by the upward floatation. Various iron and steel scraps are effectively decomposed through a redox chemical reaction and various high temperature stirring, blowing purification and evacuation modes in order to eliminate various impurities in the iron-containing raw material and the auxiliary materials and impurities generated in the production, eliminate the harms of low melting point elements, high melting point elements, nonmetal inclusions and gases and enlarge the application range of the cast iron raw materials.

Owner:襄阳康捷飞龙机械制造有限公司

Cold crucible cover for top seed crystal temperature gradient method

InactiveCN103484931AEven insulationHigh melting pointPolycrystalline material growthFrom frozen solutionsCrucibleCrystal growth

The invention relates to the field of sapphire crystal growth, and particularly relates to a cold crucible cover for a top seed crystal temperature gradient method. The cold crucible cover comprises at least two ring tungsten plates, wherein the ring tungsten plates are same in outer diameter and different in inner diameter, and the ring tungsten plates are sequentially arranged from top to bottom and from small to large based on inner diameters; a gap is reserved between the ring tungsten plates; the temperature gradient of stable crystal growth is acquired when seed crystals inside a crucible are heated by utilizing the top seed crystal temperature gradient method. The cold crucible cover disclosed by the invention has the advantages of good balance, good stability, flexibility in structural design and good consistency.

Owner:FUJIAN XINJING PRECISION CORUNDUM TECH CO LTD

Automatic sweater sewing method based on machine vision perception

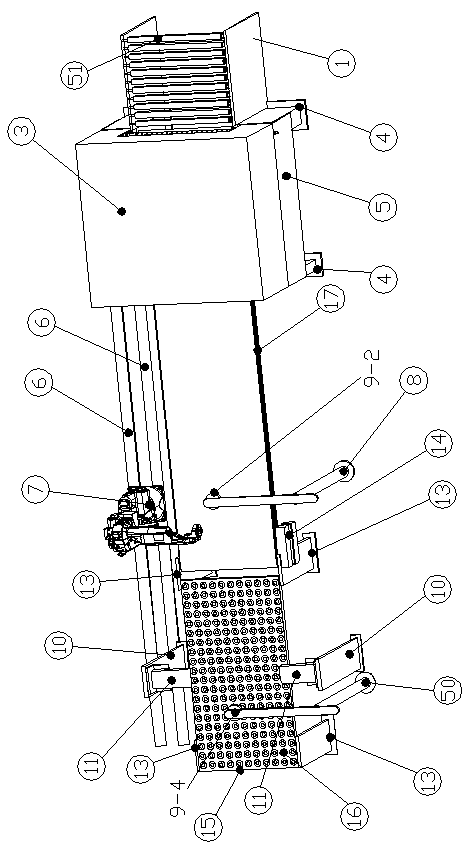

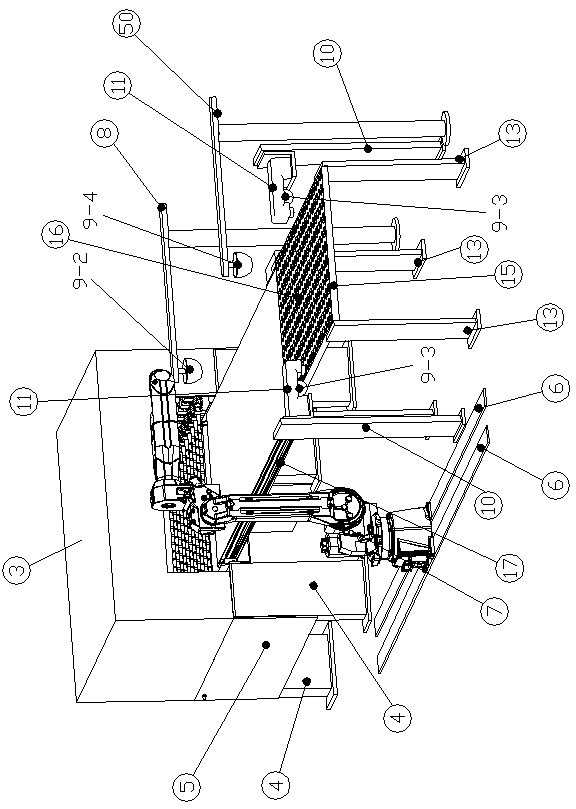

ActiveCN109457398AFacilitate automatic sewingRealize automatic stitchingProgramme-controlled sewing machinesWork-feeding meansMachine visionEngineering

An automatic sweater sewing method based on machine vision perception comprises the following steps of: (1) starting automatic sweater sewing equipment; (2) conveying a sweater weaving piece into a stretching and freezing device from front to back from an input flattening device; (3) stretching the sweater weaving piece and freezing the sweater weaving piece into a rigid body convenient for sewingin the stretching and freezing device; (4) conveying the sweater weaving piece which is stretched and frozen into the rigid body to a sewing preparation device; and (5) finishing turning, carrying, sewing auxiliary pushing and sorting of the frozen sweater weaving piece by a carrying robot, and sewing an upper sweater weaving piece and lower sweater weaving piece which are correspondingly arranged up and down by using a sewing device. The method can replace prior manual sweater sewing, improves the processing efficiency, achieves the improvement of the sewing quality, achieves the stable consistency of products in batch production, and further improves the added value of the products; and the method has certain significance for promoting the development of equipment in the sweater weavingindustry in China.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Organic fiber toughened inorganic composite artificial stone panel and preparation method thereof

InactiveCN110746152AImprove compactnessImprove production efficiencyCovering/liningsFeeding arrangmentsFiberArtificial stone

Owner:黄贺明 +1

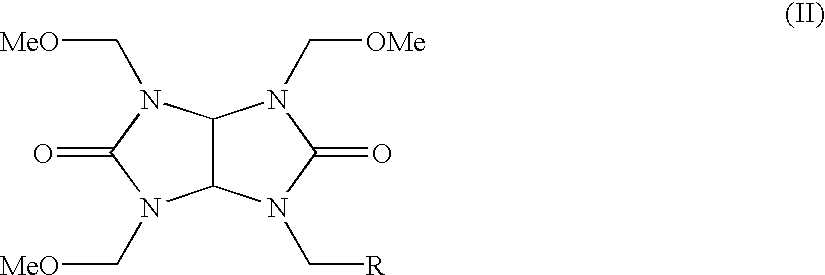

Pearlescent hair care compositions

InactiveUS7341714B2Beautiful pearlescence effectSatisfactory hair conditioning propertyCosmetic preparationsHair removalBetainePolyethylene glycol

The hair treatment composition, which is in the form a pearlescent product, contains a nonionic, amphiphilic associative thickener consisting of at least one hydrophobically modified aminoplast / polyether copolymer; a hair care active ingredient selected from the group consisting of cationic surfactants, zwitterionic surfactants, cationic polymers, cationic silicone compounds, amine-substituted silicone compounds, cationic derivatized proteins, cationic derivatized protein hydrolyzates and betaines; and a pearlescence or turbidity-inducing agent selected from the group consisting of fatty acid alkanol amides, fatty acid glyceryl esters, guanine, glycol fatty acid diesters, styrene / acrylate copolymers, polyethylene glycol fatty acid diesters, styrene / vinyl pyrrolidone copolymers and poly(trimethylammonium ethylmethacrylate chloride); in an aqueous cosmetic base. The composition is usable as a leave-in hair care composition or a hair rinse, which conditions the hair and imparts luster and volume to the hair.

Owner:WELLA GMBH

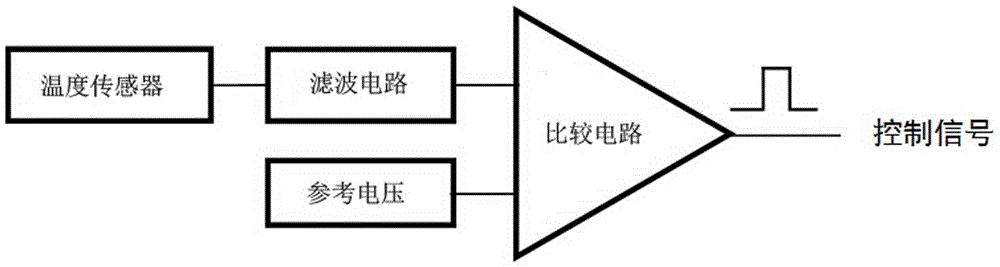

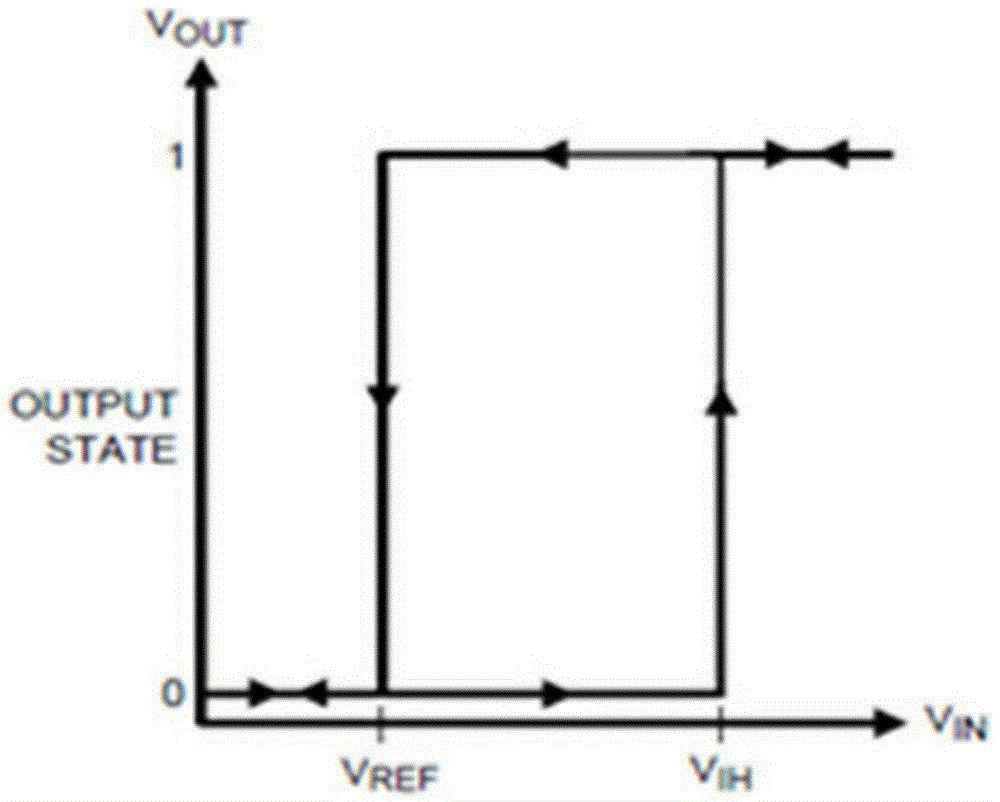

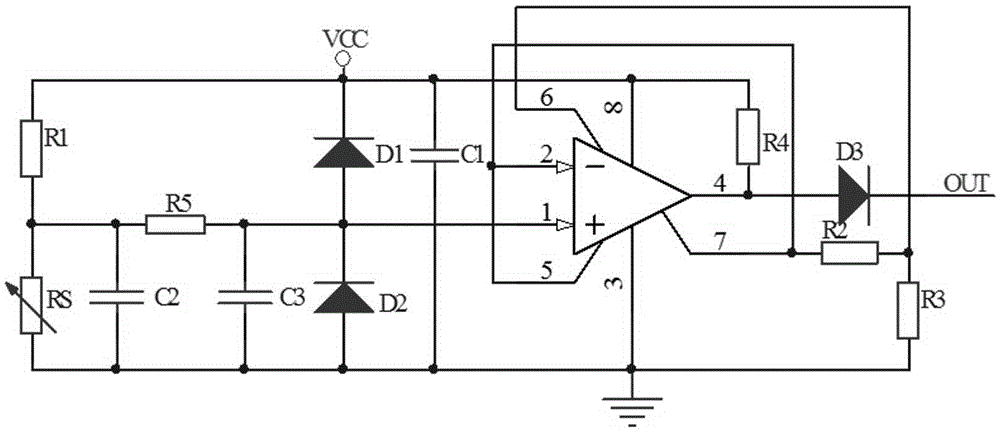

Electric control and temperature control switch circuit

The invention discloses an electric control and temperature control switch circuit, which comprises a temperature sensor, a filter circuit and a comparison circuit, namely a hysteresis comparator. A filtered voltage signal is connected to a positive phase voltage input end of a pin 1 of the hysteresis comparator; an inverse phase voltage input end of a pin 2 of the hysteresis comparator is connected to a reference voltage output end of a pin 7 to input reference voltage VREF; a cathode threshold voltage input end of a pin 5 is connected to the inverse phase voltage input end of the pin 2; the reference voltage output end of the pin 7 is connected to the ground through a resistor R2 and a resistor R3 in sequence; an anode threshold voltage V1H input end of a pin 6 is connected to a connection place of the resistor R2 and the resistor R3; and a power voltage VCC input end of a pin 8 is connected to a signal output end of a pin 4 through a pull-up resistor R4. According to the switch circuit, a signal of a temperature sensor can be converted to a voltage signal to output along with the change of the device temperature, so that the circuit can complete on-off control on a subordinate circuit at one temperature.

Owner:SINO TRUK JINAN POWER

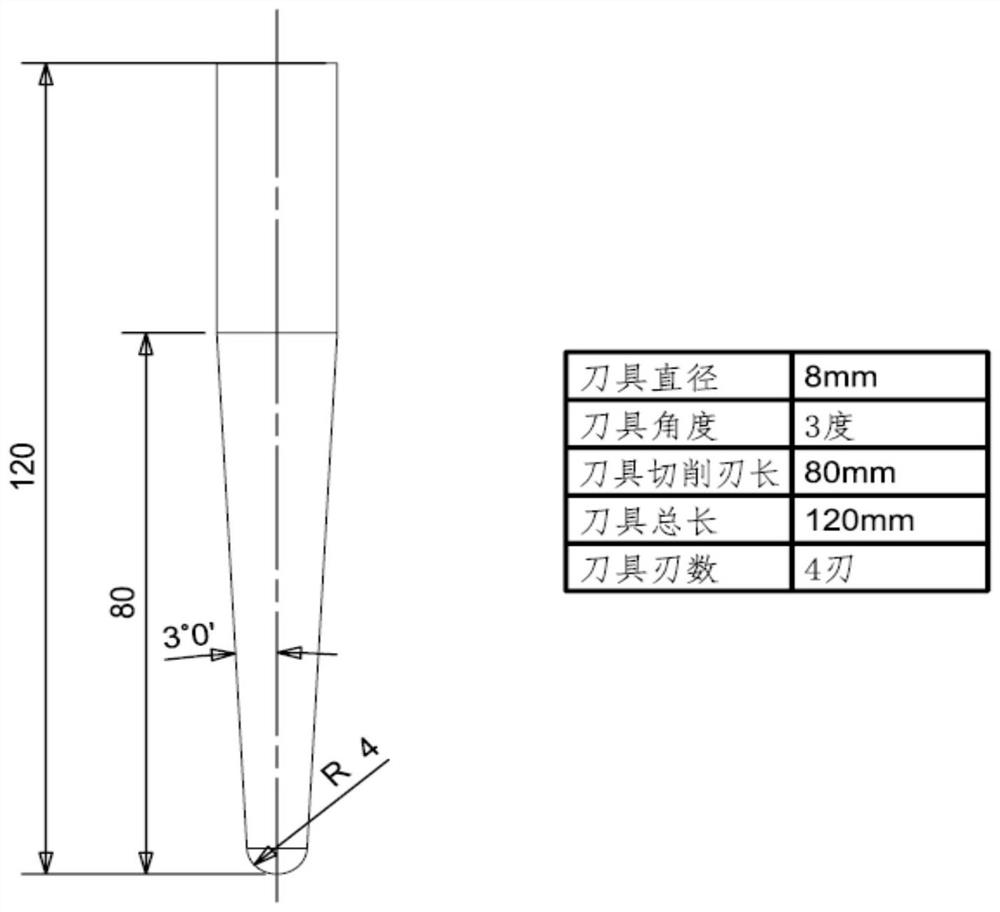

Compensation method for overcut of ruled surface impeller blades

ActiveCN111736526AAchieving size complianceOvercut errorProgramme controlComputer controlNumerical controlImpeller

The invention discloses a compensation method for overcut of ruled surface impeller blades. The method comprises the following steps: directly carrying out compensation in NX software through simple size chain calculation without manually adjusting the shapes of ruled surfaces of the blades by technicians, wherein consistency and stability of the compensation have a direct influence on the size ofthe impeller; releasing allowance through finish machining for trial cutting of the blades; obtaining dimensional parameters of the blade, overcut parameters near the leading edge and the tip portion, calculating the error angle through reverse conversion of the parameters; and finally, compensating the error angle into the size parameters of the cutter, and calculating a compensated numerical control finish machining program, so that the size of the impeller blade is qualified. The method can solve the problem that due to existing five-axis linkage, the overcut error of the triangular area,close to the blade tip, of the leading edge is caused.

Owner:无锡航亚科技股份有限公司

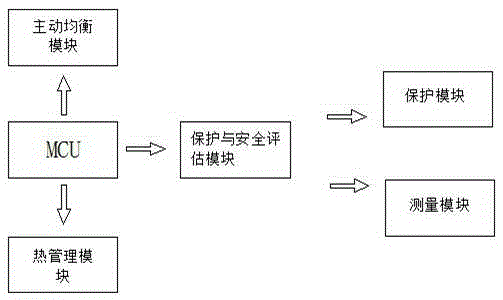

Electric automobile battery management system

InactiveCN105305548AMonitor temperature in real timeConsistency and stabilityBatteries circuit arrangementsElectric powerMicrocontrollerHigh energy

The invention discloses an electric automobile battery management system. The battery management system is characterized by comprising a microcontroller unit (MCU), a protection and safety evaluation module connected with the MCU, an active equalization module connected with the MCU, and a heat management module connected with the MCU, wherein the protection and safety evaluation module is composed of a protection module and a measurement module. According to the invention, high-energy-efficiency and large-equalization-current intelligent management can be carried out on groups of lithium ion batteries, the problem of rapid attenuation of effective capacity of battery packs, caused by inconsistency of such property parameters of lithium ion battery packs used by electric automobiles as battery capacity, internal resistance, voltage platforms, self-discharge rates and the like is solved, and the service life of the lithium battery packs is prolonged.

Owner:WUHU HONGJING ELECTRONICS

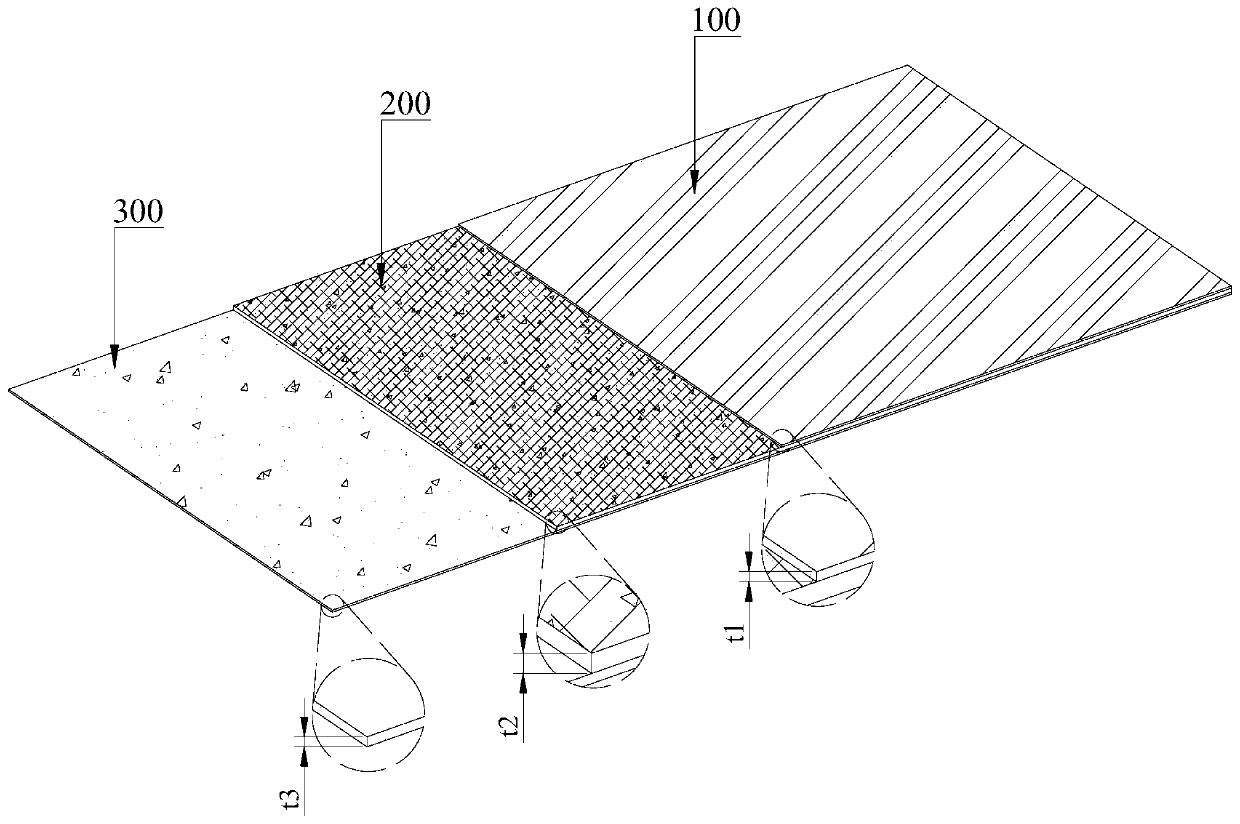

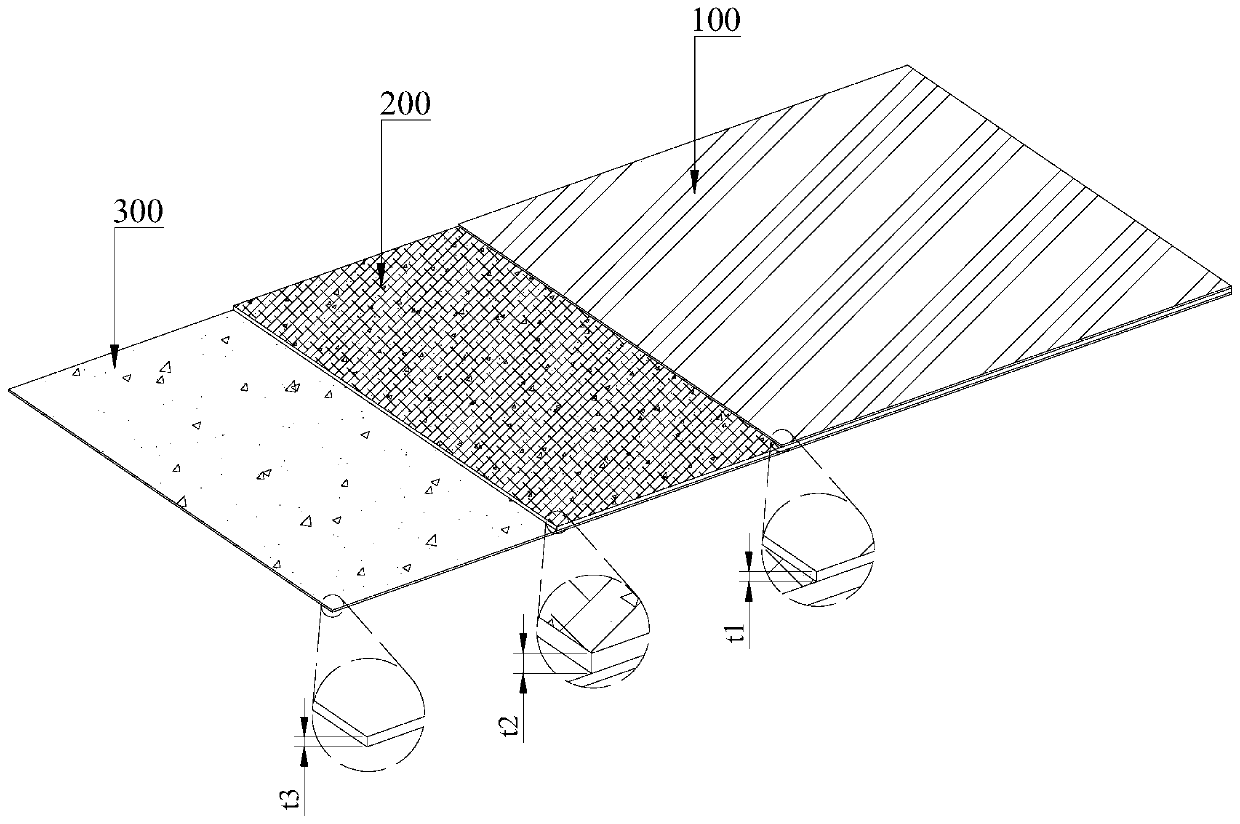

High toughness inorganic composite artificial stone panel and preparation method thereof

InactiveCN110423064AHigh strengthImprove bending resistanceLayered product treatmentLaminationMetal fibersWater reducer

A high toughness inorganic composite artificial stone panel and a preparation method thereof are disclosed. The panel comprises a surface layer, an intermediate metal fiber toughening layer and a substrate toughening layer. The surface layer comprises the following raw materials in parts by weight: 40 to 70 parts by weight of quartz sand, 10 to 30 parts by weight of quartz powder, 20 to 45 parts by weight of inorganic active powder, 0.5 to 4 parts by weight of pigment, 0.3 to 1 part by weight of water reducer and 3 to 10 parts by weight of water. The intermediate metal fiber toughening layer comprises the following raw material components in parts by weight: 40-60 parts of inorganic active powder, 45-65 parts of sand, 0.8-1.5 parts of water reducer, 6-14 parts of water and 4-8 parts of metal fiber. The substrate toughening layer comprises the following raw material components in parts by weight: 30-50 parts of inorganic active powder, 30-55 parts of quartz sand, 15-20 parts of quartz powder, 0.5-1.2 parts of water reducer, 4-8 parts of water and 0.8-2.5 parts of toughening agent. The panel has the advantages of good volume stability, low shrinkage, no warping deformation in use, extremely low water absorption, good durability, no aging and the like, strong bonding between layers, good ductility and no instant brittle fracture, and can be used as a bearing capacity structure with good surface pollution resistance, and is suitable for popularization and use.

Owner:黄贺明 +1

Vibrating diaphragm, preparation method thereof and acoustoelectric device

PendingCN112693200AImprove temperature resistanceImprove creep resistanceElectrical transducersSynthetic resin layered productsImidePolymer science

The invention relates to the technical field of acoustoelectric devices, and particularly relates to a vibrating diaphragm, a preparation method thereof and an acoustoelectric device. The vibrating diaphragm comprises a polyurethane-imide material layer, wherein polyurethane-imide is prepared by introducing a polyimide functional group to a main chain of polyurethane. The temperature resistance and creep resistance of the vibrating diaphragm can be improved by adopting the polyurethane-imide material layer, and the product consistency is relatively stable and the tone quality is mellower even under the trial of high power. Moreover, according to the vibrating diaphragm provided by the invention, the content of other modified materials is added and adjusted, so that the vibrating diaphragm has the characteristics of high stretching rate and good thermoplasticity on the basis of improving the temperature resistance of the vibrating diaphragm.

Owner:辽宁弗佰克高新材料有限公司

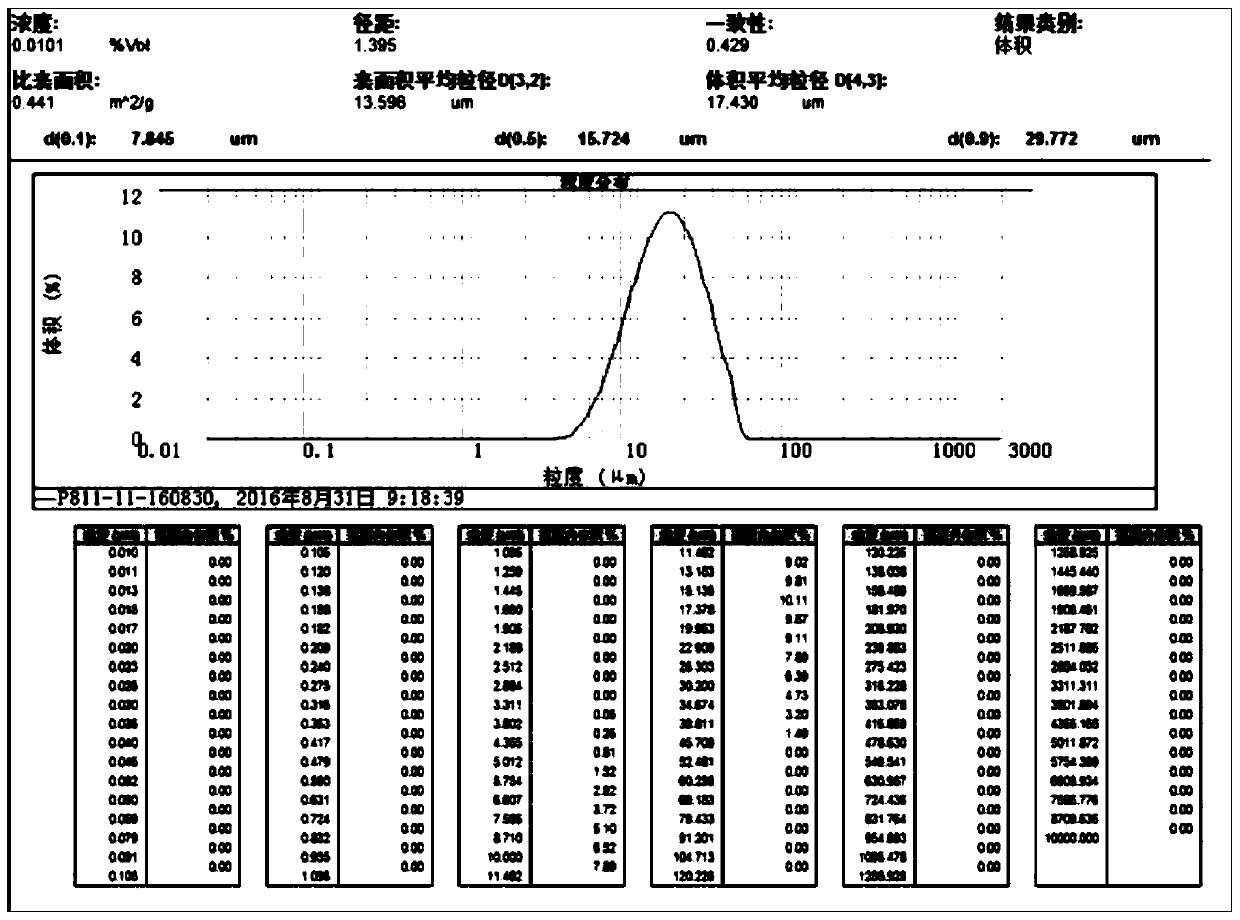

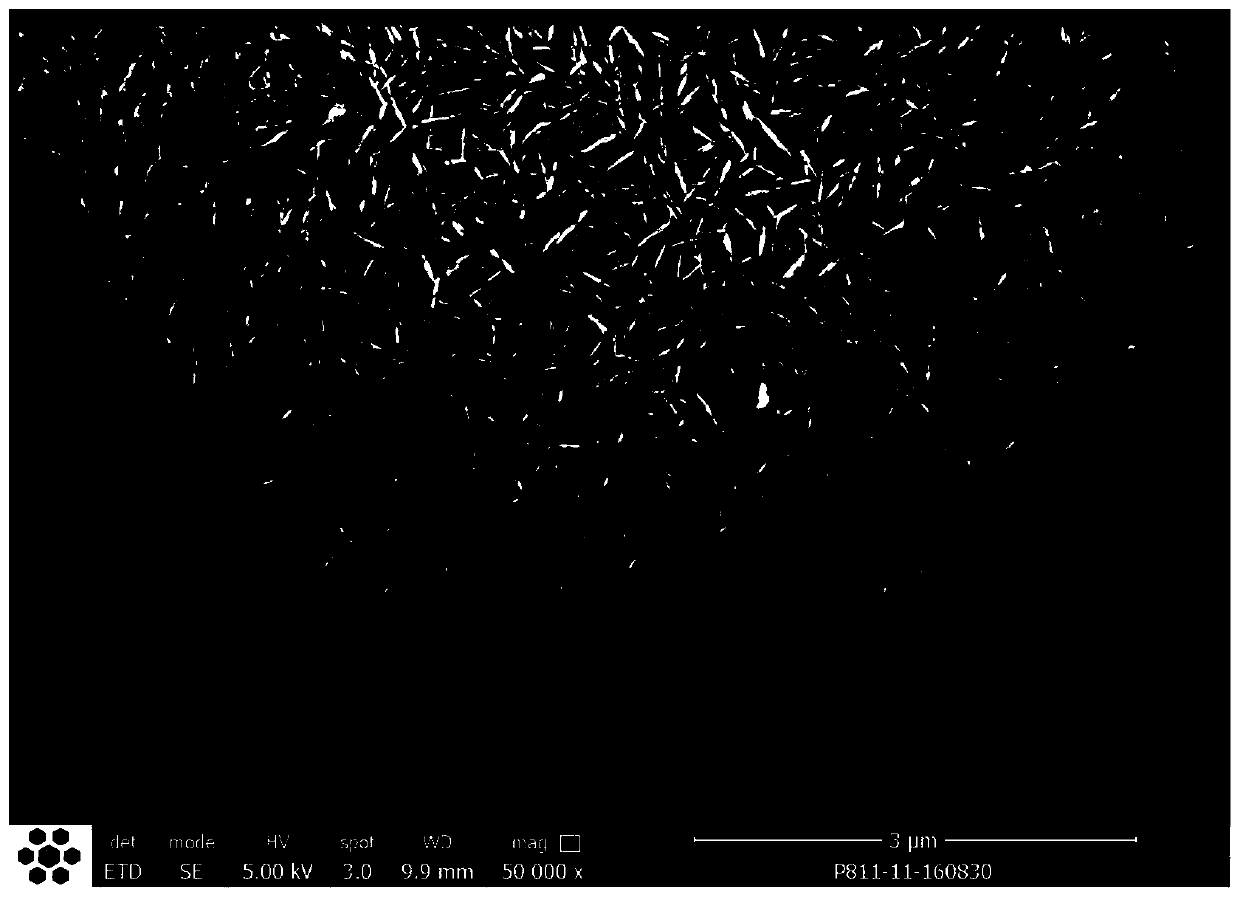

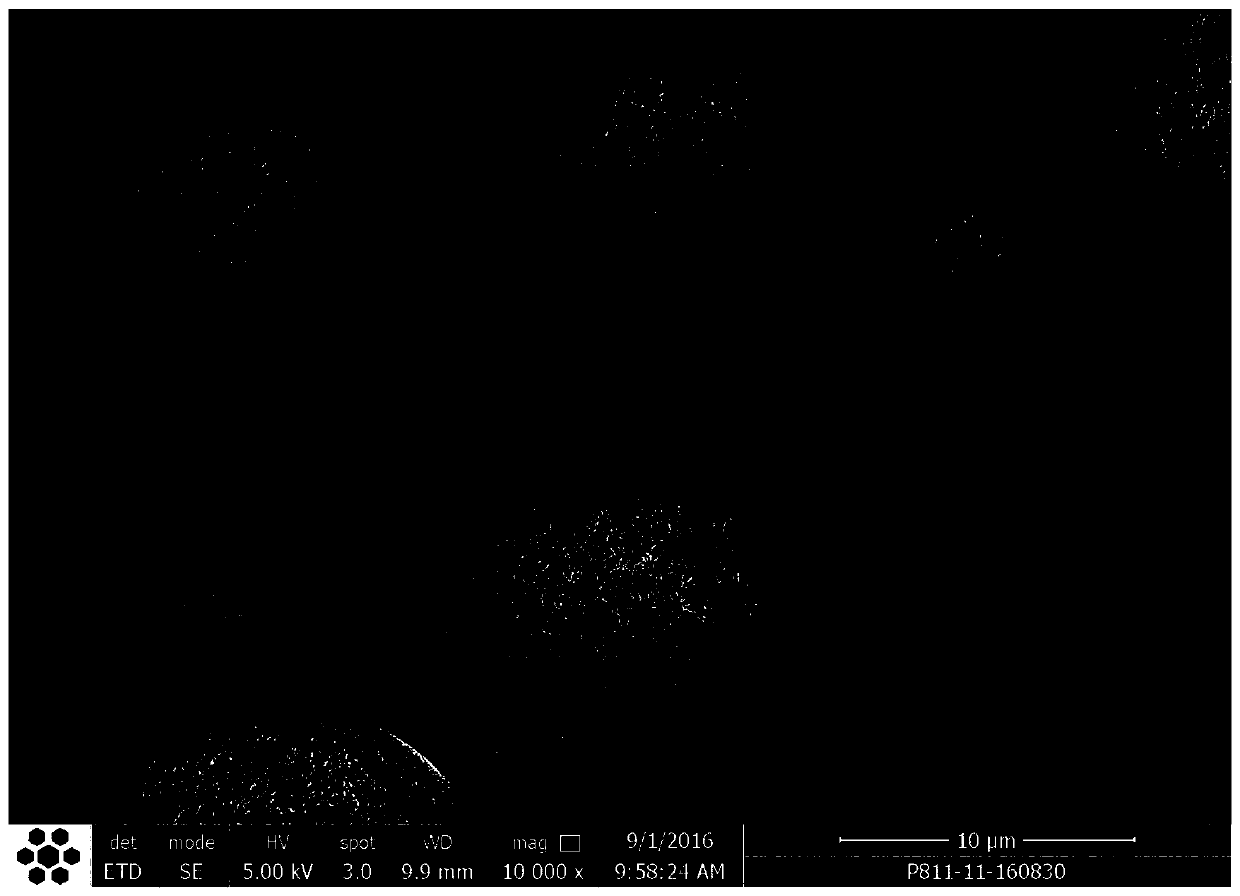

A kind of high-nickel-type nickel-cobalt lithium manganese oxide precursor with specific morphology and preparation method thereof

The invention discloses a high-nickel type lithium Ni-Co manganate precursor with specific morphology. The mean grain size of the primary particle of the precursor is 200-500nm; the granularity D10 of the secondary particle aggregate is not less than 6 microns; D50=11-15 microns, D90 is not more than 30 microns, the degree of sphericity of each of the secondary large particle and the secondary small particle is perfect, and the primary particle is filamentous. The preparation of the precursor comprises the following steps: firstly preparing a soluble mixed salt solution; adding ammonia water as the reaction kettle base solution, and regulating the pH of the base solution; inflating the nitrogen into the reaction kettle and starting the stirring; combining the configured soluble mixed water solution, the alkali and the ammonia water to add in the reaction kettle to perform the stirring reaction, reacting for some time, circularly pumping the early unqualified material into the reaction pump, performing ageing, filter-pressing and washing on the overflow material, drying, screening and then saving. The product disclosed by the invention is good in consistency and has specific morphology; the process efficiency is higher, and the product stability is better.

Owner:SHANSHAN ENERGY (NINGXIA) CO LTD

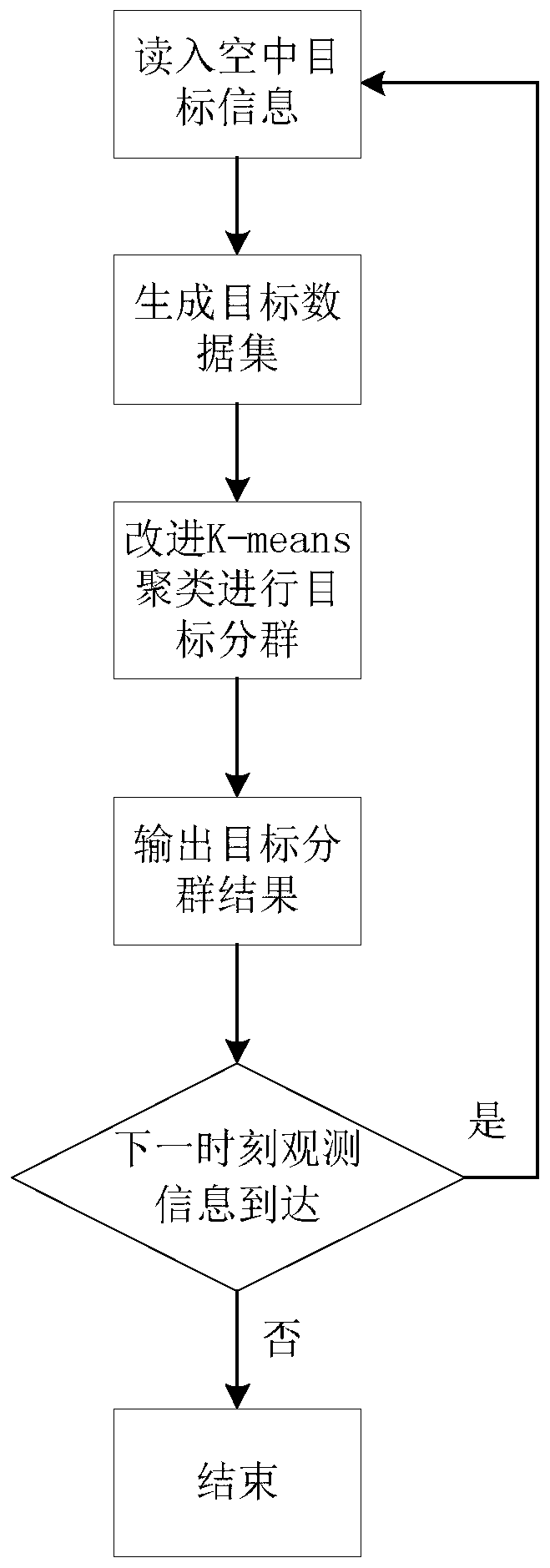

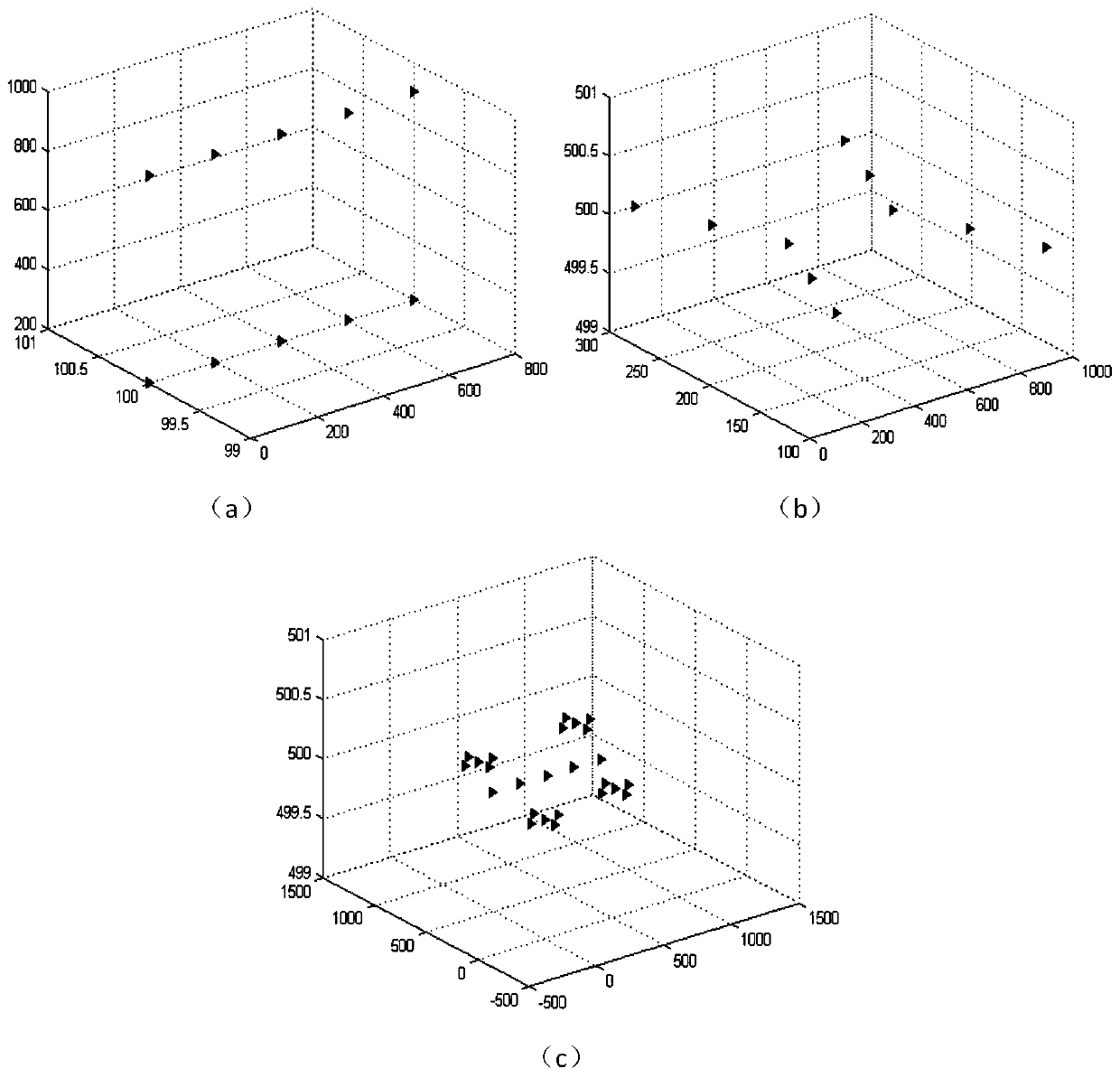

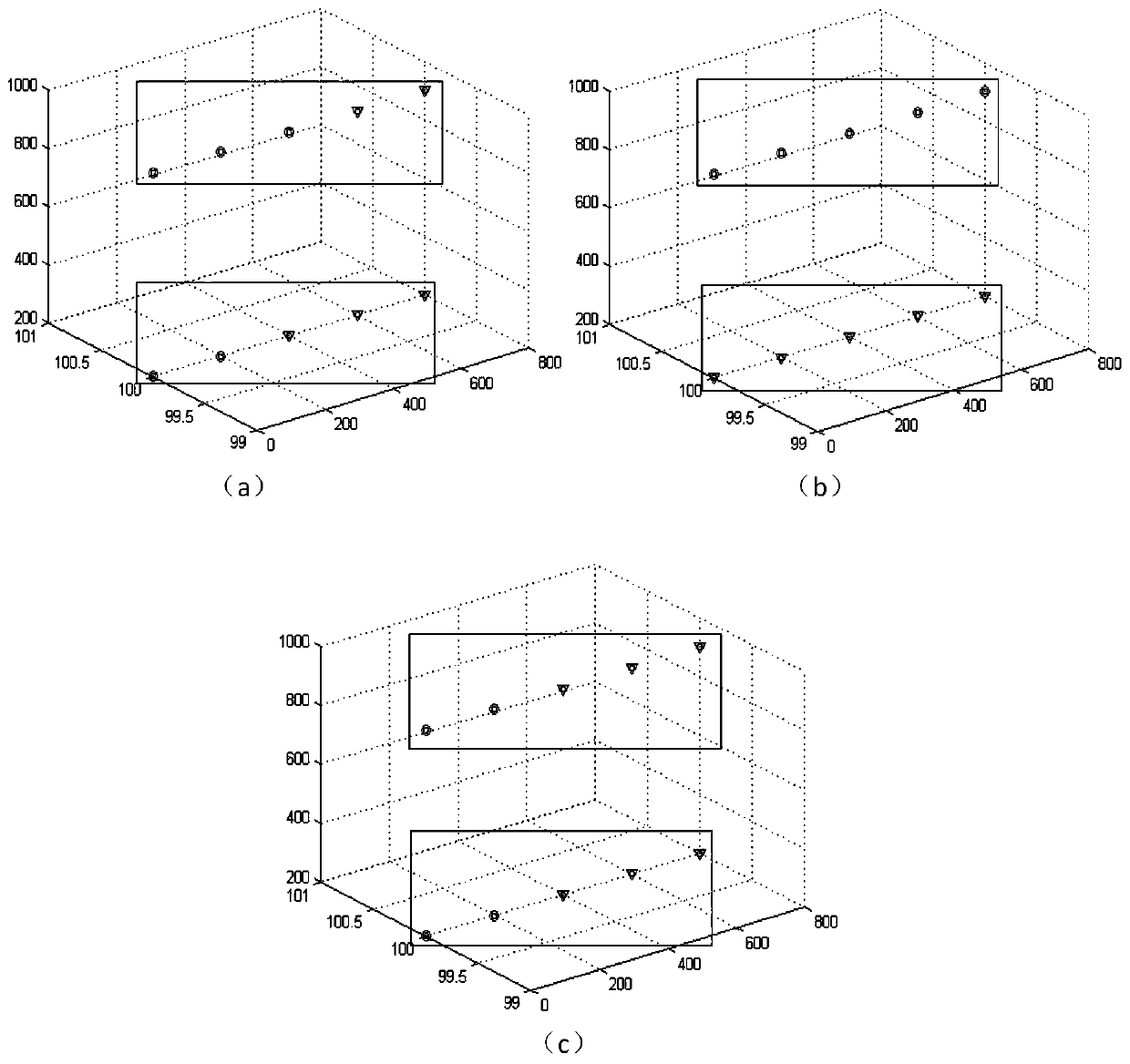

Air target clustering method based on K-means clustering

ActiveCN110781963AOvercoming the increase in the number of iterationsOvercoming the problem of increased computationCharacter and pattern recognitionData setAlgorithm

The invention discloses an air target clustering method based on K-means clustering. The method comprises the following steps: (1) reading air target information; (2) generating an aerial target dataset; (3) generating the total number of aerial target groups; (4) according to the obtained group centers of the aerial target groups and the total number of the aerial target groups, adopting K-meansclustering to perform aerial target grouping; and (5) outputting a grouping result. According to the method, the problem that the grouping number needs to be given in advance when a K-means clustering method is used for aerial target grouping is solved; effective and accurate grouping of aerial targets in actual conditions can be realized, and the method can be used for situation estimation and command control systems.

Owner:XIDIAN UNIV

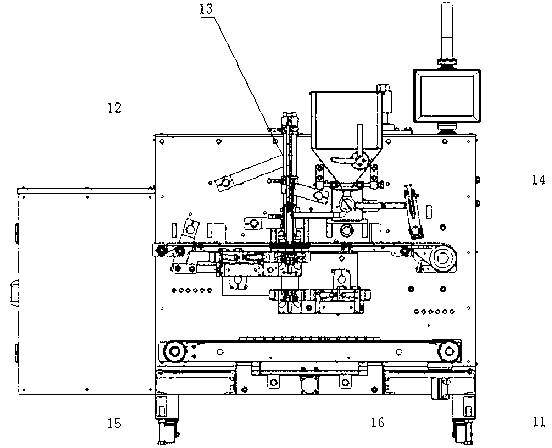

Food encrusting device

ActiveCN102177928BIncrease the number ofDoes not affect normal operationDough shaping and cutting apparatusDough dividingEngineeringBiomedical engineering

The invention relates to the technical field of food machines, in particular to a food encrusting device, which comprises a food encrusting device machine frame, a food encrusting device stuffing injection component, food encrusting, stuffing pushing and wrapper cutting devices, a wrapper delivering component, a food encrusting device wrapper forming device, a food encrusting device conveying mechanism and a food encrusting device driving mechanism, wherein the food encrusting device stuffing injection component has a plurality of independent discharging channels and a plurality of food encrusting, stuffing pushing and wrapper cutting devices which are arranged in a way of corresponding to the discharging channels and complete stuffing pushing and wrapper cutting at the same station. The food encrusting device has the advantages that: the stuffing injection and wrapper cutting device are arranged in a linear mode, so a plurality of the stuffing injection and wrapper cutting devices can operate without interference, and even if one stuffing injection and wrapper cutting device has a fault, other stuffing injection and wrapper cutting devices can still work normally; and due to the linear arrangement mode, in a range matched with a driving mechanism, the stuffing injection and wrapper cutting devices can be increased randomly, so large-scale production can be realized, and the working efficiency is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

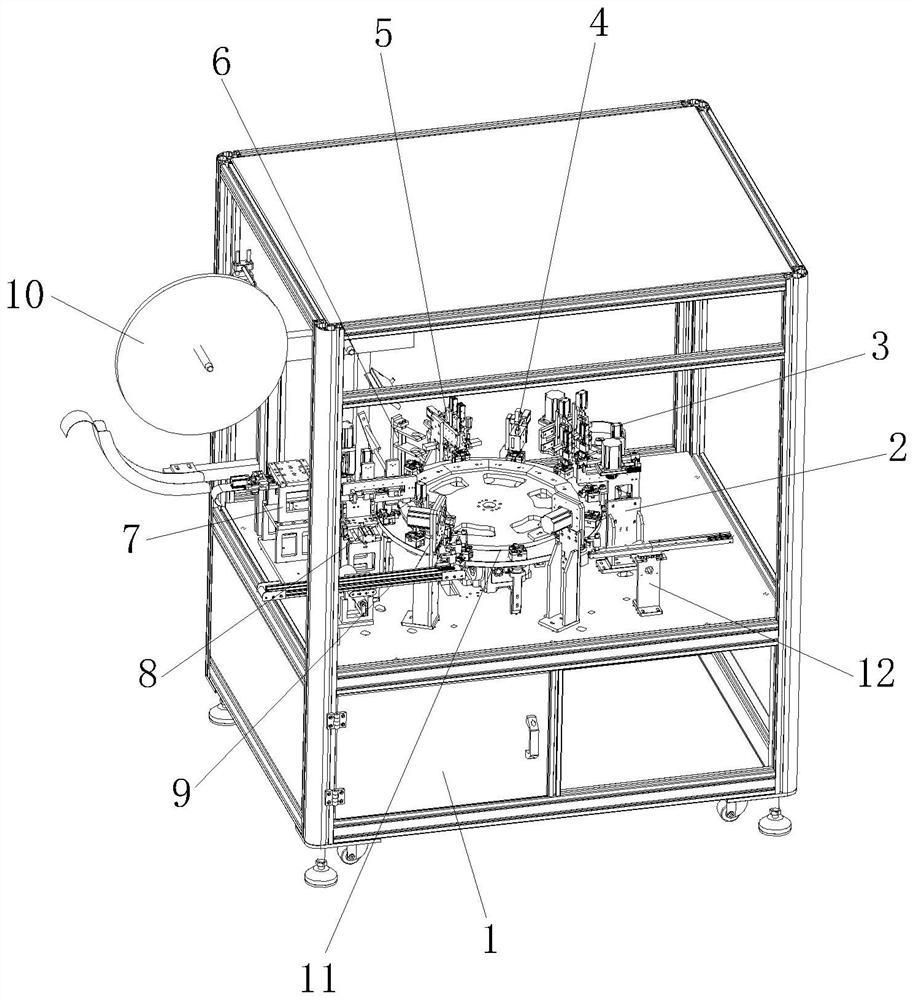

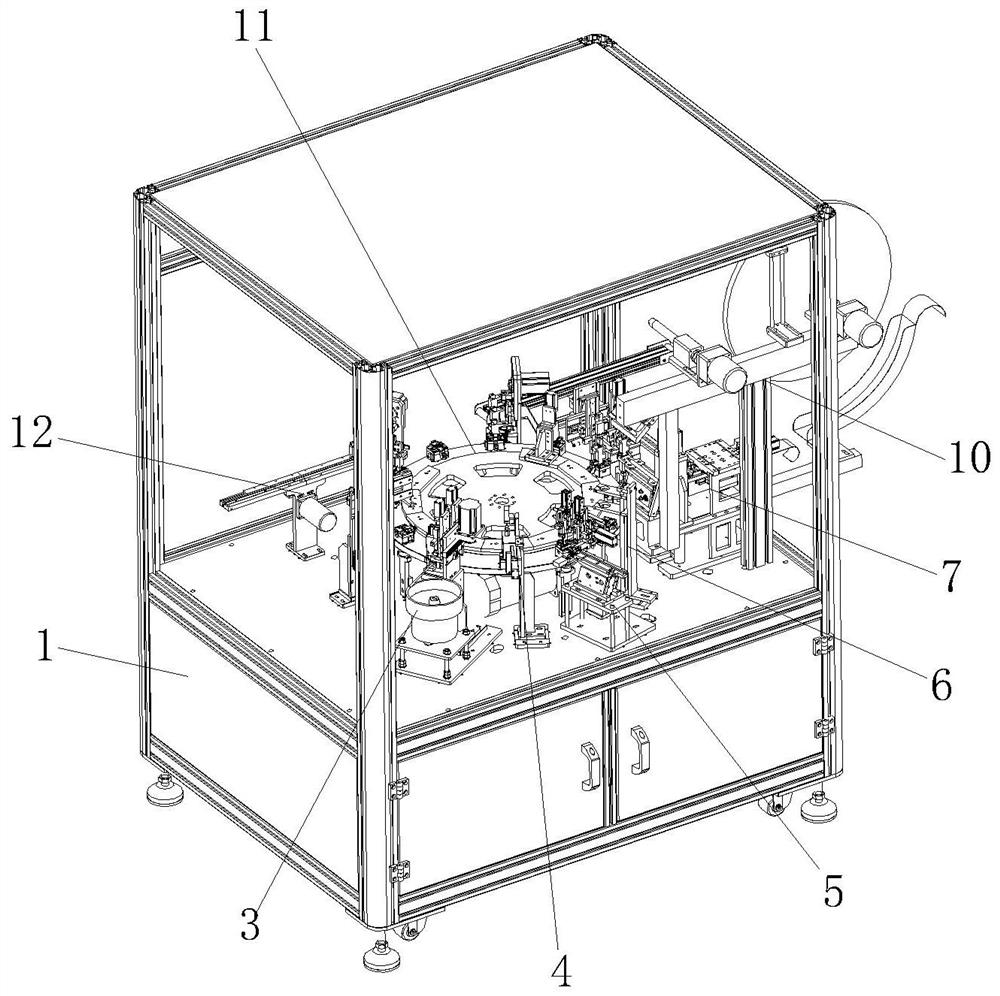

Automatic assembling equipment for self-ejection type micro storage card seat type connector

PendingCN114256714AProduct consistency and stabilityGood qualityContact member assembly/disassemblyEngineeringAutonomation

The invention discloses automatic assembling equipment for a self-ejection type miniature storage card seat type connector, and belongs to the technical field of automatic assembling equipment. The automatic assembling equipment comprises a machine case, and a main power structure is arranged in the middle of the upper end of the machine case; according to the automatic assembling machine, a main power structure, a main body feeding structure, a sliding rail assembling structure, a spring pre-assembling structure, a spring assembling in-place structure, a pull rod assembling structure, a CCD detection structure, a shell assembling structure, a shell pressing and buckling structure, an assembling completion discharging structure and a main power structure are arranged, so that one piece of equipment integrates multiple procedures for assembling, and a series of assembling processes can be completed; the work load of nine persons in the past can be completed by one person, the product consistency is more stable, the quality is better, the whole operation is completely automatic, all the assembly work of one product can be completed within 1.5 seconds, the efficiency is improved by more than two times compared with a traditional manual mode, the operation is convenient, the production efficiency is high, the used labor is less, the quality is guaranteed, and safety and reliability are achieved.

Owner:DONGGUAN OLN ELECTRONICS TECH CO LTD

Power battery case with adjustable capacity and voltage

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for producing braided cable

InactiveCN103021579AConsistency and stabilityImprove uniformityCommunication cablesInsulating conductors/cablesUltrasound attenuationElectrical conductor

A method for producing a braided cable is characterized by comprising steps of manufacturing an inner conductor; manufacturing an insulating medium; manufacturing an outer conductor; and manufacturing a sheath. The method has the advantages that a manufacturing process is accurately controlled, and stable consistency, high impedance uniformity and high stability of standing waves are guaranteed; and an insulating layer is stable in foaming degree and excellent in electric performance, and is particularly low in high-frequency attenuation property, and the outer conductor is good in bending property.

Owner:ZHEJIANG DETONG TECH

Method for producing flexible low-standing-wave corrugated coaxial cables

InactiveCN103000305AConsistency and stabilityImprove uniformityCable/conductor manufactureWaveguide type devicesUltrasound attenuationElectrical conductor

A method for producing flexible low-standing-wave corrugated coaxial cables is characterized by comprising the following steps of manufacturing inner conductors, manufacturing insulating media, manufacturing outer conductors and manufacturing a sheath. The flexible low-standing-wave corrugated coaxial cables produced by means of the method adopt through an accurate control manufacture process, stability consistency is ensured, and good impedance uniformity and standing wave stability are guaranteed. An insulating layer is stable in foaming degree and has very good electrical performance, and especially high-frequency attenuation performance is low. The outer conductors are good in bending performance.

Owner:ZHEJIANG DETONG TECH

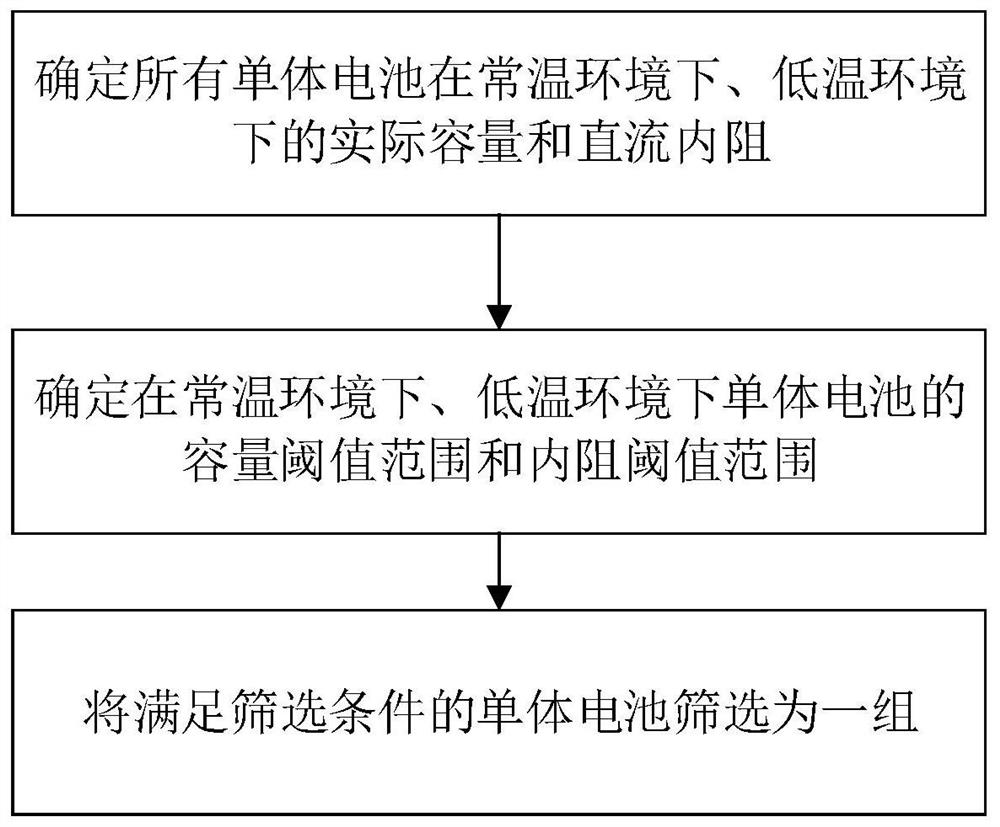

Parallel grouping screening method for single batteries

ActiveCN111965555AReasonable screeningImprove consistencyElectrical testingInternal resistanceProcess engineering

The invention discloses a parallel grouping screening method for single batteries. The method comprises the following steps: determining actual capacities and direct-current internal resistances of all single batteries in a normal-temperature environment and a low-temperature environment, determining a capacity threshold range and an internal resistance threshold range of the single batteries in the normal-temperature environment and the low-temperature environment, and screening the single batteries meeting screening conditions into one group. The plurality of single batteries screened into one group can be connected in parallel to form the battery pack, so that the consistency among the single batteries in the battery pack is higher, and the performance of the battery pack is improved.

Owner:深蓝汽车科技有限公司

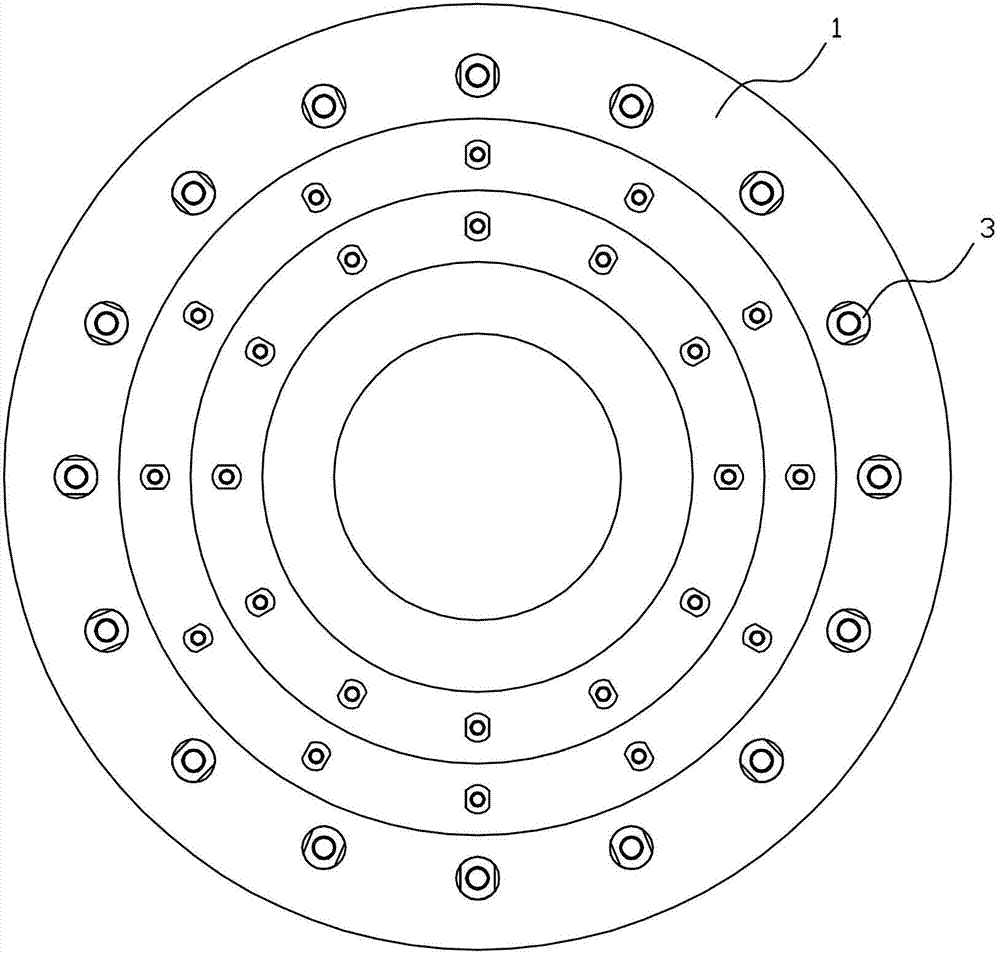

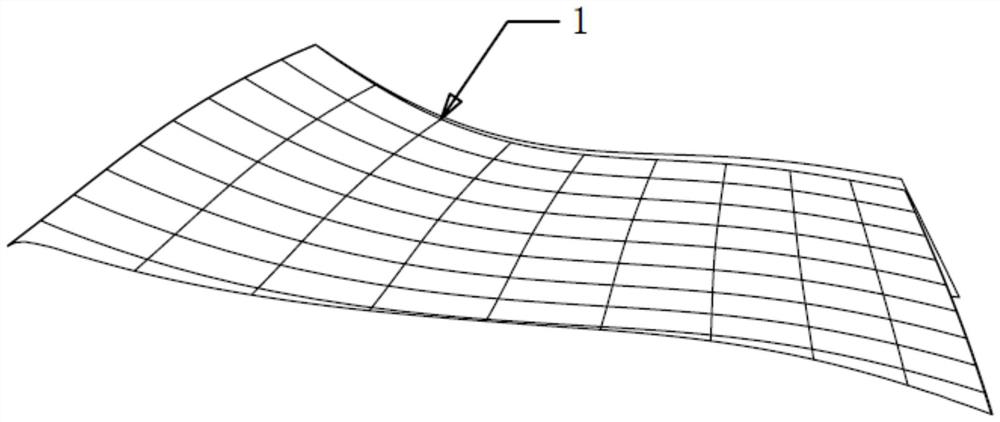

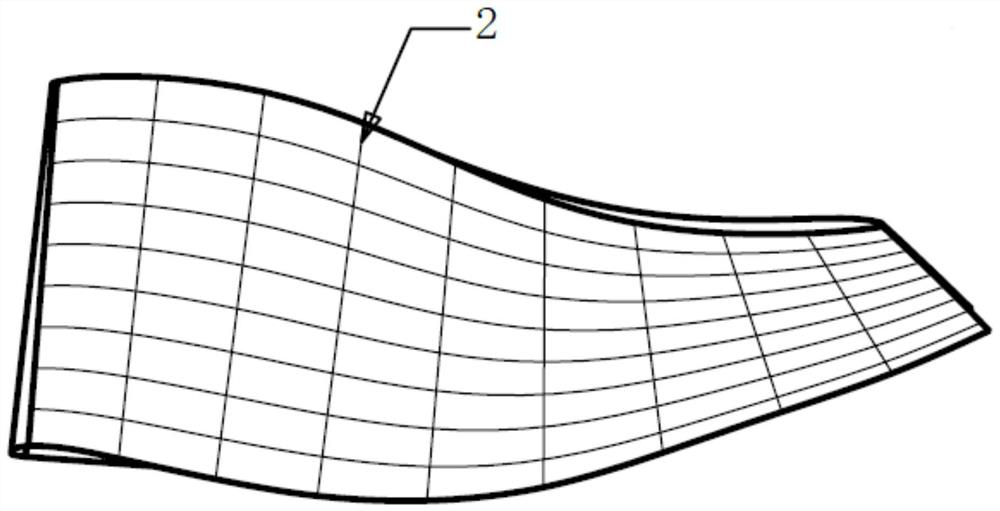

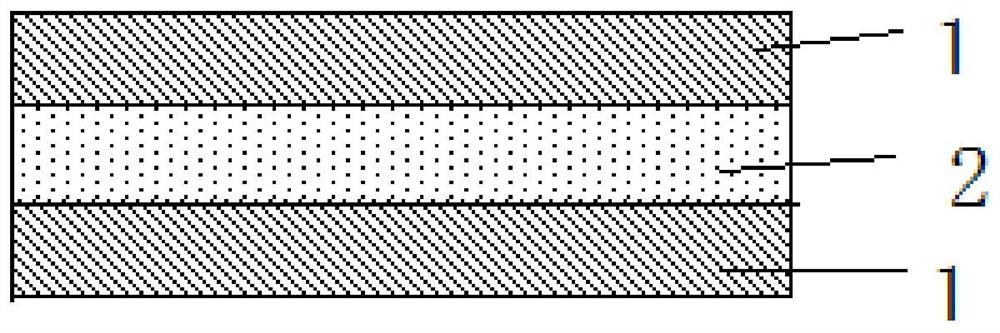

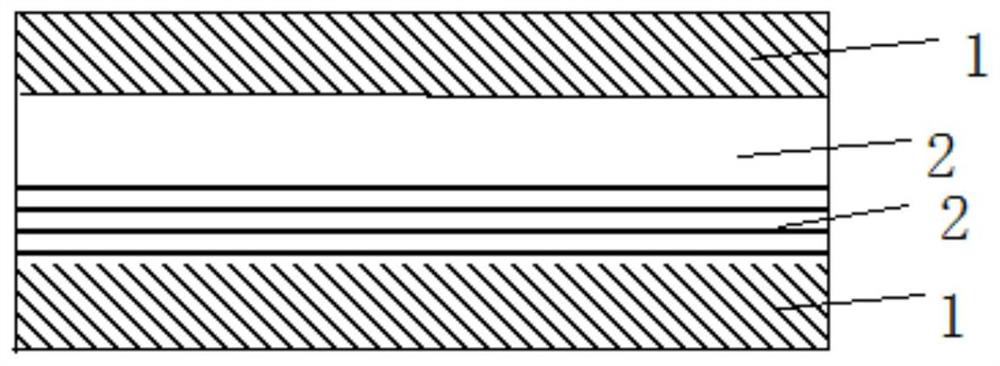

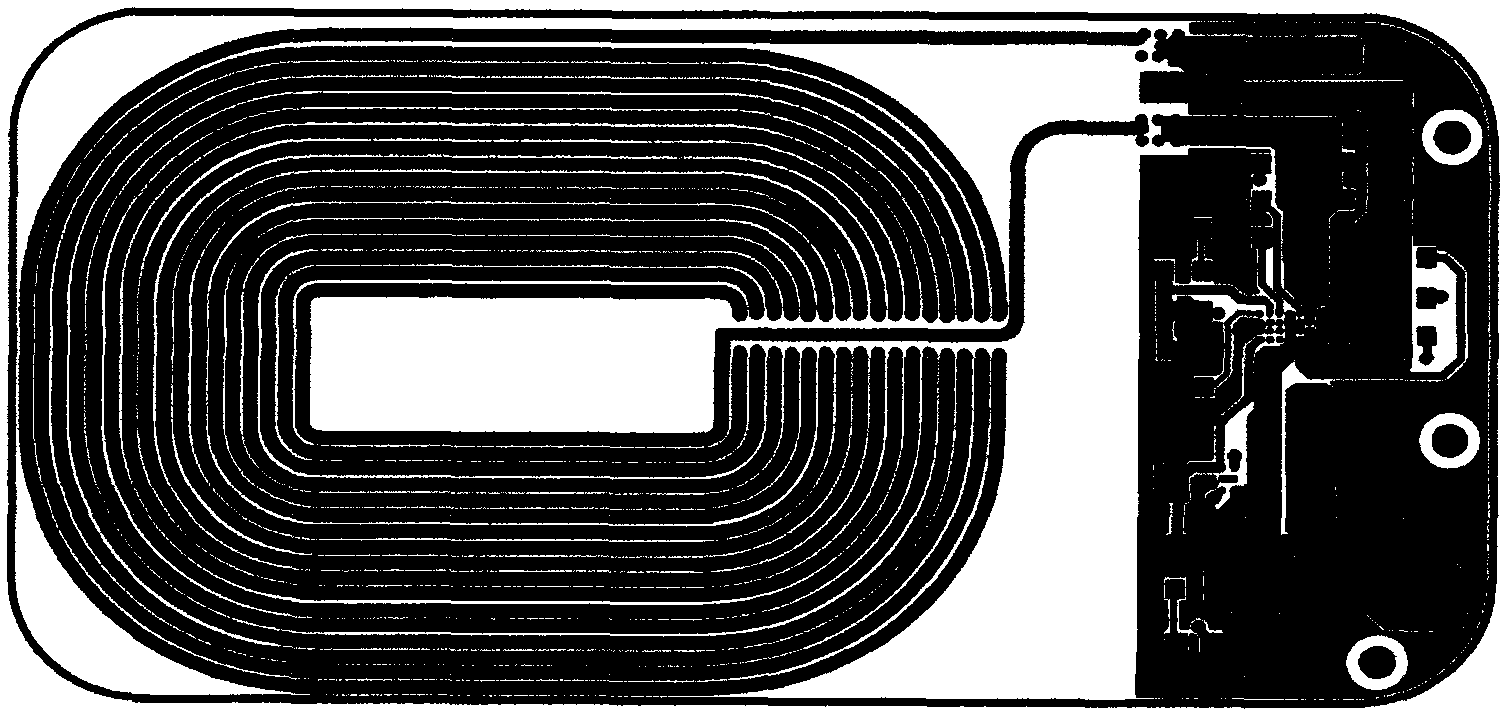

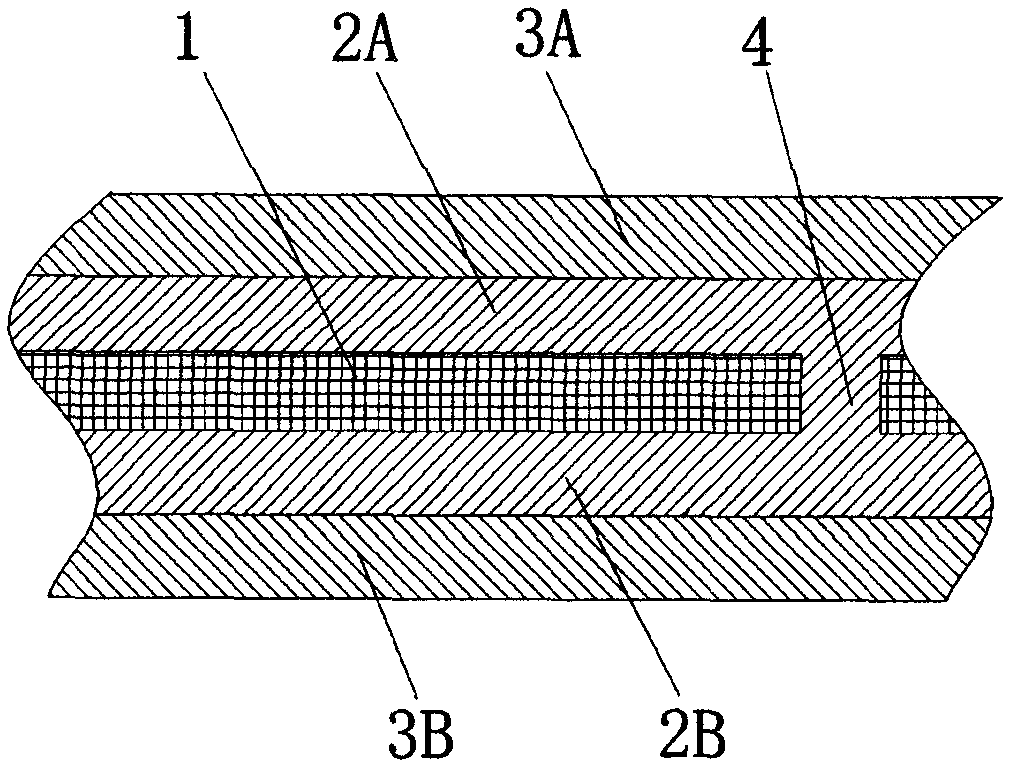

Flexible planar coil and production method thereof

The invention discloses a flexible planar coil and a production method thereof. The flexible planar coil comprises a flexible insulating plate substrate (1), wherein two helical copper foil printed circuit coils (2A and 2B) are respectively arranged on the two surfaces of the flexible insulating plate substrate (1), the helical copper foil printed circuit coils (2A and 2B) on the two surfaces of the flexible insulating plate substrate are connected through a conductive via hole (4) penetrating through the flexible insulating plate substrate (1), and two Au / Ni immersed protection layers (3A and 3B) are respectively arranged in the outer surfaces of the copper foil printed circuit coils (2A and 2B). The flexible planar coil is manufactured by the production methods including material selection, punching, copper plating, exposure etching, press-fit bonding, Au immersion, silk screening and pressing. The winding operation is not needed, the production process is simple, the consistency of product characteristics is good, the rejection rate is low, and the flexible planar coil is small and thin, uneasy to damage and is bendable.

Owner:王习力

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com