Flexible planar coil and production method thereof

A flat coil, flexible technology, applied in the direction of coil, coil manufacturing, electrical components, etc., can solve the problems of complex production process, poor consistency of product characteristics, inconvenient use, etc., to achieve fast production speed, less manpower, and less damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

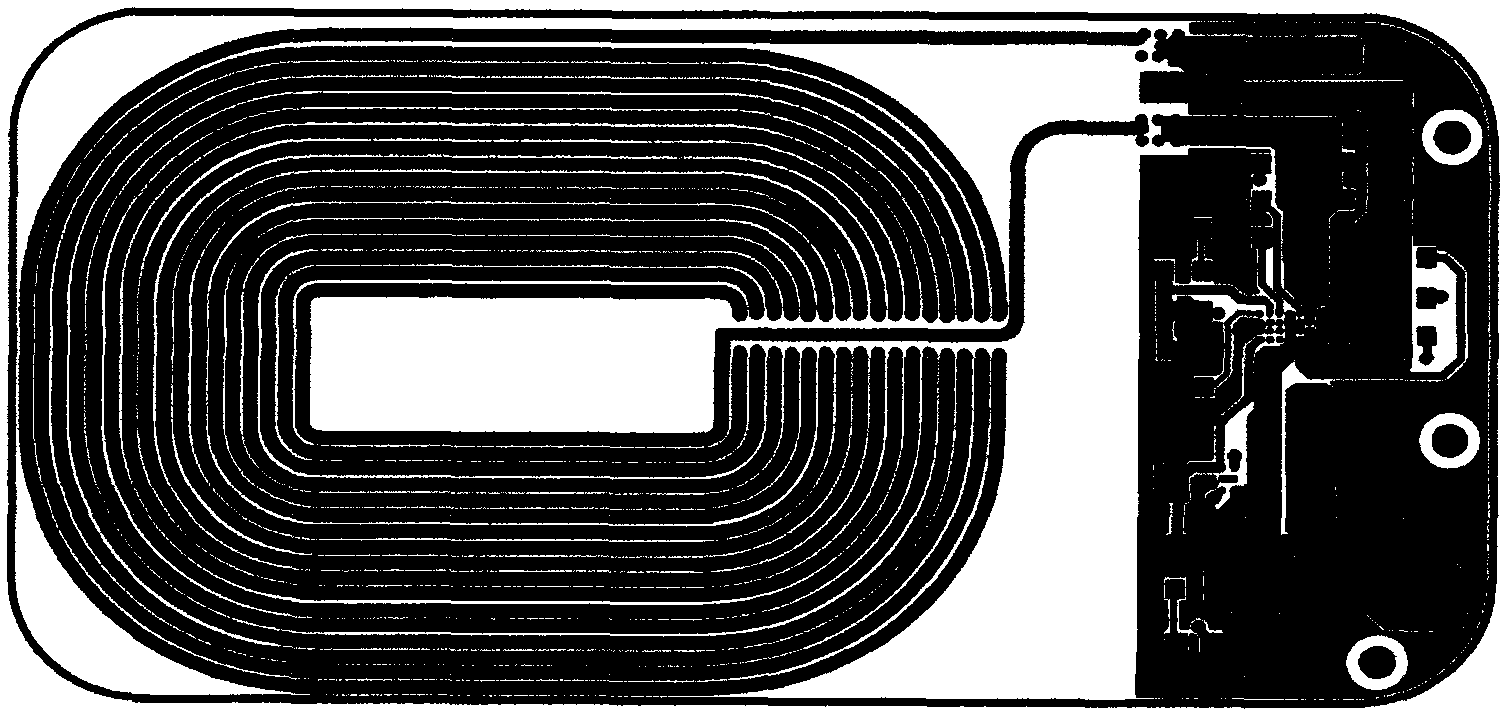

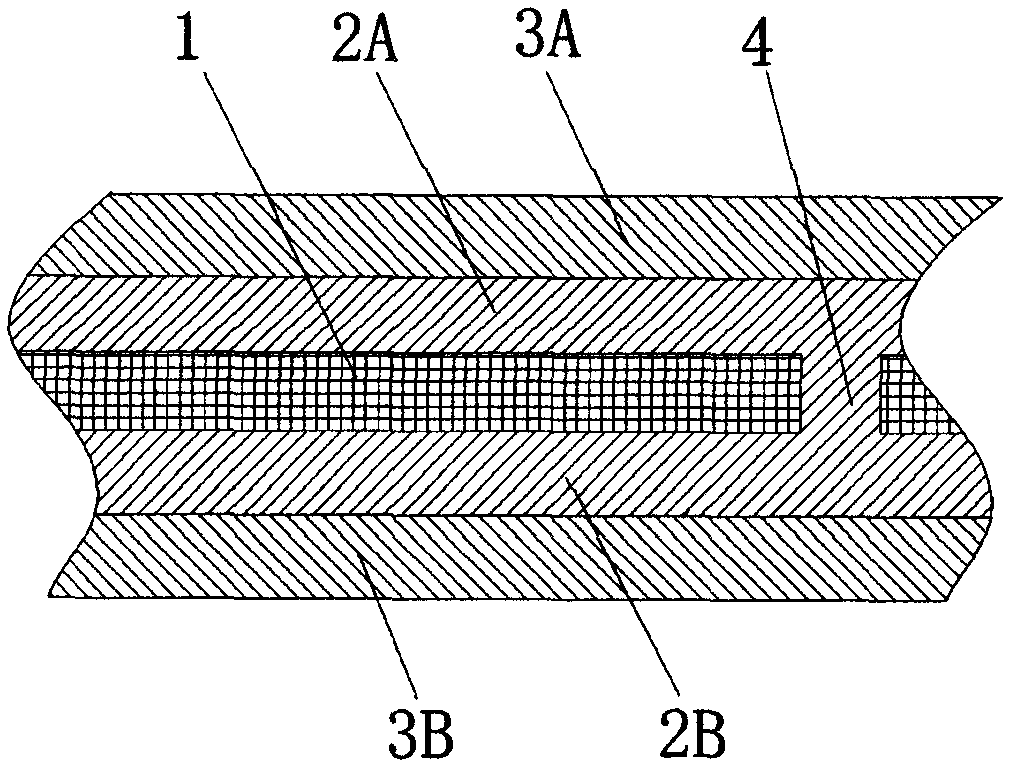

[0026] Referring to the accompanying drawings, a flexible planar coil of the present invention is characterized in that there is a flexible insulating board base layer 1, and a spiral copper foil printed circuit coil 2A, 2B is respectively arranged on both sides of the flexible insulating board base layer 1, and the copper foil printed circuit coils 2A, 2B on both sides are arranged. The foil printed circuit coils 2A, 2B are connected by conductive vias 4 passing through the base layer 1 of the flexible insulating board. The outer surface of the copper foil printed circuit coils 2A, 2B has an immersion gold or nickel immersion protective layer 3A, 3B.

[0027] An embodiment of a production method of a flexible planar coil of the present invention comprises the following steps:

[0028] 1. Select polyimide or polyester film with a thickness of 18um as the base material, and process it into a shape and size suitable for the production equipment;

[0029] 2. Drilling required via...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com