Automatic scroll spring forming apparatus

An automatic forming, scroll spring technology, used in metal processing equipment, other manufacturing equipment/tools, feeding devices, etc. Handling problems such as large area, to achieve good product consistency, more humanization and safety, and improve production efficiency and product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

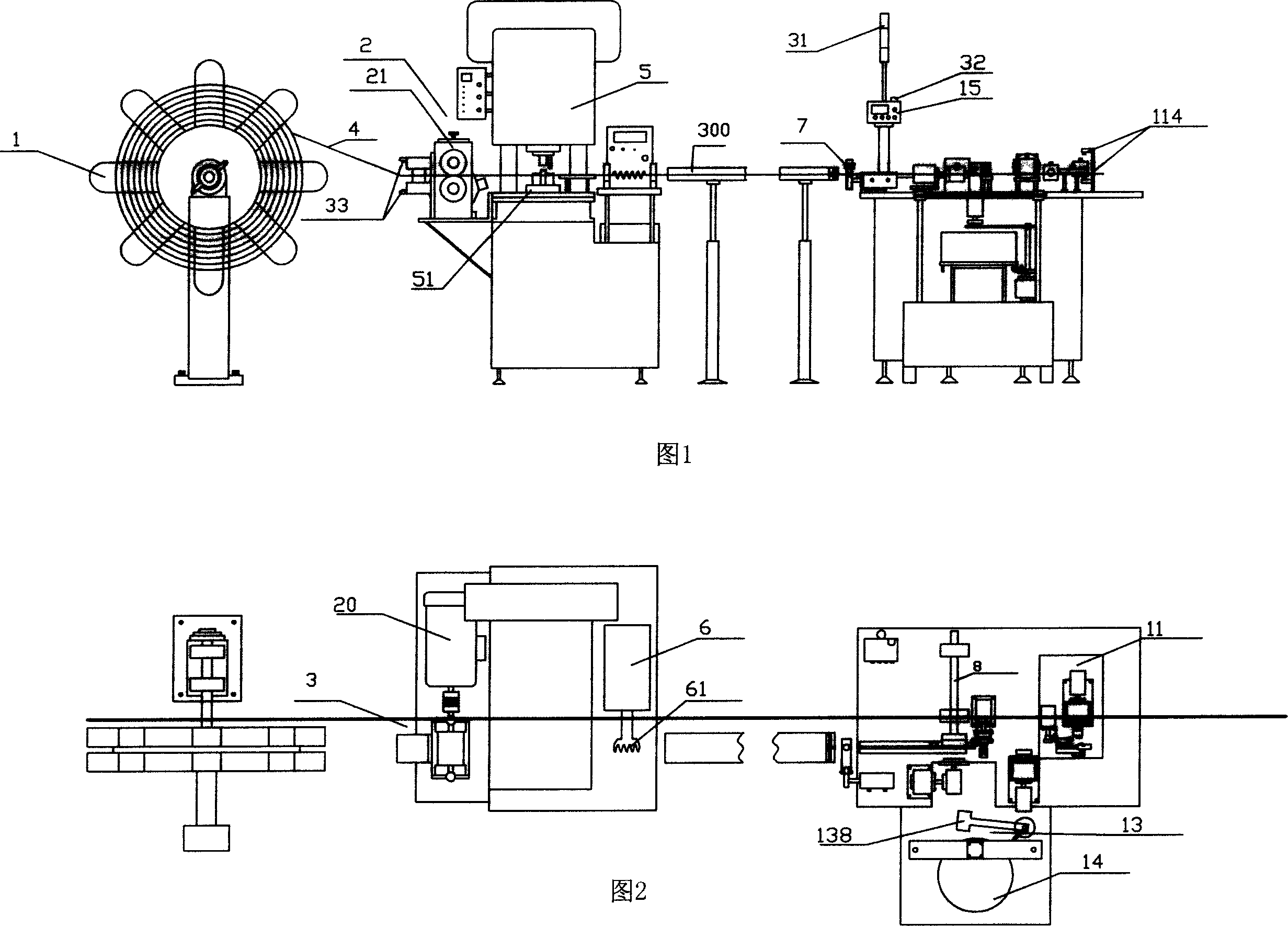

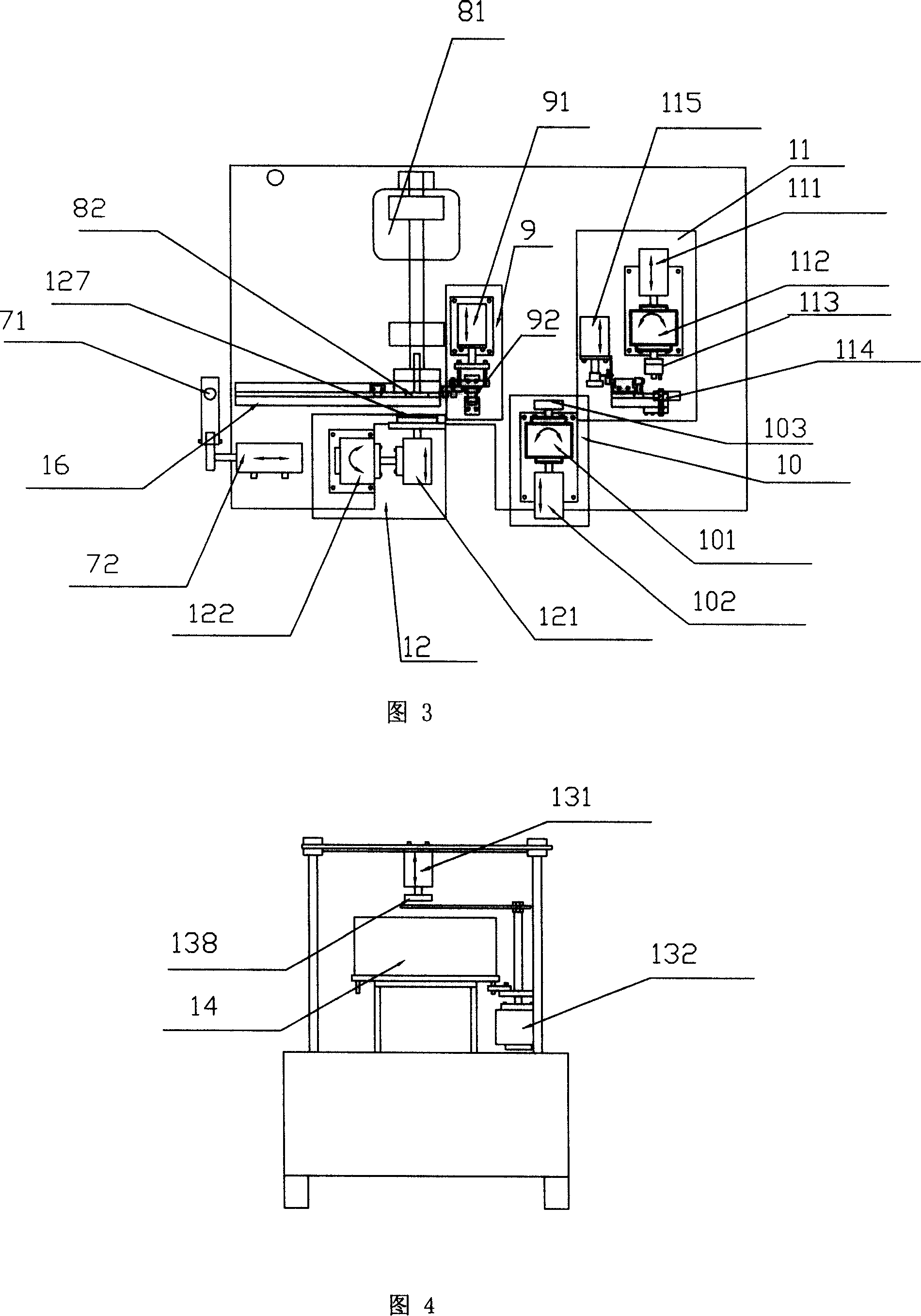

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] As shown in Figures 1 to 4, a scroll spring automatic forming equipment includes a disc feeding rack 1, a material-free photoelectric controller 3, a fixed-length feeding device 2, a punching machine 5 with a die 51, and a high-frequency Annealing device 6, electromagnetic suction head 7, crimping machine 8, forming device 9, hook feeding device 10, hook device 11, unloading device 12 placed next to crimping machine 8, material receiving device 13, collection tank 14 and control system 15.

[0023] A steel strip 4 is fixed on the shaft of the above-mentioned pan-type feeding frame 1, and the steel strip 4 is continuously removed from the pan-type feeding frame 1 under the influence of the subsequent fixed-length feeding device 2 .

[0024] Above-mentioned material-free photoelectric controller 3 is provided with a photoelectric sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com