Method for producing cast iron by adopting remelting furnace blowing smelting and purification, and apparatus thereof

A technology for remelting furnace and cast iron, which is applied in the field of iron and steel smelting, can solve the problems of difficulty in reducing the amount and harm of low-melting element inclusions and gases, and difficulty in removing impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

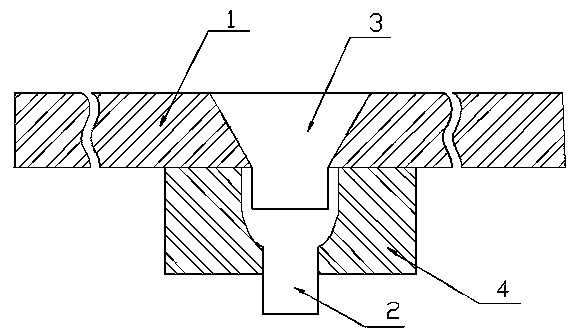

Image

Examples

Embodiment 1

[0035] Example 1: Gas Blowing Process of Acid Induction Furnace Oxidation

[0036]In the induction furnace, ceramic tubes, cermet tubes, and high-temperature metal tubes are used to blow gas into molten steel from the top or the furnace door, or open at the bottom, bury the blowing tube and the breathable brick that isolates the melt, and lay water circulation cooling protection The gas blowing system enables the traditional remelting induction furnace to have the function of bottom blowing gas. Oxygen is blown in from top to bottom or top blowing to oxidize some easily oxidizable elements, and the artificially added iron oxide and FeO generated by oxygen blowing are used to fully oxidize impurities, and FeO is reduced by C to produce CO gas, a large amount Floating to clean impurities. Use bottom or top blowing, blowing in N 2 , CO 2 , Ar, to eliminate harmful gases, and some of them float up to carry impurities. It can reduce the presence of iron-containing raw materia...

Embodiment 2

[0073] Example 2: Non-oxidizing Gas Blowing Process in Acid Induction Furnace

[0074] Oxygen is not blown in and iron oxides are not added. Others are the same as the oxidation blowing process, and the effect of removing impurities is lower than that of the oxidation blowing process.

[0075] 1) Furnace repair

[0076] With embodiment 1.

[0077] 2) Loading ingredients

[0078] Iron-containing raw material is packed into induction furnace, with embodiment 1. The amount of auxiliary materials added before slag removal in the charging and batching period and the melting period is 1.5-10% (W) of the total amount of iron-containing raw materials; in the charging and batching period, the auxiliary materials are mixed in the iron-containing raw materials, and the input auxiliary materials are auxiliary materials 20-50% of the total amount of feed; add the remaining auxiliary materials before slag removal in the melting period or in batches. The auxiliary materials are lime-ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com