Vibrating diaphragm, preparation method thereof and acoustoelectric device

A film layer and material film technology, applied in the field of acoustic and electrical devices, can solve problems such as loss of corporate profits, product failure, and increase in speaker defect rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] The preparation method of the diaphragm provided in this embodiment includes the following steps:

[0093] After the reactor is filled with nitrogen, add 9 parts of diisocyanate and organotin catalyst to 4 parts of polyether diol, stir, heat up, add 2 parts of calcium carbonate, 1 part of white carbon black and 1 part of aramid fiber and continue stirring , and then add 3 parts of a mixed solution of diphthalic anhydride and a solvent to obtain a prepolymer; lower the temperature and add 4 parts of a mixed solution of a silane coupling agent and a solvent to the prepolymer under stirring conditions, mix well, The polyurethane-imide material layer is obtained by precision coating.

[0094] The diaphragm provided by this embodiment is as figure 1 As shown, the diaphragm is a one-layer structure made of the polyurethane-imide material layer with a thickness of 140 μm.

Embodiment 2

[0096] The preparation method of the diaphragm provided in this embodiment includes the following steps:

[0097] (a) After the reactor is filled with nitrogen, add 9 parts of diisocyanate and organotin catalyst to 5 parts of polyether diol, stir, heat up, add 1 part of mica powder, 2 parts of glass microspheres and 1 part of fiber to continue Stir, then add 4 parts of a mixed solution of diphthalic anhydride and a solvent to obtain a prepolymer; lower the temperature, add 5 parts of a mixed solution of a silane coupling agent and a solvent to the prepolymer under stirring conditions, and mix well , using a precision coating method to obtain a polyurethane-imide material layer;

[0098] (b) Compounding the polyurethane-imide material layer with an acrylic adhesive to obtain a vibrating membrane.

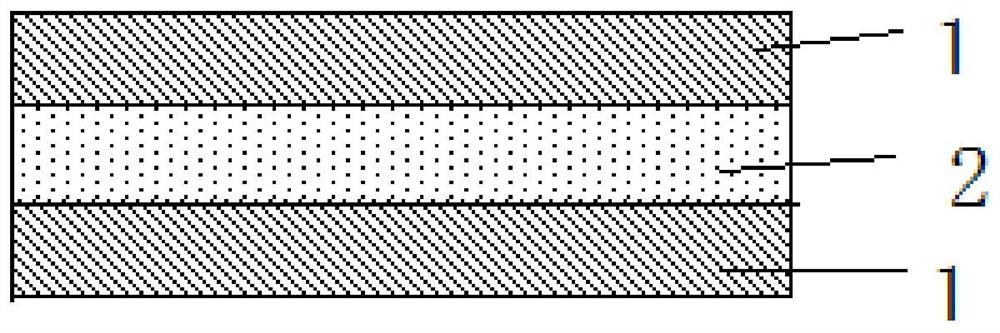

[0099] The diaphragm provided by this embodiment is as figure 2 As shown, it is a three-layer structure, as follows:

[0100] The top layer is polyurethane-imide material layer 1...

Embodiment 3

[0102] The preparation method of the diaphragm provided in this embodiment includes the following steps:

[0103] (a) After the reactor is filled with nitrogen, add 10 parts of diisocyanate and organotin catalyst to 7 parts of polyether diol, stir, heat up, add 2 parts of mica and 3 parts of kaolin and continue stirring, then add 4 parts of diisocyanate and organic tin catalyst A mixture of phthalic anhydride and solvent to prepare a prepolymer; add 6 parts of a mixture of silane coupling agent and solvent to the prepolymer under cooling and stirring, mix well, and adopt precision coating , to obtain a polyurethane-imide material layer;

[0104] (b) Compounding the polyurethane-imide material layer with a silicone adhesive to obtain a vibrating membrane.

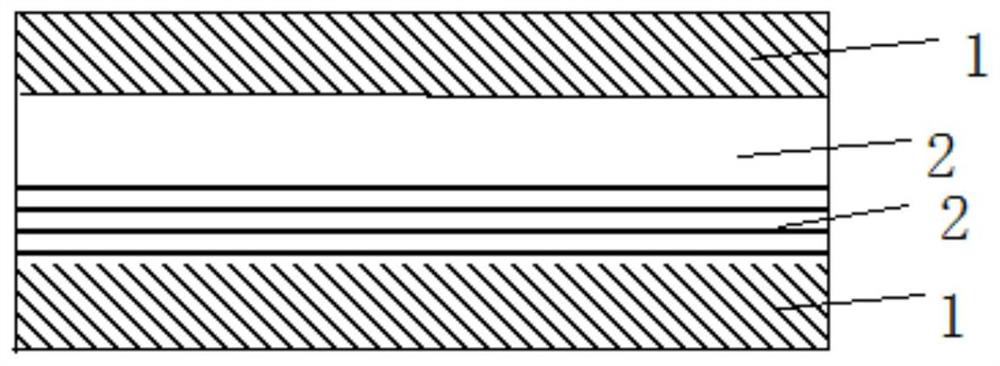

[0105] The diaphragm provided by this embodiment is as image 3 As shown, it is a four-layer structure, as follows:

[0106] The top layer is a polyurethane-imide material layer with a thickness of 30 μm. The bottom laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com