Antenna and its radome as well as the mold and molding process of the radome

A molding process and radome technology, which is applied to the radiation unit cover and other directions to achieve the effects of stable quality, simple specific steps, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

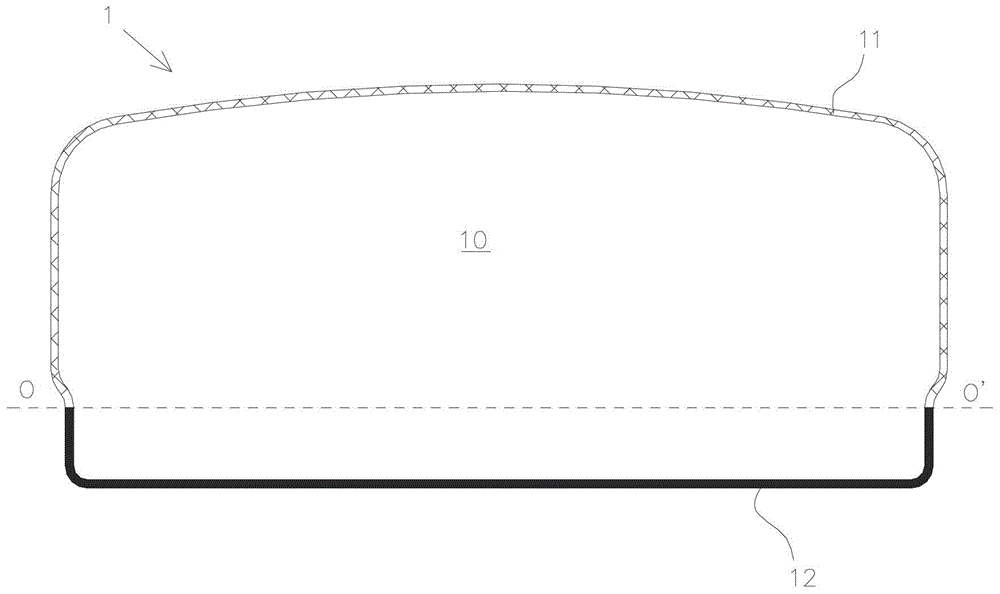

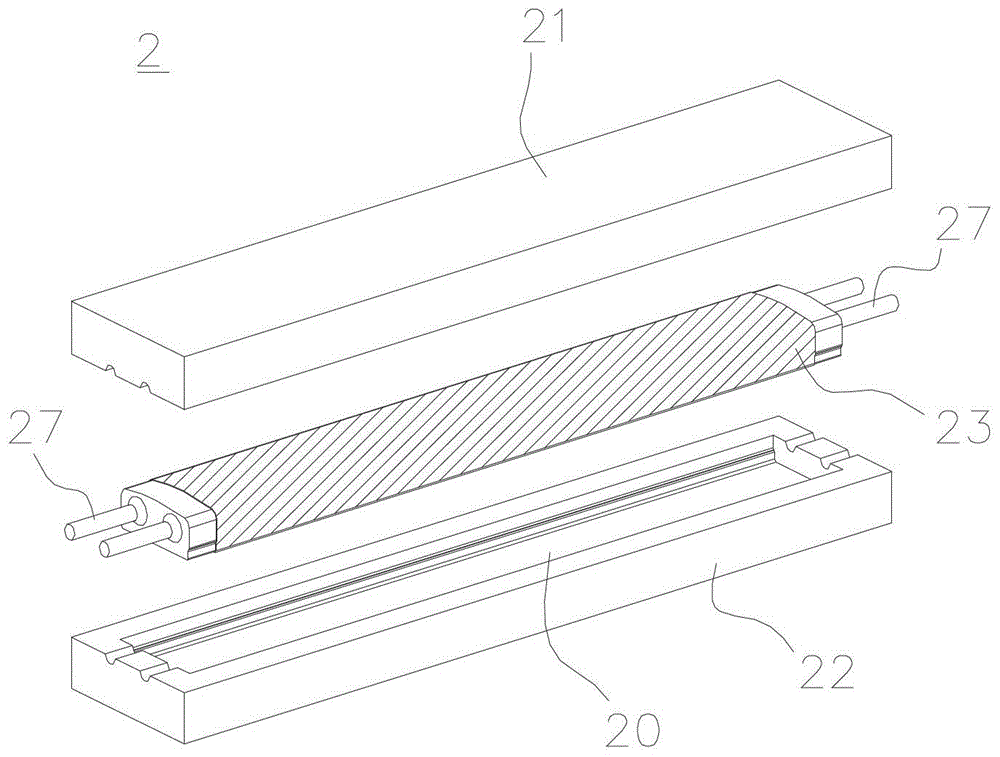

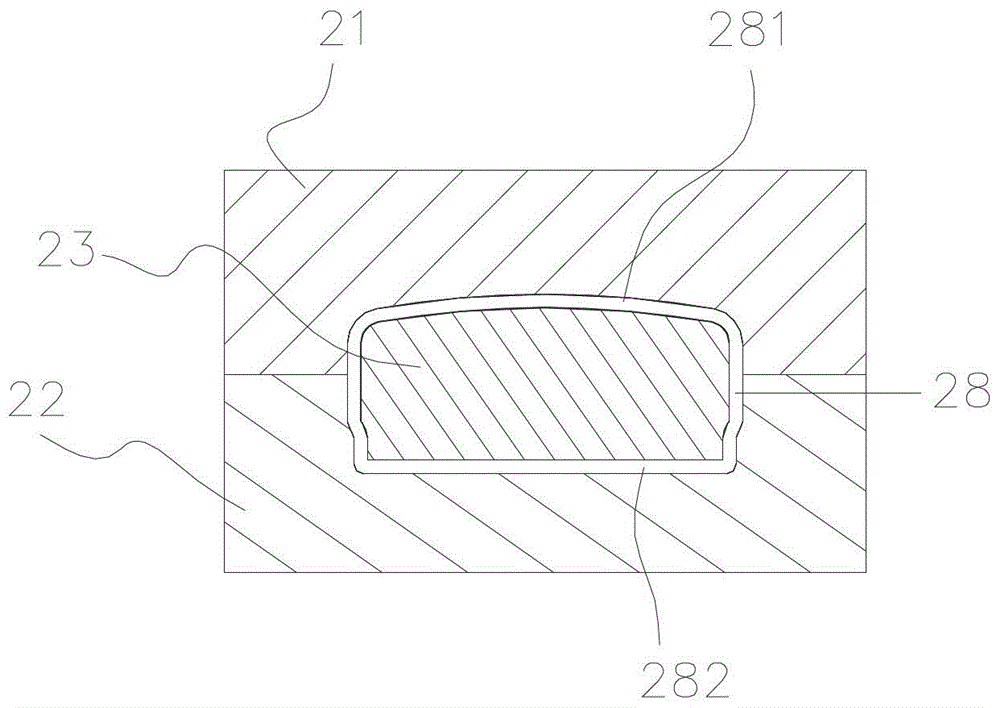

[0040] see figure 1 Shown is a schematic cross-sectional view of a radome 1 of the present invention, which can clearly reveal that the radome 1 of the present invention, as a finished product, is an integrally formed part, and the whole is in a longitudinal shape, and adopts a subsequent molding process suppressed. The radome 1 has a virtual longitudinal section (see figure 1 Section boundary line OO', which is the imaginary section where the boundary line is located), is divided into an upper cover 11 and a lower cover 12. The upper cover 11 has a hollow material structure, and a single-layer glass fiber hollow fabric blank is used as the main body. Prepreg, if necessary, add other known commonly used additives, thereby making a prepreg sheet 4 (see Figure 4), from which the sheet is further molded. Since the glass fiber hollow fabric has two u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com