Parallel grouping screening method for single batteries

A single battery and screening method technology, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of screening failure, screening, and many screening features, and achieve stable consistency, high consistency, and stability and good dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

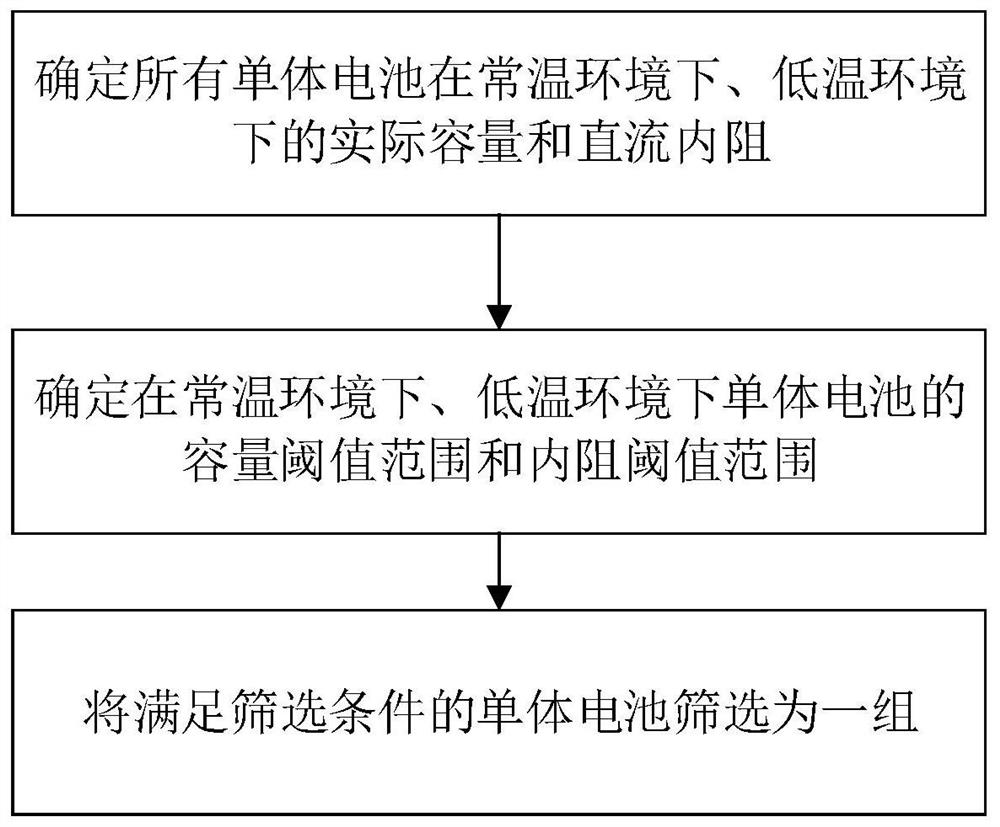

[0019] Such as figure 1 The parallel group screening method of the single cells shown includes:

[0020] Step 1. Determine the actual capacity and DC internal resistance of all single batteries under normal temperature environment and low temperature environment

[0021] Under the environment of 25°C, conduct a constant current discharge test on all the single batteries in the first fully charged state with a current of 1 / 3C, and obtain the actual capacity Q of each single battery under the environment of 25°C; among them, the first fully charged state A single battery refers to a single battery that is fully charged with a constant current of 1 / 3C at 25°C and left to stand for 4 hours at 25°C.

[0022] Under the environment of 25°C, discharge all the single cells in the first fully charged state with a constant current of 1 / 3C. During the constant current discharge process, when the SOC of the single cells is 90%, 60%, and 10% Add 1C current to conduct 10-second pulse disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com