Cold crucible cover for top seed crystal temperature gradient method

A seed crystal temperature, gradient method technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of unstable temperature field, long angle, single structure design, etc., to achieve stable crystal quality and quality consistency, Solve the problem of long angle and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

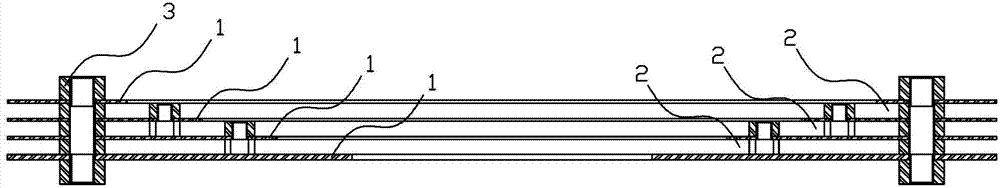

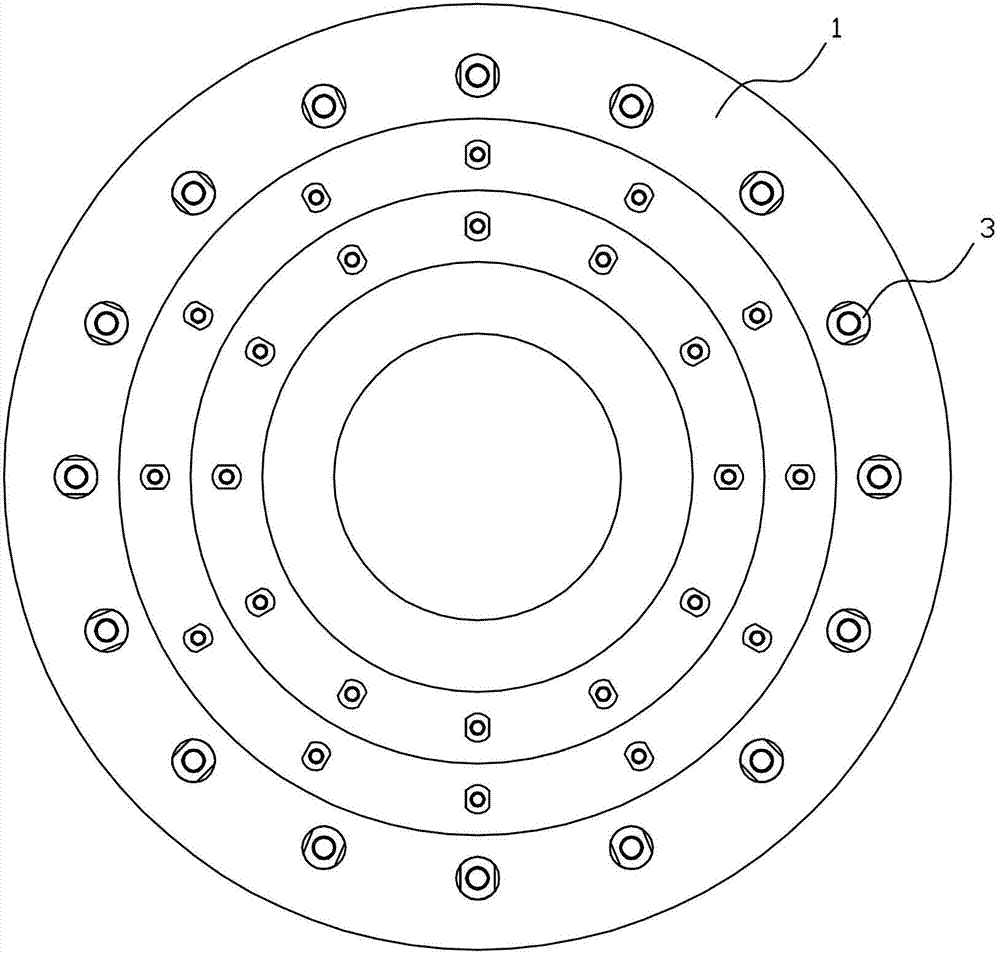

[0031] The present invention also provides a cold crucible cover for obtaining a temperature gradient for stable crystal growth, such as figure 1 , figure 2 As shown, the cold crucible cover is composed of four circular tungsten plates 1 with the same outer diameter and different inner diameters of a certain thickness. The circular tungsten plates 1 are provided with several screw holes, and the four circular tungsten plates are 1 is fixed and assembled with nut 3.

[0032] The inner diameters of the circular tungsten plate 1 from the upper layer to the lower layer are 250mm, 200mm, 150mm, and 100mm respectively, the outer diameters are 330mm, and the upper and lower gaps 2 are 5mm.

[0033] The circular tungsten plates 1 with internal diameters of 250mm and 100mm are provided with 16 screw holes with a diameter of 8.5mm, and the circular tungsten plates 1 with internal diameters of 200mm and 150mm are respectively provided with 16 screw holes with a diameter of 8.5mm and 1...

Embodiment 2

[0035] In this embodiment, the upper and lower surfaces of the ring tungsten plates are provided with adjusting nuts for adjusting the gap between the ring tungsten plates, so as to facilitate the installation or removal of the ring tungsten plates. Other parts are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com