A manufacturing process of manhole well welded parts

A manufacturing process and manhole well technology, applied in the field of welding, can solve the problems of the rigid positioning ring and the inner wall of the cylinder being too tight, the flange surface is uneven, and the welding deformation of the cylinder body is large, so as to improve the welding resistance to deformation, prevent The effect of the deformation of the cylinder and the increase of the positioning area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

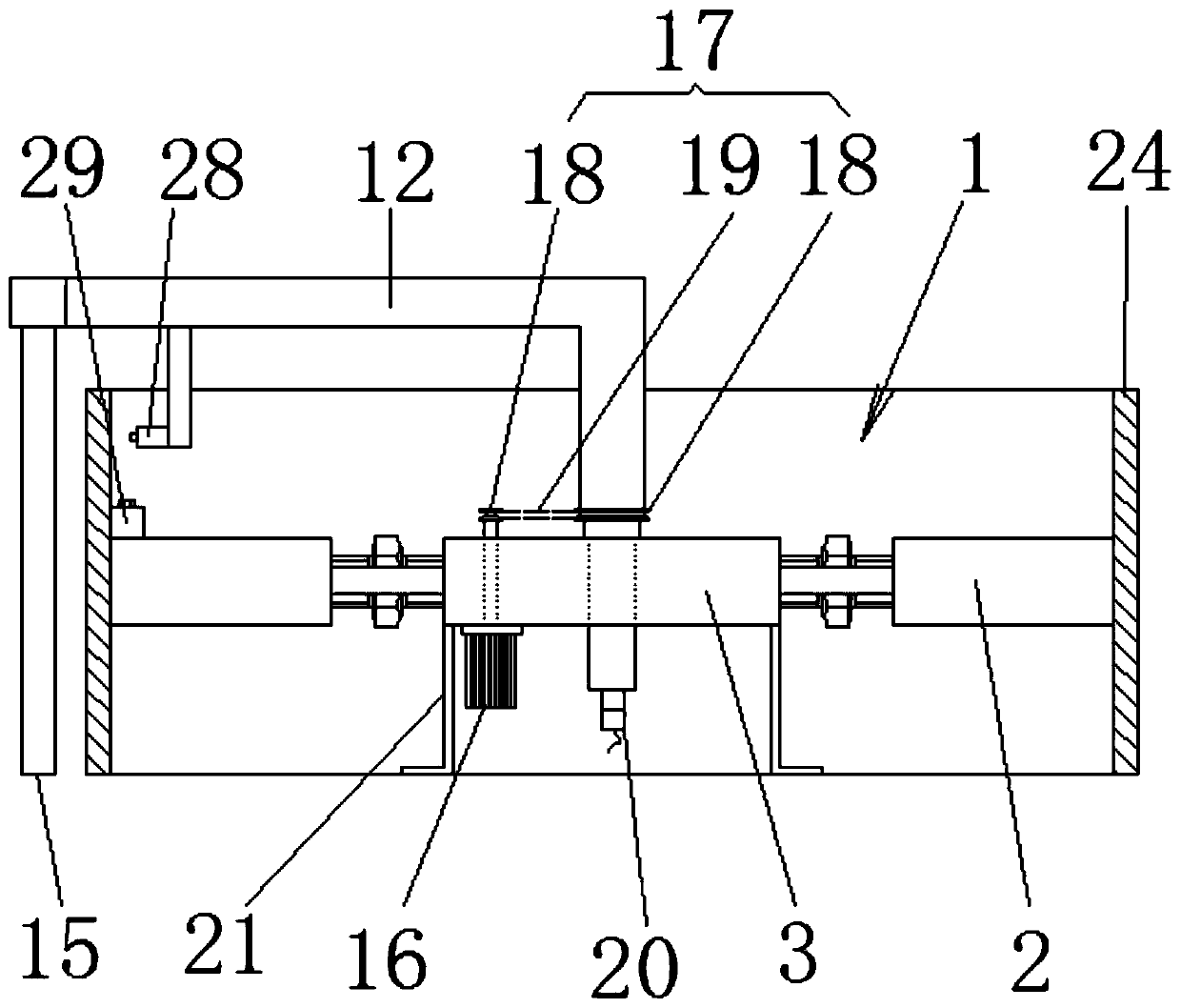

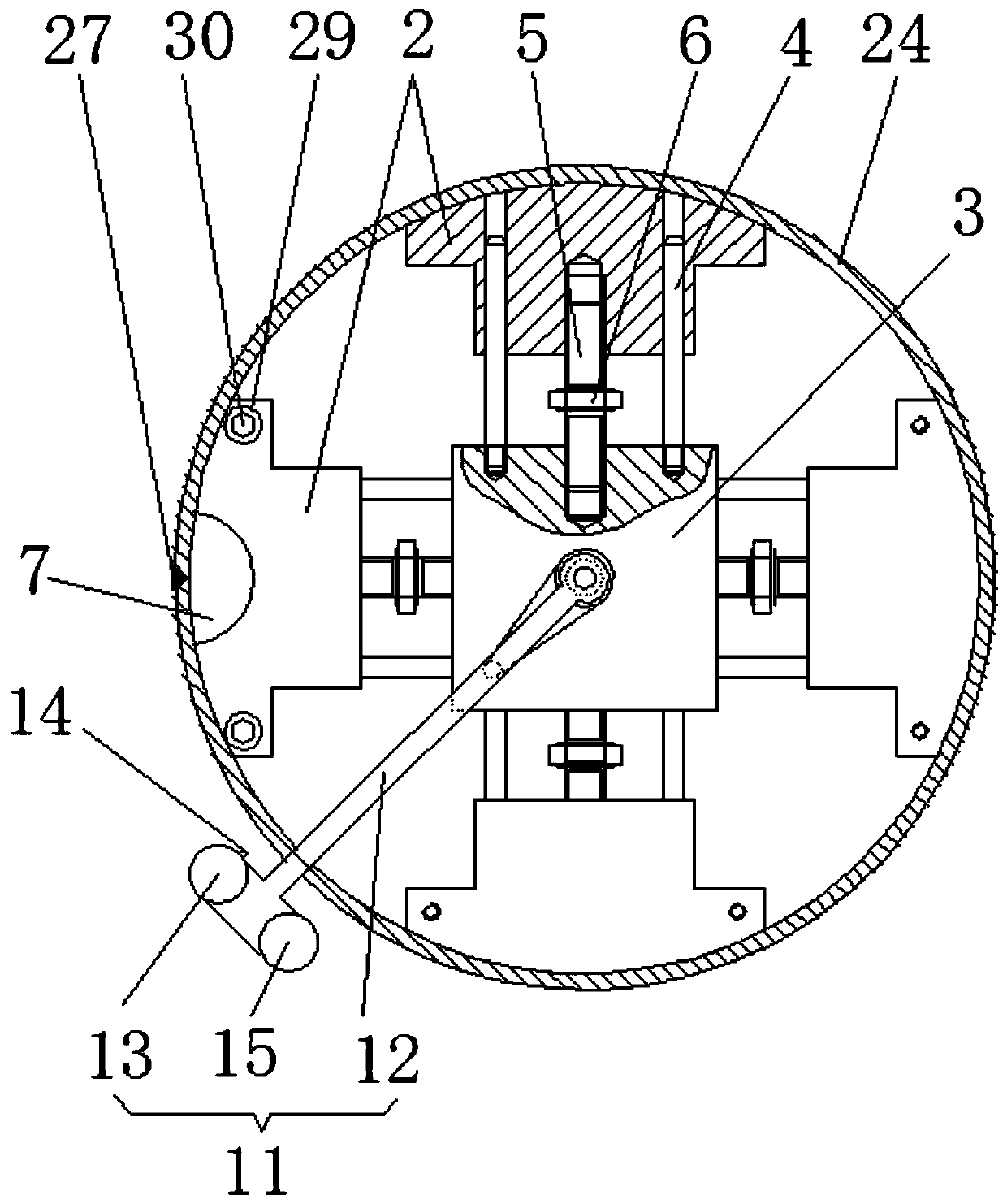

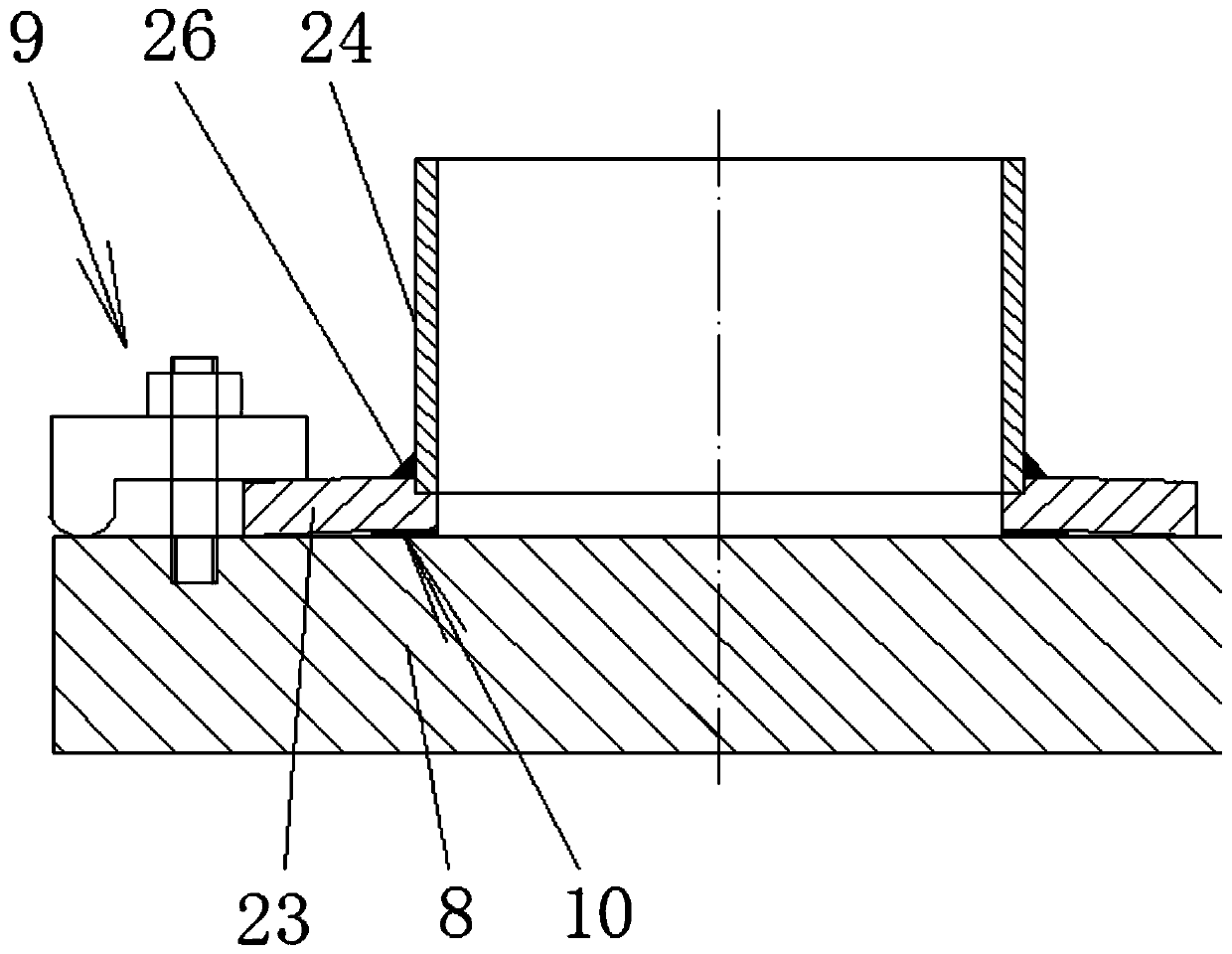

[0058] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0059] like Figures 1 to 4 Shown is the embodiment of the manufacturing process of a kind of manhole well weldment of the present invention, comprises the following steps:

[0060] Step 1. Steel plate blanking: use steel plate as the material for the manhole well, cut and blank the flange 23 of the manhole well; first draw the cylinder expansion diagram for the cylinder 24 of the manhole well, and expand Carry out cutting and blanking according to the figure and pre-cut the welding groove at the seam part of the cylinder 24;

[0061] Step 2, steel plate rolling: use a rolling machine to roll the unloaded steel plate of the cylinder body 24 to form a roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com