Liner structure, and aluminum electrolysis bath with liner structure

An aluminum electrolytic cell and lining technology, which is applied in the field of aluminum electrolytic cells, can solve the problems that the actual state of the electrolytic cell cannot be considered, the heat balance in the cell is uncontrollable, and the energy consumption of the electrolytic cell is affected. The effect of uniform field distribution and easy continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

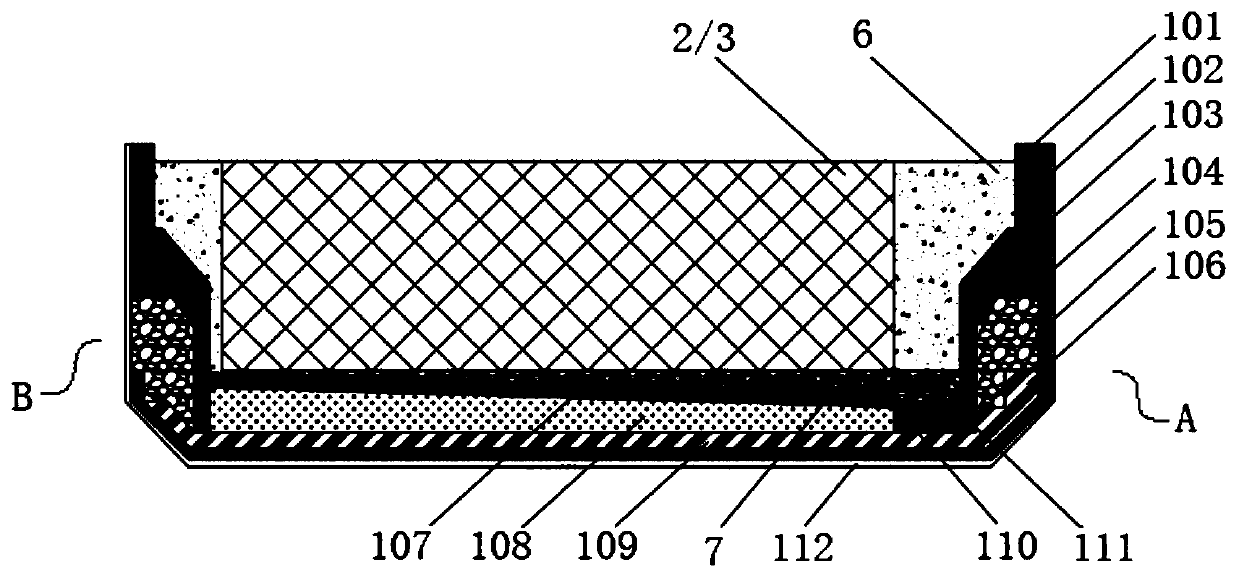

[0032] see figure 1 , the aluminum electrolytic cell body 1 shown in the figure adopts the lining structure in the present invention, and the lining structure specifically includes the side inner carbon block 101, the side heat insulation plate layer 102, the side special-shaped carbon block 103, high aluminum Bricks 104, high-strength castables 105, bottom insulation slabs 106, inclined carbon blocks 107 at the bottom of the tank, insulation bricks 108, bottom anti-seepage layer 109, carbon blocks 110 at the bottom of polyaluminum trenches, polyaluminum trenches 111 and tank shells 112, Fig. The input side A in the illustration refers to the side where the anode in the aluminum electrolytic cell is connected to the input side, and the output side B refers to the side where the cathode in the aluminum electrolytic cell is connected to the output side.

[0033] The lining structure is integrally fixed on the inner wall of the tank shell 112 of the tank body. According to the ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com