Organic fiber toughened inorganic composite artificial stone panel and preparation method thereof

An organic fiber and inorganic composite technology, applied in chemical instruments and methods, manufacturing tools, ceramic molding machines, etc., can solve the problems of high water absorption, insufficient compressive performance, poor bending strength and toughness, etc., and achieve low water absorption. , good bonding performance, good ductility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

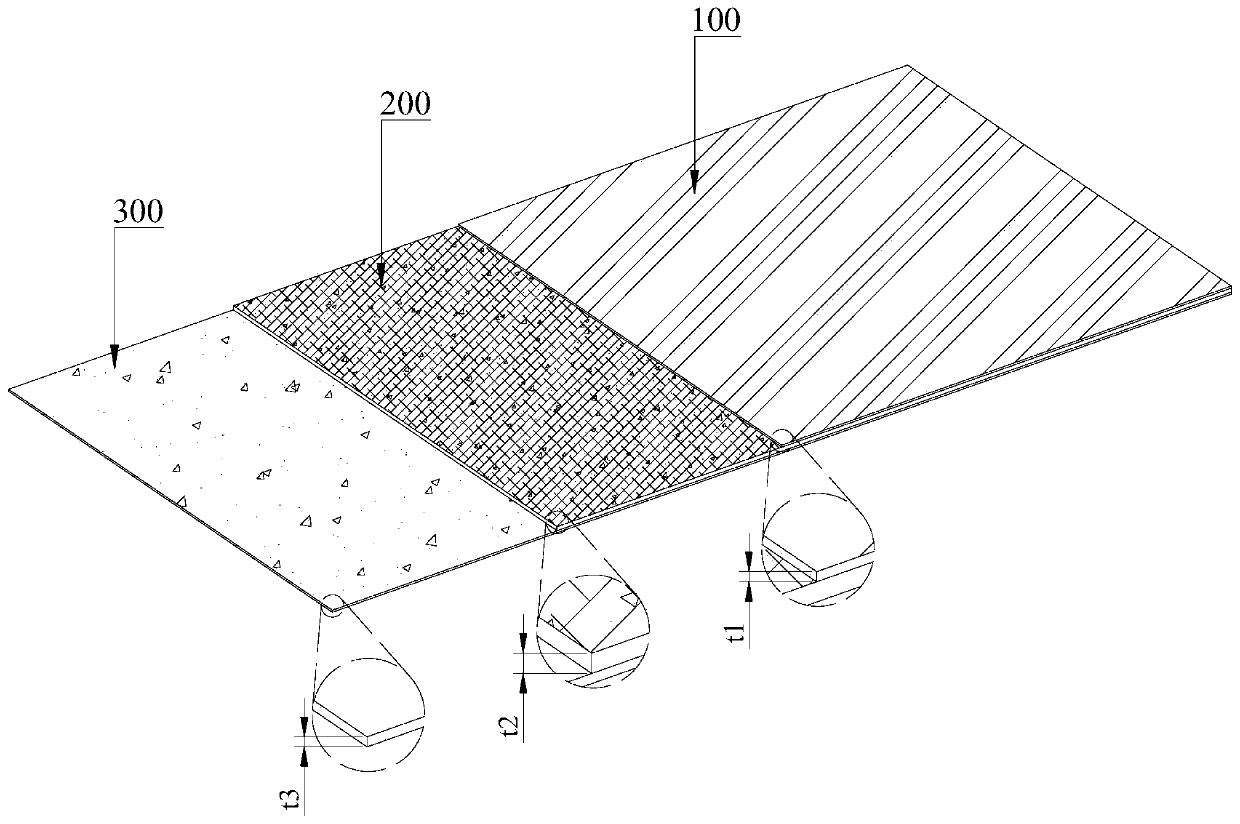

[0032] Such as figure 1 As shown, an organic fiber toughened inorganic composite artificial stone panel has an overall thickness (t1+t2+t3) of 15-50 mm, including a surface layer with a thickness t1 of 3-5 mm, a middle organic fiber toughened layer and a thickness t3 of 3 mm. ~5mm base toughening layer, the surface layer includes the following raw material components in parts by weight: quartz sand 40, quartz powder 10, inorganic active powder 20, pigment 0.5, water reducing agent 0.3, water 3; middle organic fiber toughening layer Including the following raw material components in parts by weight: inorganic active powder 40, sand 45, water reducer 0.8, water 6, organic fiber 0.5; the base toughening layer includes the following raw material components in parts by weight: inorganic active powder 30 , Quartz sand 30, Quartz powder 15, Water reducing agent 0.5, Water 4, Toughening agent 0.8.

[0033] Among them, the fineness modulus of the quartz sand is 2.3 (the fineness modul...

Embodiment 2

[0048] Except that the formulation of the organic fiber toughened inorganic composite artificial stone panel is different, other conditions are the same as in Example 1.

[0049] An organic fiber toughened inorganic composite artificial stone panel, comprising the following raw materials in parts by weight: the surface layer includes the following raw material components in parts by weight: quartz sand 70, quartz powder 30, inorganic active powder 45, pigment 4, water reducing Agent 1, water 10; the middle organic fiber toughening layer includes the following raw material components in parts by weight: inorganic active powder 60, sand 65, water reducing agent 1.5, water 14, organic fiber 1.2; the base toughening layer includes the following weight Each raw material component of the part: inorganic active powder 50, quartz sand 55, quartz powder 20, water reducer 1.2, water 8, toughening agent 2.5.

Embodiment 3

[0051] Except that the formulation of the organic fiber toughened inorganic composite artificial stone panel is different, other conditions are the same as in Example 1.

[0052] An organic fiber toughened inorganic composite artificial stone panel, comprising the following raw materials in parts by weight: the surface layer includes the following raw material components in parts by weight: quartz sand 50, quartz powder 15, inorganic active powder 27, pigment 1.5, water reducing agent 0.5, water 4.5; the middle organic fiber toughening layer includes the following raw material components in parts by weight: inorganic active powder 45, sand 50, water reducing agent 0.9, water 8, organic fiber 0.7; the base toughening layer includes the following weight Each raw material component of the part: inorganic active powder 35, quartz sand 36, quartz powder 16, water reducer 0.65, water 5, toughening agent 1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com