Narrow amplitude satellite type flexographic plate printing machine

A technology for flexographic plates and printing presses, applied in printing presses, rotary printing presses, rotary printing presses, etc., which can solve problems such as affecting sanitation, environmental protection and human health, loss of opportunities for cooperation, and complex structure of the whole machine, and achieve stable imprinting. Reliable and precise, reliable inking accuracy, avoiding the effect of over- or under-pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

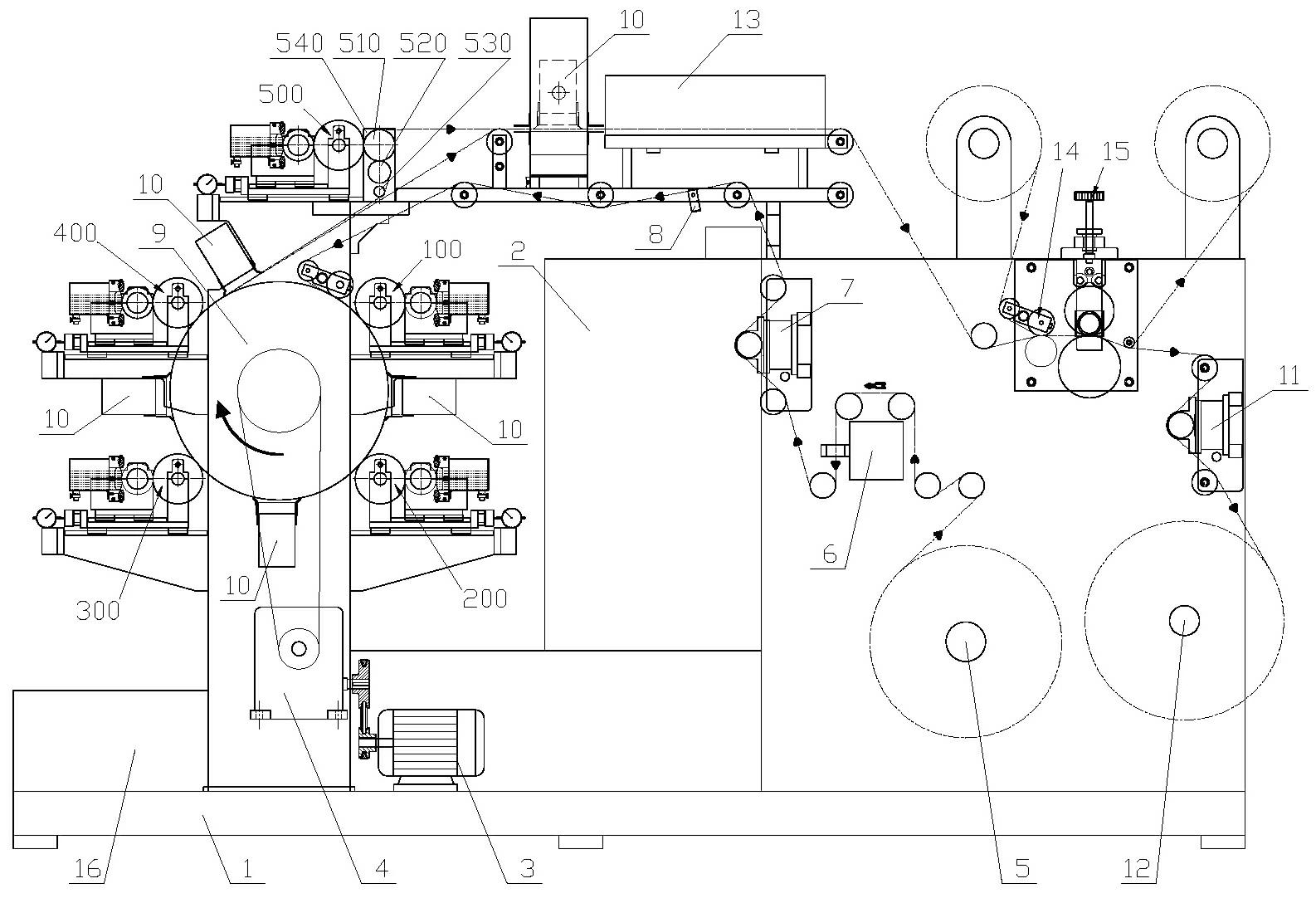

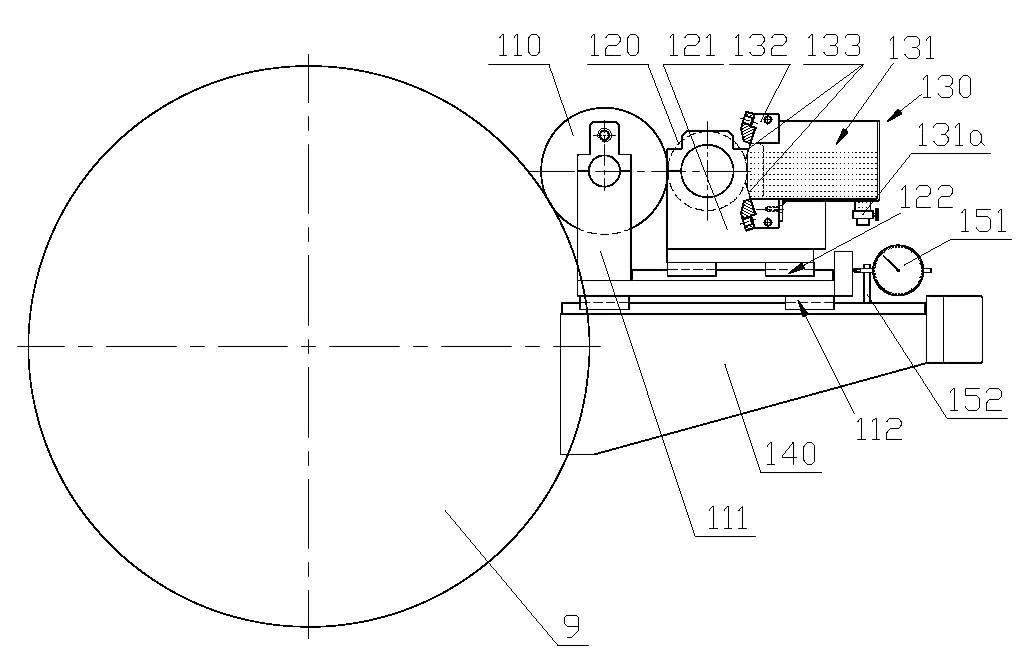

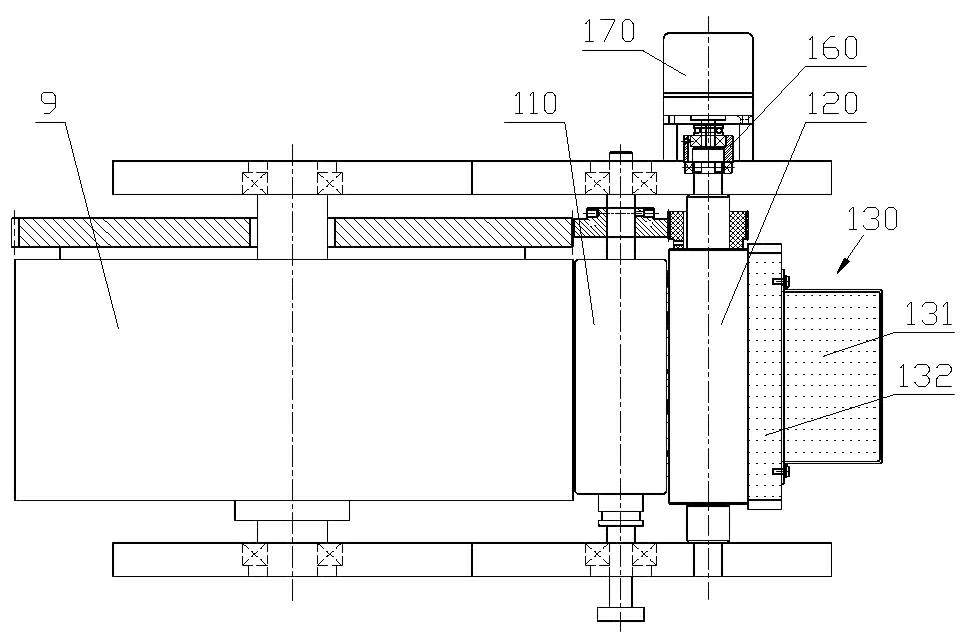

[0025] see figure 1 , a narrow-width satellite-type flexographic printing machine, including a frame 1, an electrical control part 2 arranged on the frame, a main motor 3 and a reducer 4 driven by the main motor, and the frame 1 is also assembled in sequence. Unwinding air shaft 5 for installing roll-shaped printing materials, printing material running deviation correction device 6, unwinding tension detector 7, static eliminator 8, central embossing roller 9, arranged in the center embossing roller in a satellite manner The multi-color printing groups around the cylinder 9 and the ultraviolet drying device 10 on the rear side of each color printing group, the winding tension detector 11, and the air expansion shaft winding device 12. The reducer 4 provides corresponding power for each operating device of the complete machine.

[0026]The multi-group color printing group includes the first color printing group 100, the second color printing group 200, the third color printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com