Liquid level control device and control method of reduction distillation reactor

A distillation reactor and liquid level control technology, which is applied in liquid level control, control/regulation system, non-electric variable control, etc., can solve the problems of excessive impurity element content, iron element exceeding standard, and reaction zone rise, so as to avoid absorption Oxygen, ensuring product quality, and avoiding large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

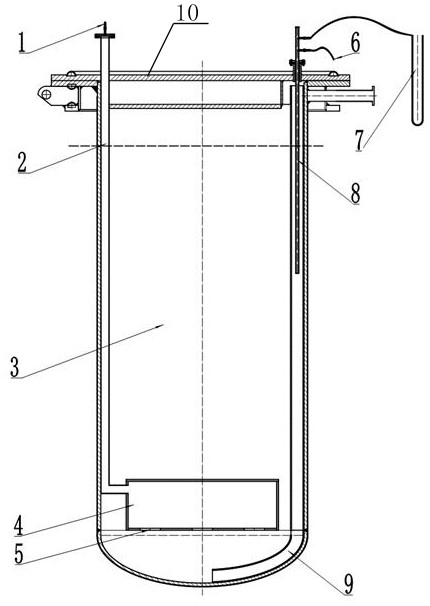

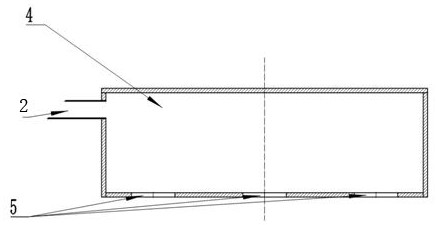

[0024] Referring to the accompanying drawings, a liquid level control device for a reduction distillation reactor, the upper opening of the reduction distillation reactor 3 is equipped with a sealed large cover 10, and one end of the liquid level measuring device for measuring the liquid level passes through the large cover 10 goes deep below the liquid level in the reduction distillation reactor 3, and the reduction distillation reactor 3 is also provided with a magnesium chloride discharge pipe 9, the lower end of the magnesium chloride discharge pipe 9 extends along the arc at the bottom of the reactor, and the upper end of the magnesium chloride discharge pipe 9 extends from the large The side walls of the reactor below the cover 10 protrude. In addition to the liquid level measuring de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com