Boiler drum water level control method and boiler drum water level control device

A boiler steam drum and water level control technology, applied in the field of automation, can solve the problems of inability to accurately control the boiler steam drum water level, affecting the boiler energy efficiency ratio, affecting the gas-liquid conversion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

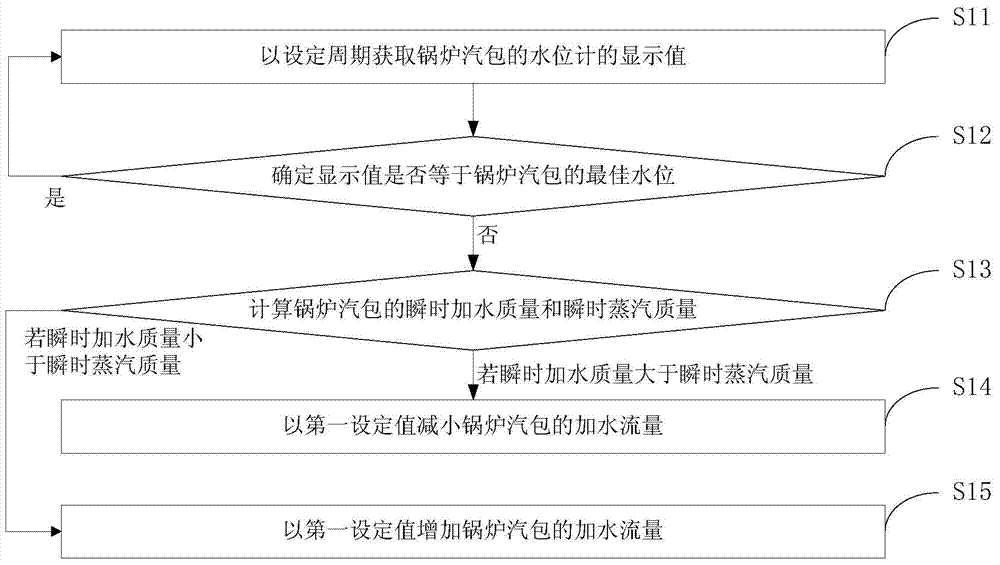

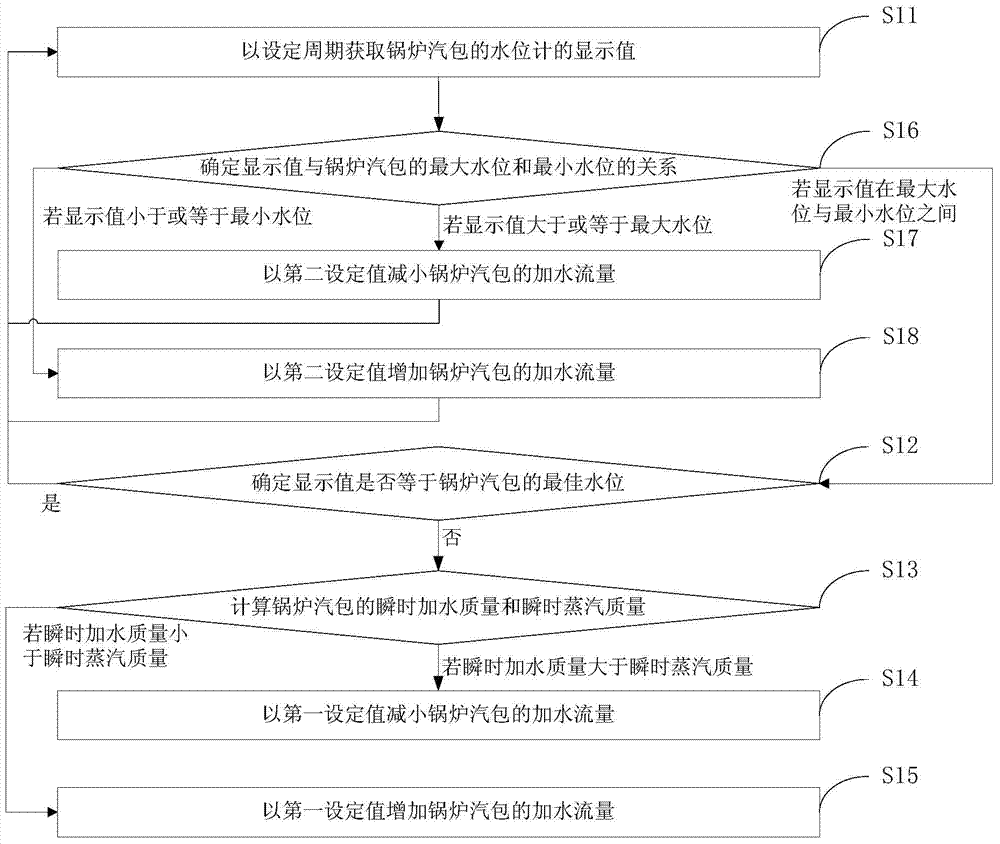

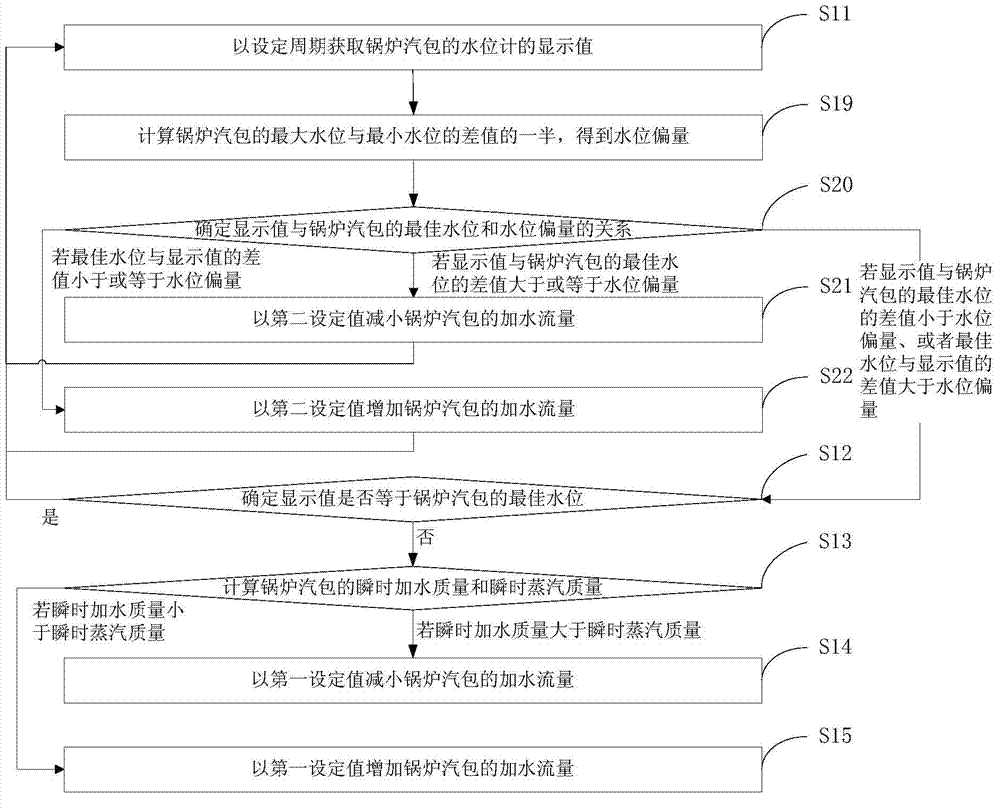

[0058] Aiming at the problem in the prior art that the water level of the boiler drum cannot be accurately controlled, resulting in large fluctuations in the water level of the boiler drum, which in turn affects the gas-liquid conversion and even affects the energy efficiency ratio of the boiler, the inventor conducted in-depth research and found that , steam and water are stored in the boiler drum, and the water level is used to describe the storage volume of water in the boiler drum. The instantaneous inflow quality of the boiler drum is the instantaneous water quality, and the instantaneous outflow quality of the boiler drum is the instantaneous steam quality. When the water quality is equal to the instantaneous steam quality, the water level of the boiler drum tends to be stable, so the water level of the boiler drum can be controlled by adjusting the instantaneous steam quality to be equal to the instantaneous water quality. Based on this, an embodiment of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com