Method for controlling air volume of air blower

A technology for air volume control and blower, applied in the field of control, can solve the problems of unsolved measurement device signal distortion, control loop fluctuation, sudden change of blast furnace air supply air volume blower unit, etc., to improve stability and automatic input rate, improve signal stability, Avoid the effect of large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: A blower air volume control method, the control method is as follows: Take Meishan Iron and Steel 2# blower as an example,

[0051] Step 1. Introduce the concept of air volume at the inlet of blower 1, and use the throat differential pressure to initially reflect the air volume at the inlet of the axial flow compressor according to the working principle of the blower;

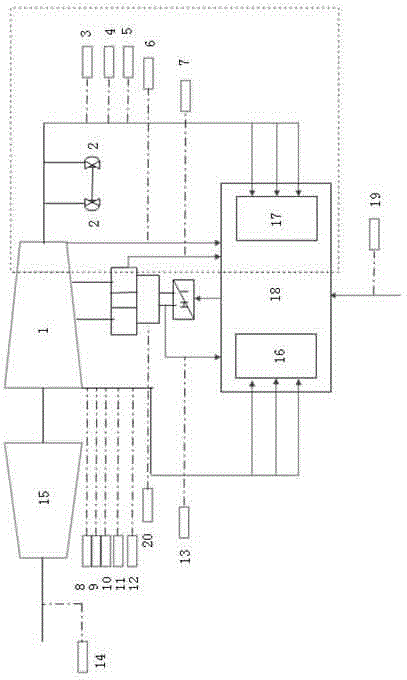

[0052] Step two, such as figure 1 As shown, the flow calculation is performed by using the throat differential pressure 8, throat differential pressure 9, throat differential pressure 10, inlet air pressure 11, and inlet air temperature 12 to calculate the air volume at the inlet of the blower unit.

[0053] (Formula 1);

[0054] Among them, Fa: predicted inlet air volume;

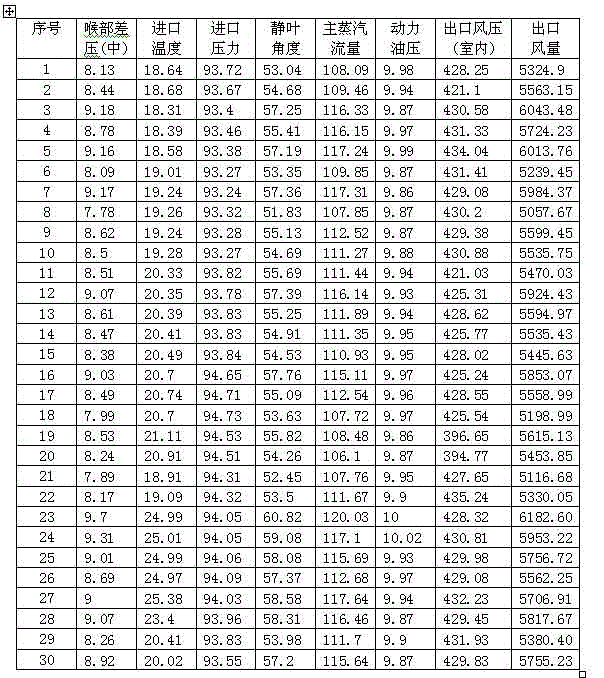

[0055] ?p: Throat differential pressure, sent to the DCS control system 18 through the throat differential pressure transmitter, and the final throat differential pressure value is obtained by taking the median value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com