Electrically-driven high-speed turnout reversing device

A reversing device and electric drive technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of accelerating the speed of pushing blocks, equipment shutdown, long response time, etc., to reduce equipment use and maintenance costs, reduce roughness Degree requirements, the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

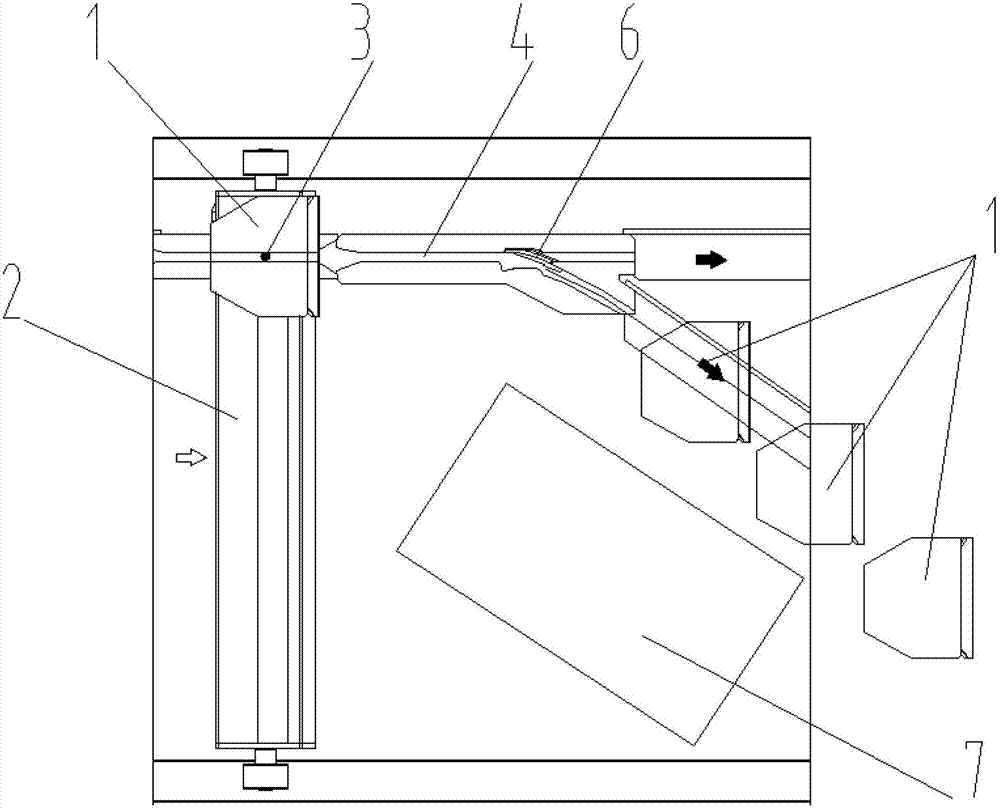

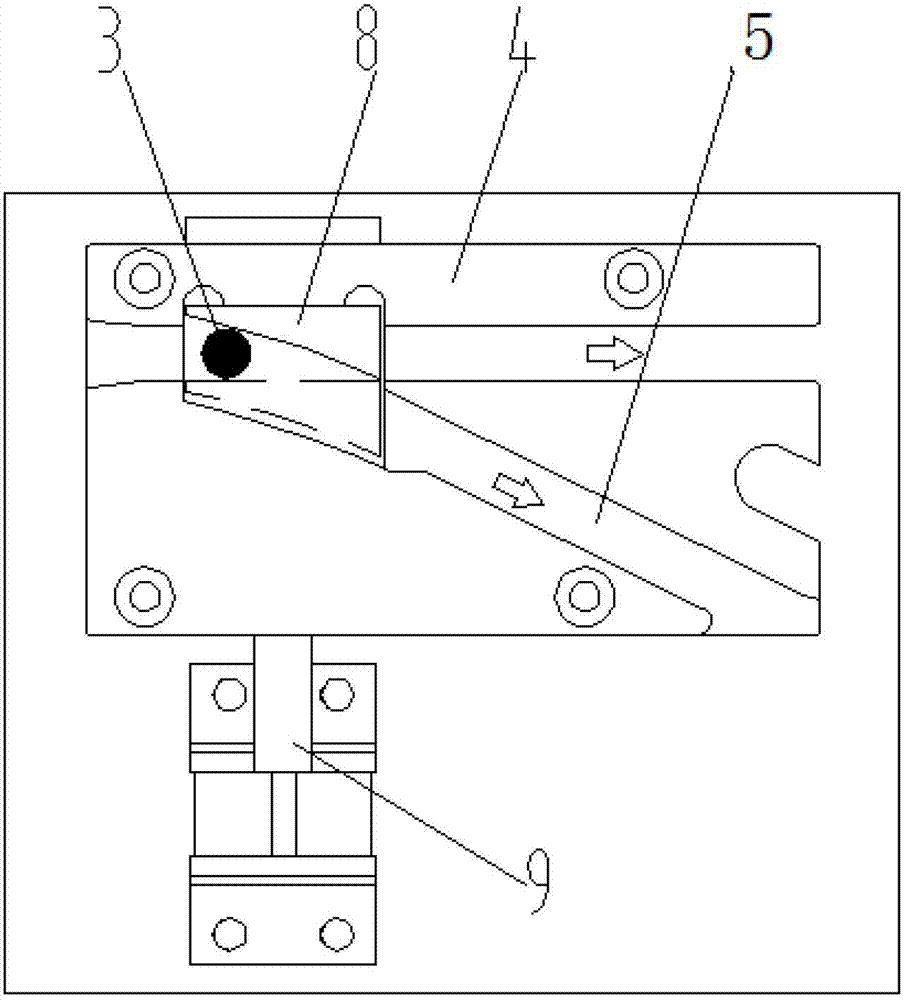

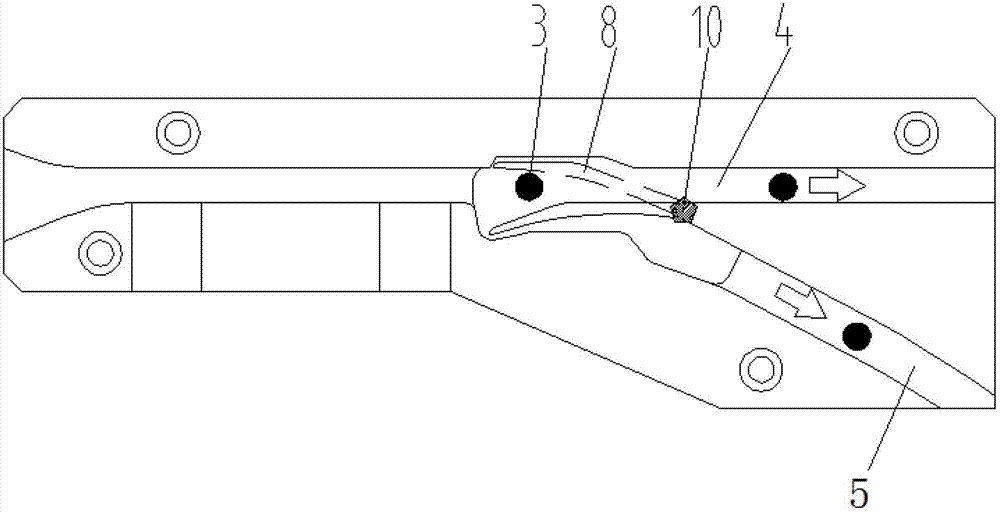

[0026] like figure 1 , image 3 As shown, an electrically driven high-speed turnout reversing device includes: a traveling mechanism 2, the traveling mechanism 2 is in the shape of a horizontal rod, and a roller perpendicular to the rod is provided at both ends of the rod, and the two rollers are arranged on a pair of parallel tracks. Rolling inside, the rod is covered with a push block 1, the push block 1 can slide along the rod, a push block travel pin 3 is provided at the bottom of the push block 1; a travel pin guide rail, the guide rail is located below the push block 1 and Perpendicular to the traveling mechanism 2, parallel and connected with the guide groove 4, the traveling pin 3 can enter the guide groove 4 at the same time; the switch reversing mechanism 6, the switch reversing mechanism 6 includes a switch base, and the switch base is provided with There is a shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com