Plug assembly of borescope and cartridge receiver plugging method

A hole detector and plugging technology, which is applied in the direction of engine sealing, instruments, mechanical equipment, etc., can solve the problems of inconsistent deformation of the two-layer casing, save inspection maintenance and management costs, improve inspection efficiency, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

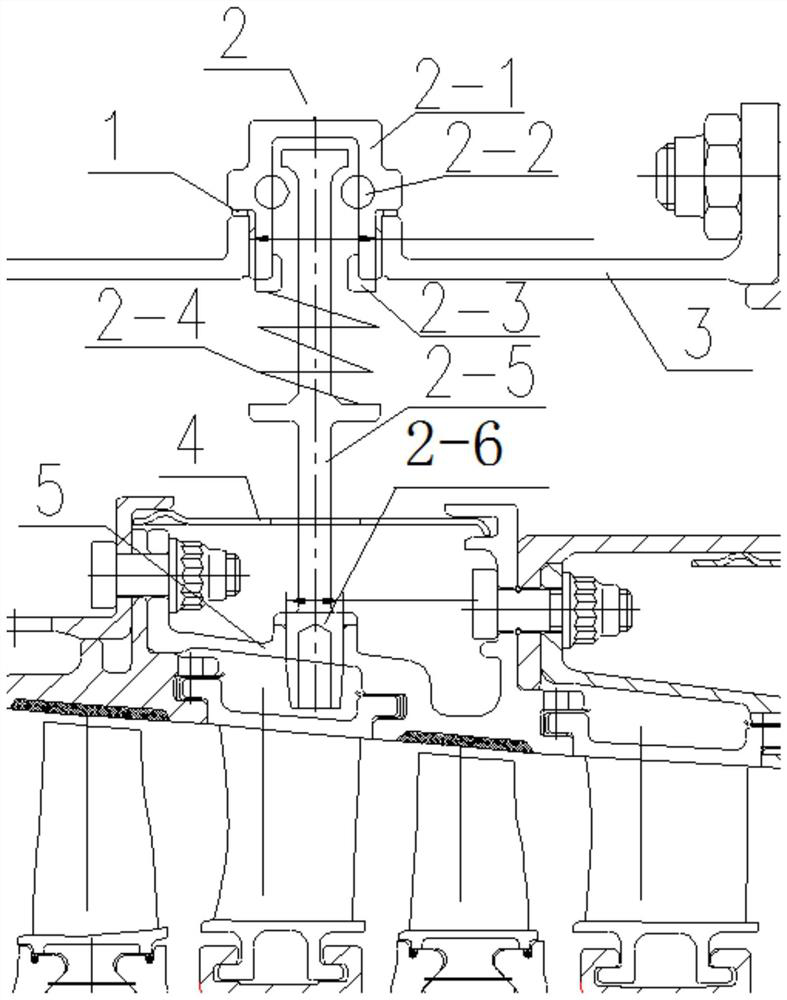

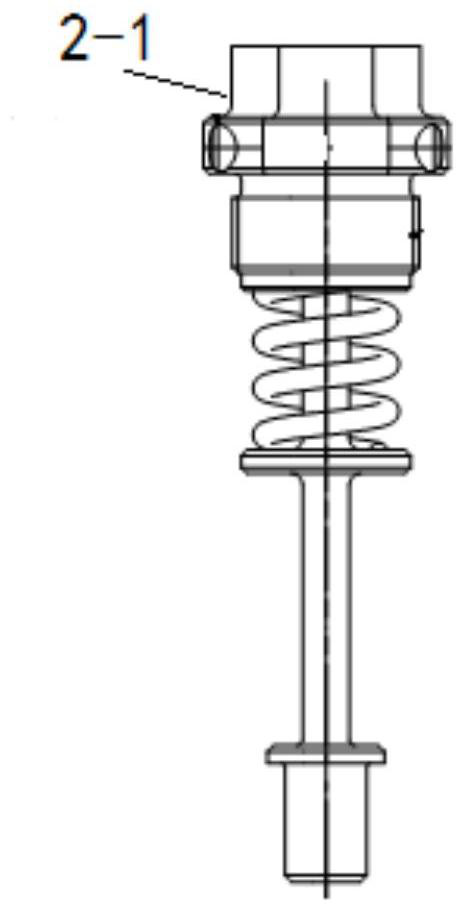

[0028] figure 1 It is a schematic diagram of the installation of the hole detector plug for the multi-layer casing, figure 2 is a schematic diagram of the hole finder plug assembly, combined with figure 1 and figure 2 As shown, this embodiment provides a plug assembly 2 for a borescope, and the plug assembly 2 includes a nut 2-1, a positioning member, a gasket 2-3, an elastic member, and a plug rod 2-5; The cap 2-1 is connected with one end of the blocking rod 2-5 through a positioning piece, and the blocking rod 2-5 has a degree of freedom in the radial direction of the casing; the nut 2-1 is threadedly connected with the outer casing 3; one end of the elastic member It is limited in the middle of the blocking rod 2-5, and the other end is in contact with the gasket 2-3, which is used to exert force on the blocking rod 2-5 in the radial direction of the casing; the gasket 2-3 and the nut 2-1 are close to the inside One end of the receiver contacts. The head of the block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com