Method for producing polyacrylamide microsphere water shutoff agent

A technology of polyacrylamide and manufacturing method, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of unfriendly environment, complex preparation method, uneven particle size of products, etc., and achieve environmental friendliness and simple process , swelling rate and the effect of improving salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

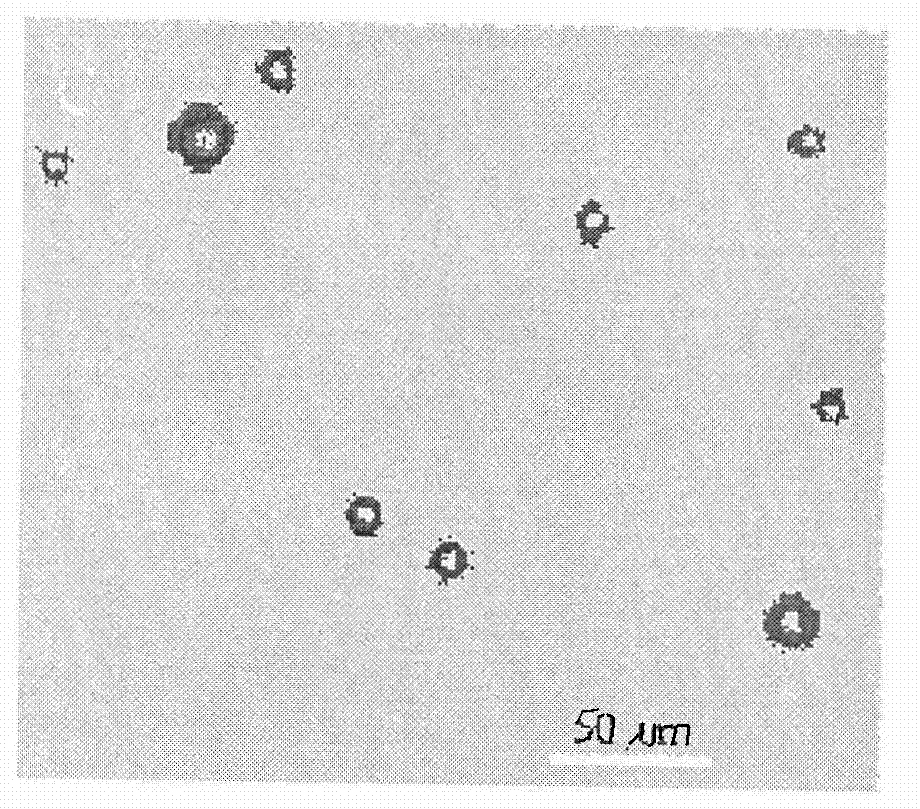

Image

Examples

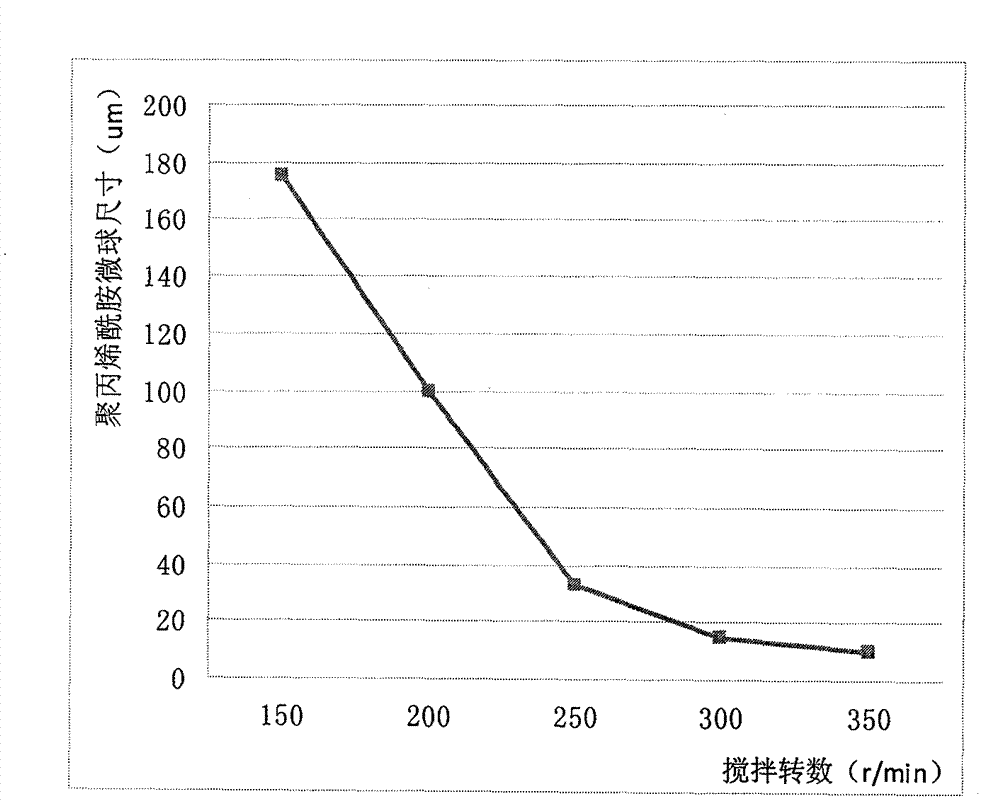

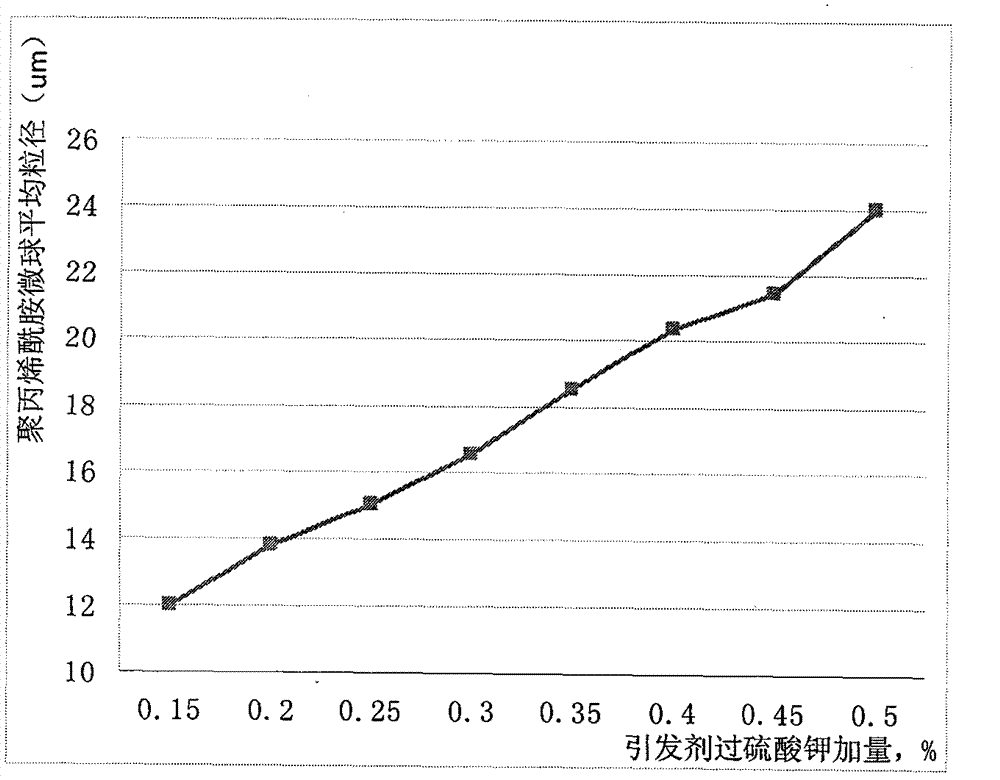

Embodiment 1

[0044] Weigh the raw materials by weight ratio, wherein the ratio of raw materials is: acrylamide 15wt%, 2-acrylamide-2-methylpropanesulfonate sodium anti-salt monomer 15wt%, N, N-methylenebisacryloyl 0.025wt %, Span 8010wt%, potassium persulfate 0.15wt%, cyclohexane 30wt%, deionized water 10wt%; at room temperature, add Span 80 dispersant in a container equipped with a thermometer, agitator, and condensing reflux device and cyclohexane, stir and mix evenly to form solution A; dissolve acrylamide monomer, salt-resistant monomer, N,N-methylenebisacryloyl in deionized water, and add potassium persulfate initiator after it is completely dissolved , stir until potassium persulfate is completely dissolved, the stirring speed is 150r / min, and the dissolved mixed solution is added to the solution A of step 2); the container is placed in a constant temperature water bath at 40°C, and under the protection of nitrogen, slowly add a concentration of 10 % sodium bisulfite aqueous solution...

Embodiment 2

[0046] Weigh the raw materials by weight ratio, wherein the ratio of raw materials is: 25wt% of acrylamide, 5wt% of salt-resistant monomer of sodium 2-acrylamide-2-methylpropanesulfonate, 0.05wt of N,N-methylenebisacryloyl %, Span 8025wt%, potassium persulfate 0.1wt%, cyclohexane 30wt%, deionized water 5wt%; at room temperature, add Span 80 dispersant in a container equipped with a thermometer, agitator, and reflux device and cyclohexane, stir and mix evenly to form solution A; dissolve acrylamide monomer, salt-resistant monomer, N,N-methylenebisacryloyl in deionized water, and add potassium persulfate initiator after it is completely dissolved , stirred until the potassium persulfate was completely dissolved, the stirring speed was 200r / min, and the dissolved mixed solution was added to the solution A of step 2); the container was placed in a constant temperature water bath at 37°C, and under the protection of nitrogen, slowly added a concentration of 10 % sodium bisulfite aq...

Embodiment 3

[0048] Weigh raw materials according to weight ratio, wherein the ratio of raw materials is: acrylamide monomer 18wt%, N-vinylpyrrolidone anti-salt monomer 10wt%, N, N-methylenebisacryloyl 0.03wt%, Span 8015wt% , potassium persulfate 0.2wt%, cyclohexane 40wt%, deionized water 10wt%; at room temperature, add Span 80 dispersant and cyclohexane in the container equipped with thermometer, stirrer, condensing reflux device, stir Mix evenly to form solution A; dissolve acrylamide monomer, salt-resistant monomer, N,N-methylenebisacryloyl in deionized water, add potassium persulfate initiator after it is completely dissolved, and stir until potassium persulfate Completely dissolve, the stirring speed is 300r / min, add the dissolved mixed solution into solution A of step 2); place the container in a constant temperature water bath at 43°C, and slowly add sodium bisulfite with a concentration of 10% under nitrogen protection The aqueous solution is used as a reducing initiator, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com