Motor-driven connecting rod type cushion folding mechanism

A technology driven by a motor and a linkage mechanism, applied in the direction of movable seats, etc., can solve the problem of large space occupied by the seat cushion, and achieve the effects of ingenious design, increasing available space, and improving convenience and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

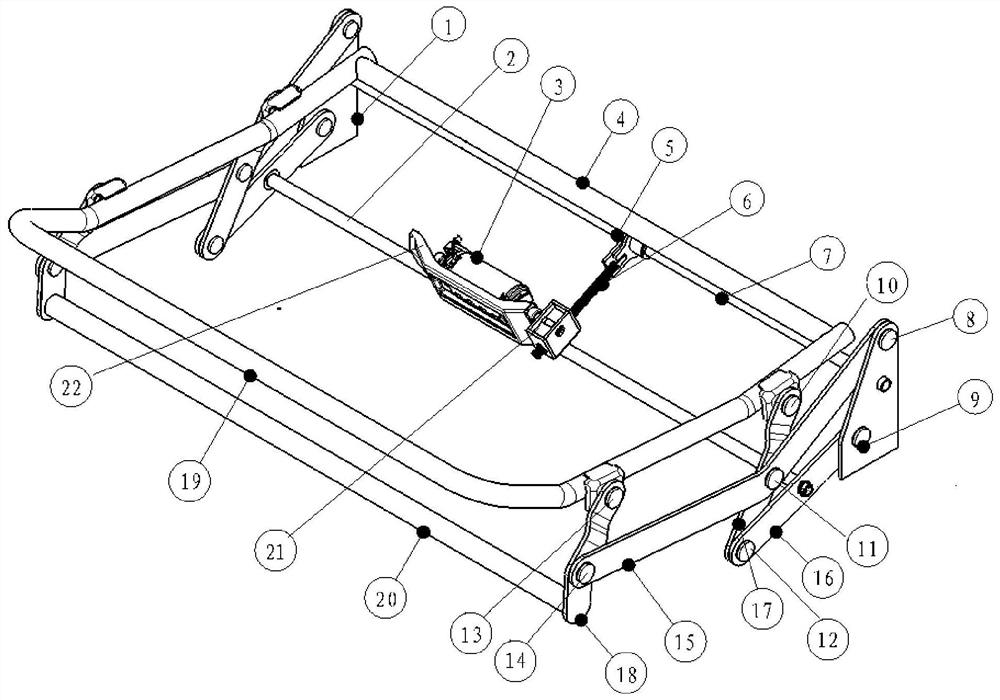

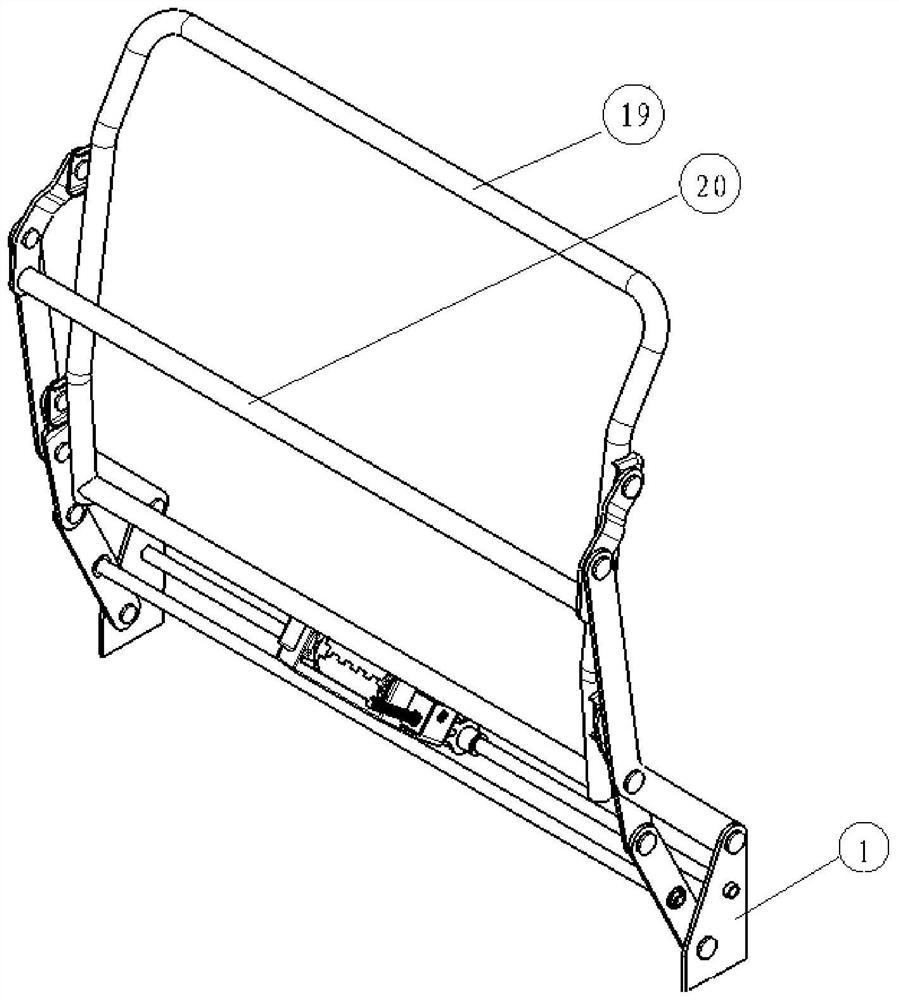

[0013] Such as Figure 1-2 A motor-driven connecting rod type cushion folding mechanism shown is mainly composed of a cushion skeleton, a driving motor 3, a transmission device and a connecting rod mechanism. The cushion frame at least includes a rear cross tube 4 and a seat frame elbow 19 , and the seat frame elbow 19 is fixed on the rear cross tube 4 .

[0014] Two mounting brackets 1 are arranged symmetrically on both sides of the rear cross tube 4, and the two mounting brackets 1 are fixedly connected with the vehicle body. Two connecting rod mechanisms are symmetrically arranged on both sides of the seat frame elbow 19, and each connecting rod mechanism includes four connecting rods. .

[0015] The rear end of the first connecting rod 15 is hinged on the upper side of the mounting bracket 1 by the first pivot pin 8; the rear end of the second connecting rod 16 is hinged on the lower side of the mounting bracket 1 by the second pivot pin 9; The upper end is hinged to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com