Deep foundation pit earth pressure controlled blasting method

A technology for controlling blasting and deep foundation pits, applied in blasting and other directions, can solve problems such as slow non-blasting progress, and achieve the effects of reducing economic losses of enterprises, controlling disturbance to residents, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

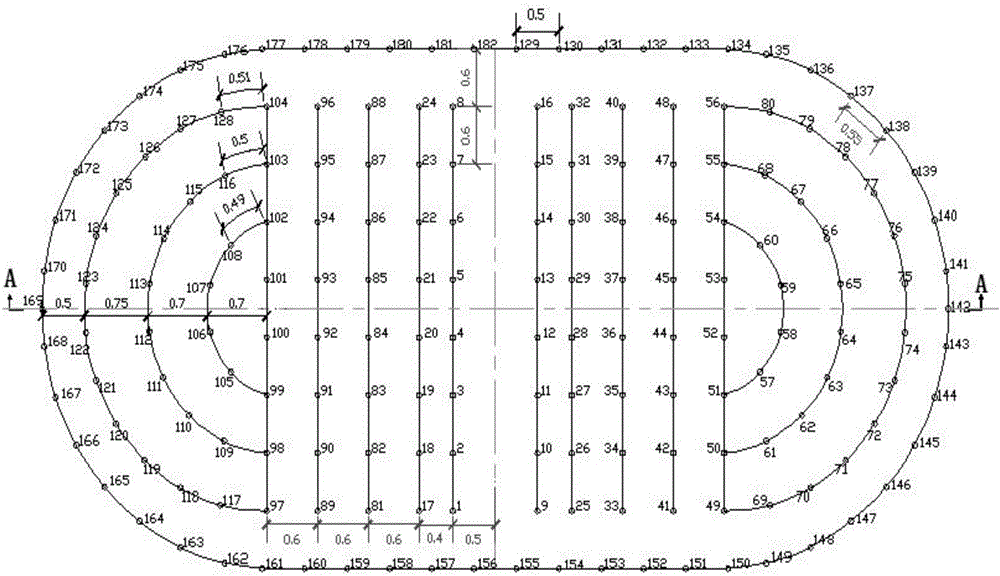

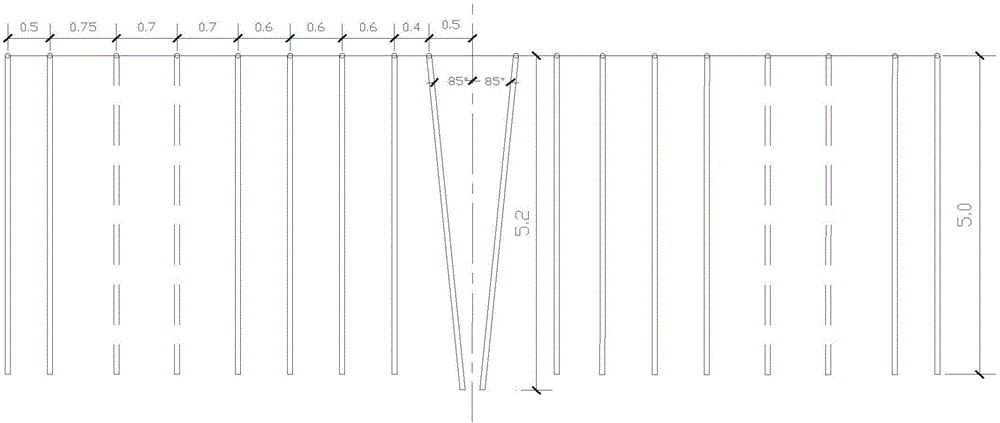

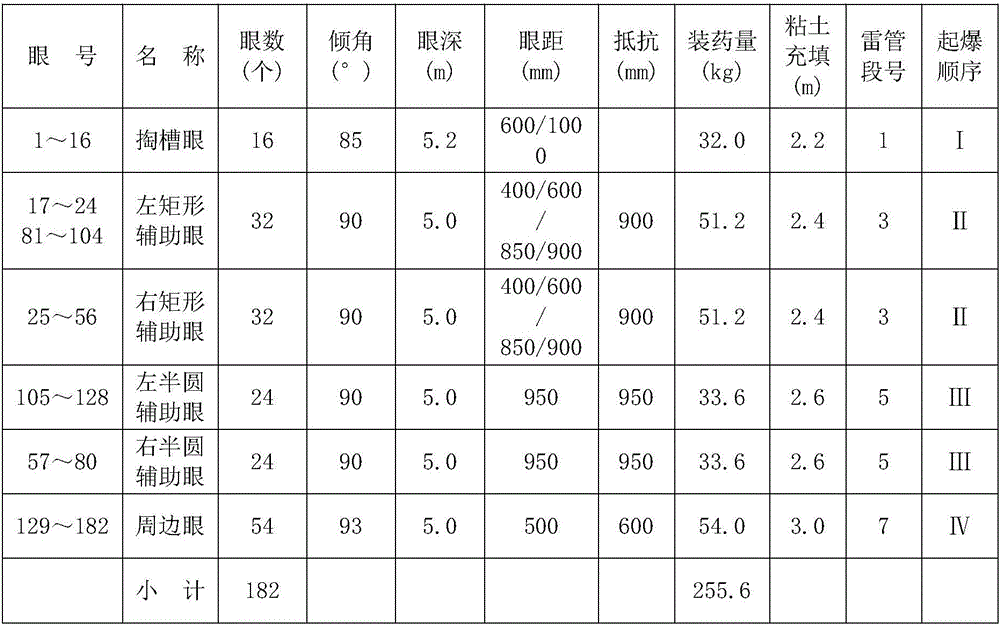

[0020] Such as Figure 1-2 As shown, a controlled blasting technique covering sand above the blasting body. The specific implementation process is as follows:

[0021] 1. Before drilling, clean up the floating rocks and accumulated water on the working face to avoid inaccurate positioning and drill sticking during the drilling process.

[0022] 2. The entire working face is basically flat, the holes are evenly laid out, and the holes are fixed accurately. Use the YT-29 pneumatic drill to remove the air legs and drill vertically. Type-shaped alloy steel drill bit, the bottom of the blasthole is basically on a horizontal plane.

[0023] 3. After the drilling is completed, use the eye sweeper to connect the pressurized air to clear the hole to ensure that the powder is loaded to the end.

[0024] 4. Select Φ30mm×200mm×200g emulsified explosives, and make blast clay with a diameter of Φ35mm and a length of about 200mm on site, which is beneficial for putting into the blast hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com