A construction method for new pipe connection and original pipe plugging in large-scale sewage pipeline relocation

A technology of sewage pipeline and construction method, which is applied in the field of submerged water, can solve the problems of water leakage, large impact force of water flow, and insufficient sealing of original pipeline, so as to reduce the impact force, reduce the impact force of water flow, and solve the problem of blockage puzzle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

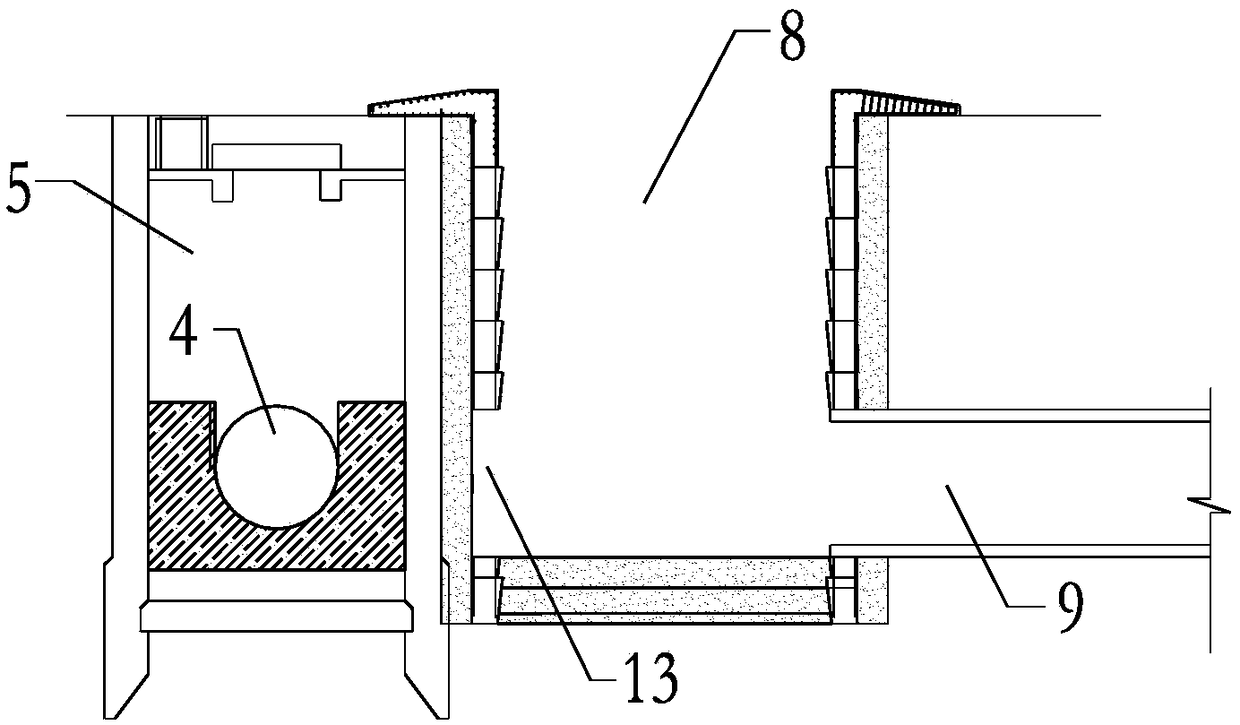

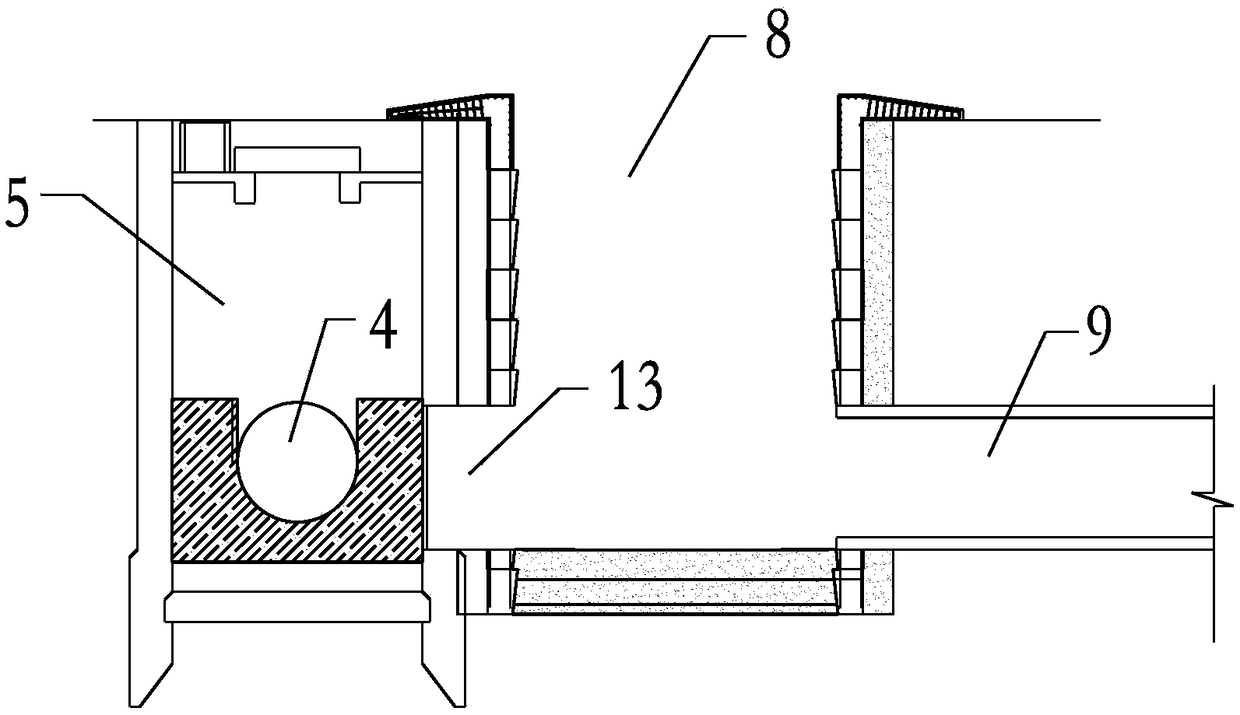

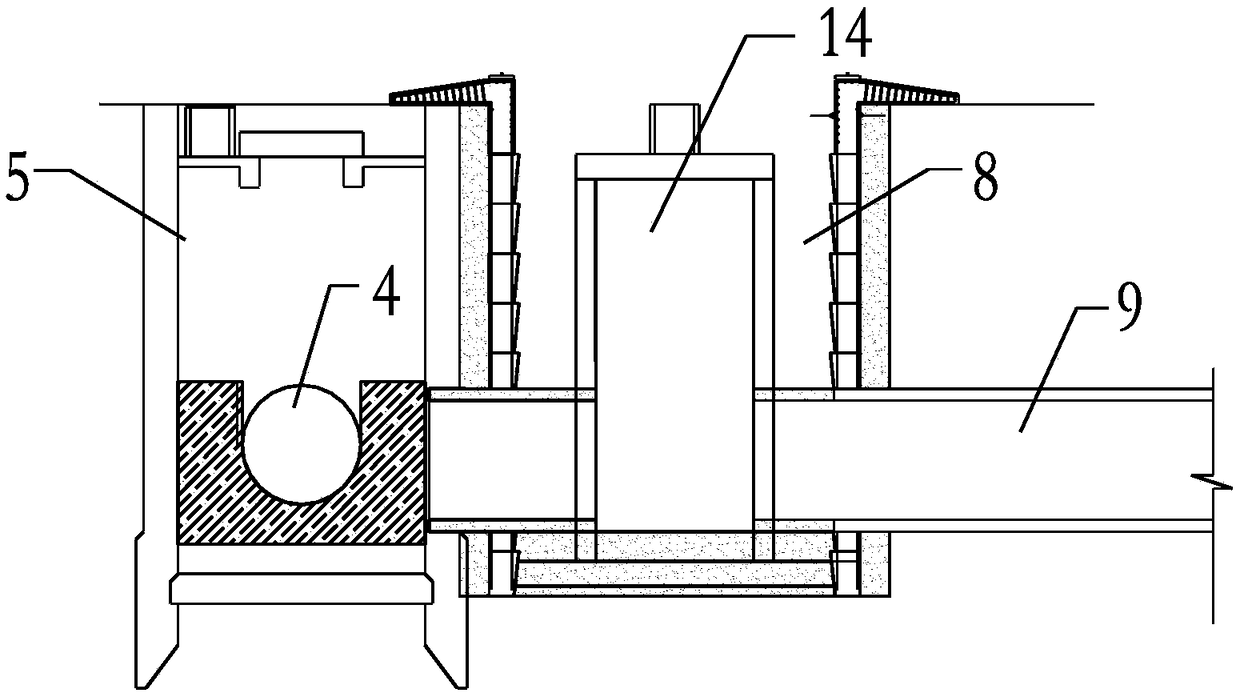

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The specific structure of the temporary blocking flashboard in the embodiment of the present invention is as follows Figure 9 with Figure 10 As shown, it includes a grid steel frame 1 and a steel baffle 2. The steel baffle 2 is a thick steel plate with a thickness of 20 mm. The shape of the arc; the grid steel frame 1 is a shaped steel grid bracket that is welded by channel steel and has the same shape as the steel baffle plate 2, and a plurality of supports 3 are arranged on the rear side of the grid steel frame 1, The grid steel frame 1 adopts 40#a channel steel, and the support member 3 adopts H20 type steel. The distance between two adjacent horizontal and vertical channel steels in the grid steel frame 1 is 500mm. The shapes of the grid steel frame 1 and the upper part of the steel baffle plate 2 are matched with the inner cavity of the existing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com