Patents

Literature

282results about How to "Reduce water flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

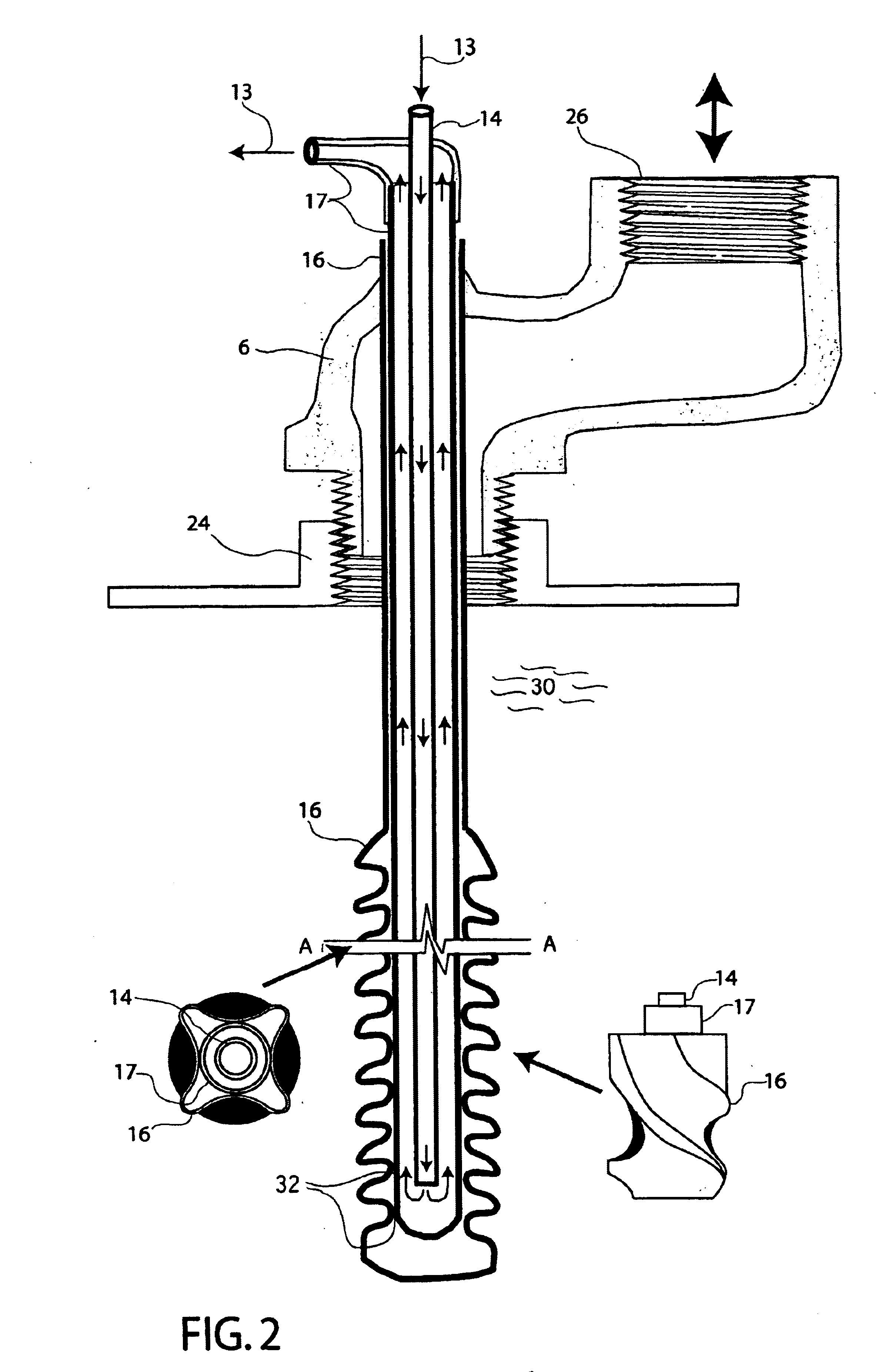

Isolation of soil with a low temperature barrier prior to conductive thermal treatment of the soil

InactiveUS6854929B2Low costAvoid flowSolid waste disposalContaminated soil reclamationSoil remediationEngineering

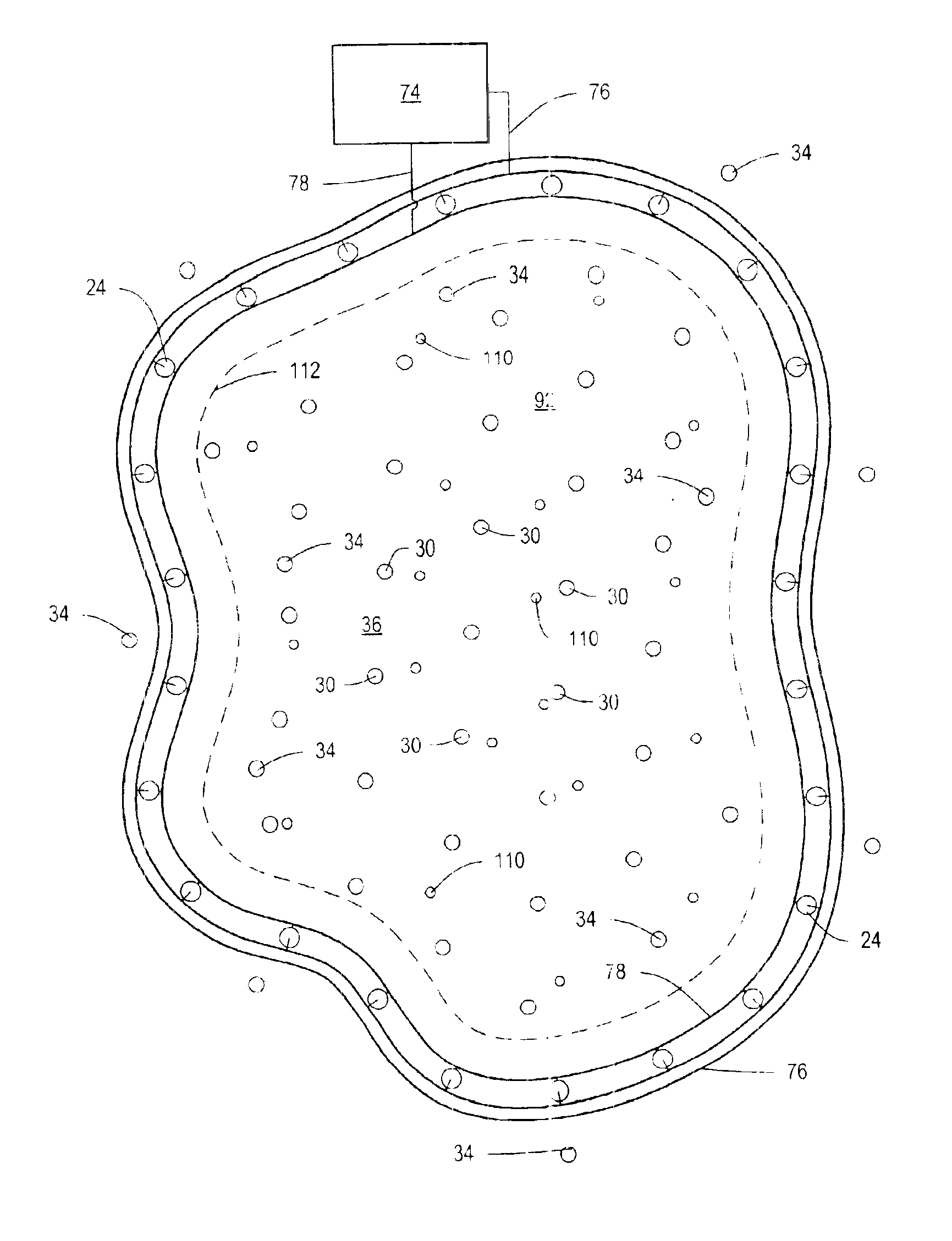

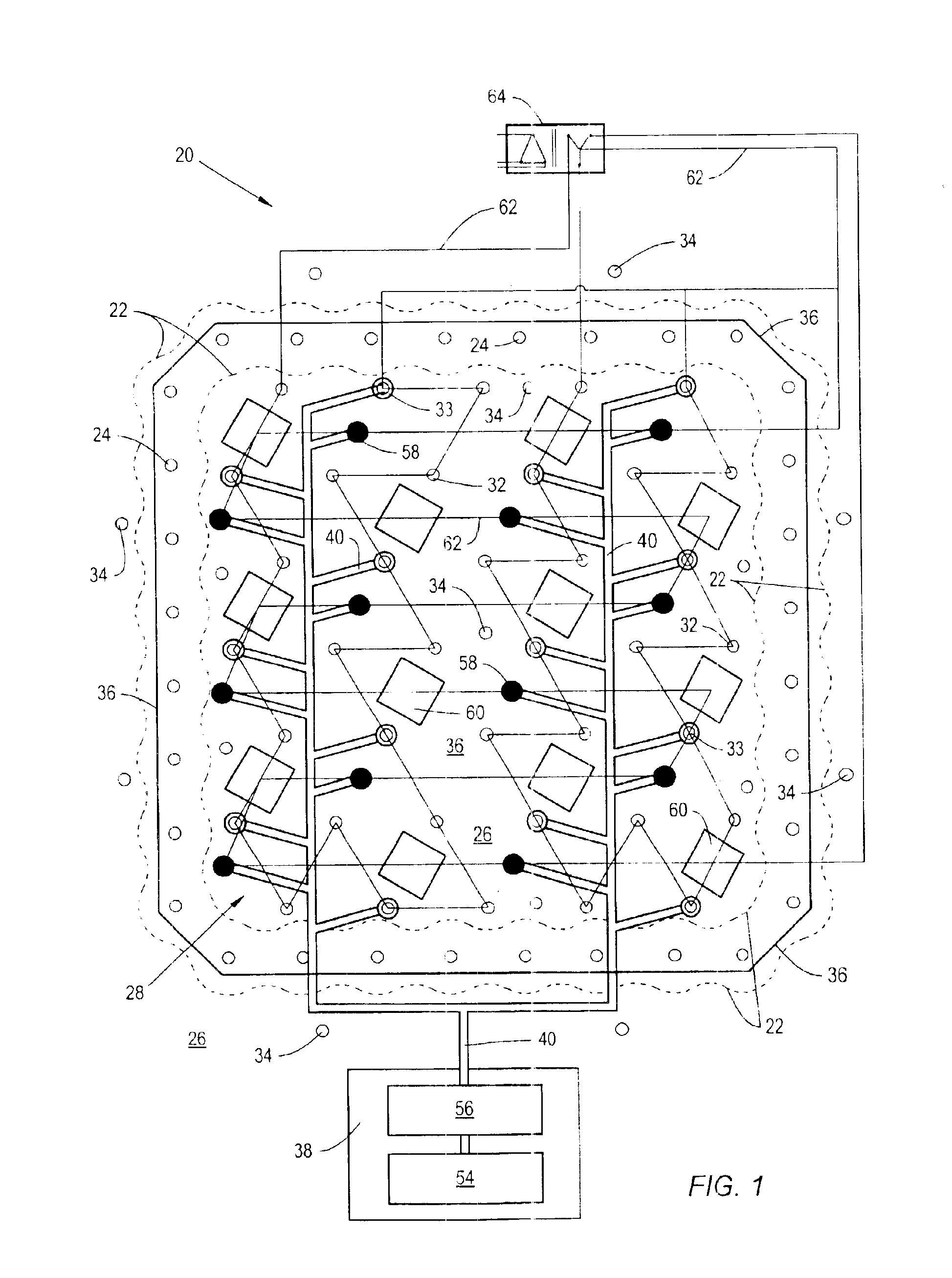

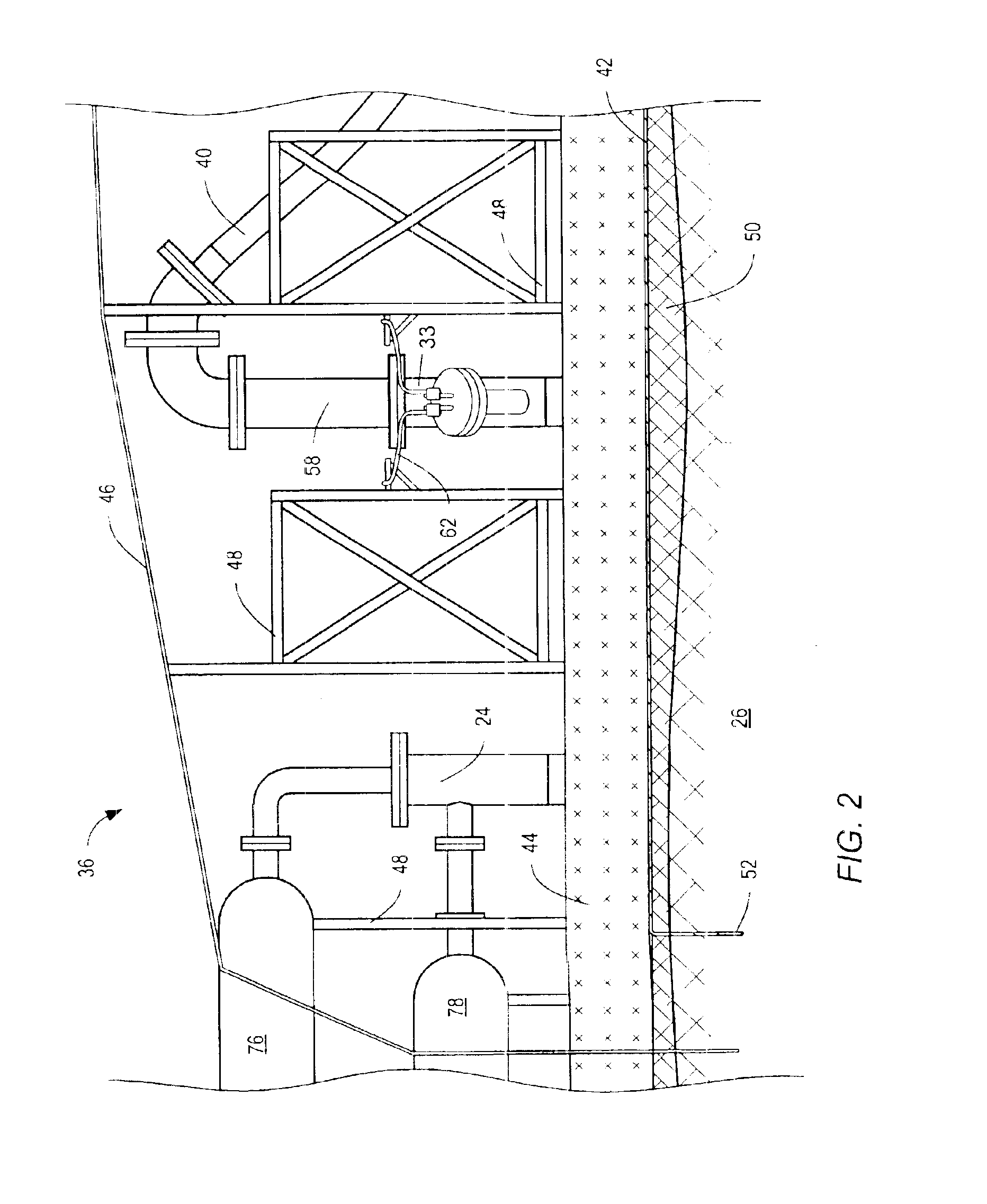

Freeze wells may be used to isolate an area for soil remediation. Freeze wells may form a frozen barrier around a treatment area. The frozen barrier may inhibit fluid from entering into the treatment area. The frozen barrier may also inhibit migration of contamination out of the treatment area. The frozen barrier may be used to surround all of the perimeter of the treatment area. A frozen barrier may also be formed above or below a treatment area. Freeze wells may be activated in advance of soil remediation so that a frozen barrier is formed when soil remediation is begun. The soil remediation may be accomplished by any type of soil remediation system, including a thermal soil remediation system. Heaters of a thermal soil remediation system may be may be placed close to the frozen barrier without the barrier being broken through during remediation.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

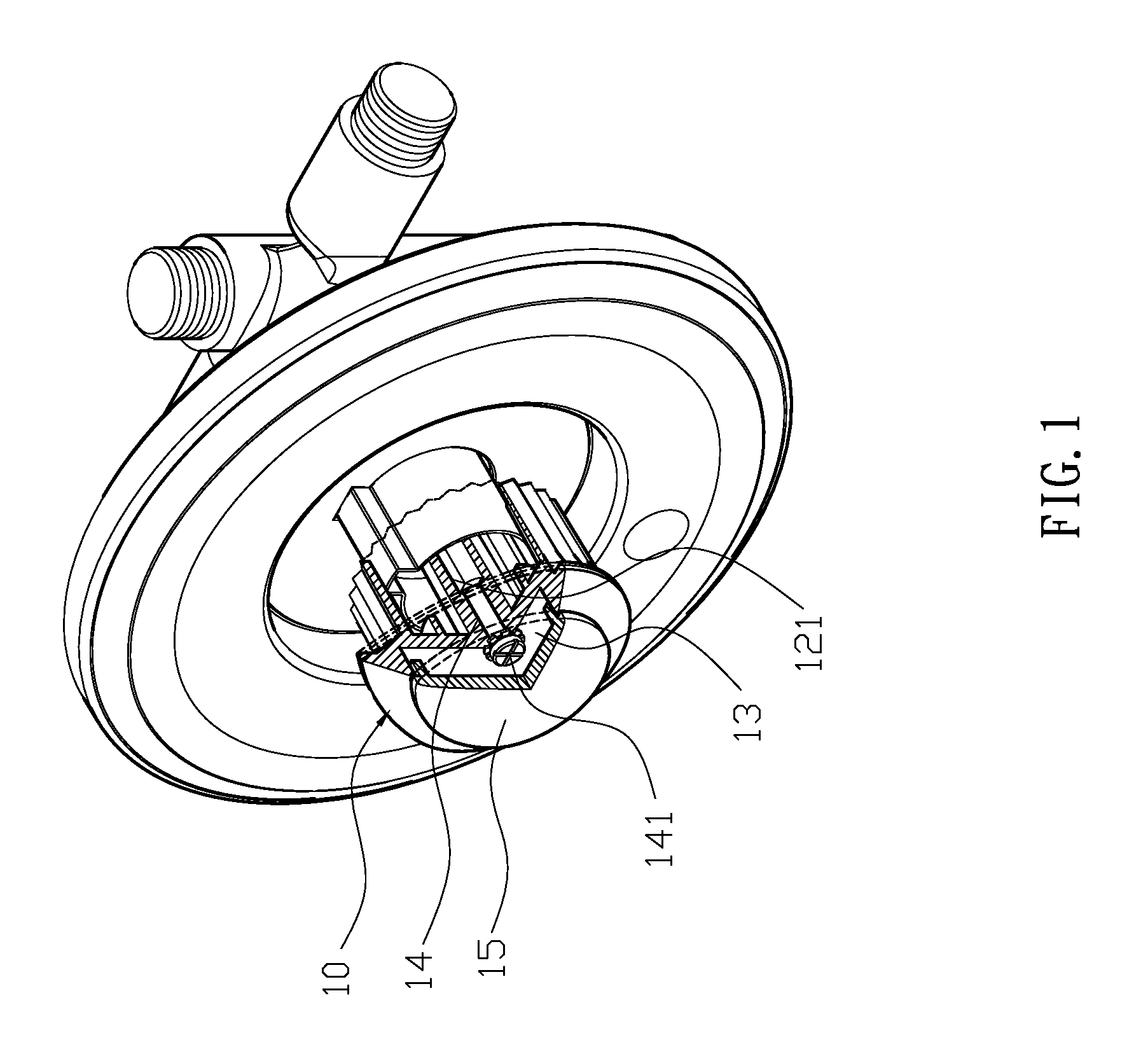

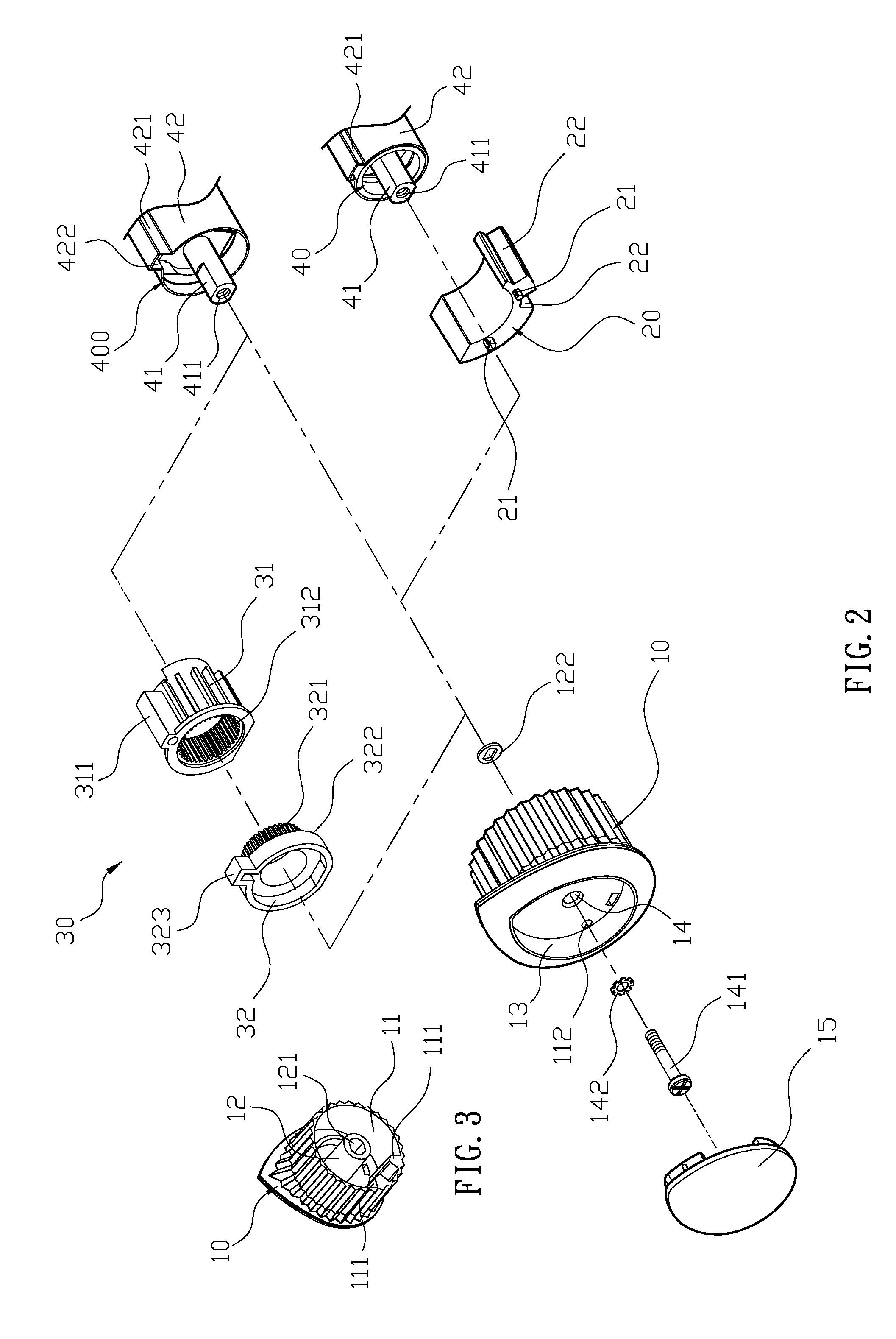

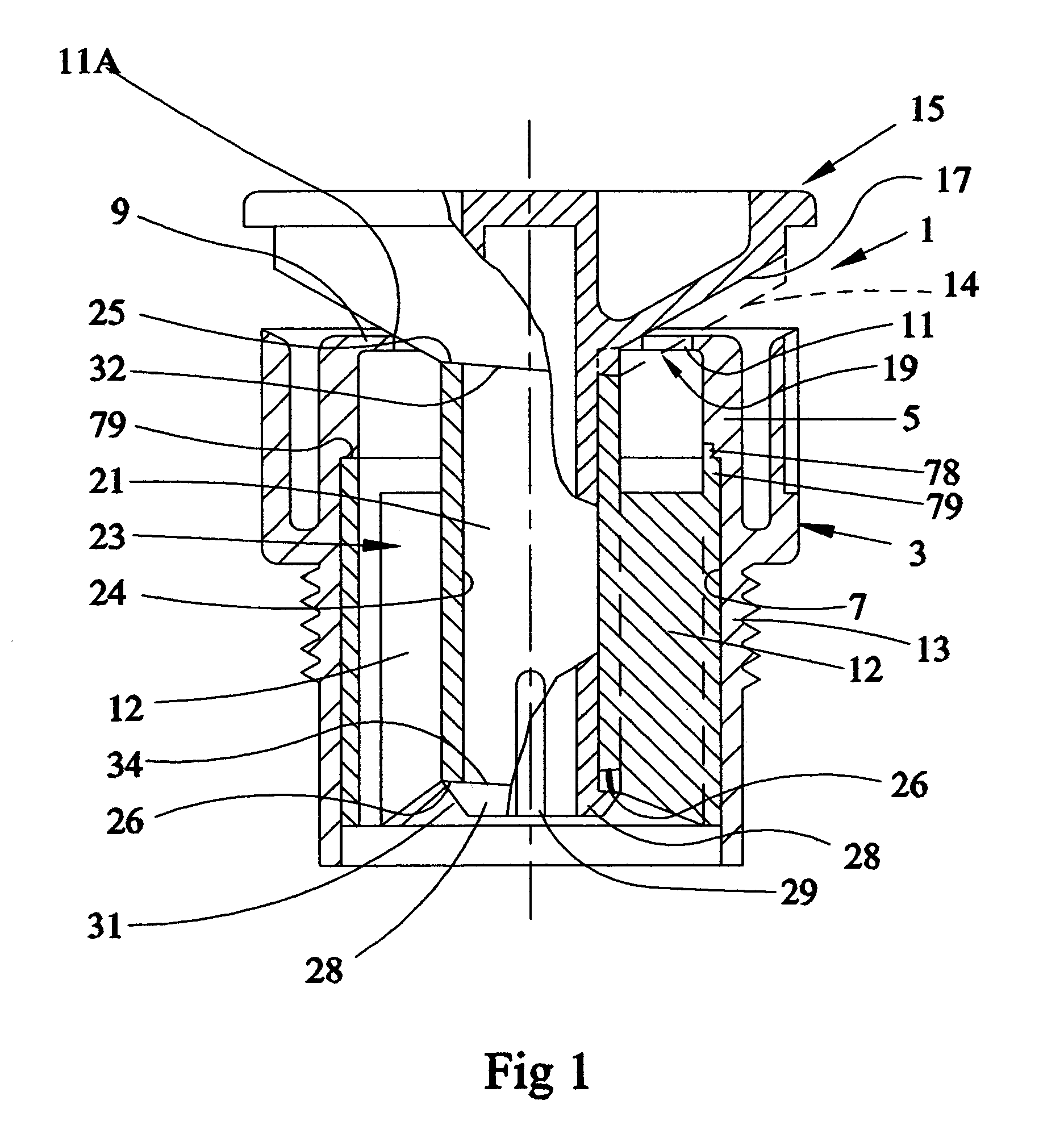

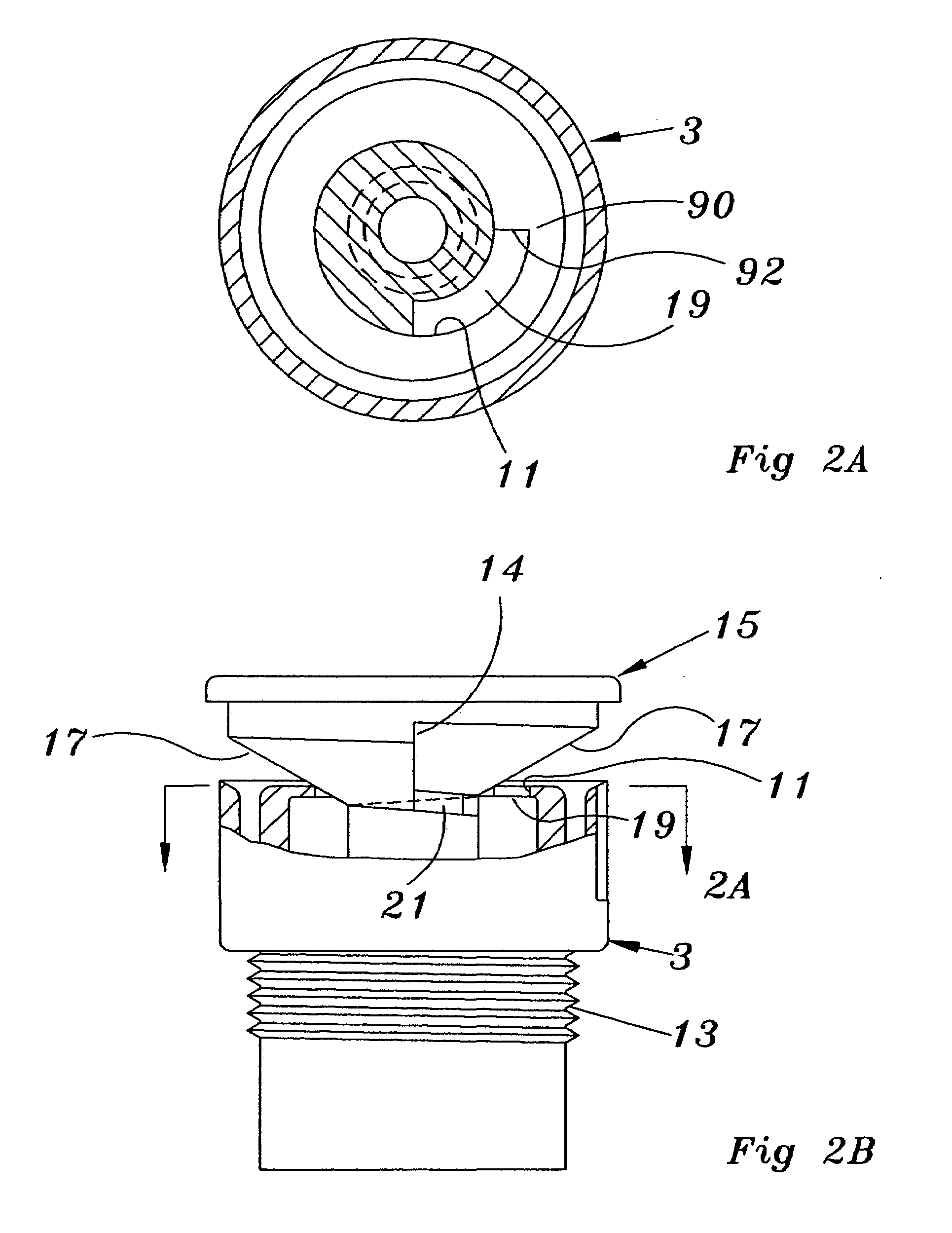

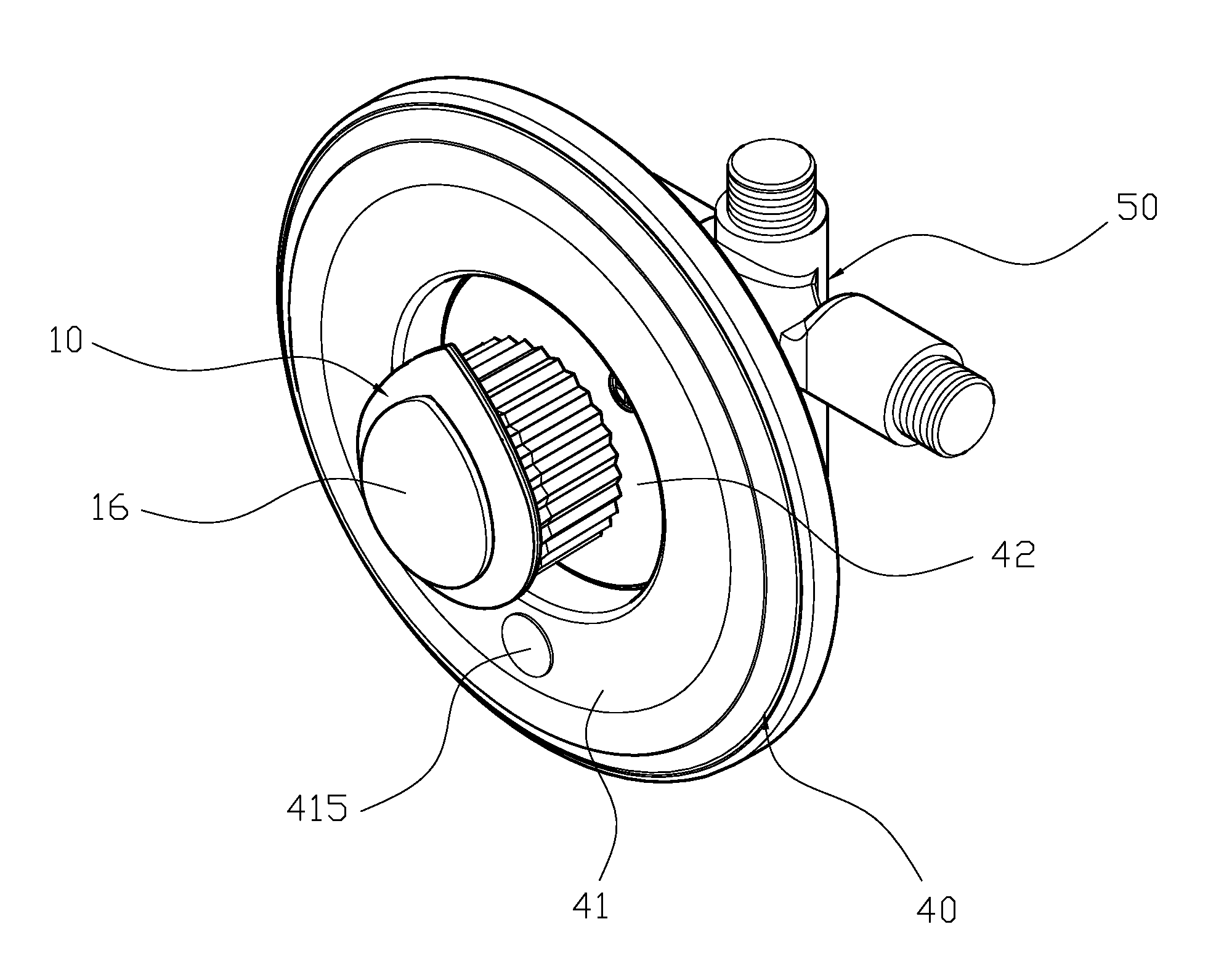

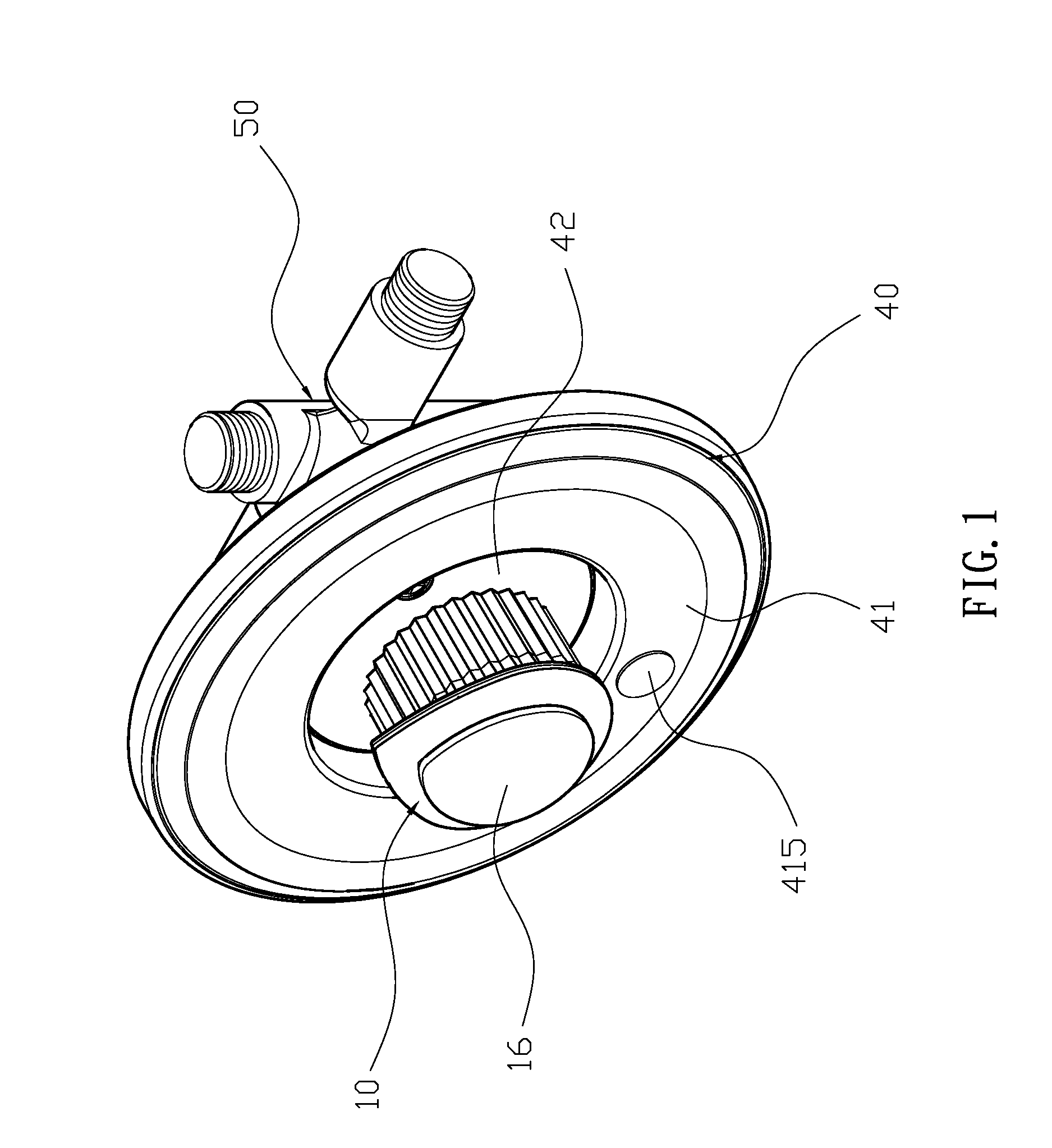

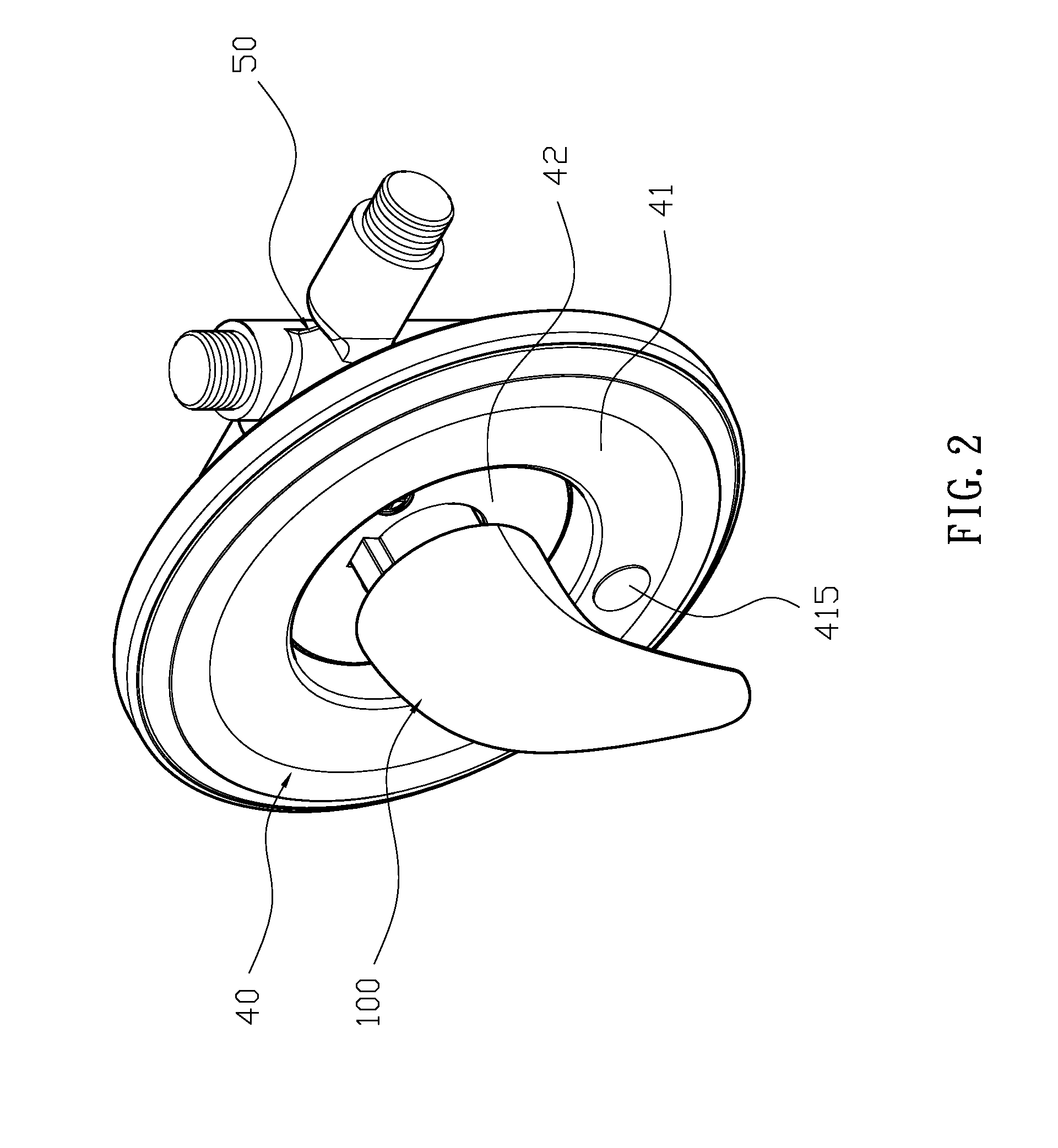

Wall-mounted faucet control components

ActiveUS8607662B2Improve practicalityReduction in rotation angleControlling membersOperating means/releasing devices for valvesEngineeringMechanical engineering

Owner:ALEXANDER YEH IND

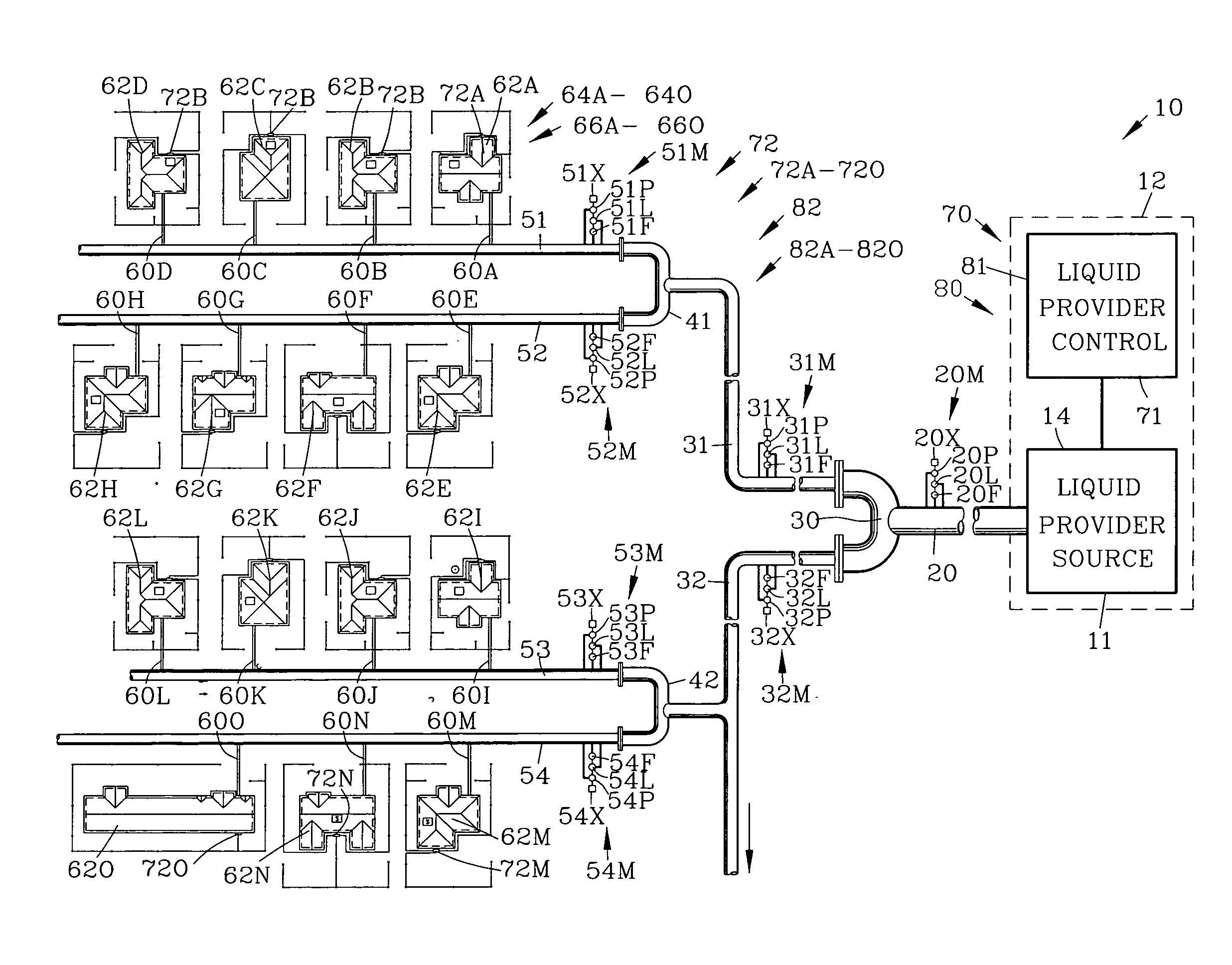

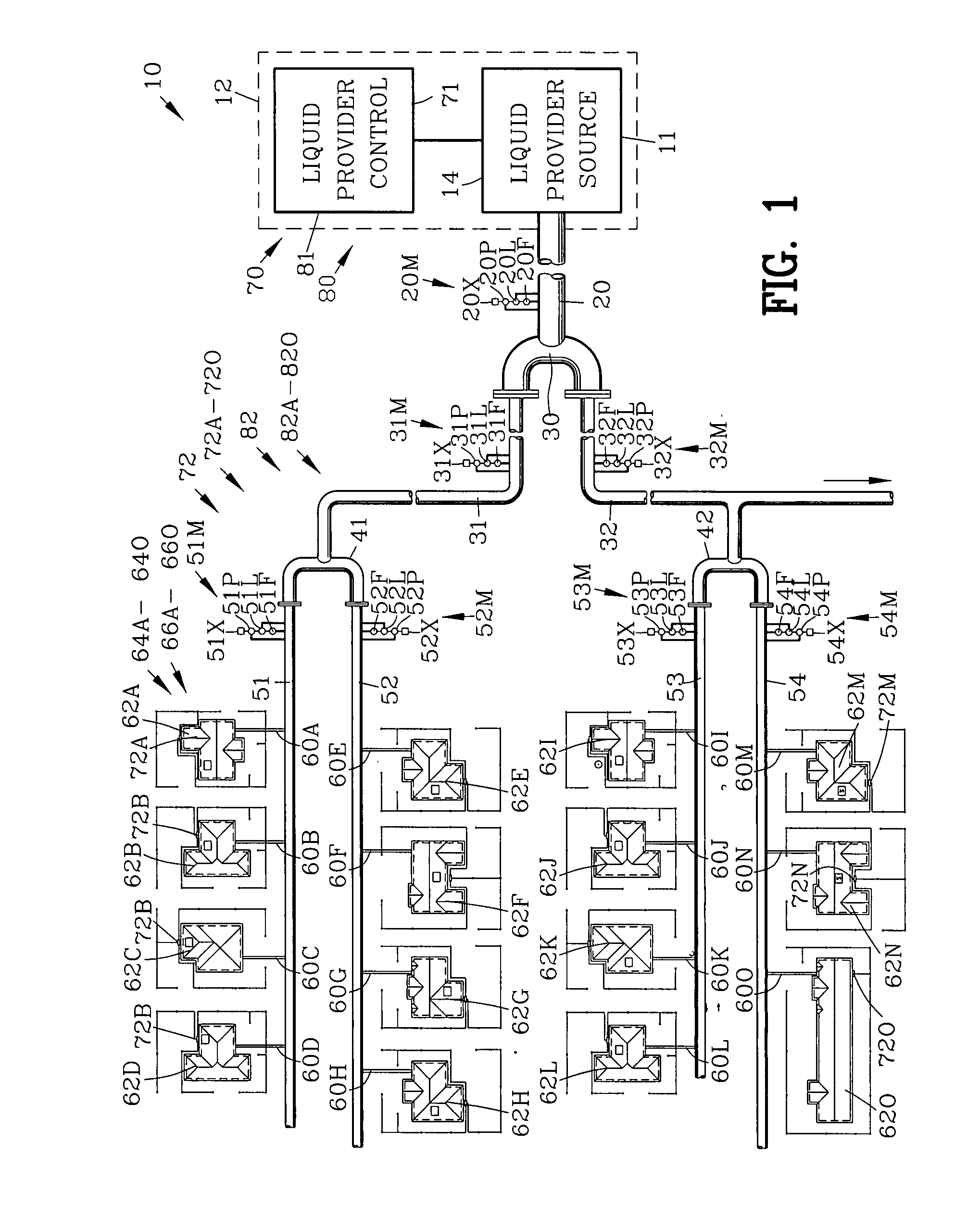

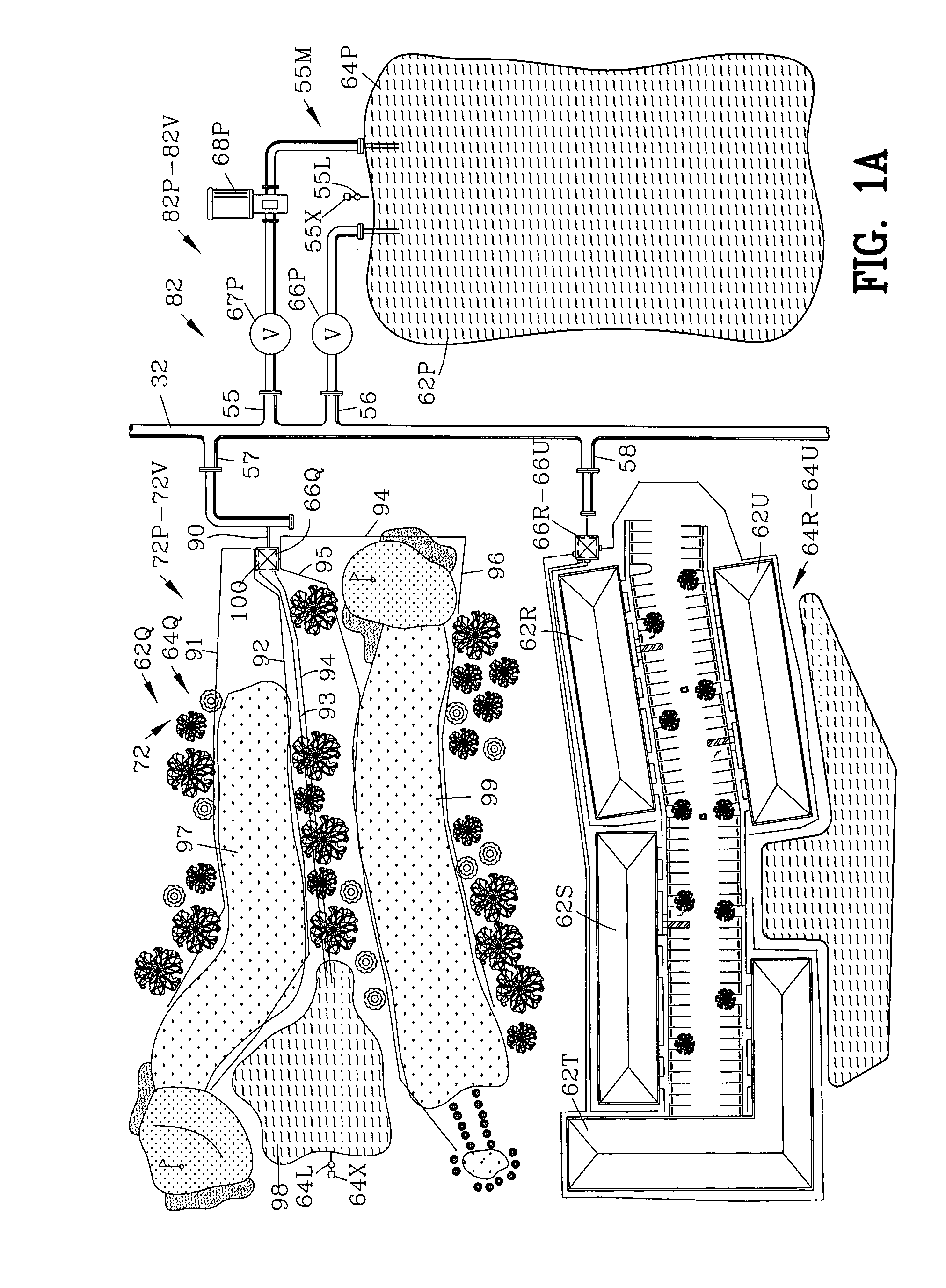

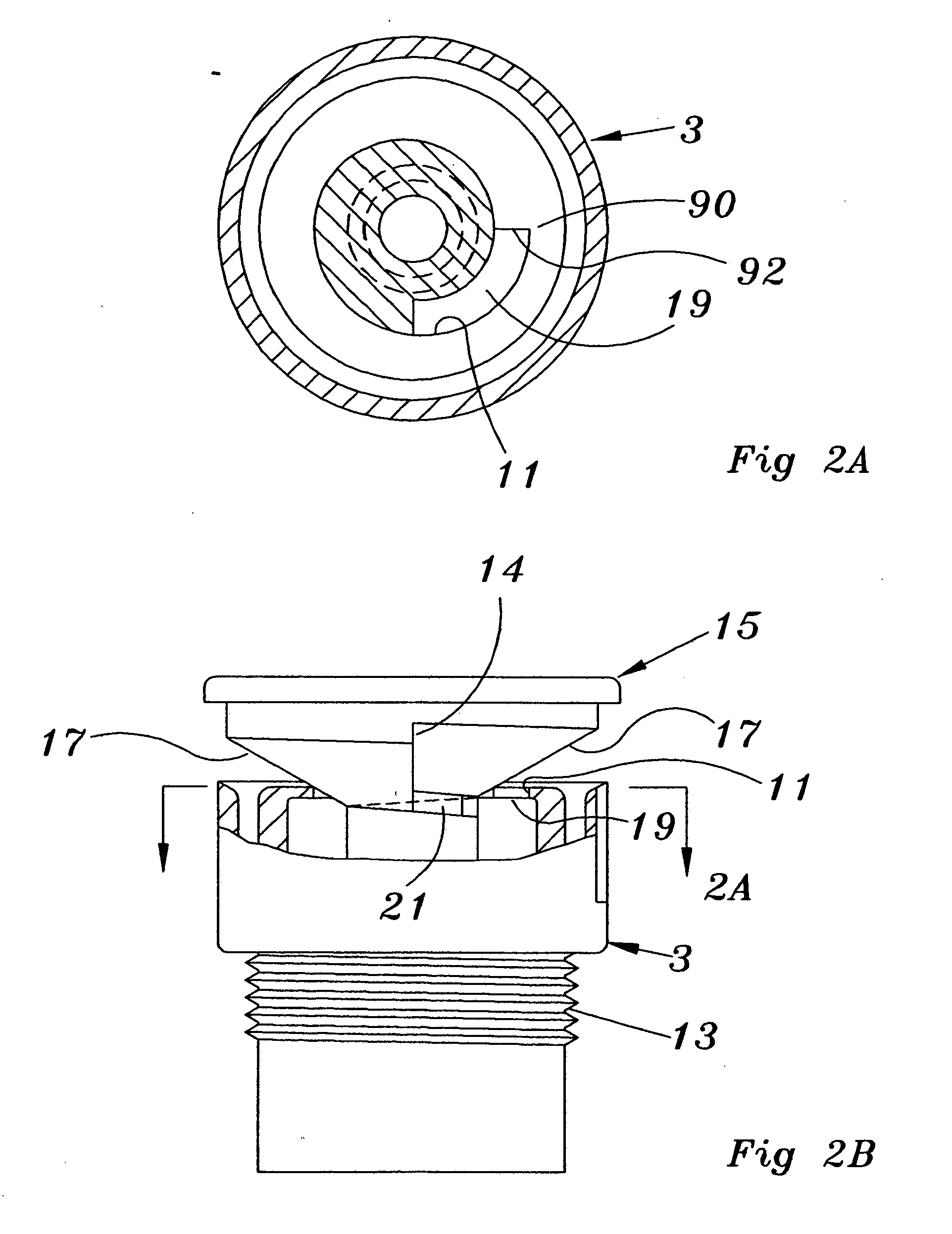

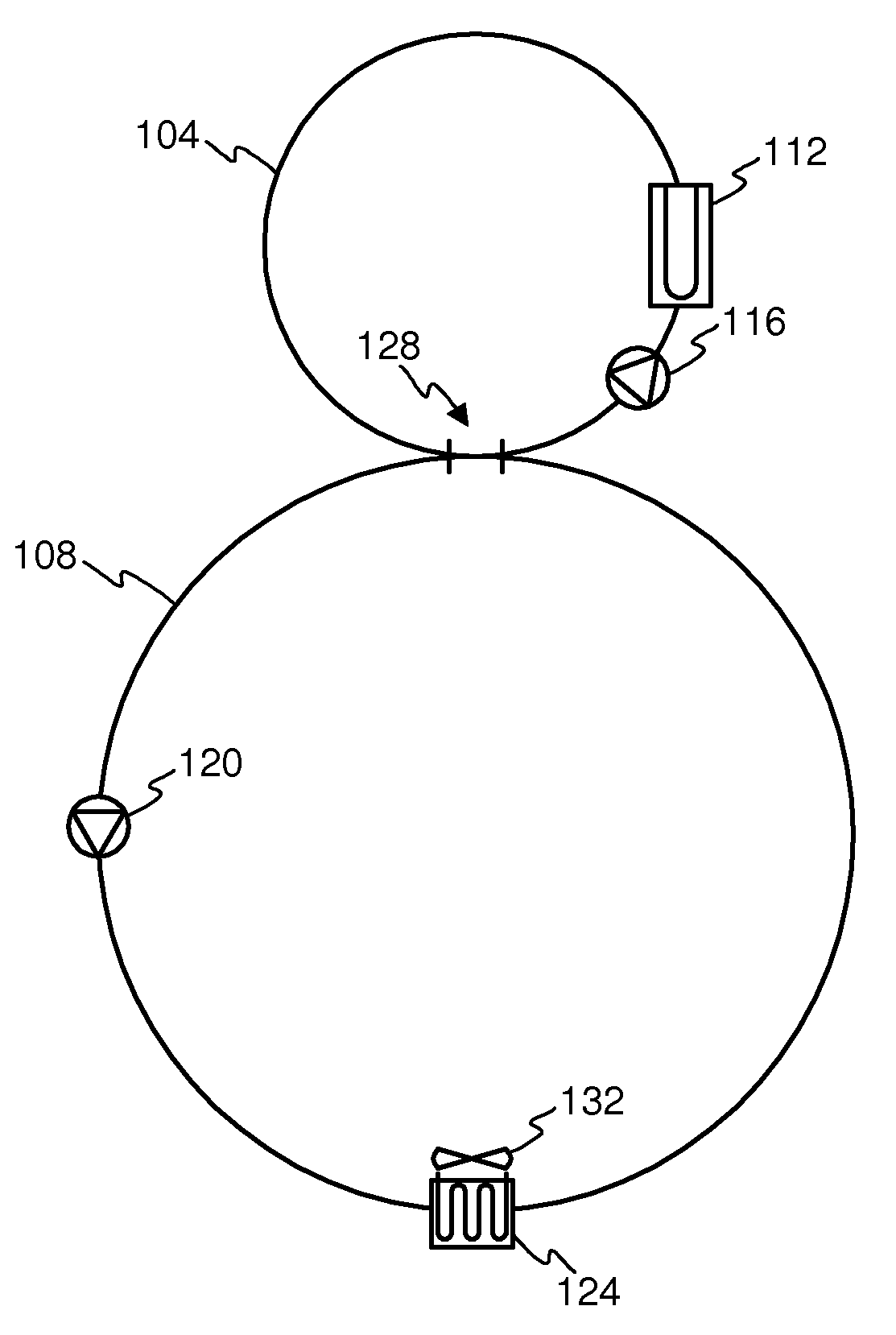

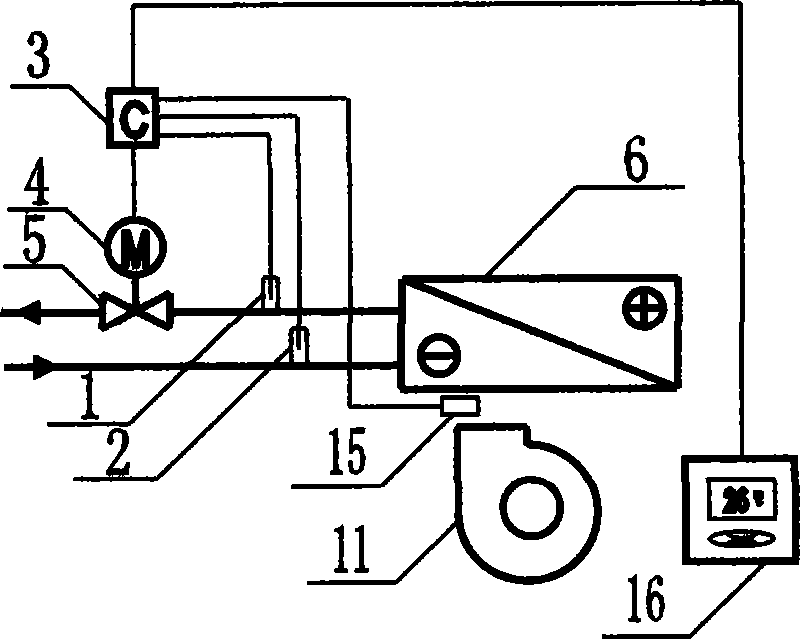

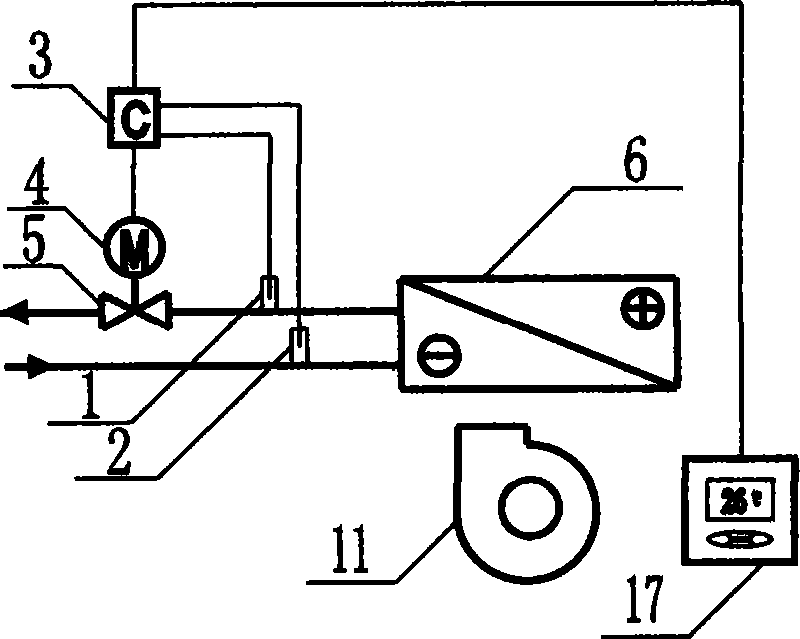

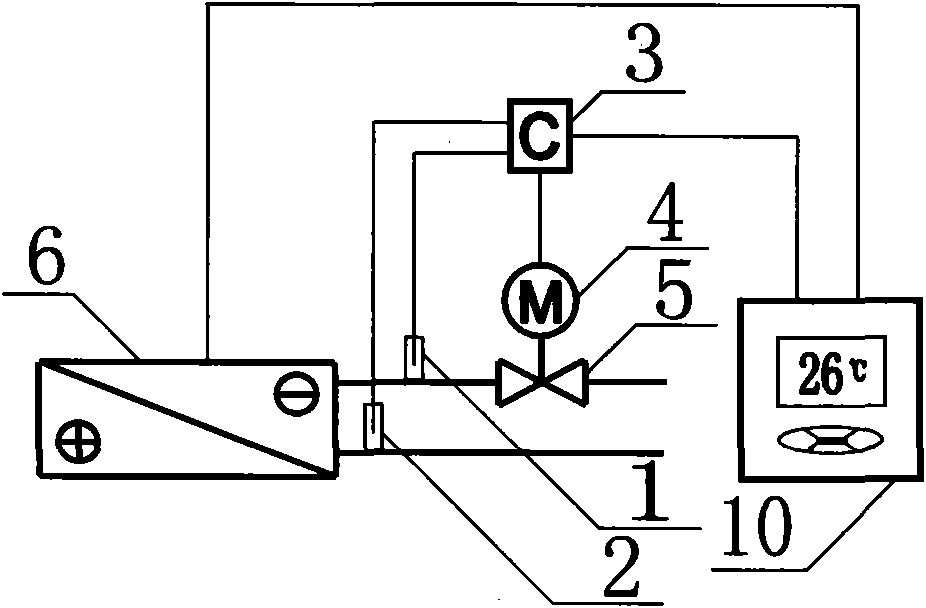

Control system

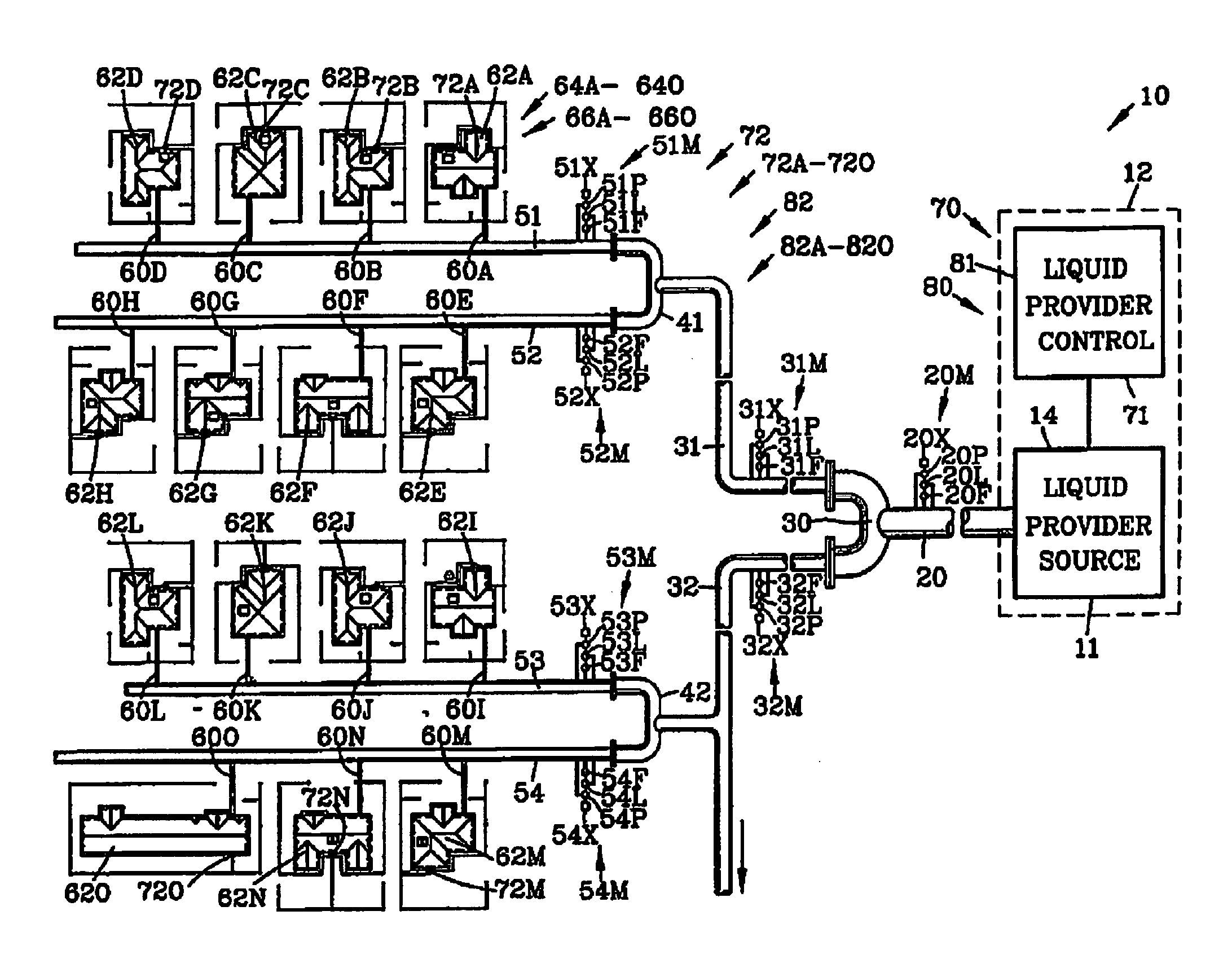

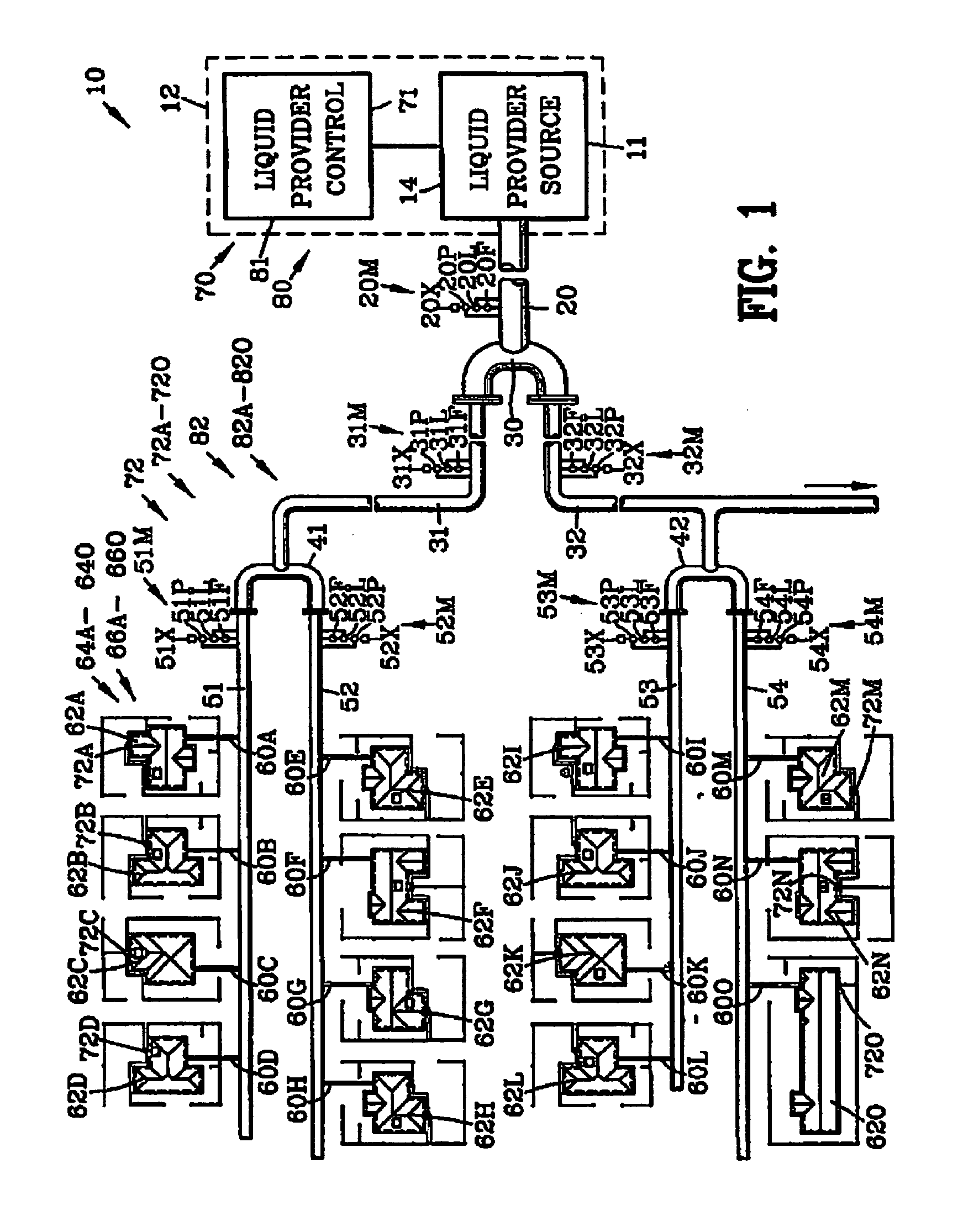

InactiveUS20080119948A1Reduce water flowIncrease pressureFunctional valve typesTesting/calibration apparatusControl systemDistribution system

A control system is disclosed for regulating the flow of a liquid from a liquid provider through a liquid distribution system. The distribution system has a major liquid distribution channel connected to a plurality of minor liquid distribution channels providing the liquid to a multiplicity of users. A plurality of controllable user valves are interposed in the multiplicity of user channels. A liquid monitor senses a liquid flow characteristic within the liquid distribution channel. A user control changes selective controllable user valves for restoring a desired liquid flow characteristic within the liquid distribution channel.

Owner:WATER OPTIMIZER

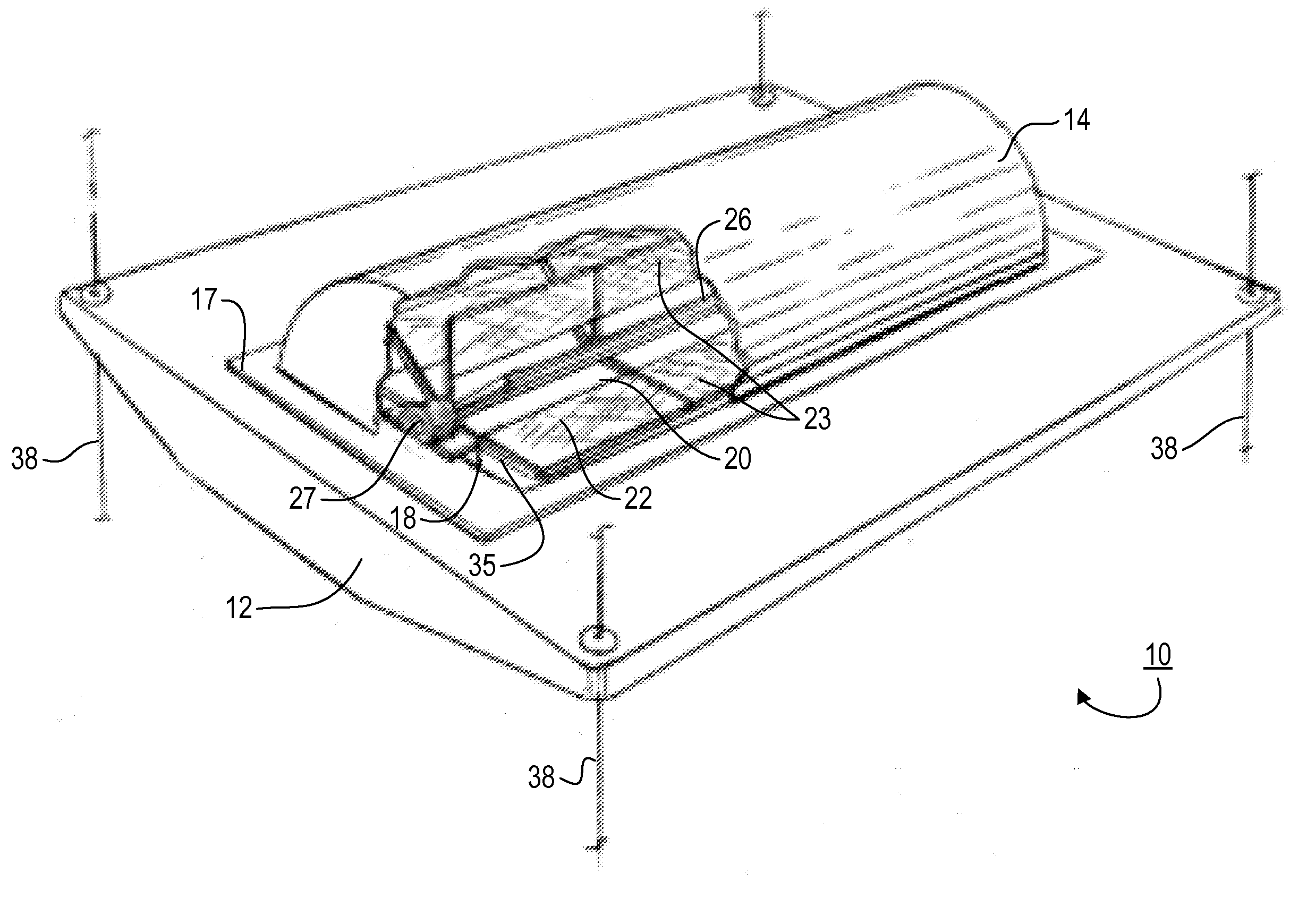

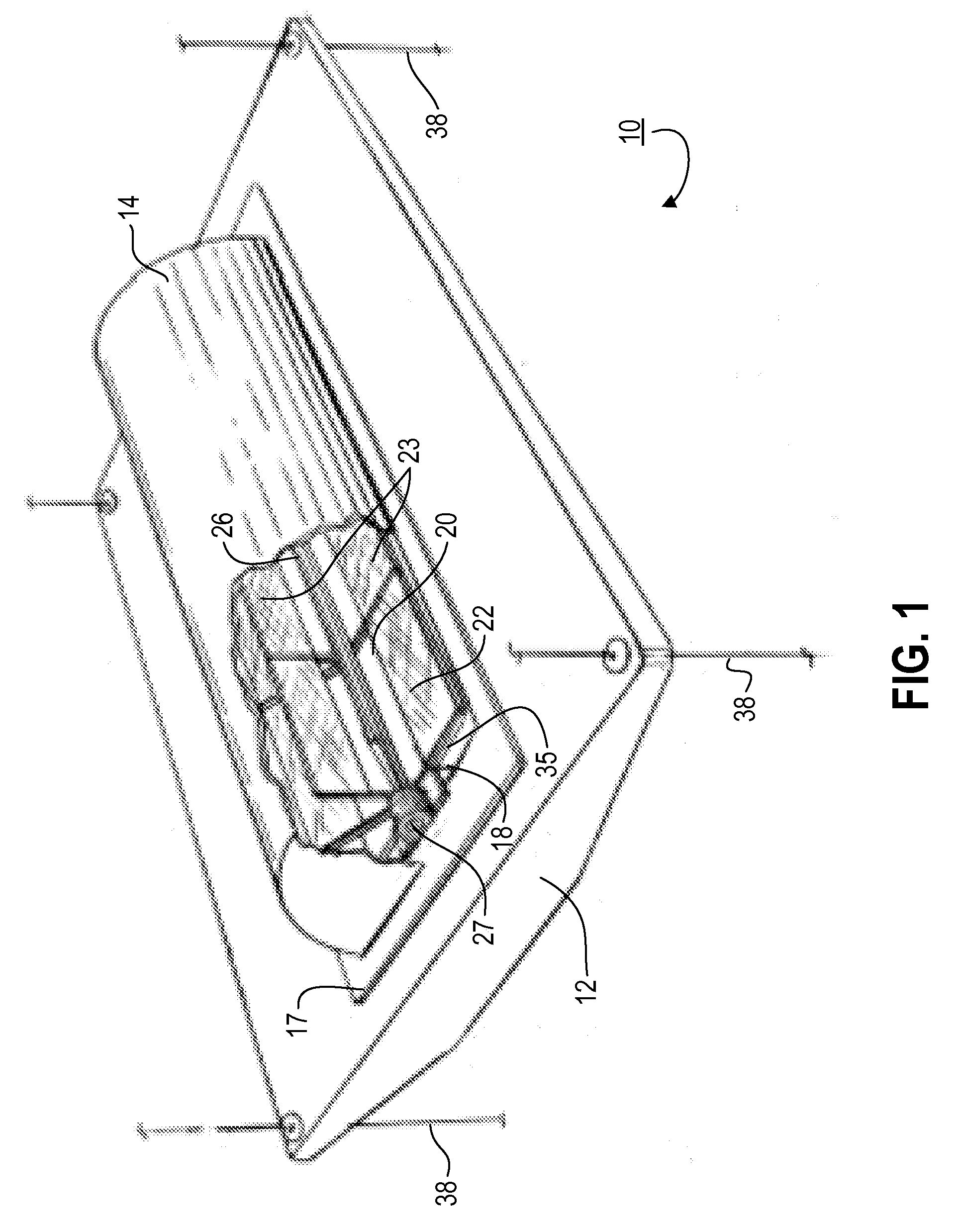

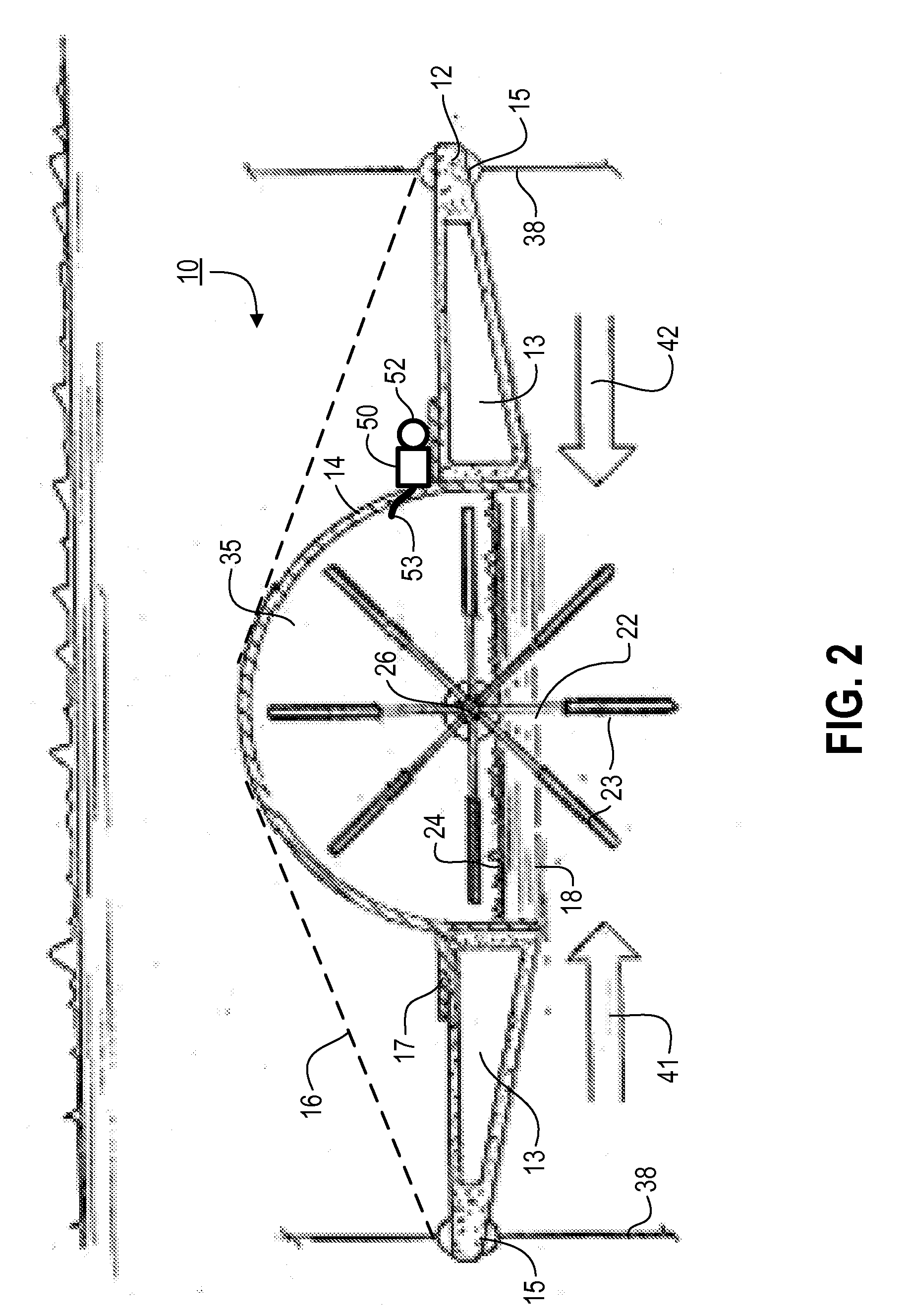

Generation of energy from subsurface water currents

Provided are, among other things, systems, methods and techniques for generating energy. According to one representative embodiment, a main housing includes an air chamber having an open bottom, and a paddlewheel is attached to the main housing so that the paddlewheel is free to rotate and thereby generate kinetic energy. An anchor is attached to the main housing, and an electrical generator which converts the kinetic energy of the paddlewheel into electrical energy is coupled to the paddlewheel. An upper portion of the paddlewheel is enclosed by the air chamber. When the main housing is submerged underwater and maintained in a level orientation, air within the air chamber remains trapped within the air chamber, thereby reducing resistance to rotation of the paddlewheel.

Owner:DEMPSTER HARRY EDWARD

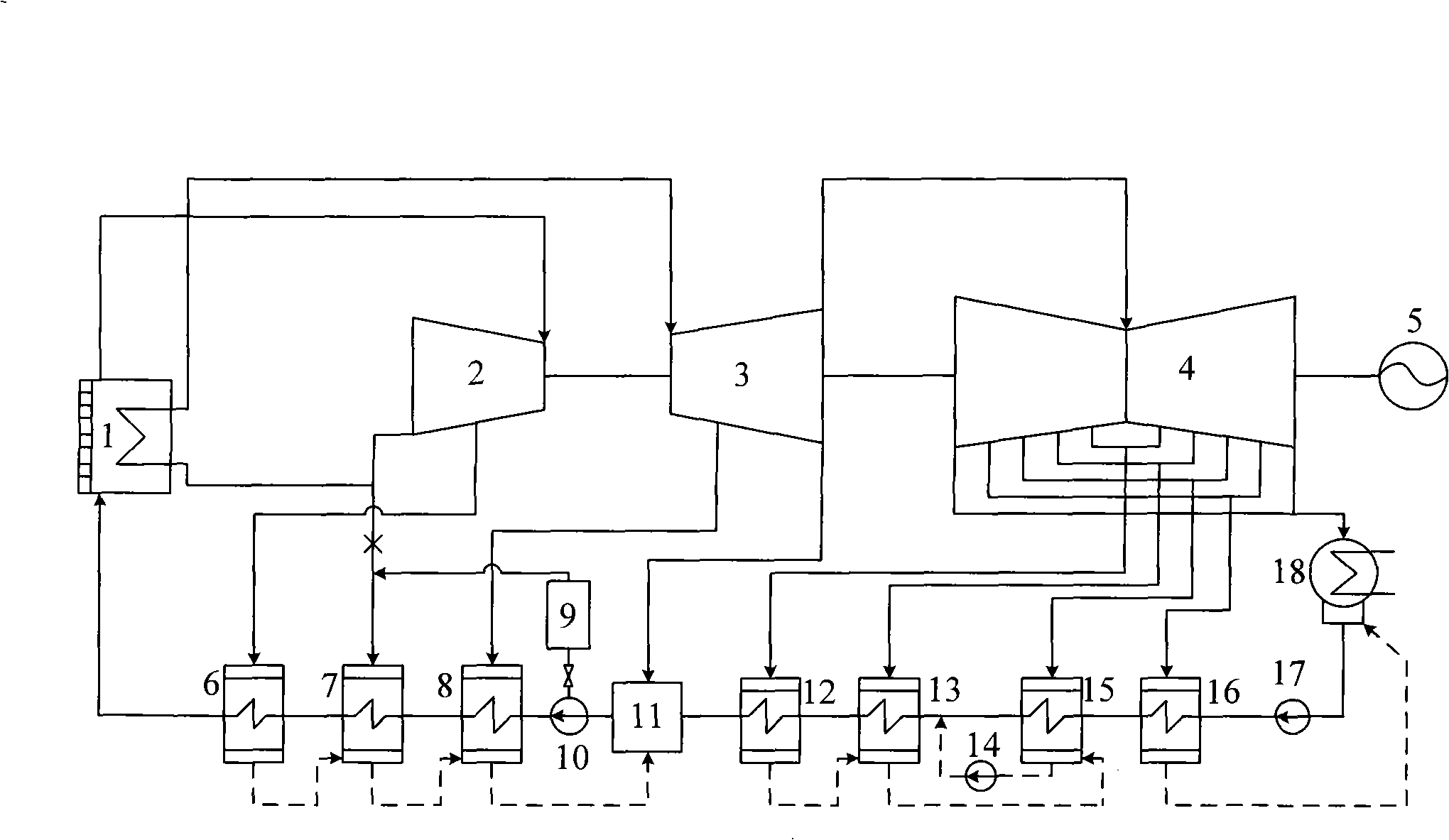

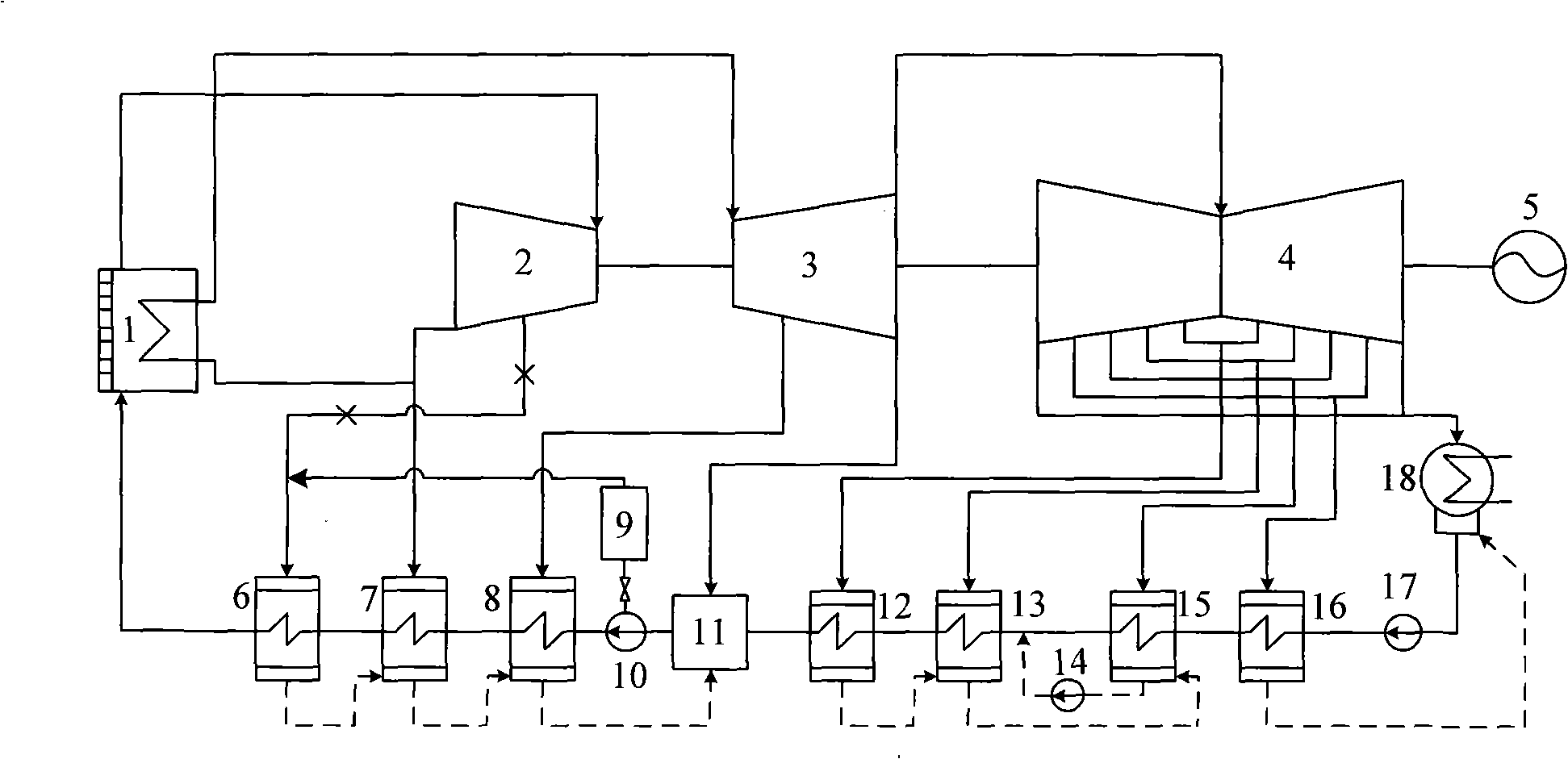

Paraboloid trough type solar heat-collector auxiliary coal-burning boiler mixing heat power generation system

InactiveCN101260815AHigh thermal efficiencyLess coal consumptionSteam engine plantsDeaeratorEngineering

The invention belongs to the generating equipment scope and in particular relates to a mixed heat power generating system with a paraboloid groove type solar heat collector to assist a coal burning boiler. A solar heat collector field is connected with a feed pump and a second or a third high-pressure heater; a condenser, an extraction pump, a low-pressure heater, a deaerator, the feed pump, the high-pressure heater, the coal burning boiler and a steam turbine are connected in series in turn; and the steam turbine drives a dynamo and discharges steam to the condenser. Condensed water flows out from the condenser and is heated up and pressurized up by a the low-pressure heater, deoxidized by the deaerator, fed with water by a leading-out part of the feed pump and enters the solar heat collector field for heat absorption; after reaching a stream drawing parameter of a certain stage high-pressure heater, the condensed water returns and joins the drawing gas of the corresponding stage heater; the other part of feeding water enters the coal burning boiler through the high-pressure heater and becomes steam with high temperature and high pressure; and the steam enters the stream turbine, applies work and flows into the condenser to complete a thermodynamic cycle. The mixed heat power generating system with the paraboloid groove type solar heat collector to assist the coal burning boiler reduces coal consumption of a coal burning unit, improves thermal efficiency of the solar heat power generation and reduces the investment on the simple paraboloid groove type solar heat power generation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

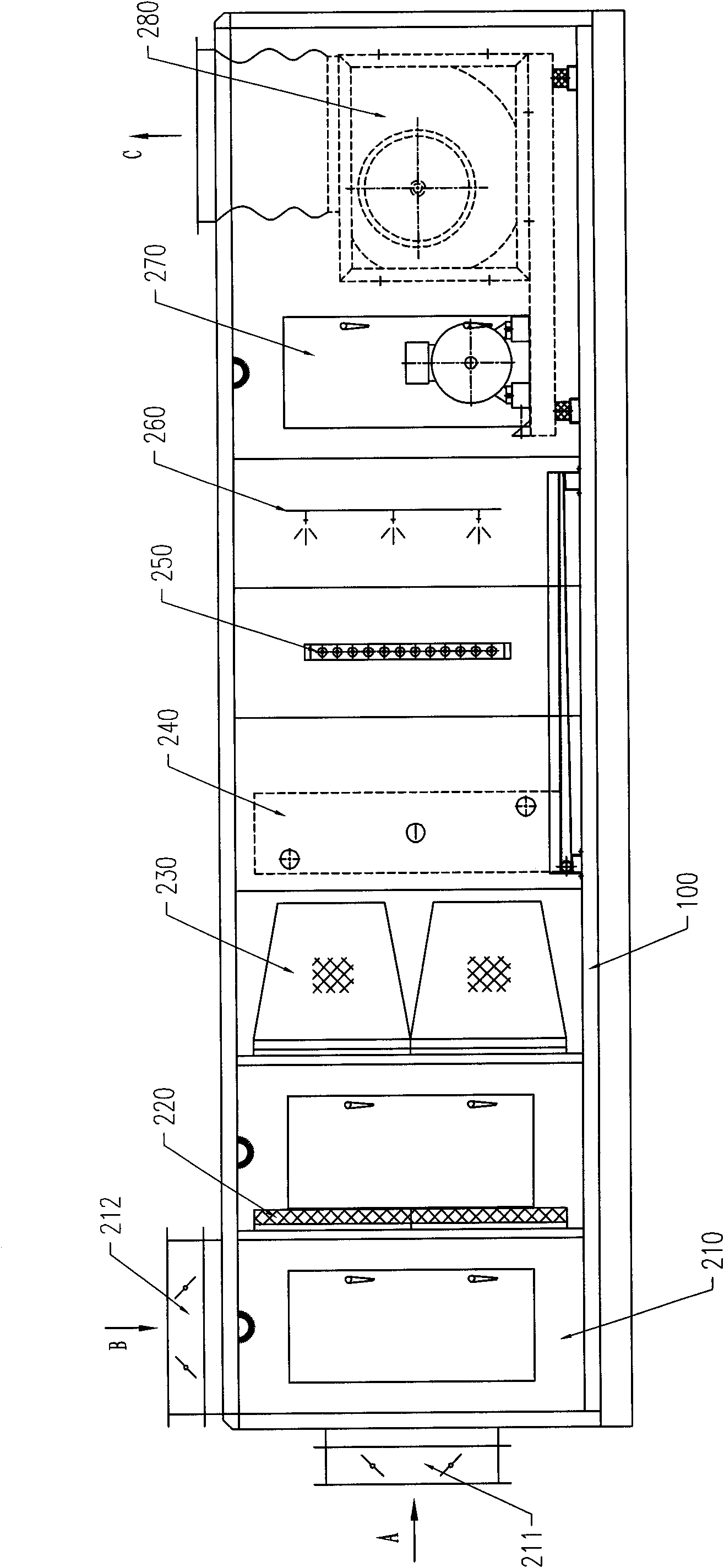

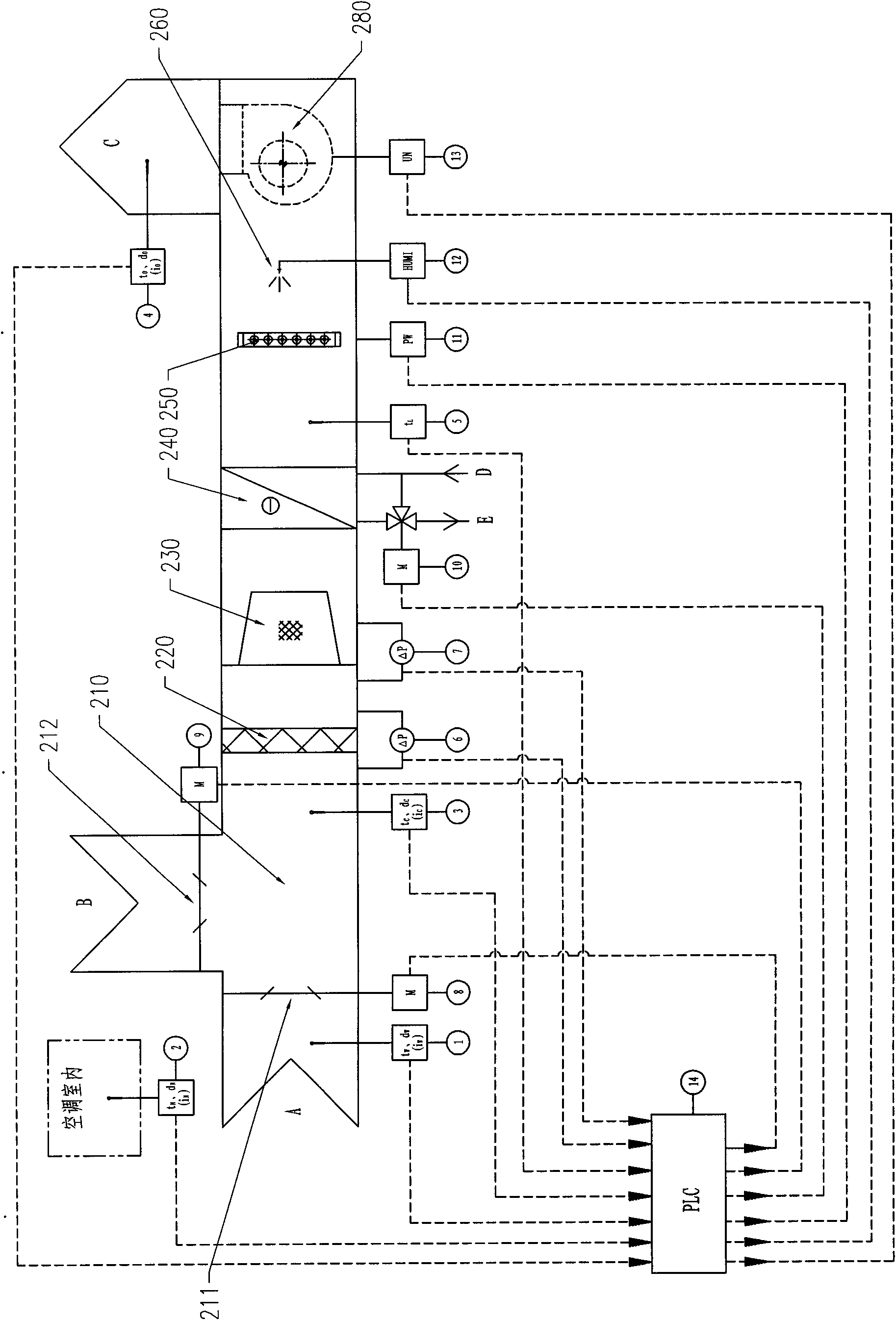

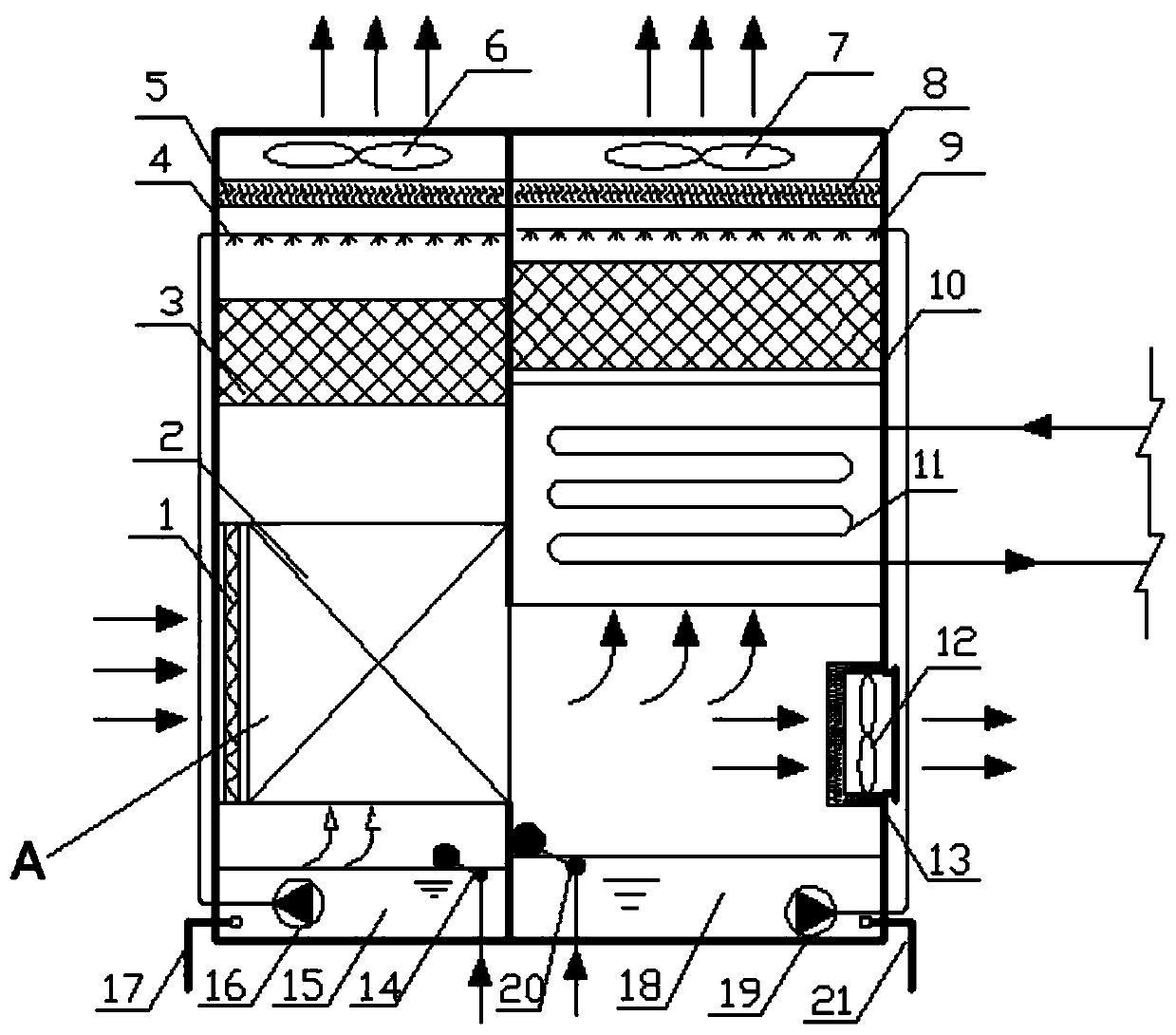

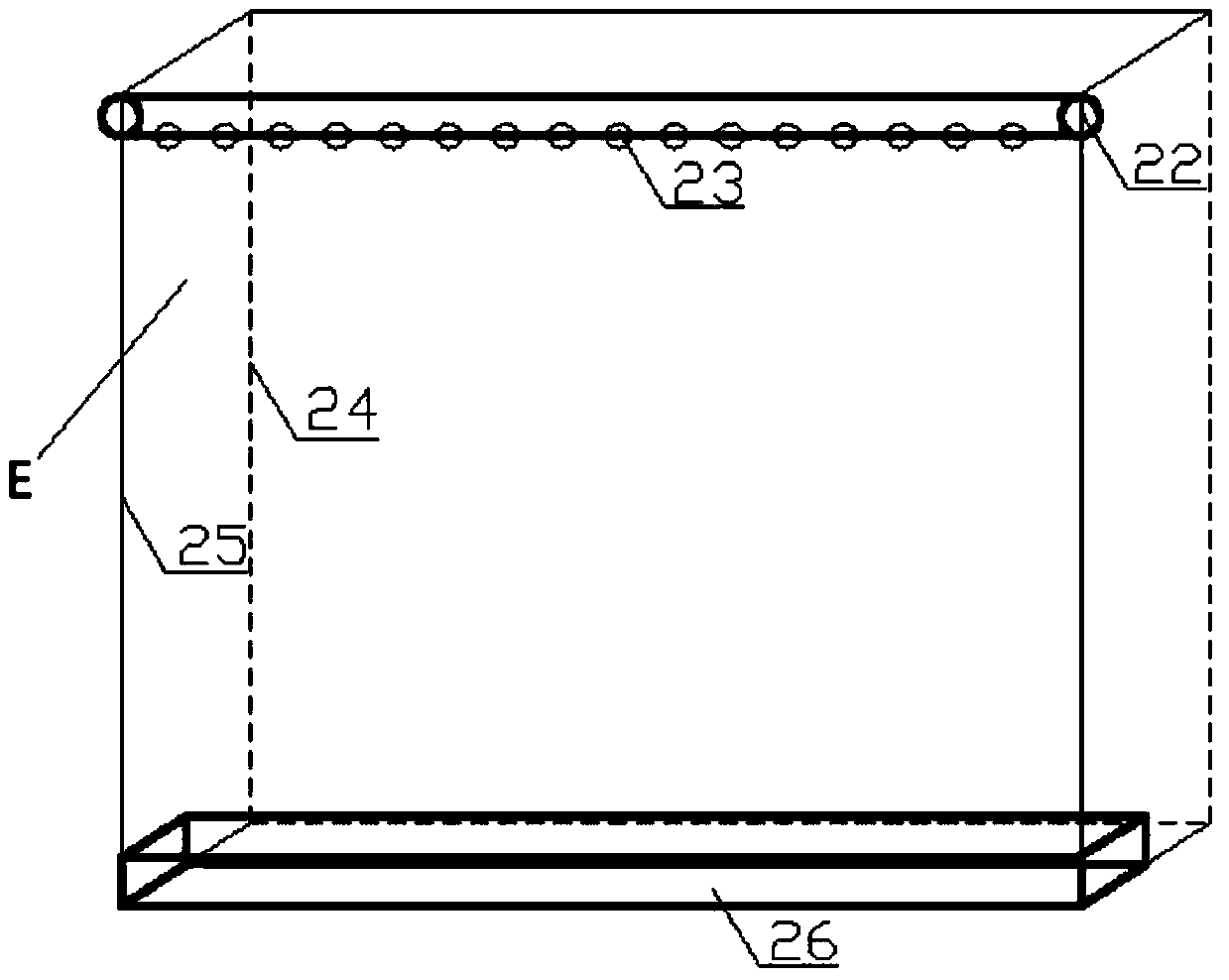

Multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with thermometal compound box body structure

ActiveCN101782263AReduce resistanceFully contactedSpace heating and ventilation safety systemsLighting and heating apparatusControl systemNuclear power

The invention relates to a multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with a thermometal compound box body structure special for nuclear power stations. The air conditioning unit comprises a control system and a box body structure, wherein a primary-efficiency filter, a medium-efficiency filter, a surface cooler, a heater, a humidifier and a blow-off device are sequentially arranged in the box body; the front side of the primary-efficiency filter is provided with a fresh air and return air mixing section, and inlets of fresh air and return air are respectively provided with a fresh air proportioning valve and a return air proportioning valve; the control system adopts a programmable logic controller (PLC) and adopts air conditioning multi-operating mode zone control to realize the energy-saving operation of the unit; the surface cooler adopts a large temperature difference cold water heat exchanging technology and can save the investment and operation expenses of a water system; and the box body adopts a double-layer compound structure and an anti-shock device to meet the special requirements on the nuclear power stations. The invention has the characteristics of high efficiency, energy saving, good tightness, strong anti-shock capacity, safety, reliability, long service life, and the like.

Owner:广东吉荣核电设备暖通技术有限公司

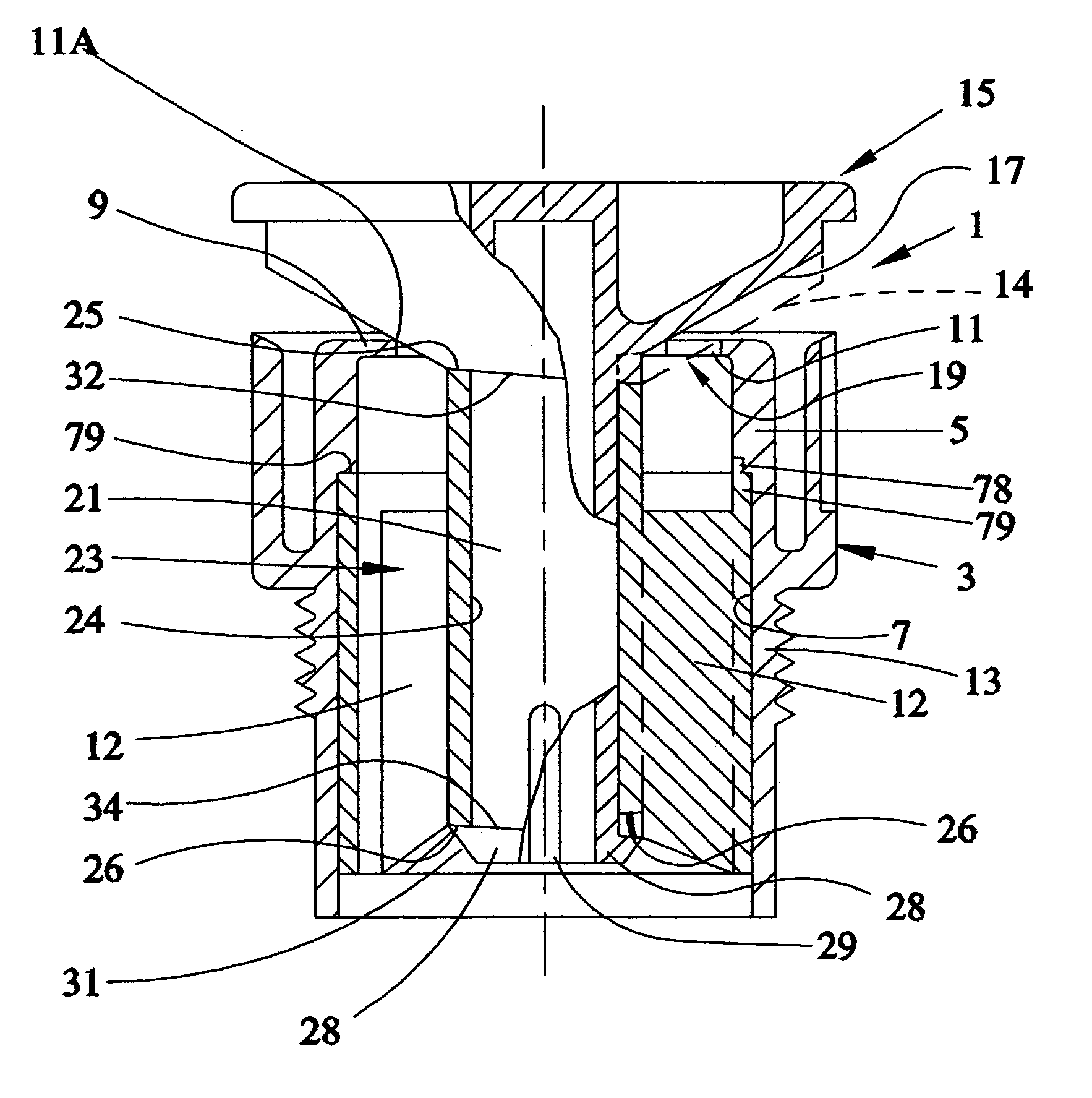

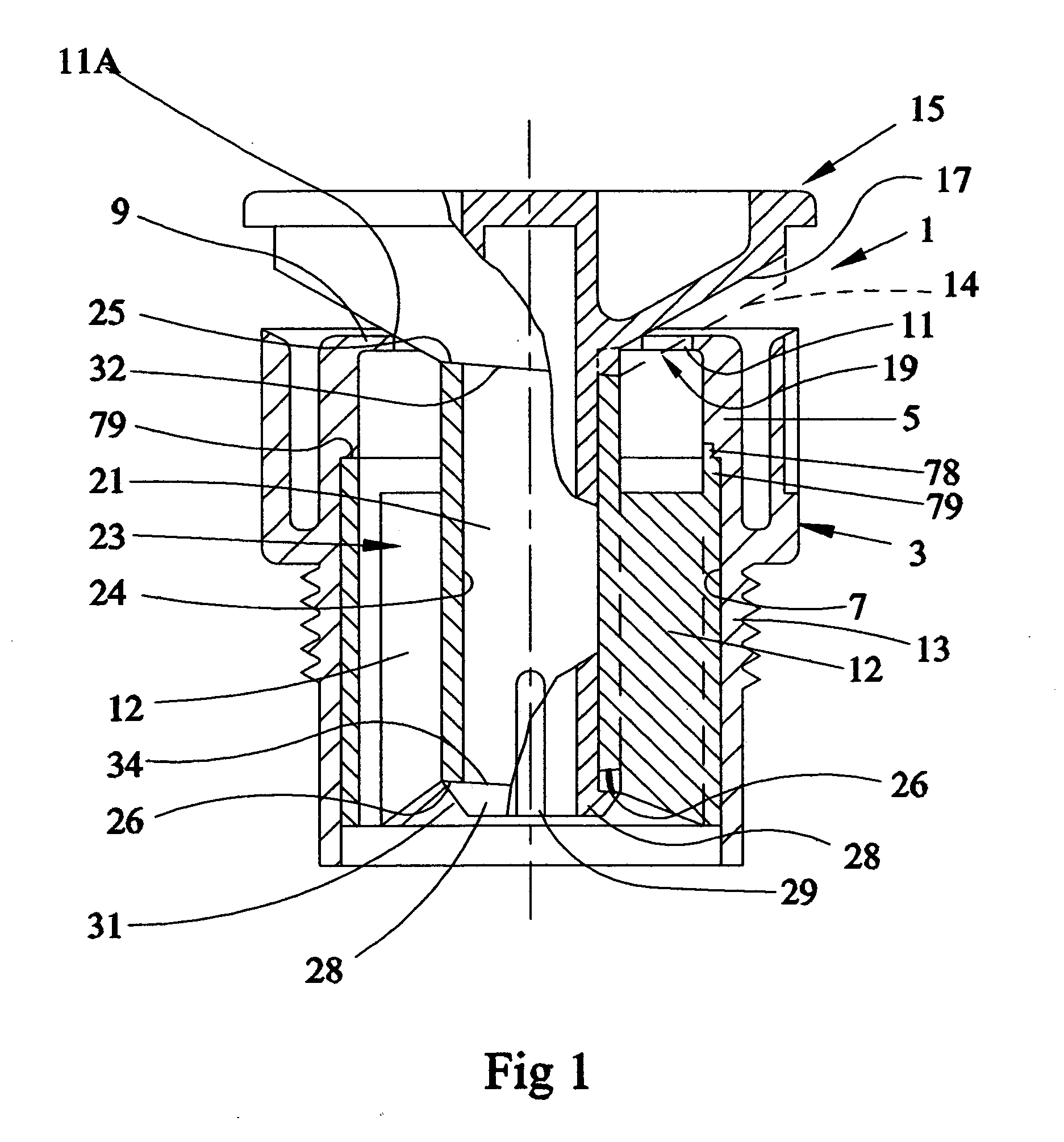

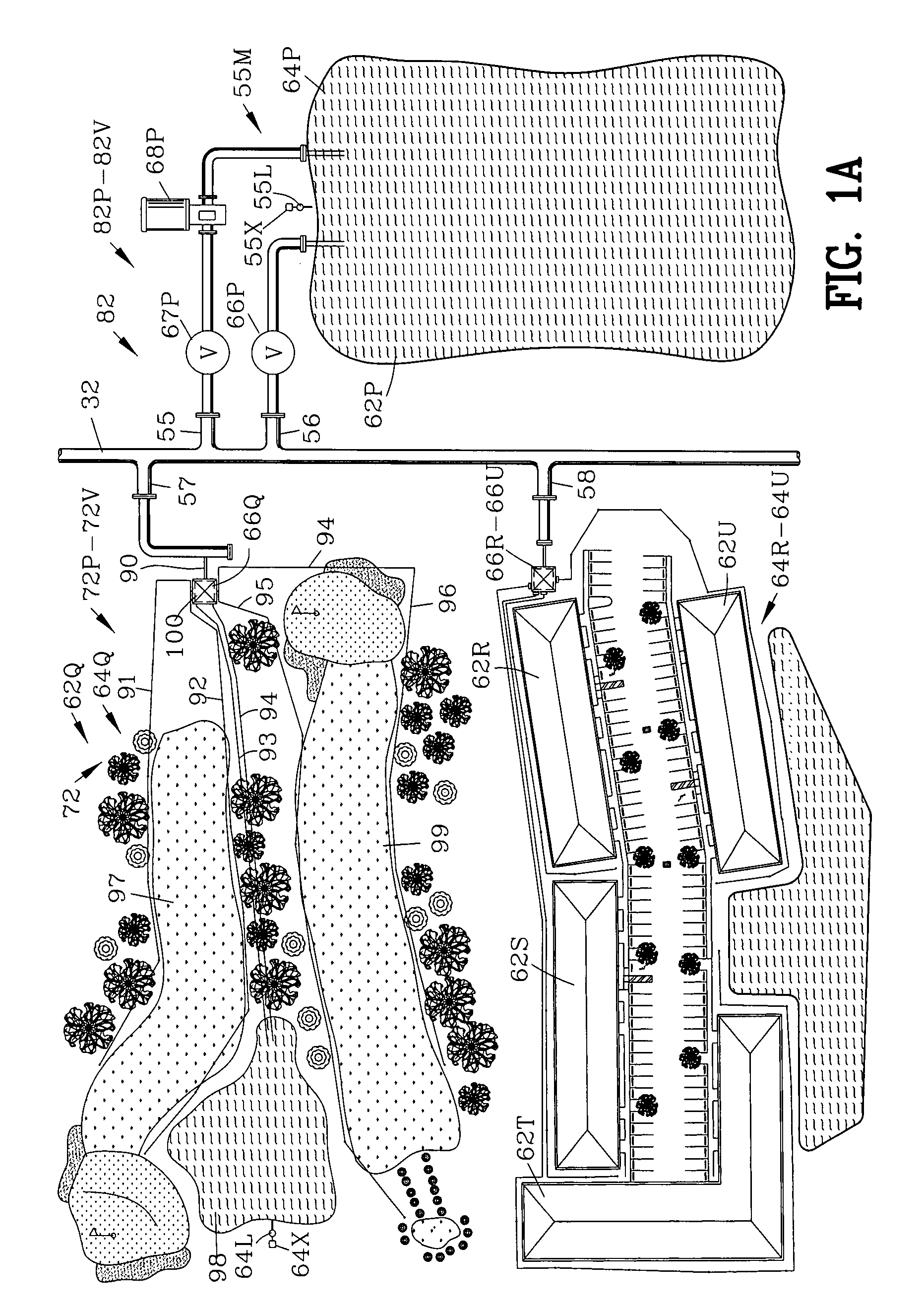

Spray nozzle with adjustable ARC spray elevation angle and flow

An adjustable spray nozzle with adjustable arc of coverage as well as spray elevation angle and flow rate. A very simple adjustable arc of coverage spray nozzle configuration is also disclosed which may be easily assembled for a particular precipitation rate and / or range of coverage at a selected nominal pressure. Also disclosed is a simple fixed arc of coverage spray nozzle with selectable ranges for a particular precipitation rate.

Owner:KAH JR CARL L +1

Spray nozzle with adjustable ARC spray elevation angle and flow

Owner:KAH JR CARL L +1

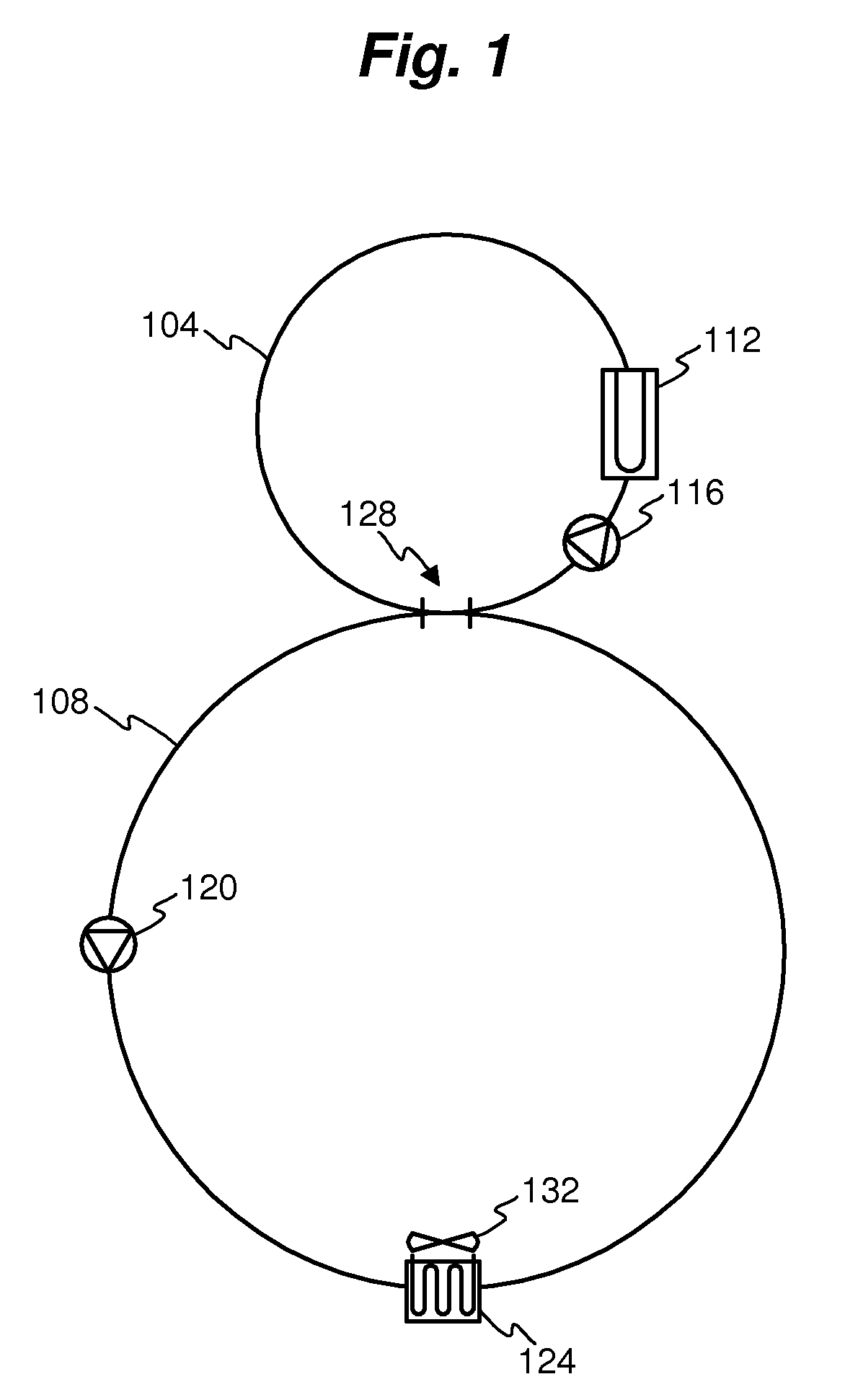

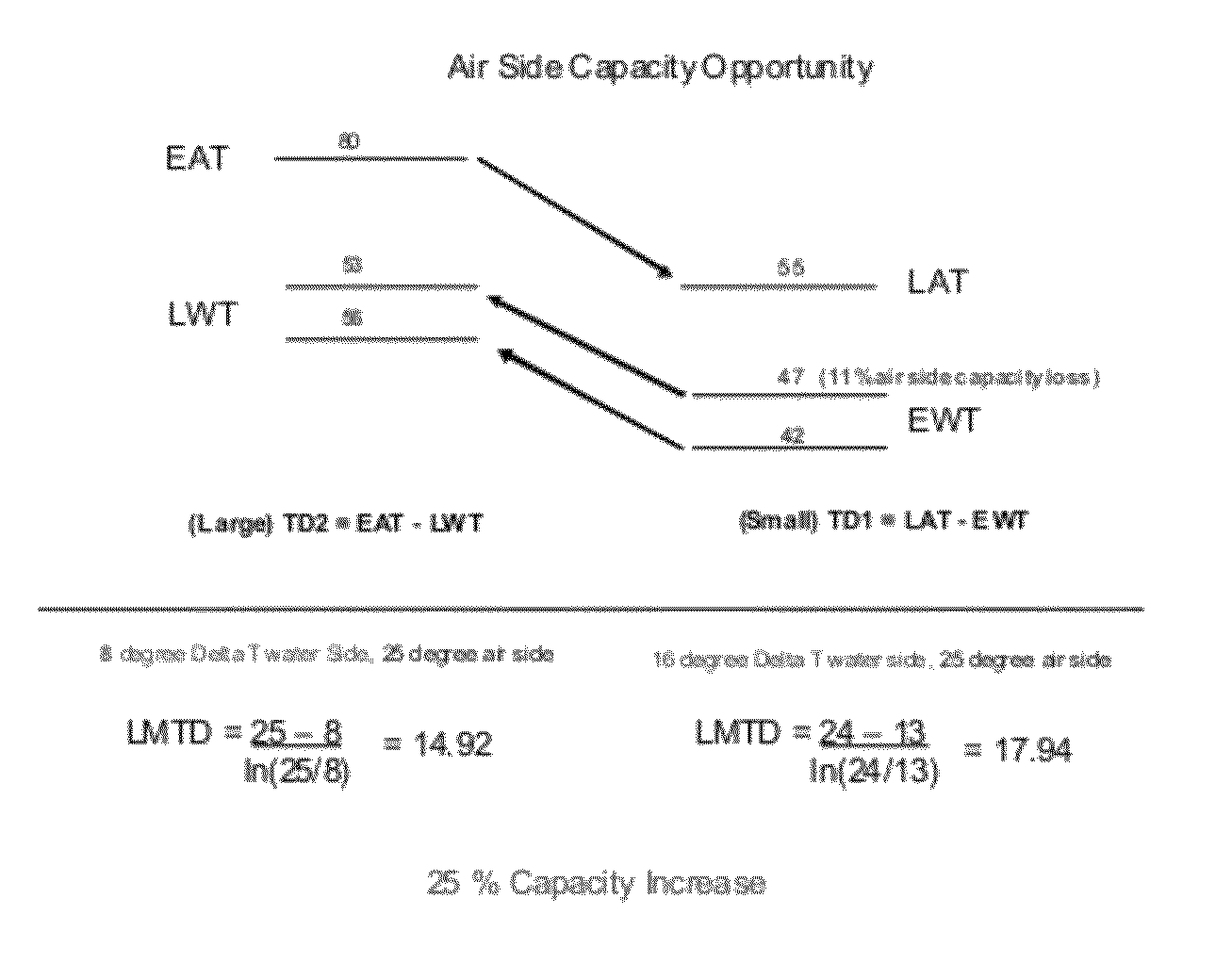

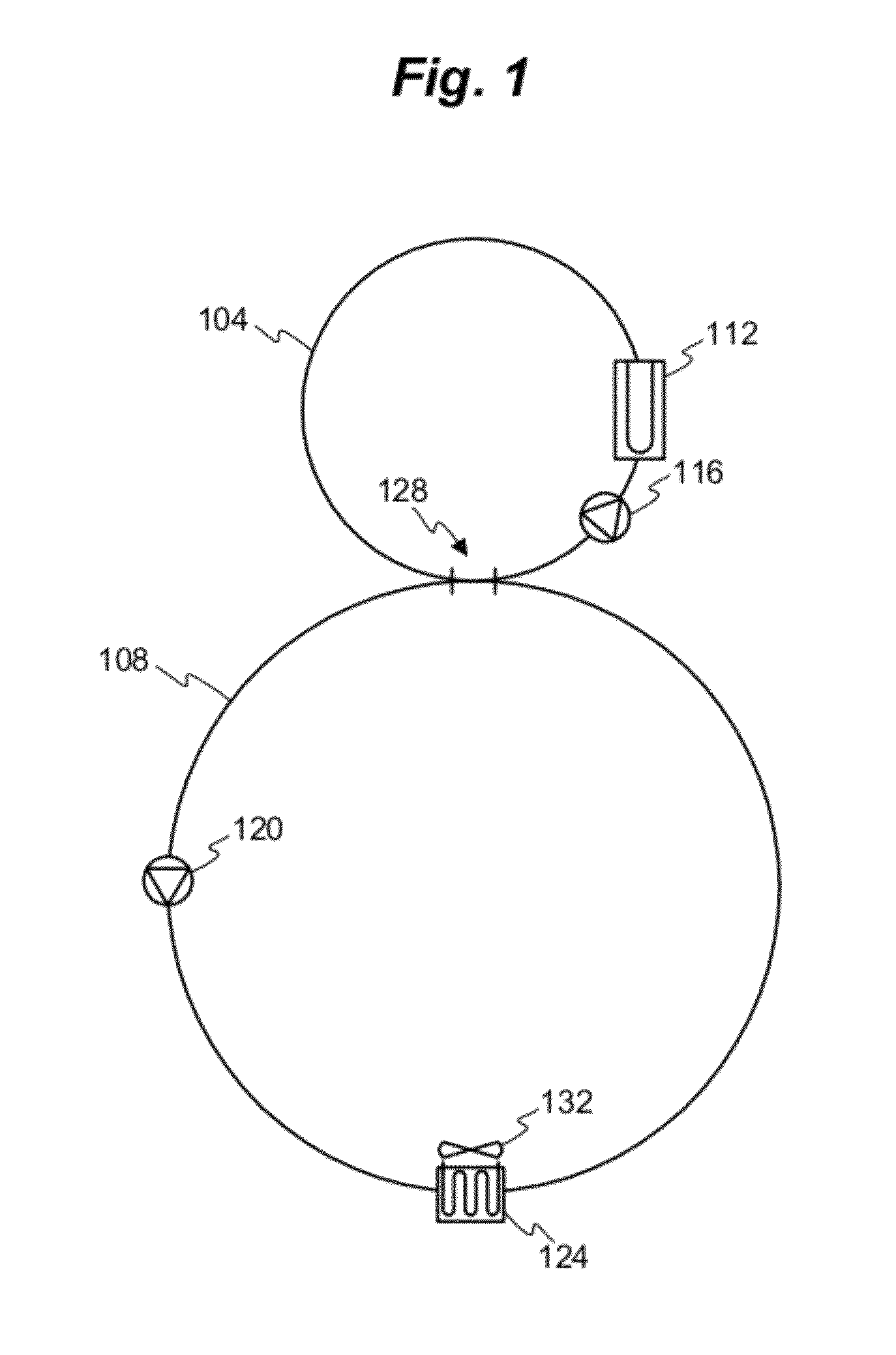

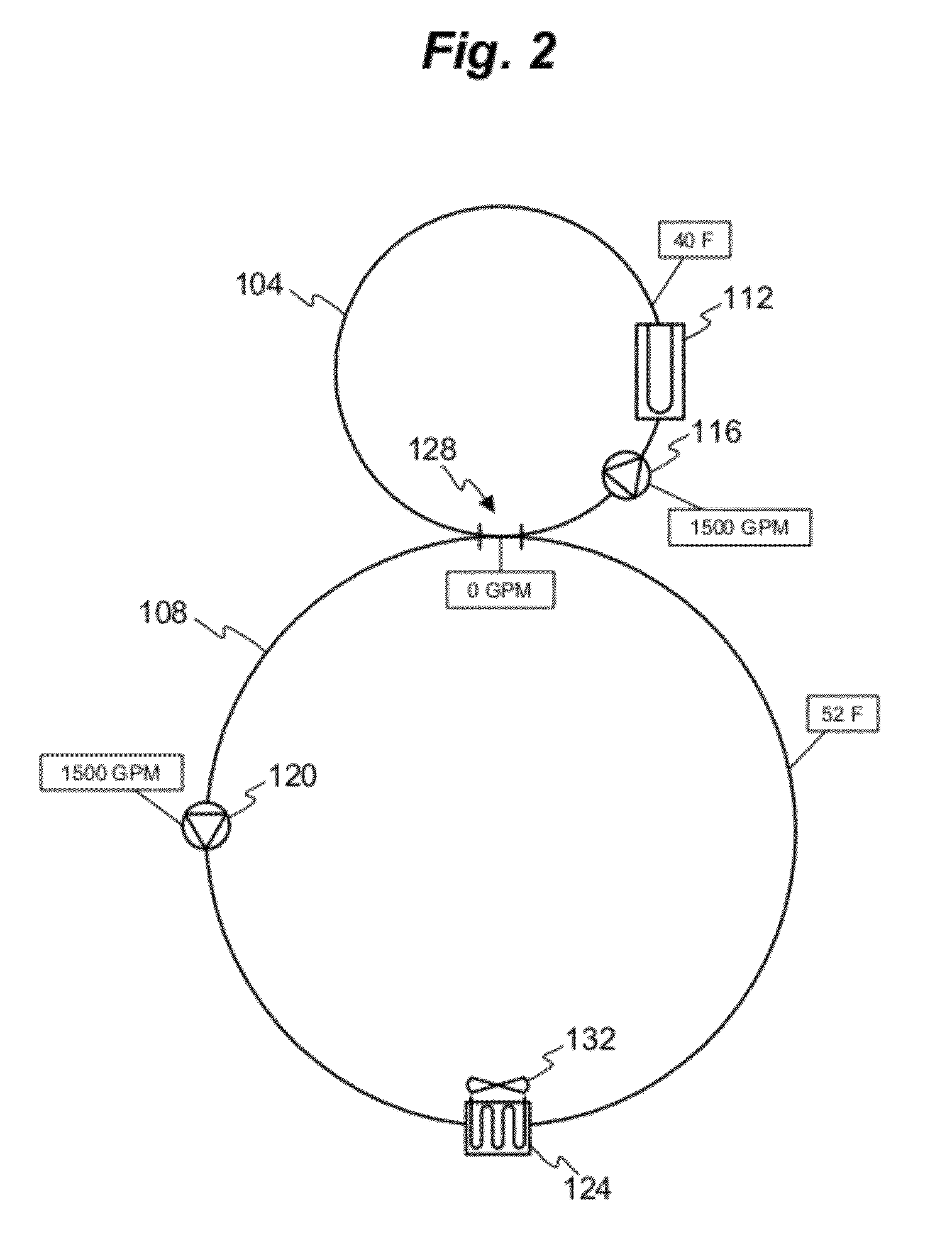

Demand flow pumping

ActiveUS20110022236A1Easy to operateSignificant energy savingMechanical apparatusTemperatue controlAir handlerEngineering

Demand Flow operates chilled water plants at substantially improved efficiency, regardless of plant load conditions. In general, Demand Flow utilizes an operating strategy which controls chilled and condenser water pumping according to a constant Delta T line, which is typically near or at design Delta T. This reduces or eliminates Low Delta T Syndrome and reduces energy usage by chilled and condenser water pumps for given load conditions. Operation of chilled water pumps in this manner creates a synergy which generally balances flow rates throughout the plant, reducing undesirable bypass mixing and energy usage at air handler fans and other components of the chilled water plant. At plant chillers, application of Demand Flow increases the refrigeration effect through refrigerant sub-cooling and superheating, while preventing stacking. Demand Flow includes a critical zone reset feature which allows the constant Delta T line to be reset to adjust to changing load conditions.

Owner:SIEMENS IND INC

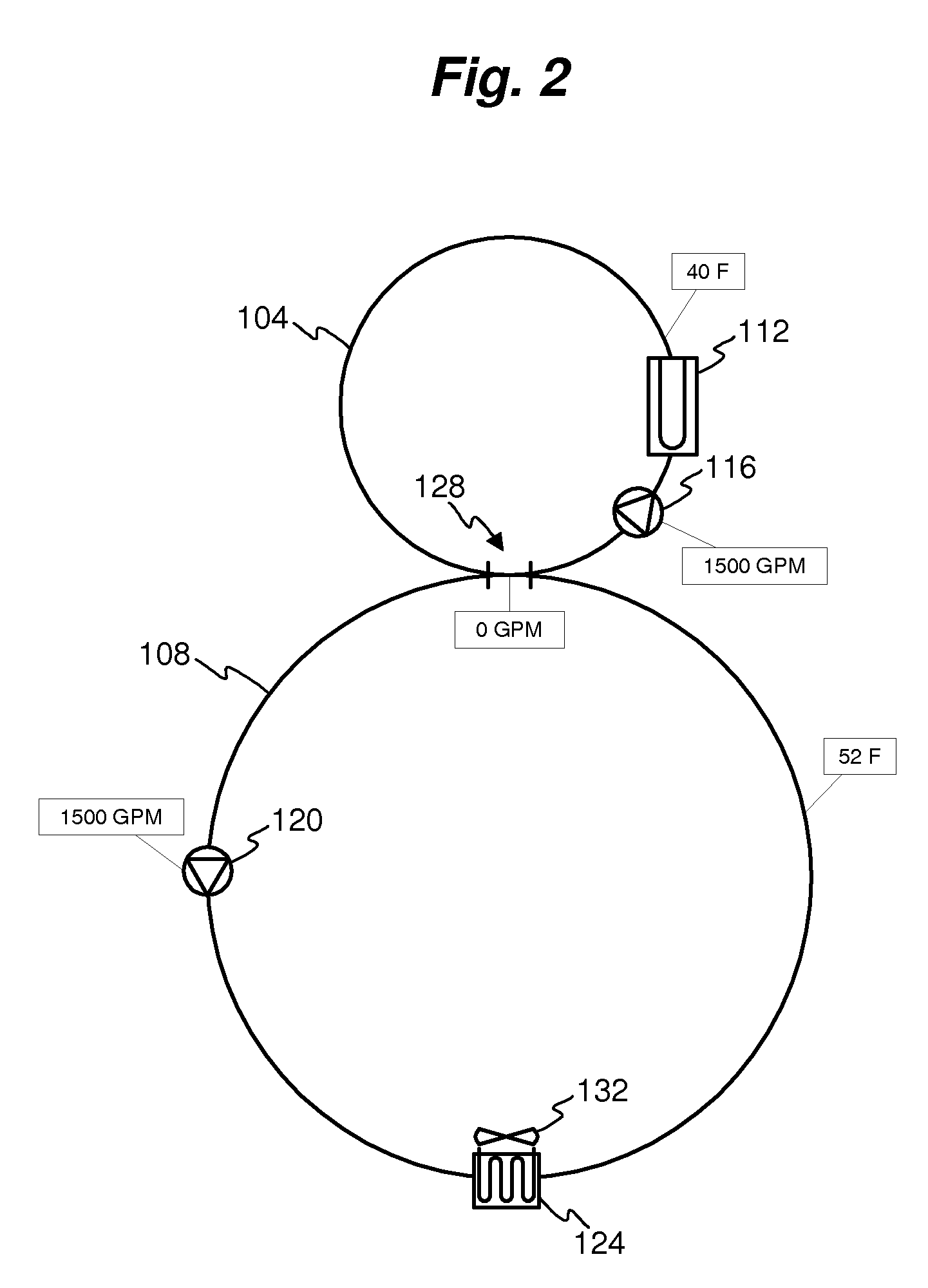

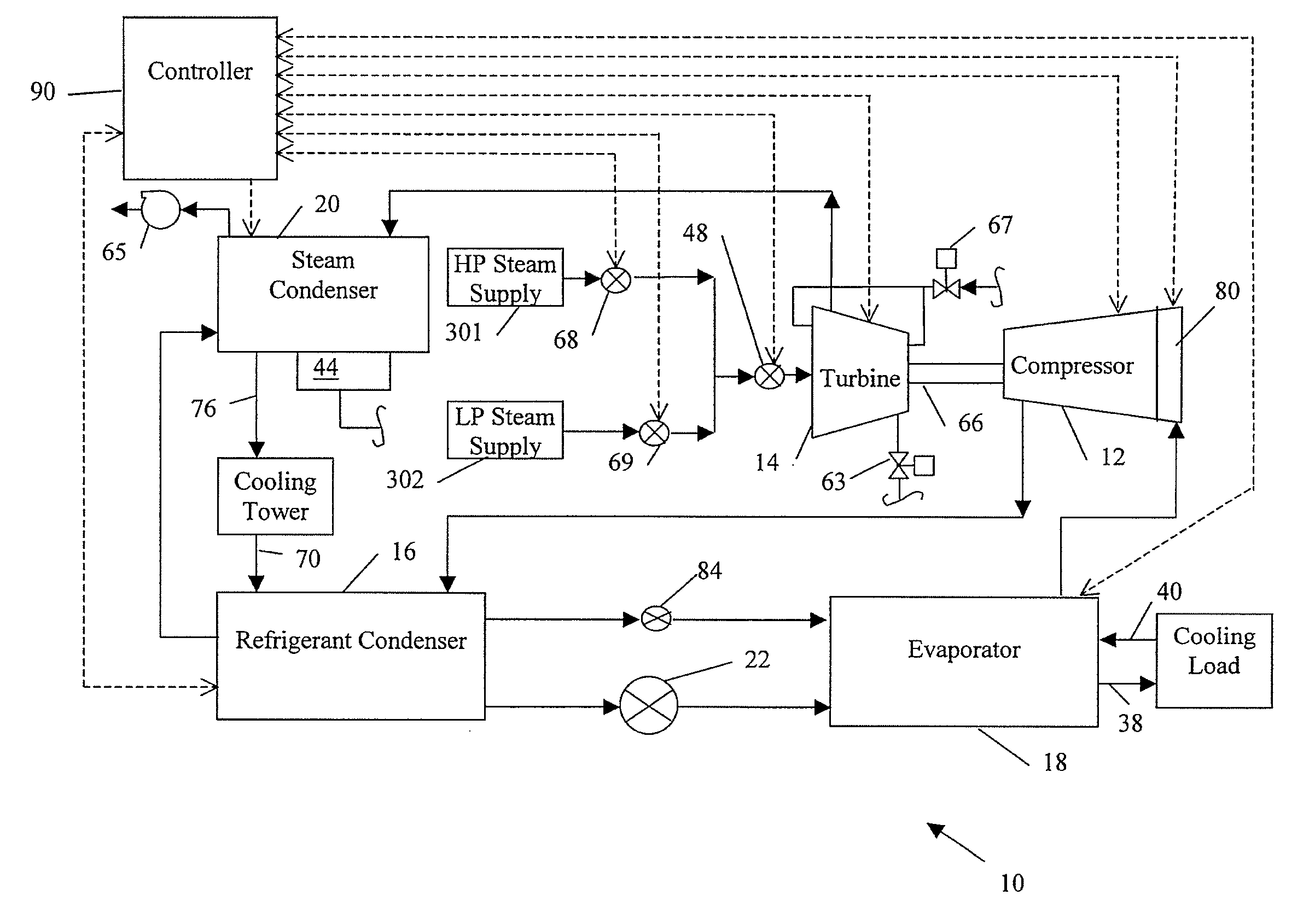

Automated inlet steam supply valve controls for a steam turbine powered chiller unit

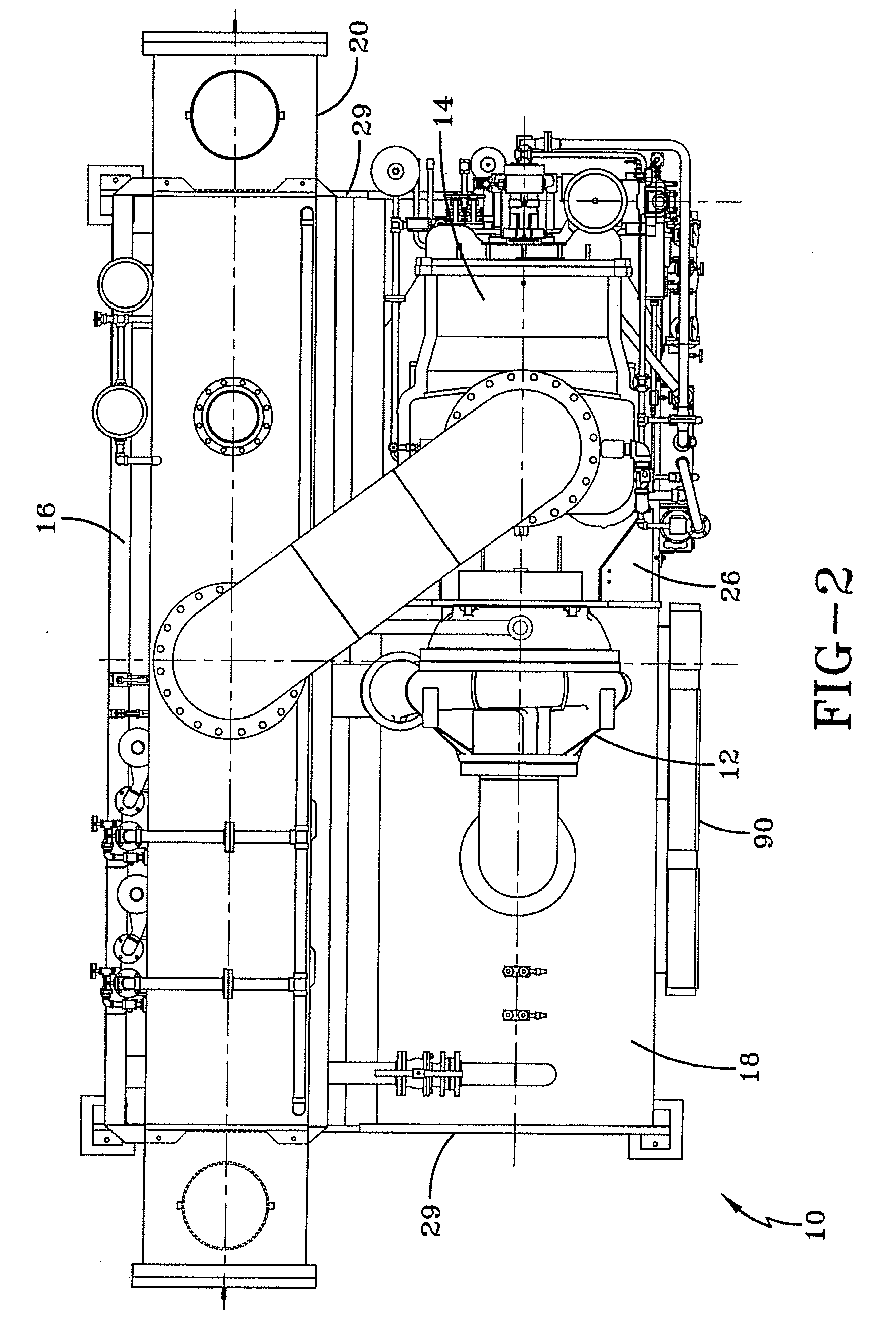

InactiveUS20070271938A1Reduce cooling water flowReduce water flowCompression machines with non-reversible cycleRefrigeration safety arrangementControl systemEngineering

A control system and method are provided for the controlling of steam supplies used by a steam turbine driven chiller unit. The steam turbine can receive steam from a high pressure steam source and / or a low pressure steam source depending on the operating mode of the steam turbine. The high pressure steam is used for operating at the steam turbine at rated speed and to provide the breakaway torque when starting the steam turbine. The low pressure steam is used for extending idling of the steam turbine that enables the steam turbine to transition more quickly to rated speed when desired.

Owner:JOHNSON CONTROLS TECH CO

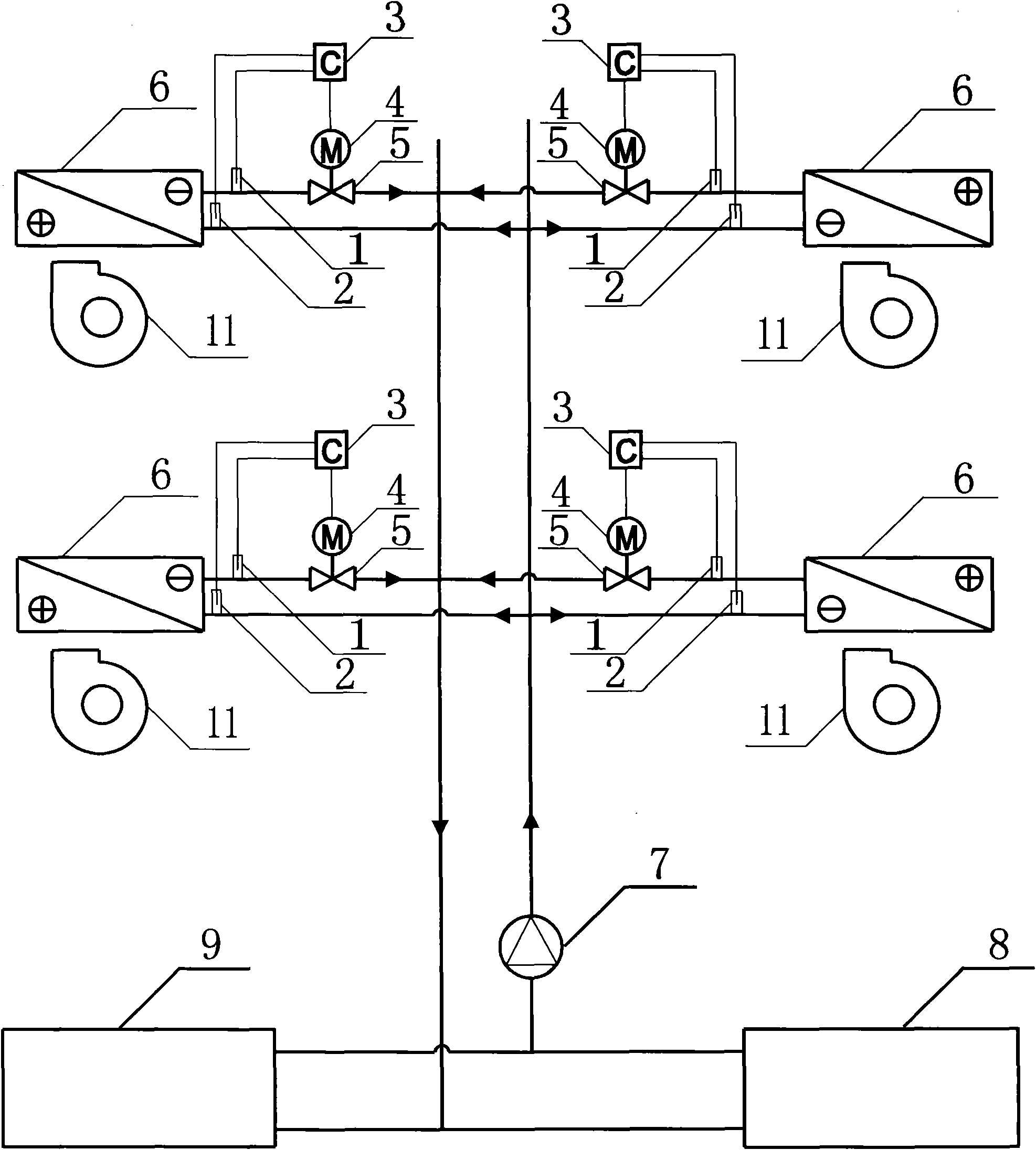

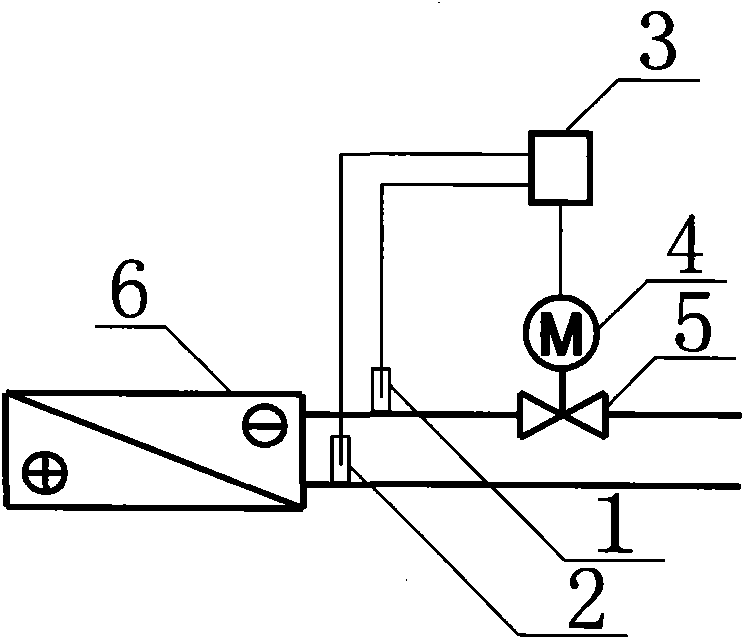

Control system for regulating liquid flow

InactiveUS8615329B2Reduce water flowIncrease pressureFunctional valve typesTesting/calibration apparatusControl systemDistribution system

A control system is disclosed for regulating the flow of a liquid from a liquid provider through a liquid distribution system. The distribution system has a major liquid distribution channel connected to a plurality of minor liquid distribution channels providing the liquid to a multiplicity of users. A plurality of controllable user valves are interposed in the multiplicity of user channels. A liquid monitor senses a liquid flow characteristic within the liquid distribution channel. A user control changes selective controllable user valves for restoring a desired liquid flow characteristic within the liquid distribution channel.

Owner:WATER OPTIMIZER

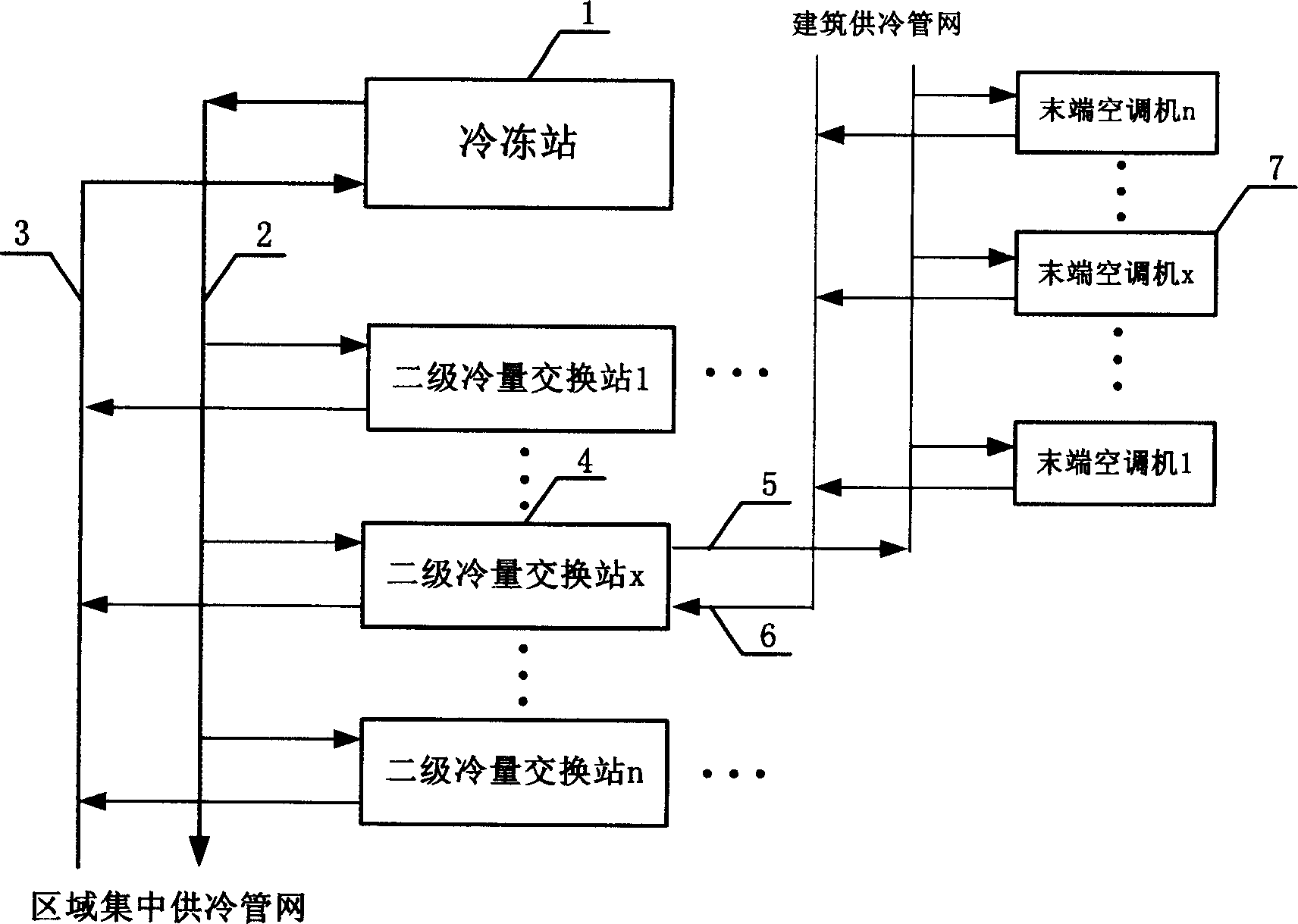

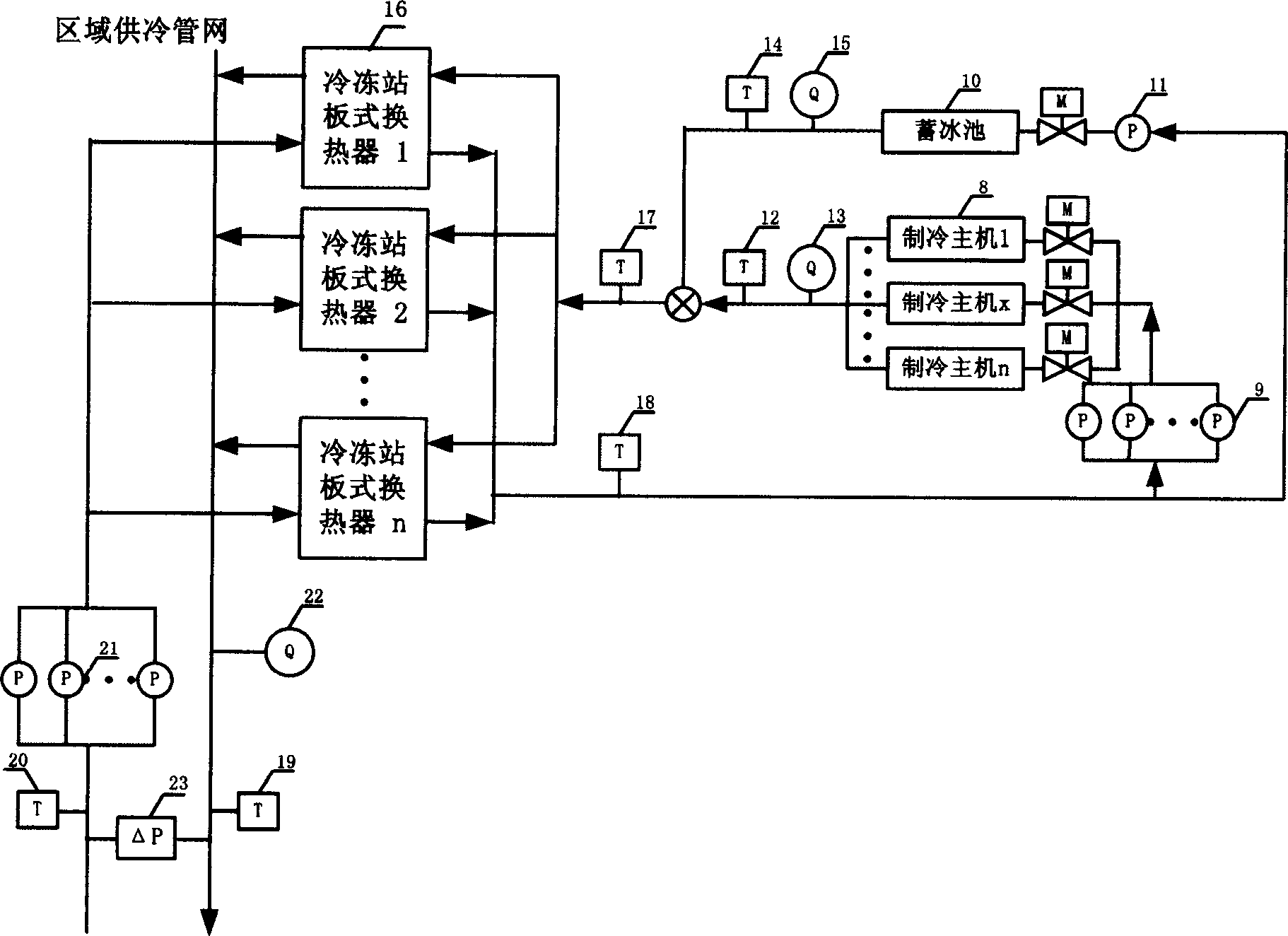

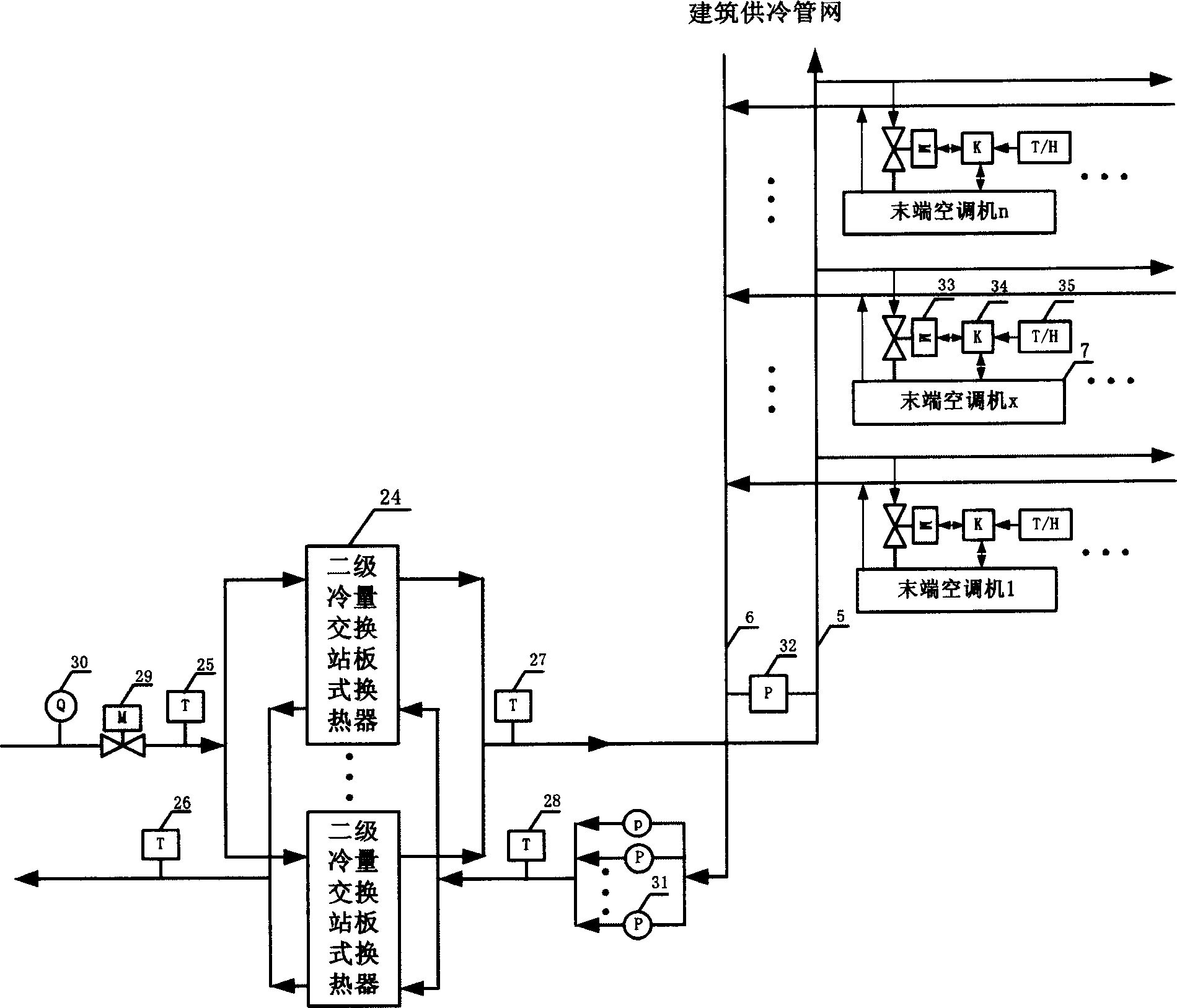

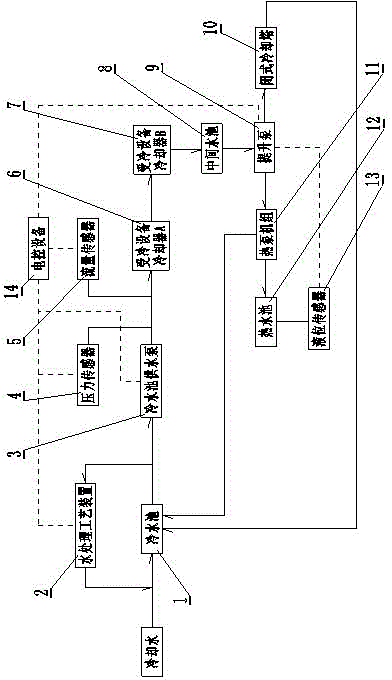

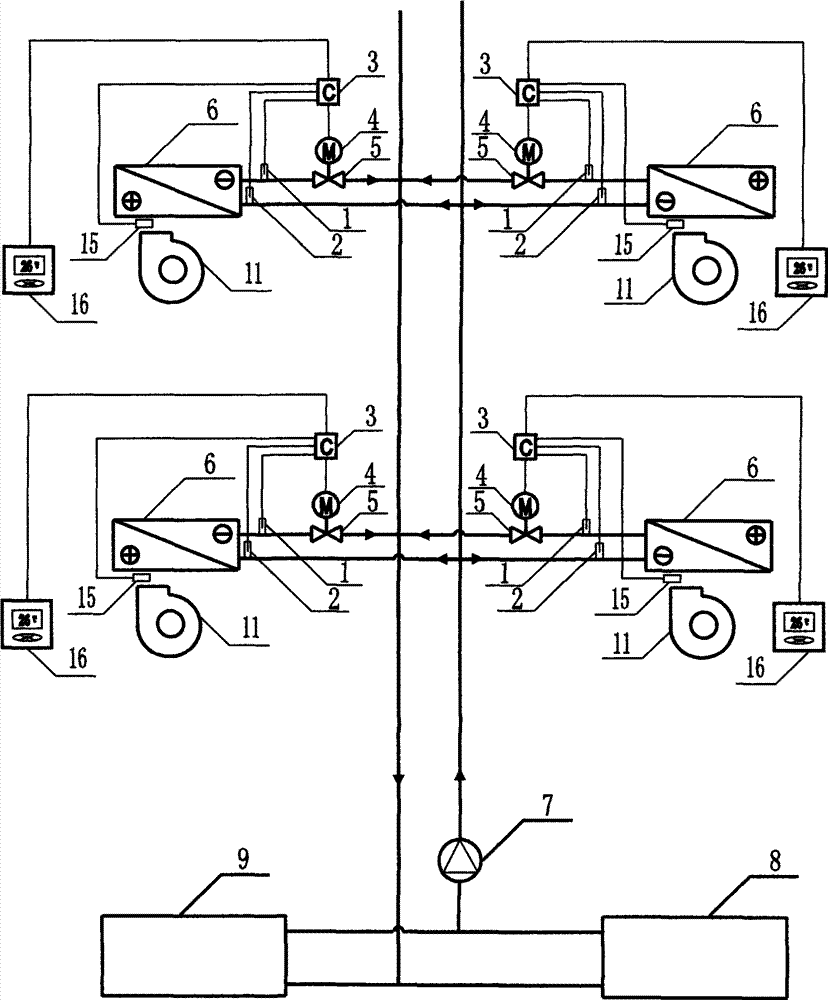

System of adjusting quantity of cold, and adjustment method for central cooling in region

ActiveCN1916519AReduce energy consumptionRaise the temperature of the water supplySpace heating and ventilation safety systemsLighting and heating apparatusEmbedded systemWater temperature

A cold regulation device in cold supplying system of local centralized type is prepared as connecting server of refrigerating station (SRS) to controller of refrigerating station (CRS) and controller of secondary cold exchanging station (CSCES) through converter, connecting multiple remote monitor computer to CRS and multiple CSCES through converter, connecting each CSCES to local monitor computer and multiple tail end controllers separately through industrial control network, carrying out cold regulation on tail device of central air-conditioning and on secondary cold exchanging station, carrying out water temperature regulation on local centralizing cold supplying network.

Owner:GUANGZHOU YUANZHENG INTELLIGENCE TECH

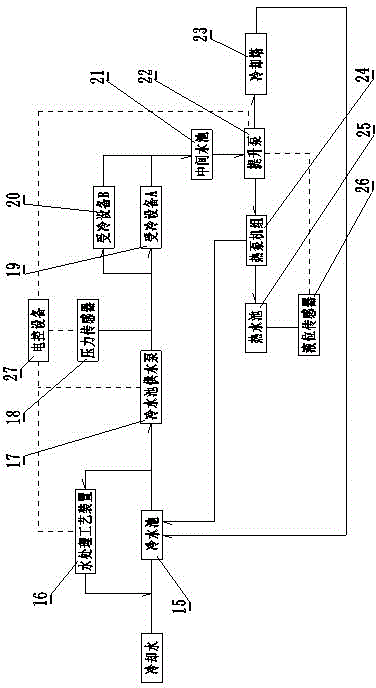

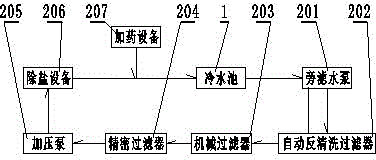

Energy-saving recycling combination system for industrial circulating cooling water

InactiveCN104478137AIncrease profitIncrease return water temperatureLighting and heating apparatusTreatment involving filtrationCooling towerWater quality

The invention discloses an energy-saving recycling combination system for industrial circulating cooling water. The system comprises two circulating cooling water systems, namely, a sealed-type circulating cooling water system and an open-type circulating cooling water system and specifically comprises a cold water tank, a water treatment process device, a cooling water supply pump, a pressure sensor, a flow sensor, a cooled device, an intermediate water tank, a lift pump, a cooling tower, a heat pump set, a hot water tank, a liquid-level sensor and an electronically controlled device and is an energy-saving and water-saving optimized combination system for industrial circulating cooling water. Serial-type water supply is adopted in the sealed-type circulating cooling water system, parallel-type water supply is adopted in the open-type circulating cooling water system, the utilization rate of the cooling water is increased to a maximize extent and the water supply amount of the cooling water is decreased. Since the system is provided with the water treatment process device, the water quality of the circulating water is improved, the sewage discharge capacity is decreased and the concentration multiple of the circulating water is increased. By arranging the heat pump set in the system, the low-temperature waste heat of the return water of the cooling water is effectively recovered, the evaporation amount is reduced and the effective utilization of the heat source is achieved and the system has important practical values.

Owner:CHINA FIRST HEAVY IND

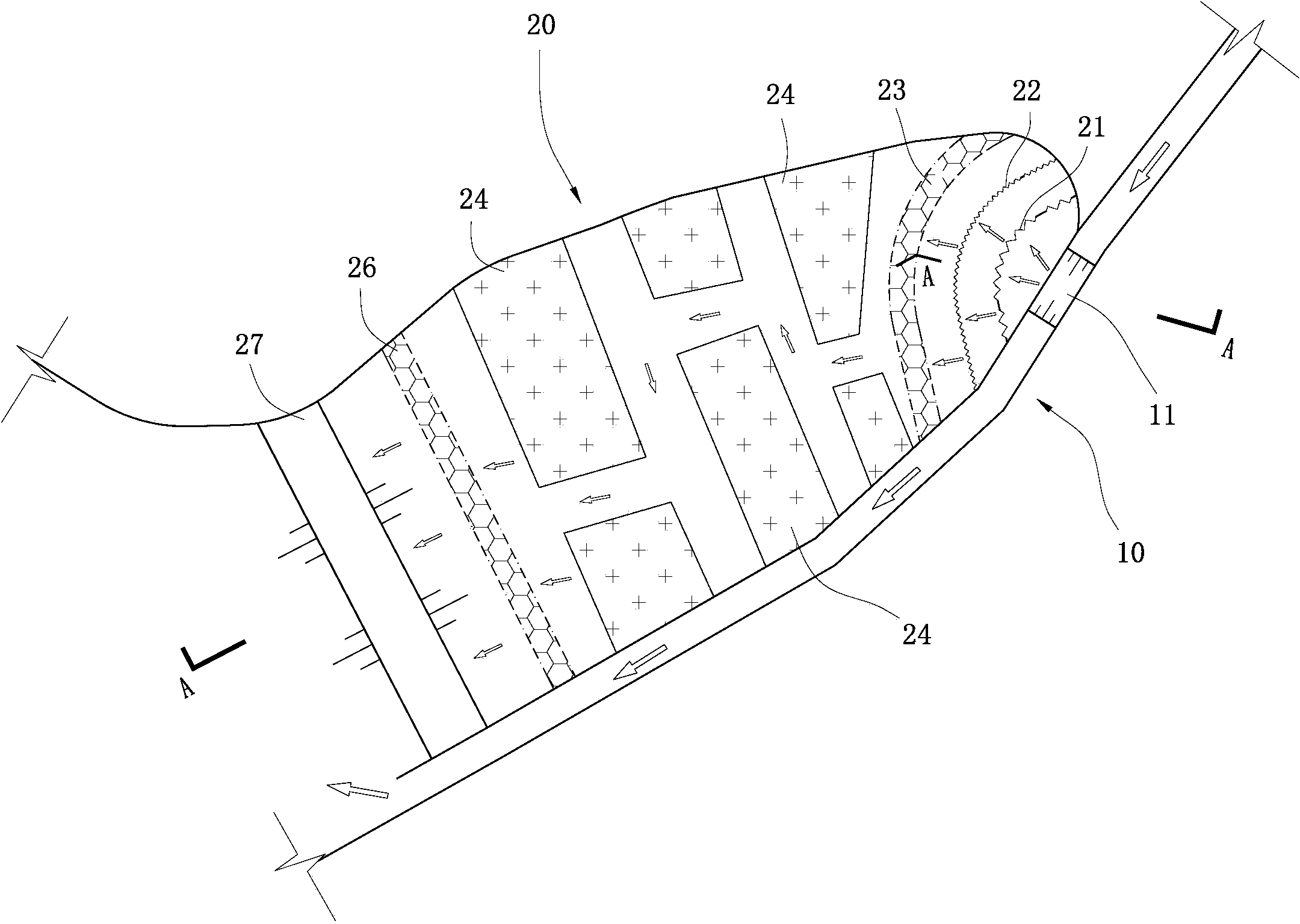

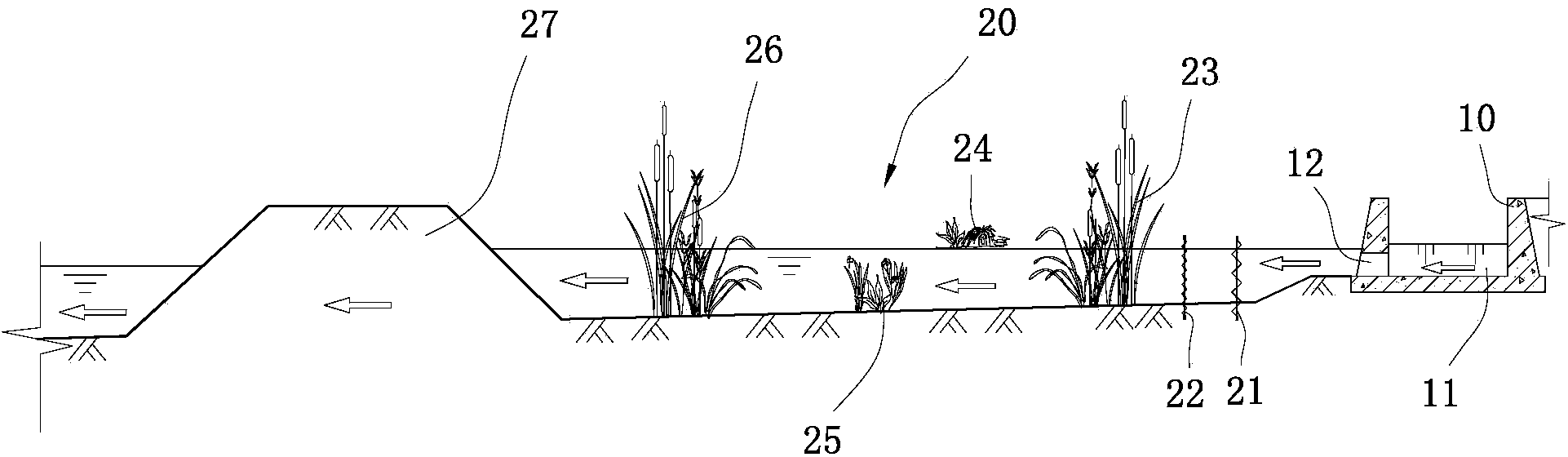

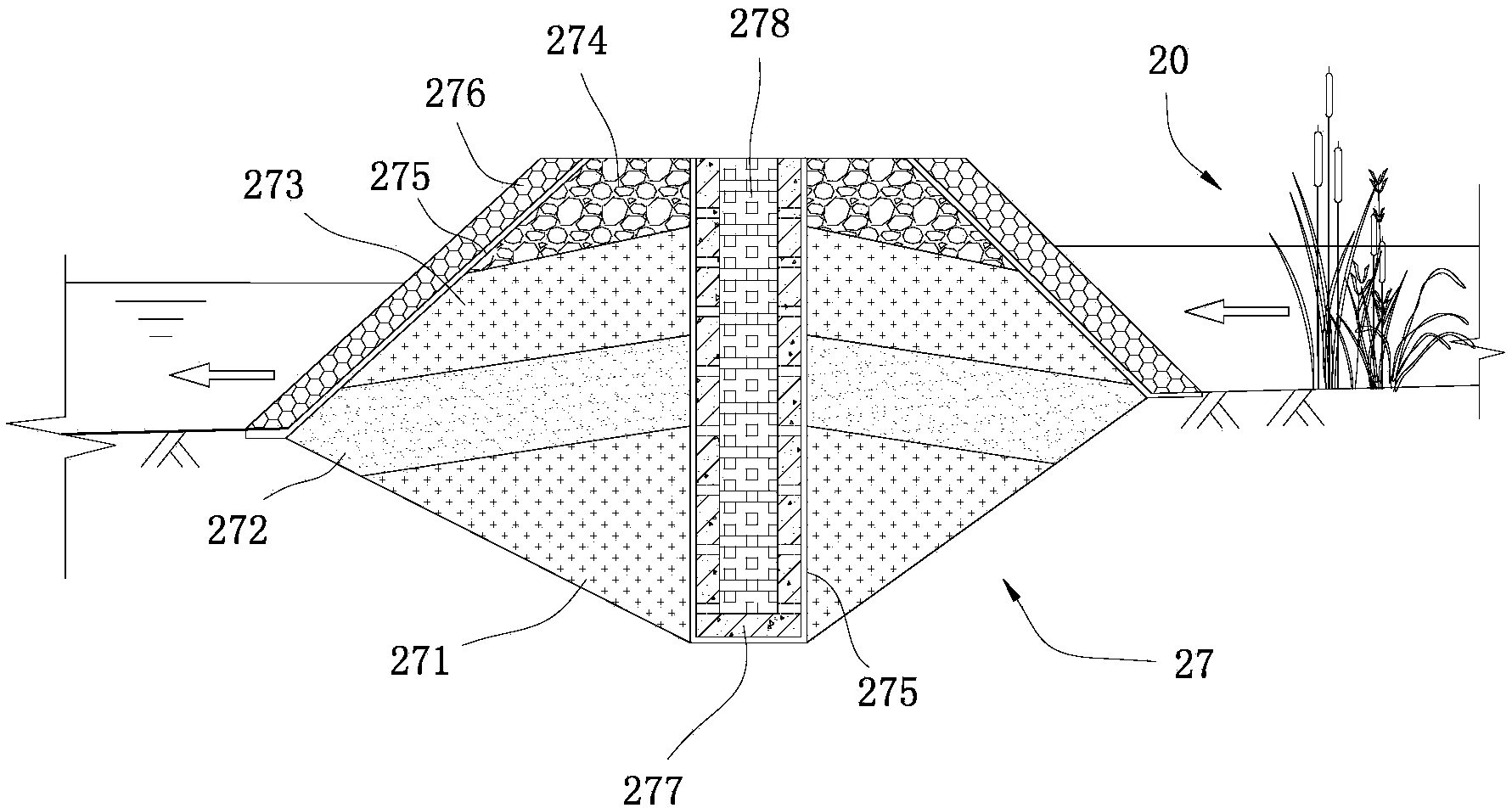

Initial rainwater and mixed rain-sewage overflow water impounding sewage facility

ActiveCN103821218ARealize purificationReduce water flowDamsFatty/oily/floating substances removal devicesWater flowSewage

The invention discloses an initial rainwater and mixed rain-sewage overflow water impounding sewage facility comprising a rainwater guide canal and a regulation reservoir arranged beside the rainwater guide canal. The rainwater guide canal is provided with a sinking intercepting channel which is provided with a side guide port communicated with the regulation reservoir. A grille area, a wetland filter plant area and a seepage filter area are arranged in the regulation reservoir sequentially along the water flow direction. Initial rainwater and mixed rain-sewage overflow water are low in flow; when guided via the rainwater guide canal, the initial rainwater and the mixed rain-sewage overflow water fall and flow into the intercepting channel at first and then flow into the regulation reservoir for purification, through the side guide port of the intercepting channel; with the passage of time, water level of the regulation reservoir rises, the intercepting channel is supported up to raise the water level thereof, and accordingly when flowing by the intercepting channel, late rainwater directly overflows from the intercepting channel and flows into downstream water through the lower segment of the rainwater guide canal; therefore, the initial rainwater and mixed rain-sewage overflow water which are severely contaminated, and the late rainwater, which is clean, are discharged separately.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

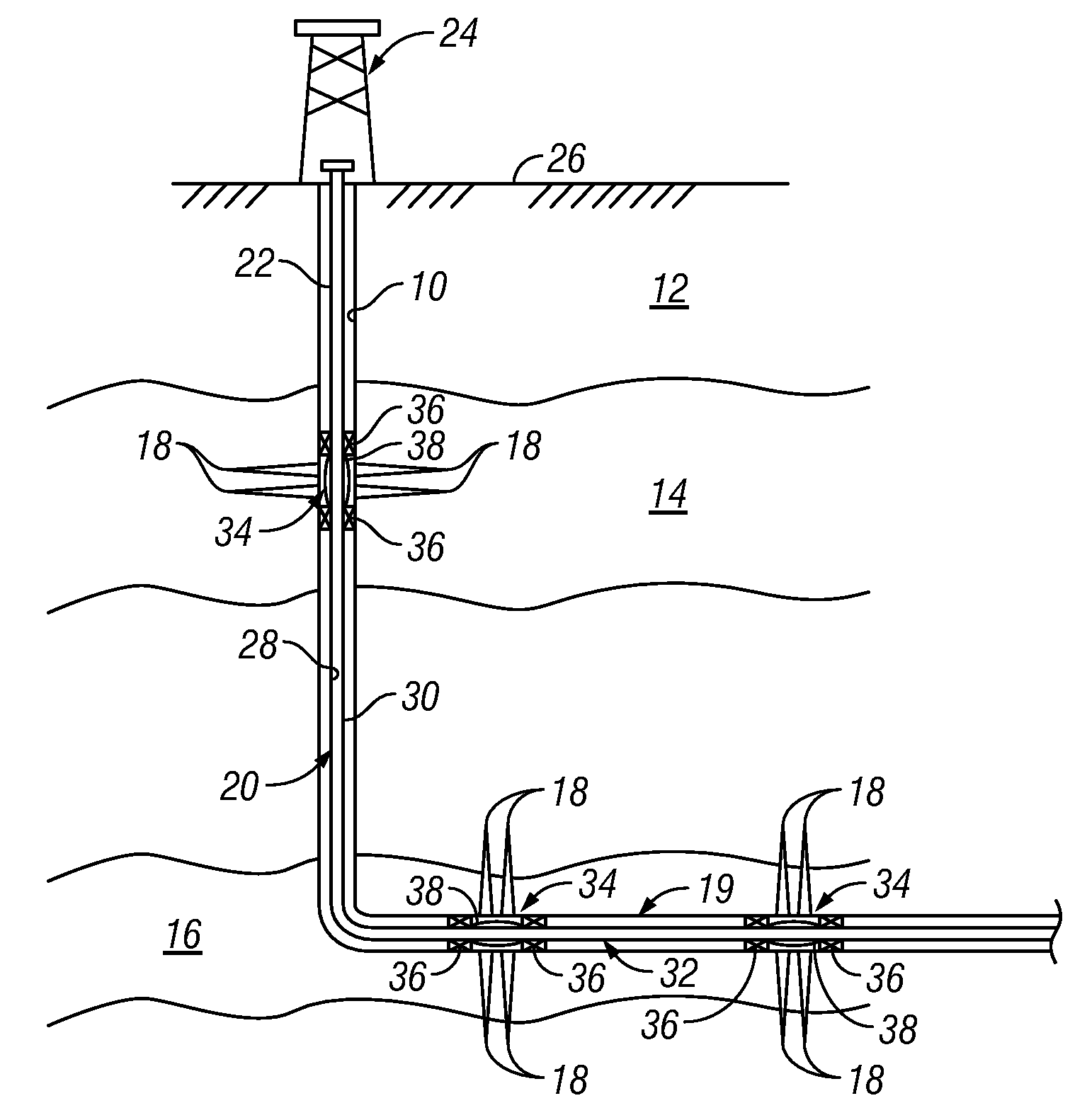

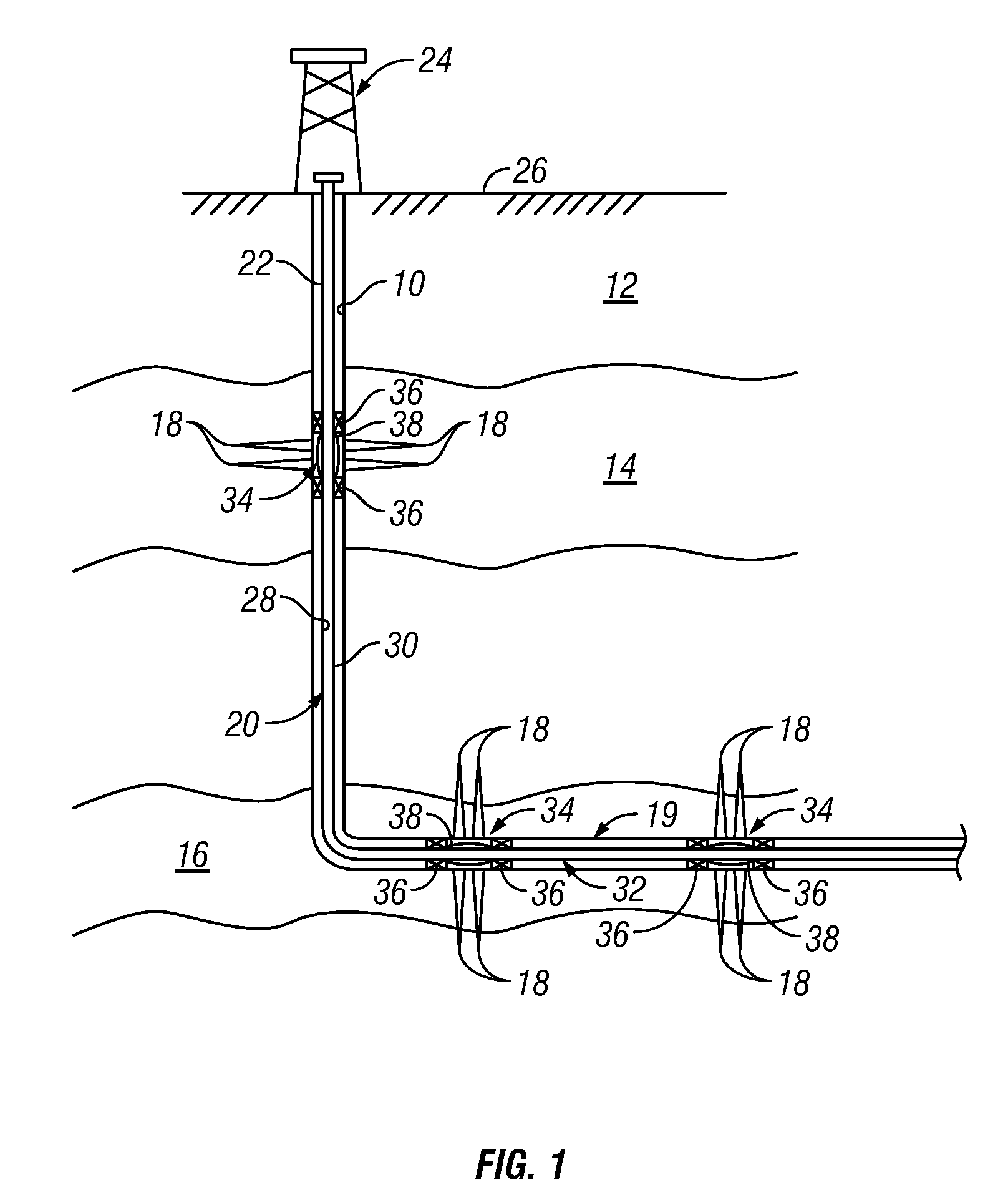

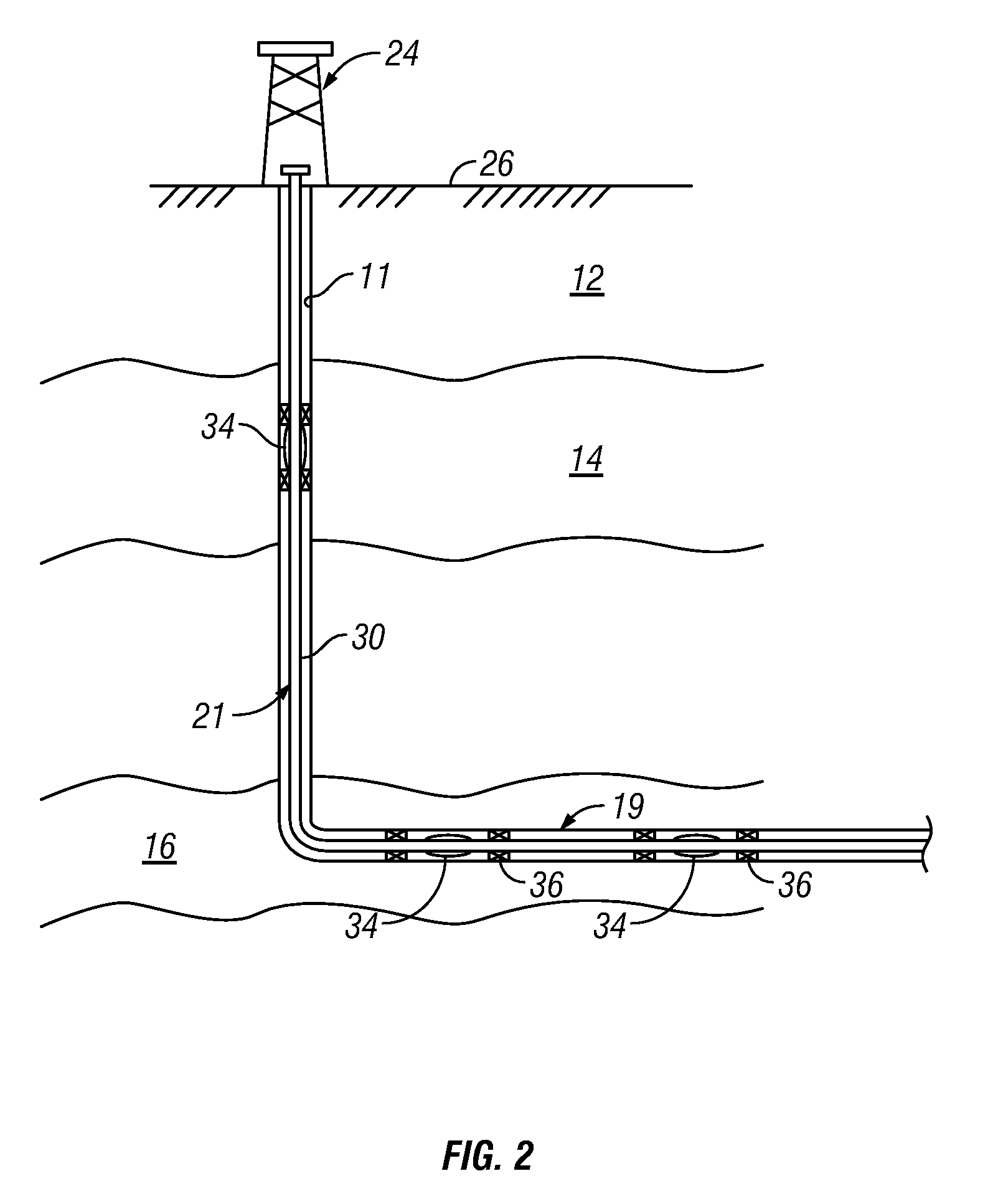

Water Absorbing Materials Used as an In-flow Control Device

ActiveUS20090101353A1Reduce water flowIncrease densityFluid removalWell/borehole valve arrangementsEffective densityEngineering

A device or system for controlling fluid flow in a well includes a flow restriction member that transitions from a first effective density to a second effective density in response to a change in composition of the flowing fluid. The flow restriction member may increase in effective density as the water cut of the flowing fluid increases and / or disintegrate when exposed to a selected fluid in the flowing fluid. The flow restriction member may be formed of a water-absorbing material and / or a porous material. The pores may be water permeable but not oil permeable. A method for producing fluid from a subterranean formation includes controlling a flow of fluid into a wellbore tubular with a flow restriction member. The method may include reducing a flow of water into the wellbore tubular when a percentage of water in the flowing fluid reaches a predetermined value.

Owner:BAKER HUGHES INC

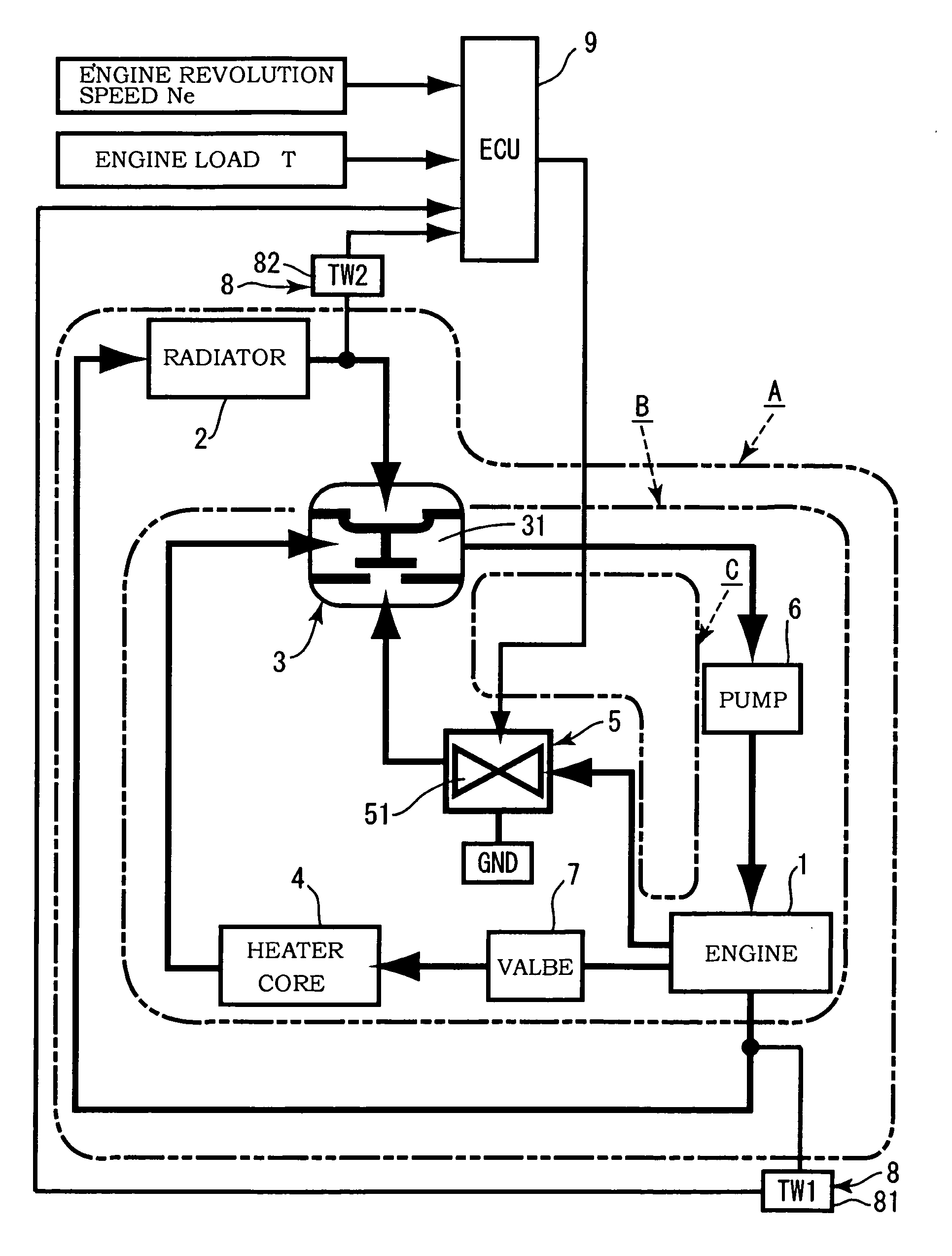

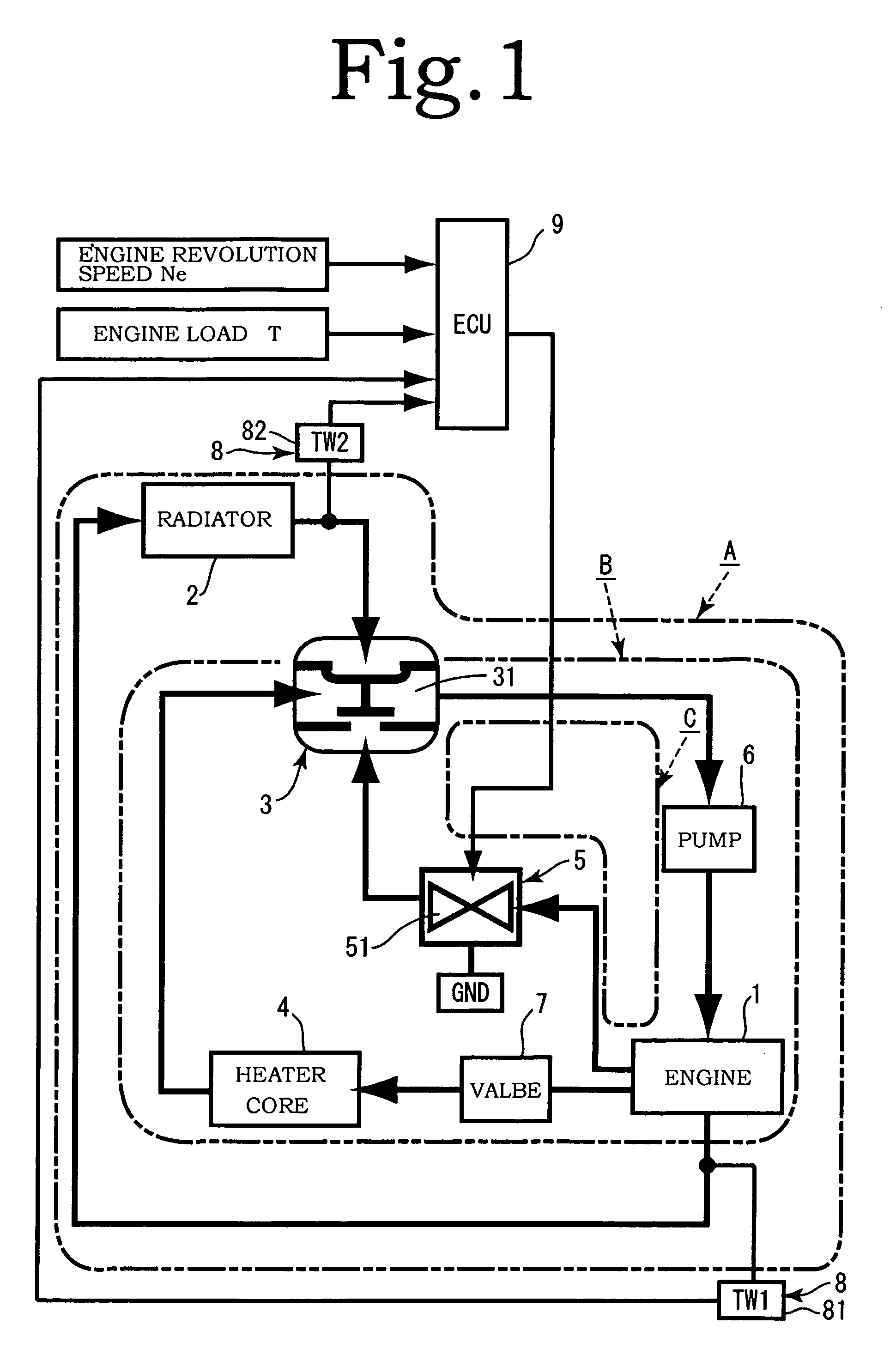

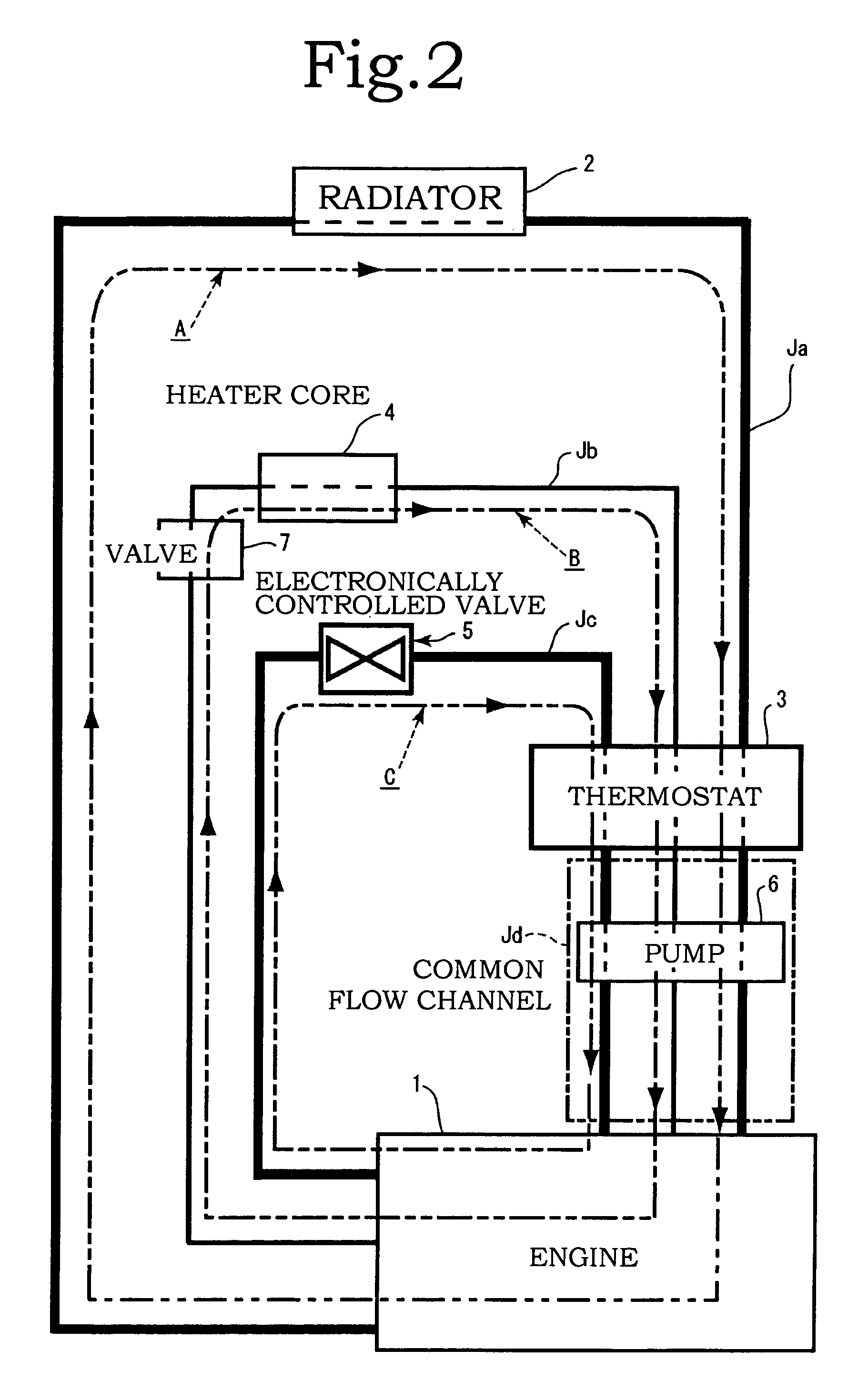

Cooling device for engine

InactiveUS20090255488A1Rapid temperature riseExtend service lifeCoolant flow controlCylinder headsWater circulationCooling water temperature

A cooling device for an engine that can raise the temperature of cooling water within a short period of time during the warm-up operation and allows a simple structure. The cooling device has a radiator circulation flow channel for circulation via an engine, a radiator, and a thermostat; a heater circulation flow channel for circulation via the engine, a heater core, and the thermostat; a bypass circulation flow channel for circulation via the engine and the thermostat; an electronically controlled valve; and a pump. The radiator circulation flow channel, heater circulation flow channel, and bypass circulation flow channel merge in the thermostat and form a common flow channel between the thermostat and the engine. The pump is provided in the common flow channel. At the start of the warm-up period and during the warm-up operation, the circulation in the radiator circulation flow channel is substantially stopped by the thermostat, cooling water circulation is actuated in the bypass circulation flow channel, and an opening degree of the electronically controlled valve is gradually increased from a minimum as the cooling water temperature rises. At the end of the warm-up period, circulation is actuated in the radiator circulation flow channel and substantially stopped in the bypass circulation flow channel.

Owner:YAMADA SEISAKUSHO KK

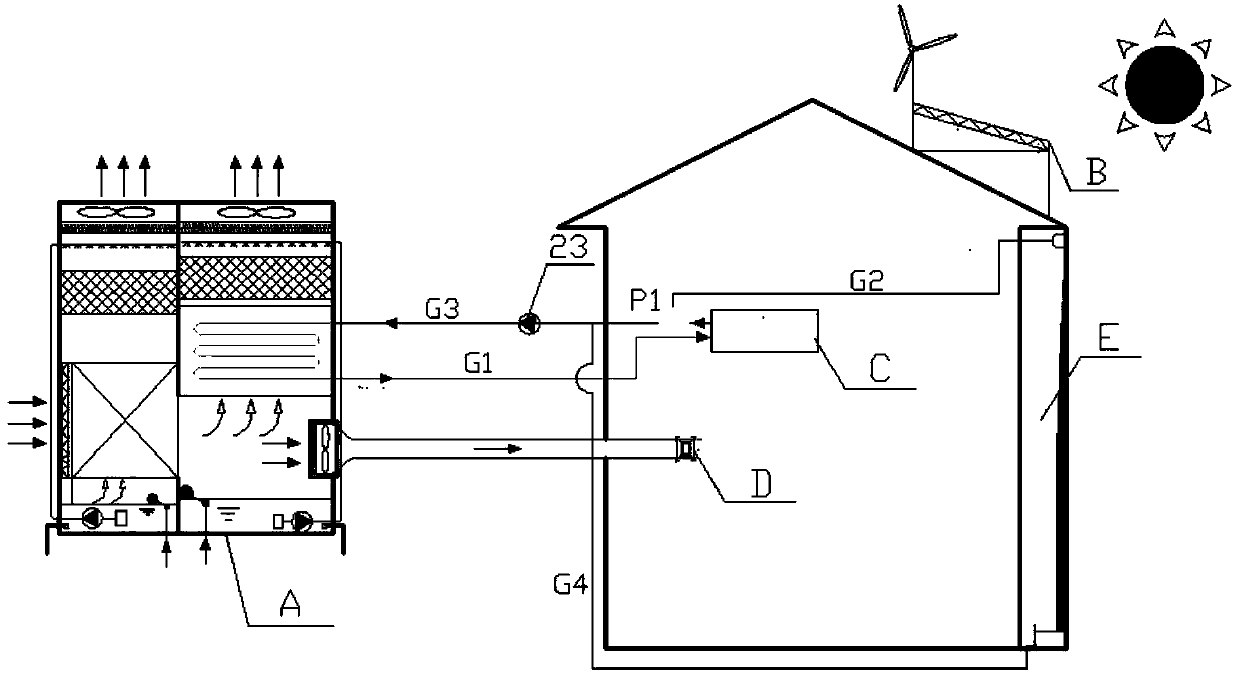

Evaporative cooling air-conditioning system, dispense with water tank for cool storage, utilizing wind and solar power generation

ActiveCN103743012ASimple structureSave spaceLighting and heating apparatusClimate change adaptationEvaporative coolerCold air

The invention discloses an evaporative cooling air-conditioning system, dispense with a water tank for cool storage, utilizing wind and solar power generation. The evaporative cooling air-conditioning system is formed by an evaporative cooling cold air / water unit, a wind and solar power generation system and a water curtain wall structure, wherein the water and wind power generation system is arranged on an external roof, and the water curtain wall structure is adopted for the side walls of a house. The evaporative cooling cold air / water unit is connected with the tail end in the house through a water feeding pipe and a water return pipe respectively. An air port is formed in the house, and the evaporative cooling cold air / water unit is communicated with the air port through an air duct. According to the evaporative cooling air-conditioning system, the evaporative cooling air-conditioning technology, the wind and solar power generation technology, the cool storage technology and the water curtain wall technology are combined, the peak-valley electricity price difference at night and in the day is utilized for forming cold air and cold water, the purposes of ventilation and cool storage at night are achieved, and therefore the evaporative cooling air-conditioning system is environmentally friendly and economical and saves energy.

Owner:新疆华奕新能源科技有限公司

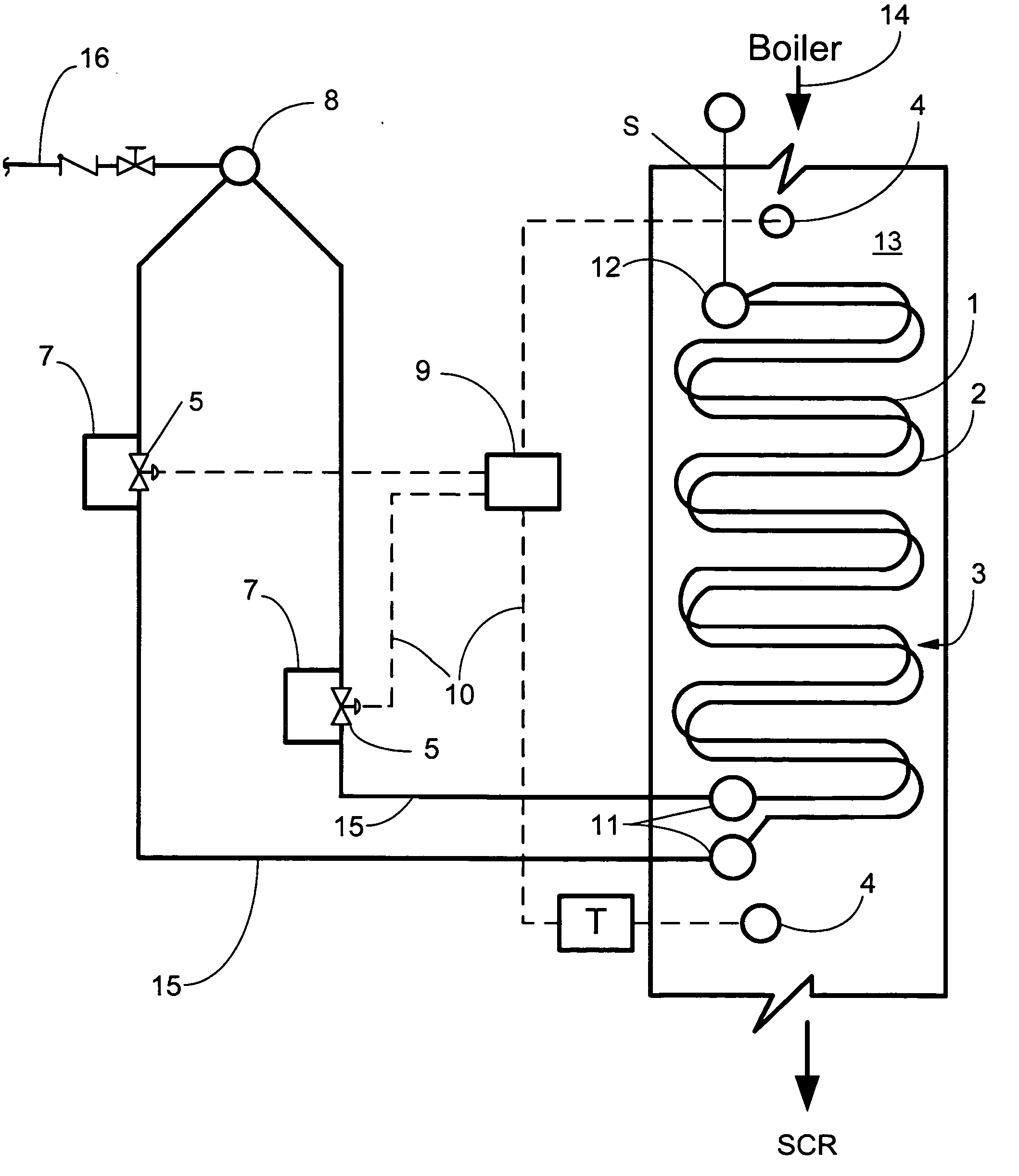

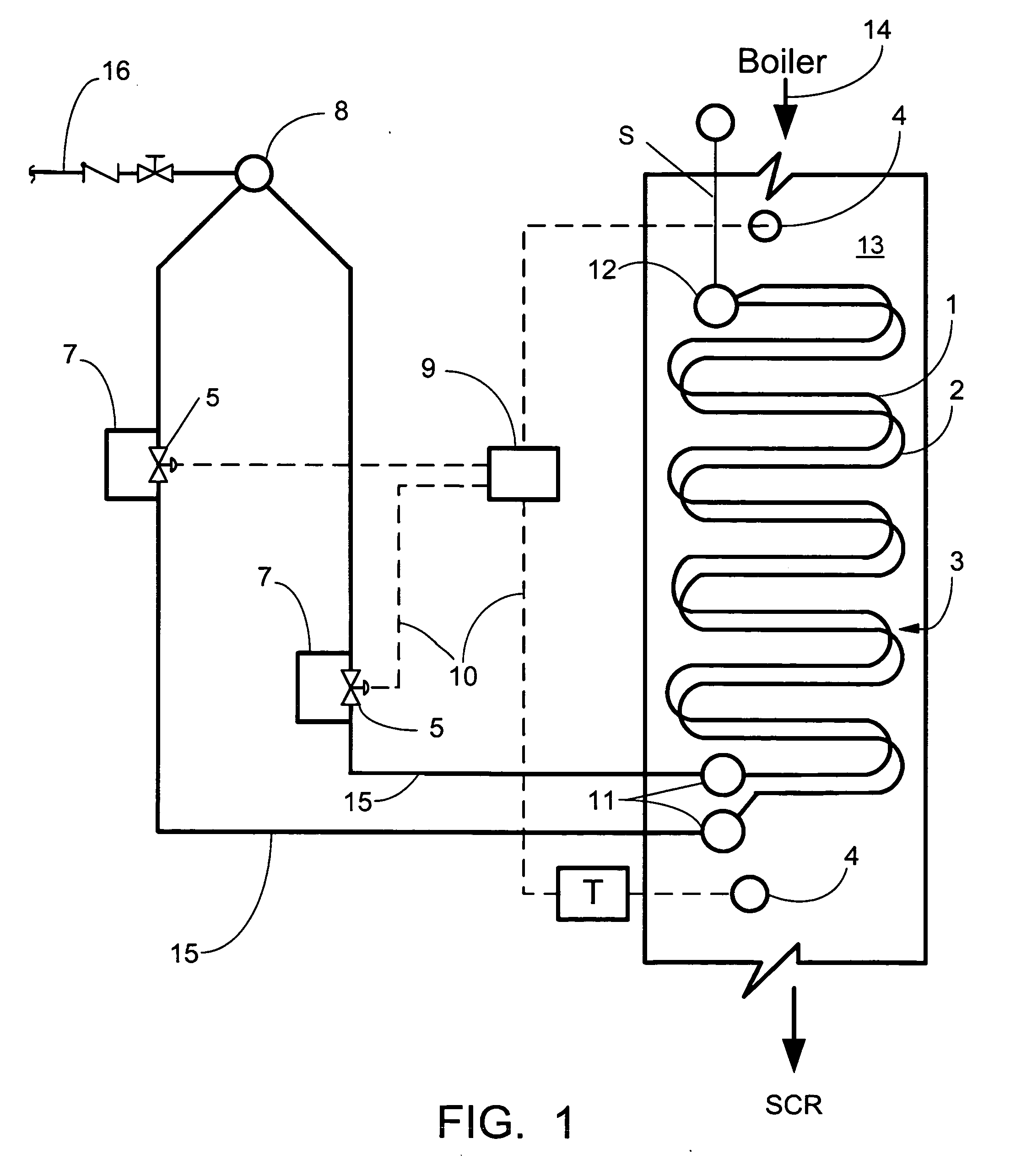

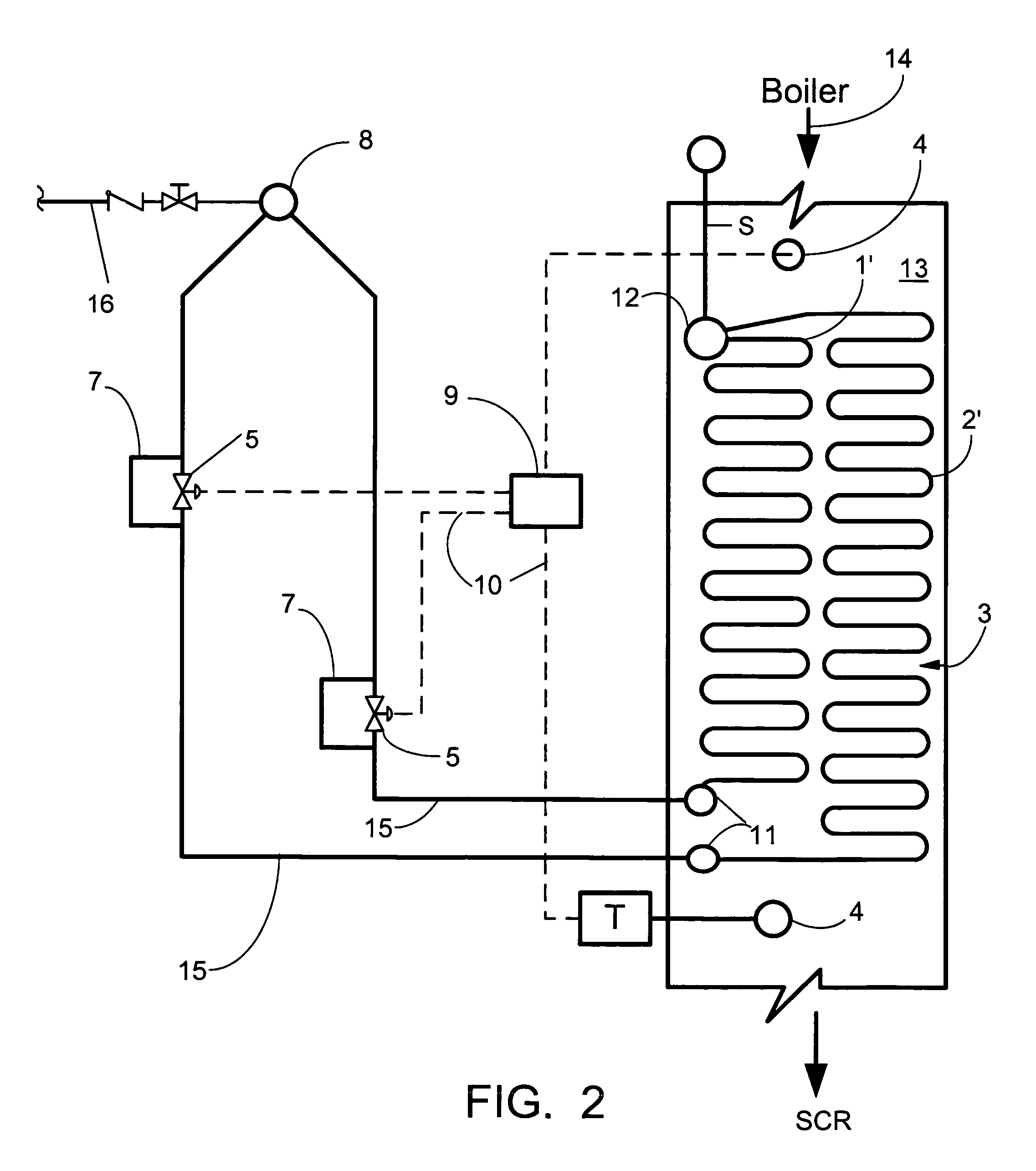

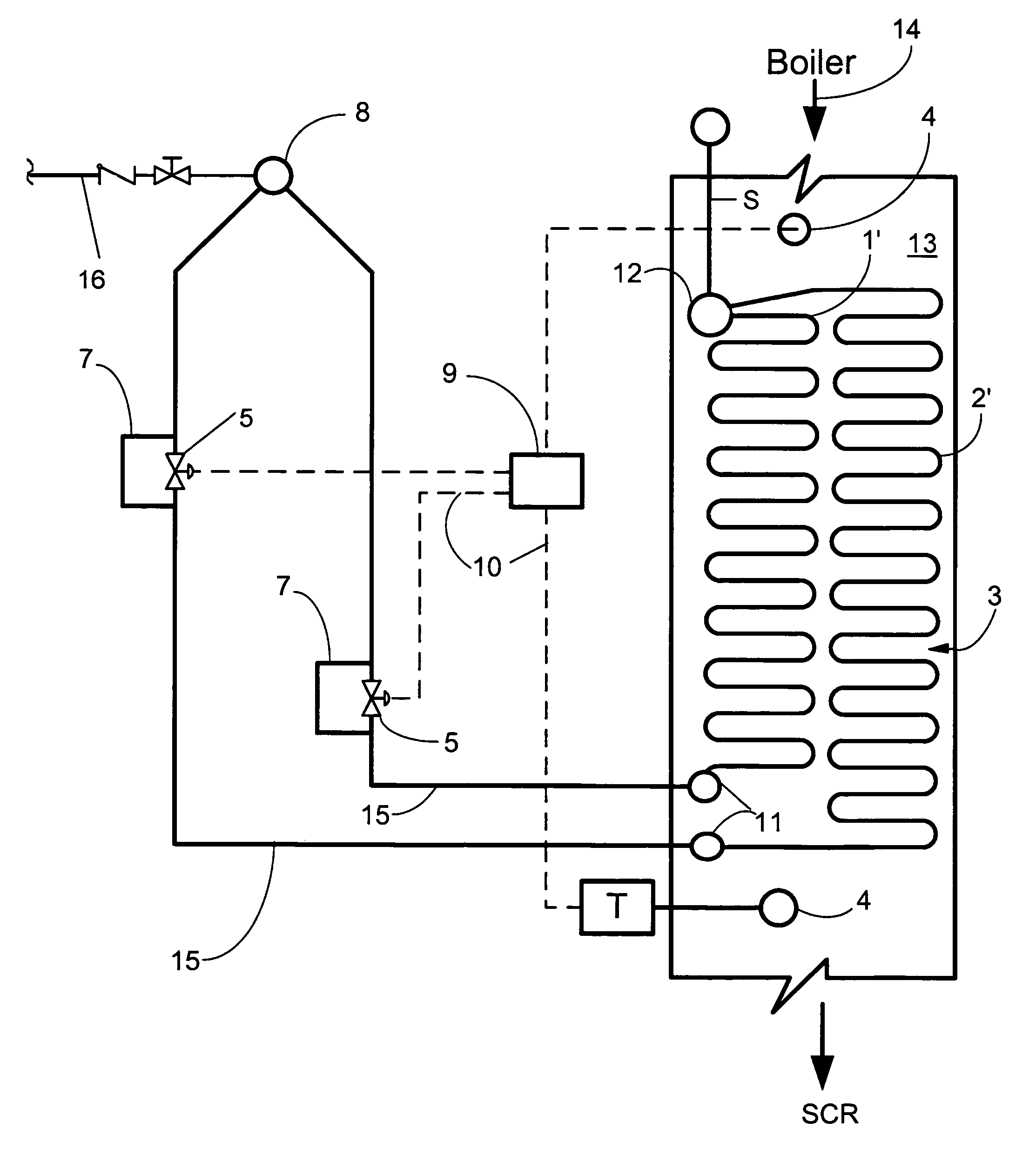

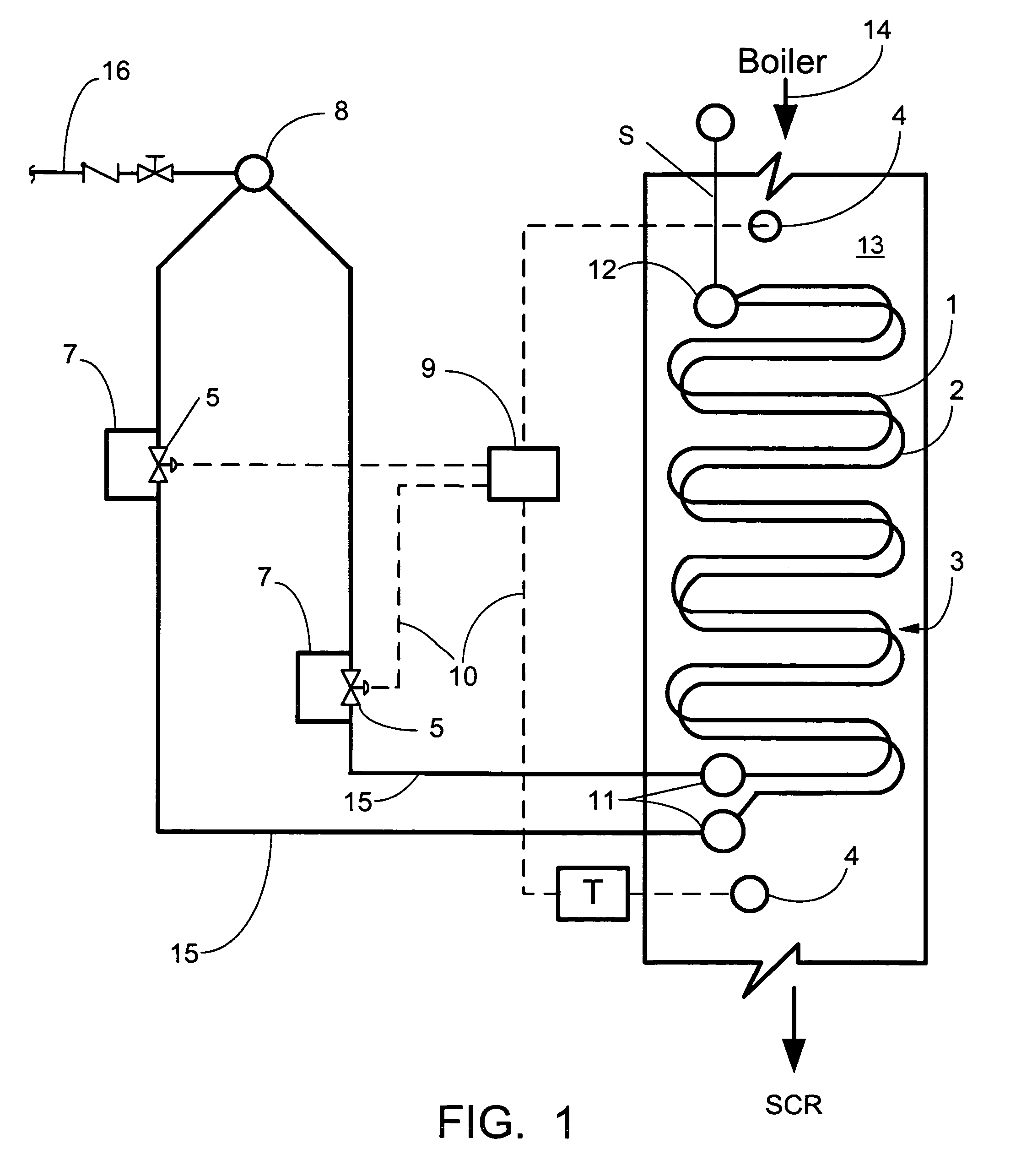

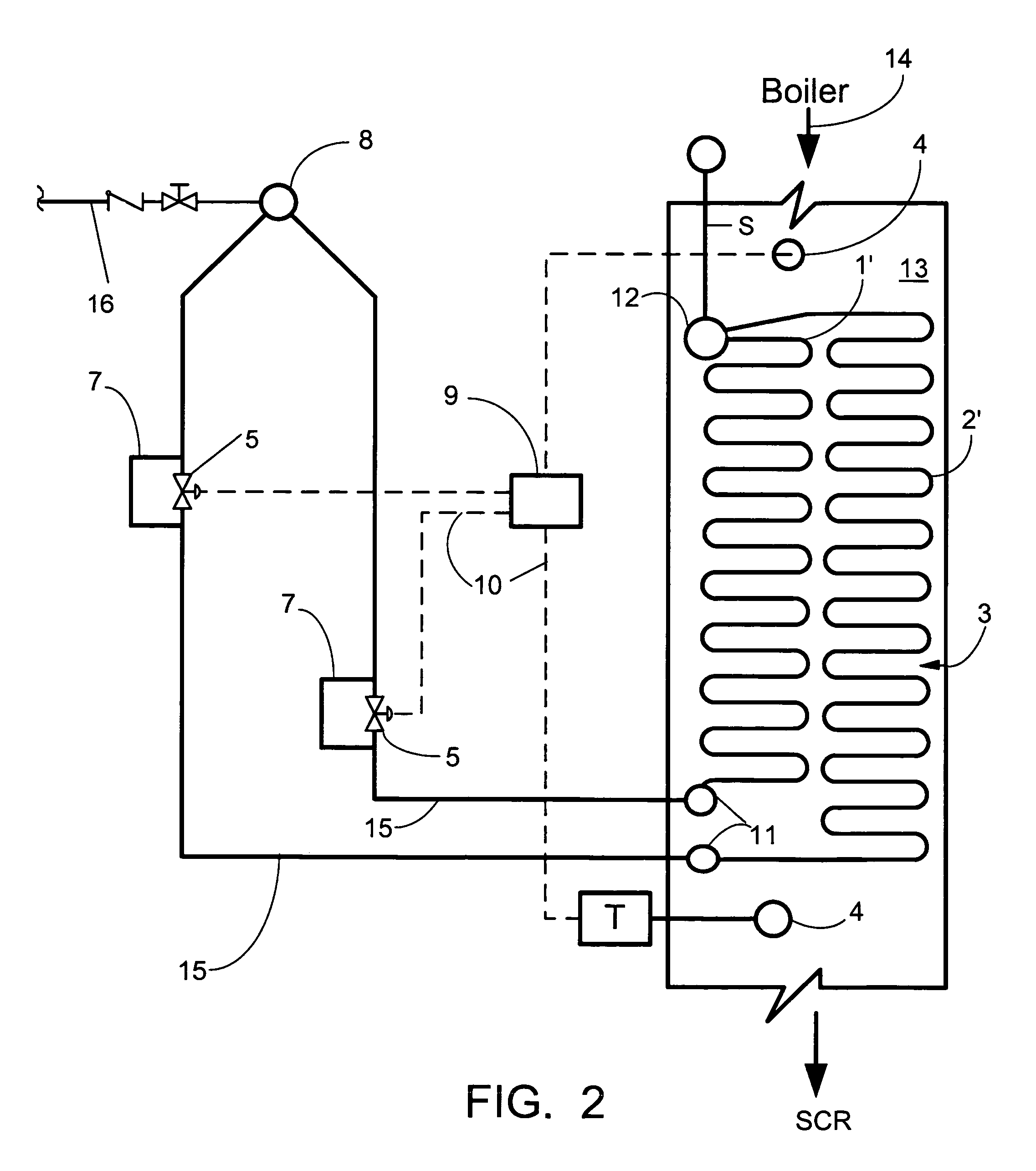

Multiple pass economizer and method for SCR temperature control

InactiveUS20070261647A1Raise outlet temperatureReduce water flowWater circulationFuel injection apparatusFlueProduct gas

A gas temperature control system for maintaining a desired economizer outlet gas temperature across a range of boiler loads comprises a plurality of tubular configurations having surfaces that are in contact with the flue gas. Each tubular configuration, preferably, comprises a plurality of serpentine or stringer tubes arranged horizontally or vertically back and forth within the economizer, and each tubular configuration having a separate feedwater inlet. Heat transfer from the flue gas is accomplished by controlling the feedwater flow rates through the tubular configurations. In a temperature control system having two tubular configurations, the overall heat transfer capacity of the economizer may be reduced to maintain the desired economizer outlet gas temperature during low boiler loads by reducing feedwater flow through one tubular configuration and by overflowing the other tubular configuration, such that total flow of feedwater through the economizer is maintained substantially constant. Feedwater flow rate entering the economizer may be used to engage / disengage the economizer water internal proportion or bias system. Once engaged, the measured feedwater flow to the economizer is used to generate a proportioned or biased flow rate demand signal. The demand signal is then compared to the measured underflow proportioned or biased flow rate. If there is a difference between the demand signal flow rate and the measured flow rate, control valve(s) modulating the proportioned or biased flow is / are adjusted.

Owner:THE BABCOCK & WILCOX CO

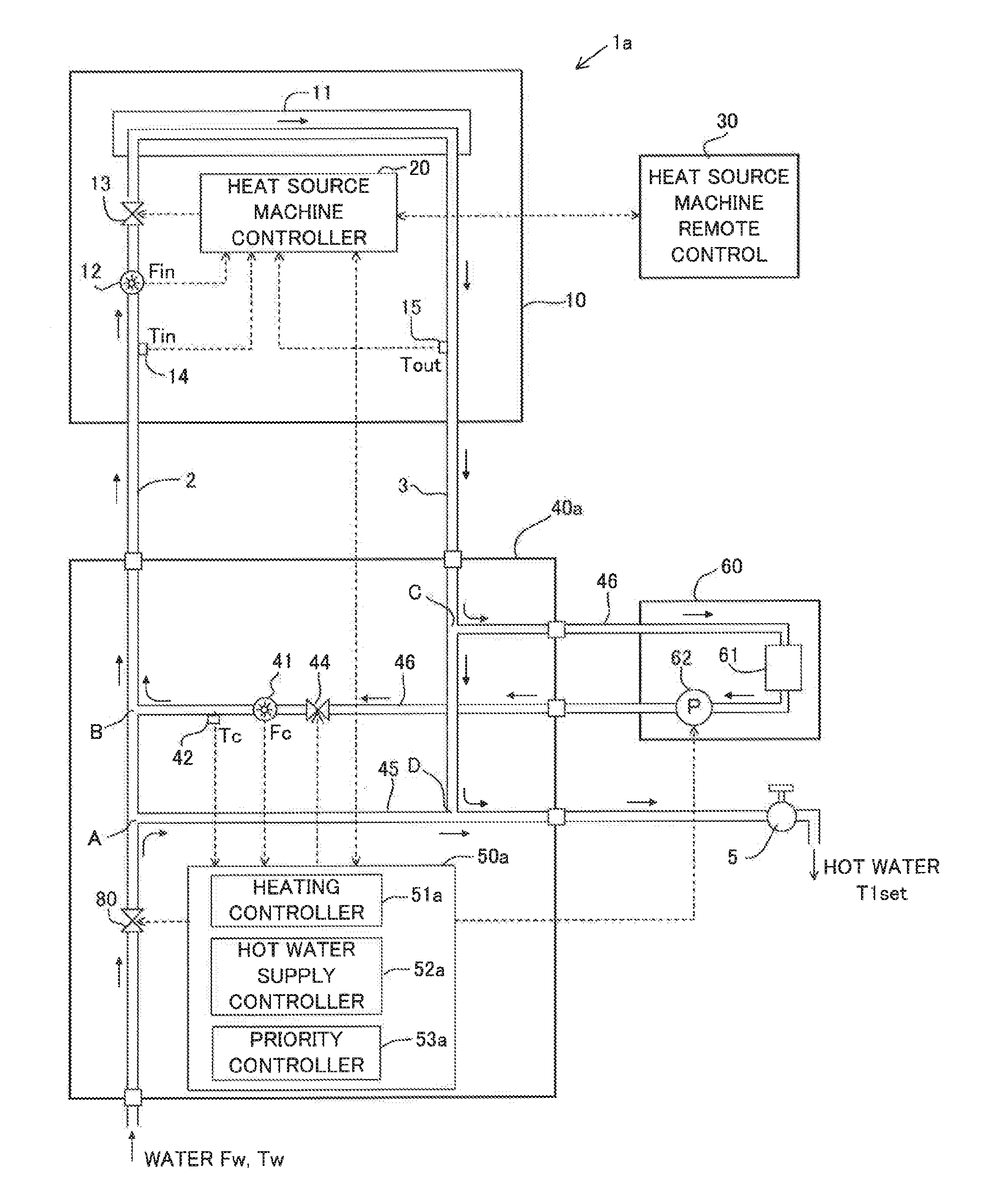

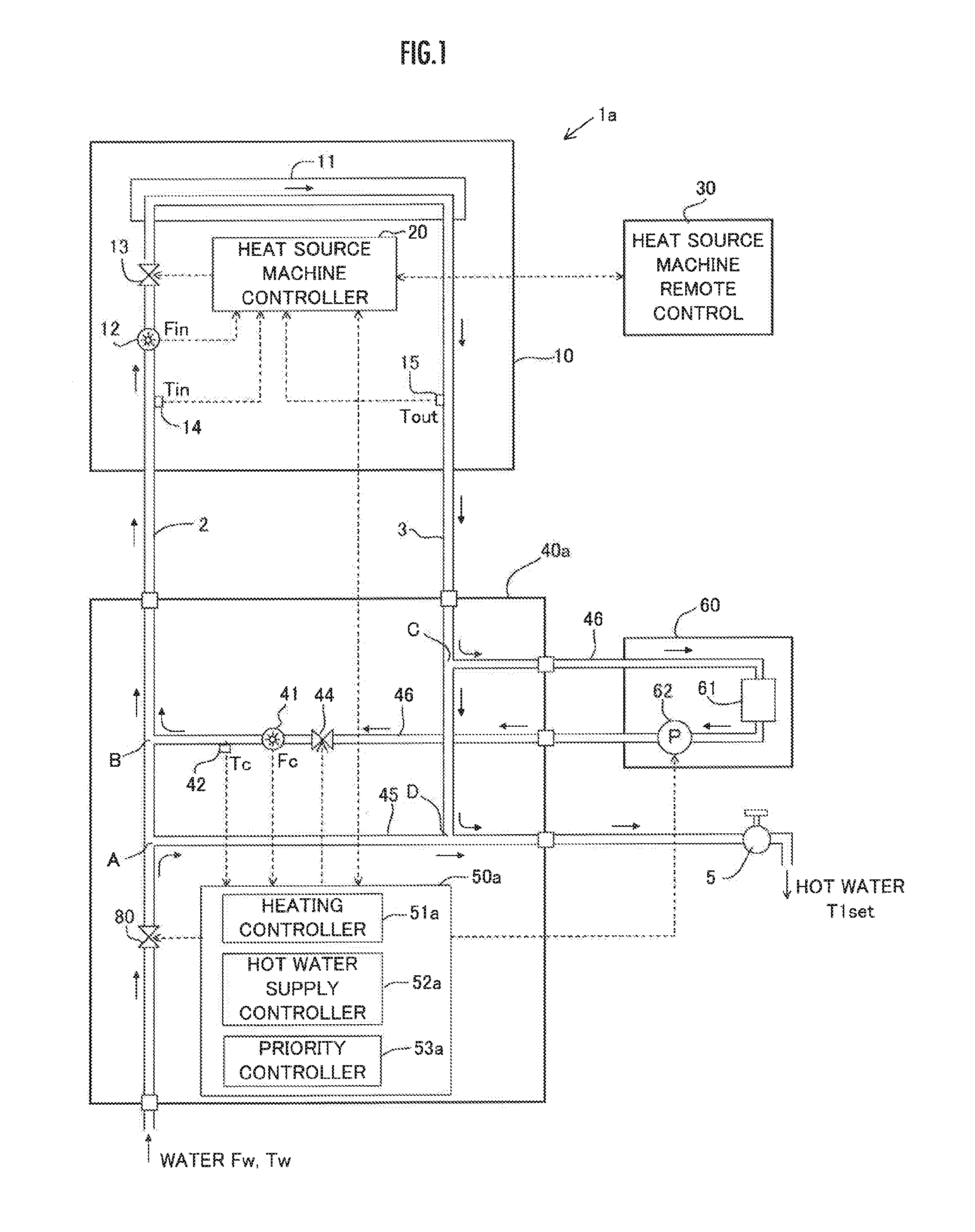

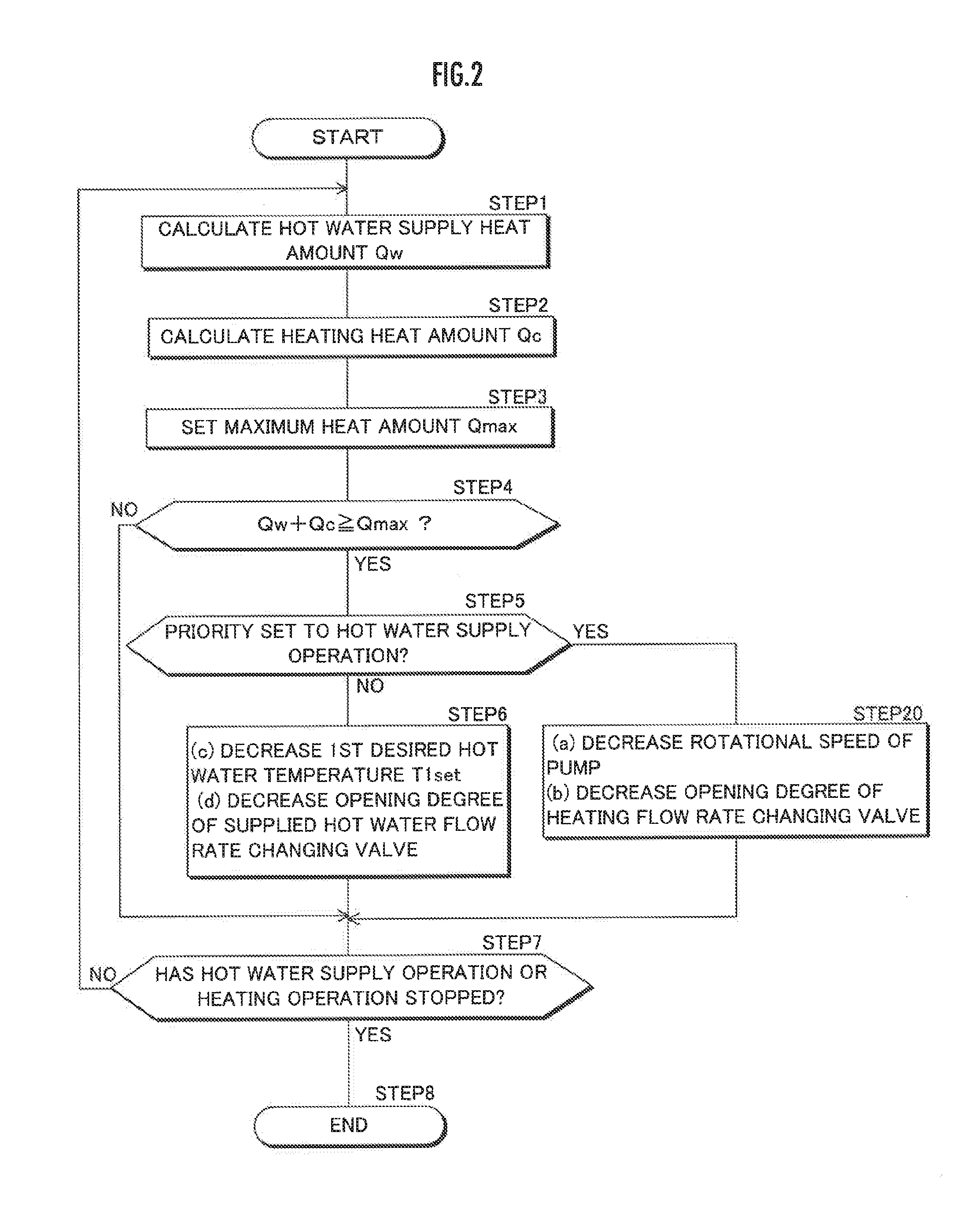

Hot water supply and heating system

InactiveUS20160047558A1Reduce flow rateReduce water flowAir-treating devicesVehicle heating/cooling devicesWater flowEngineering

A hot water supply and heating system 1a includes a heating flow rate changing valve 44 that changes the flow rate of hot water flowing through a heating pipe 46 and a priority controller 53a that carries out hot water supply priority control whereby to reduce the flow rate of the hot water flowing through the heating pipe 46 by the heating flow rate changing valve 44 in the case where the total of the amount of heat consumed in a heating operation and the amount of heat consumed in a hot water supply operation is equal to or more than a maximum amount of heat that can be applied by the heat source machine 10 during a simultaneous operation of the heating operation and the hot water supply operation.

Owner:RINNAI CORP

Multiple pass economizer and method for SCR temperature control

InactiveUS7637233B2Raise the outlet temperatureReduce water flowWater circulationFuel injection apparatusTemperature controlFlue gas

A control system for maintaining a desired heat exchanger outlet flue gas temperature across a range of boiler loads. The heat exchanger includes a plurality of tubular configurations in heat exchange contact with the flue gas with each tubular configuration having a separate feedwater inlet. Flue gas temperature control is achieved by modulating the feedwater flow rates through the tubular configurations. In a system having two tubular configurations, the overall heat transfer capacity of the heat exchanger may be reduced to maintain the desired heat exchanger outlet flue gas temperature by reducing feedwater flow through one tubular configuration and overflowing the other, while maintaining the total flow of feedwater through the heat exchanger substantially constant.

Owner:THE BABCOCK & WILCOX CO

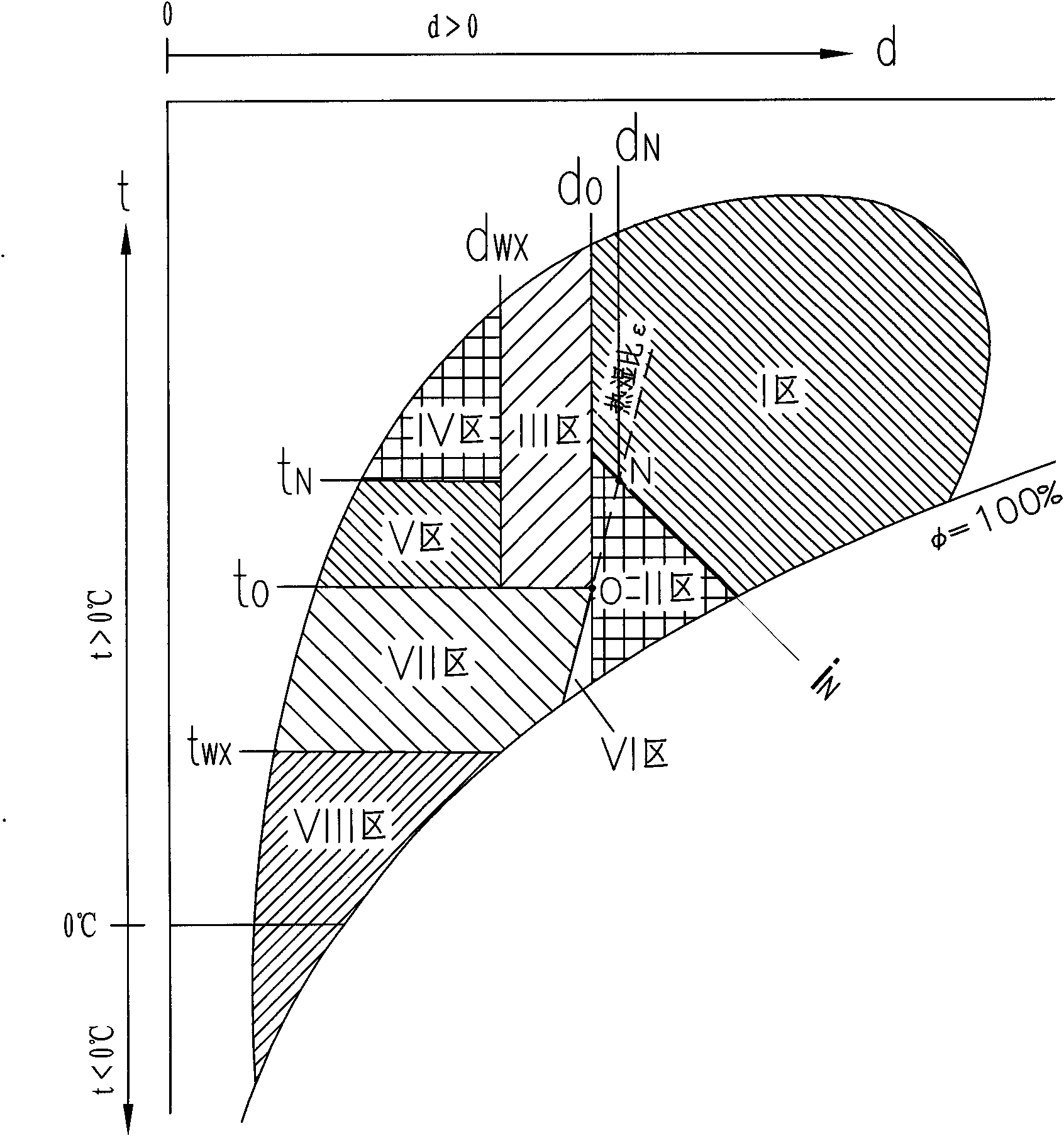

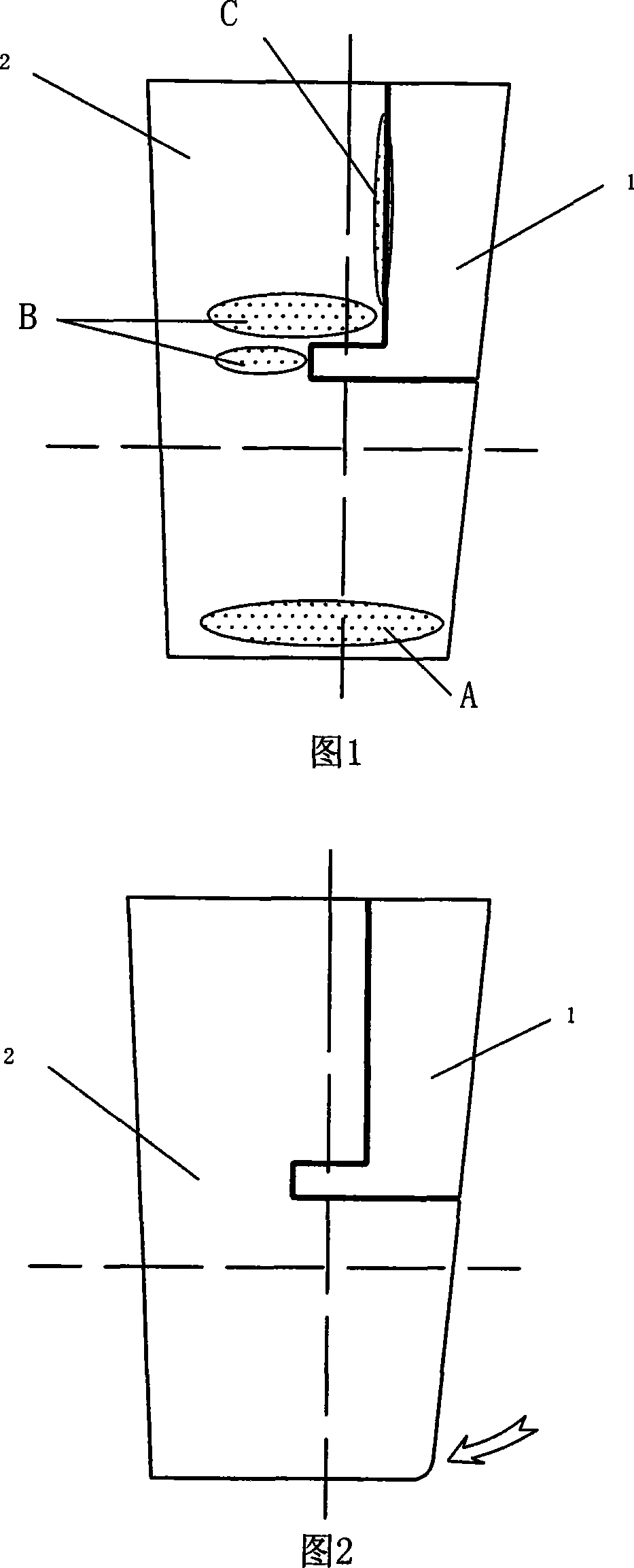

Method for reducing water flow of air conditioning system and dynamic temperature difference flow regulating valve

InactiveCN103047740AReduce energy consumptionReduce water flowOperating means/releasing devices for valvesSpace heating and ventilation safety systemsPipe waterWater flow

The invention discloses a method for reducing a water flow of an air conditioning system and a dynamic temperature difference flow regulating valve. The air conditioning system is composed of devices of a cooling main machine, a heating main machine, a water pump, a fan, a heat exchanging coil pipe and the like. The dynamic temperature difference flow regulating valve comprises a water flow regulating valve, a driver, heat exchanging coil pipe water inlet and outlet temperature sensors, a controller, an indoor air temperature sensor, an indoor air temperature setting device or an indoor cooling and heating load calculator. In the cooling work condition, the controller independently runs after the temperature sensors detect water temperatures and always keeps temperature difference of inlet and outlet water to be at the optimum value so that cooling and dehumidification effects can be guaranteed, and the phenomenon that large flow and small temperature difference occur to a water system is avoided; in the dry cooling work condition or the heating work condition, the controller always keeps the temperature difference of the inlet and outlet water to be at the maximum value according to the indoor air temperature sensor and the indoor air temperature setting device or the indoor cooling and heating load calculator, namely, the dynamic temperature difference flow regulating valve can achieve minimum flow operation in multiple work conditions, and energy consumption of the water pump is further reduced.

Owner:陈建平

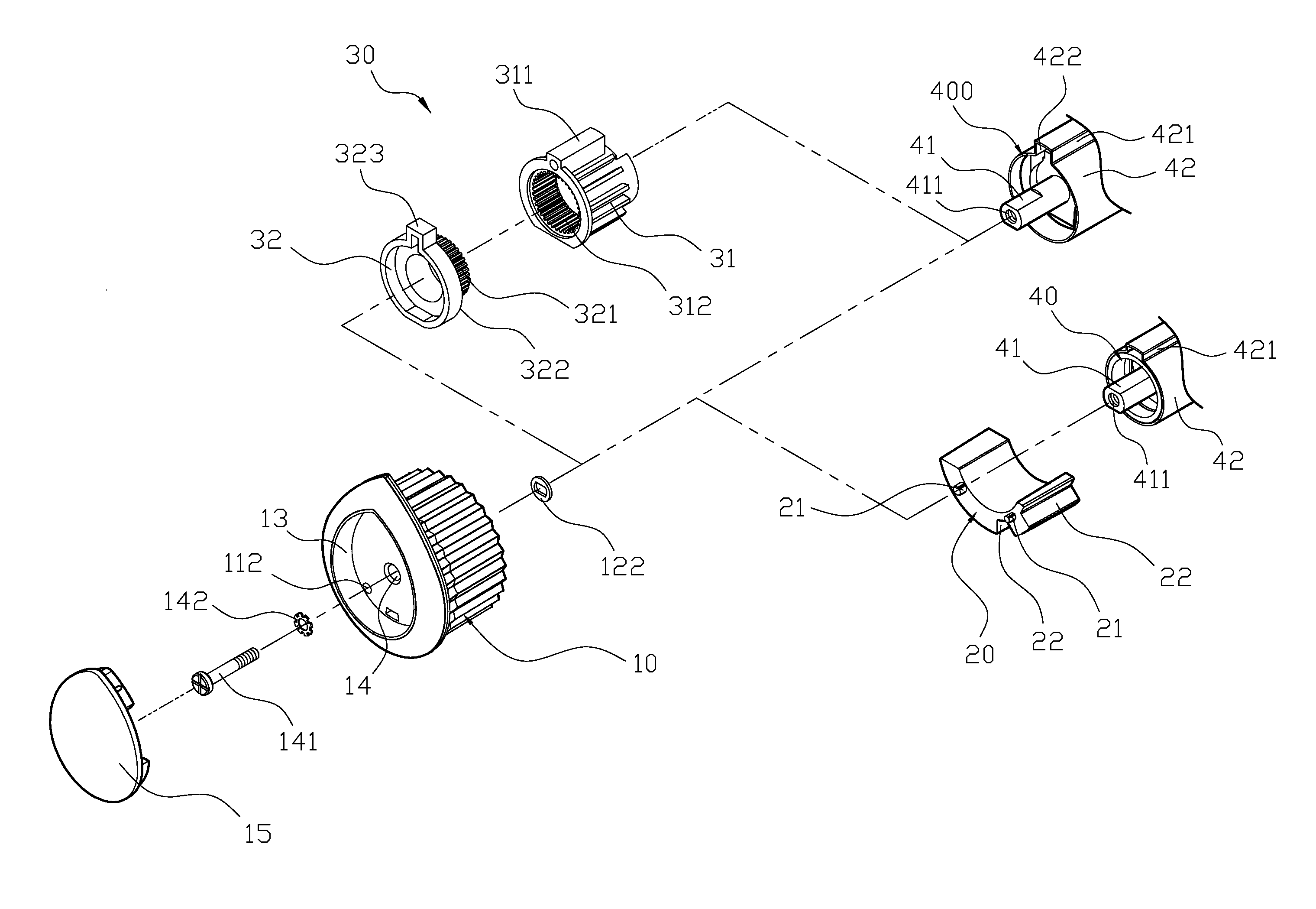

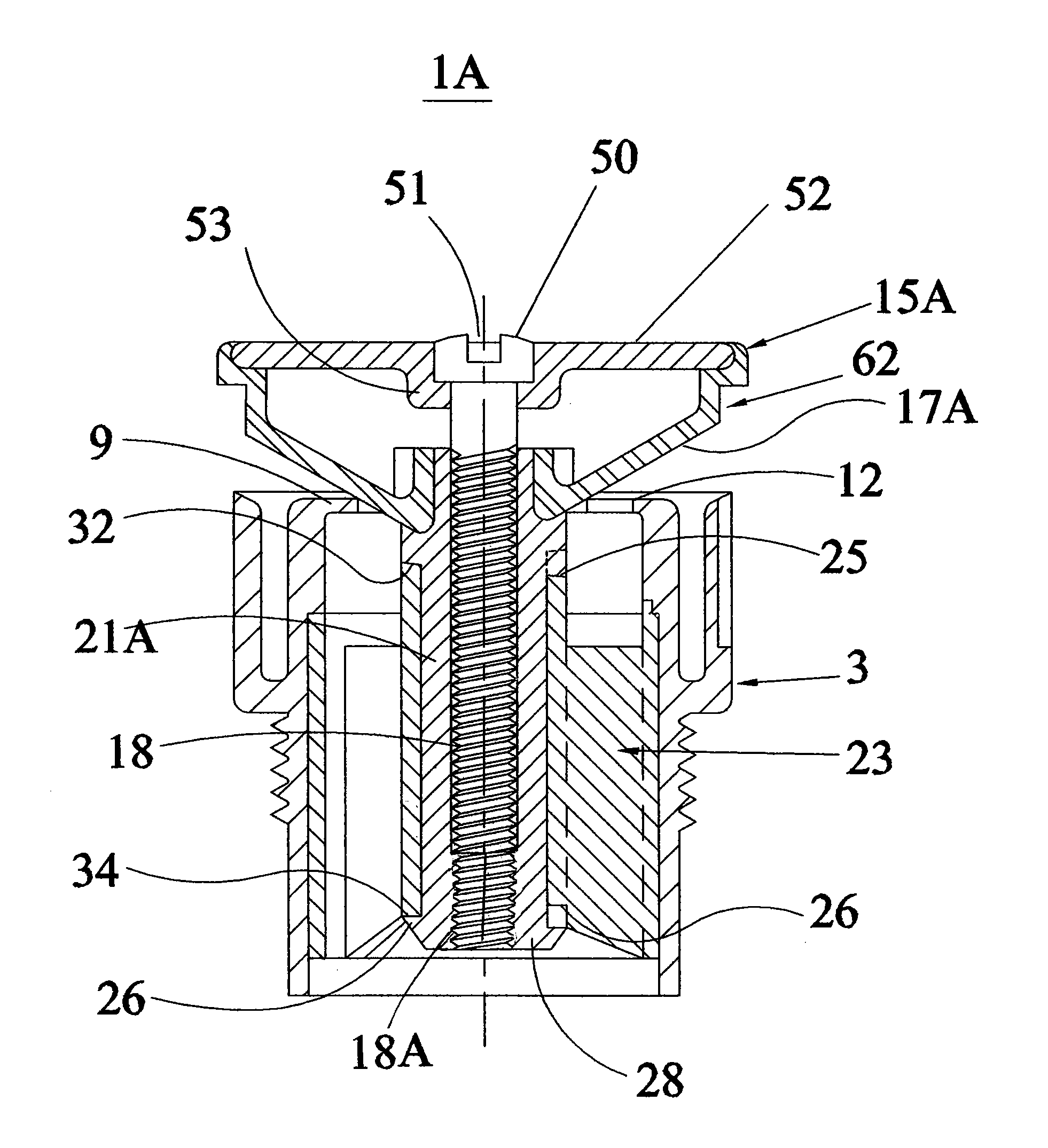

Wall-mounted faucet control module

ActiveUS20130036855A1Improve practicalityReduction in rotation angleControlling membersOperating means/releasing devices for valvesEngineeringControl valves

A wall-mounted faucet control module that can be applied to different water control valves with different sizes, includes two control handles, two transforming heads, a restricting device and a panel set, wherein detachable transforming heads and conversion block are located at the receiving space of two control handles, and the panel set has detachable adjusting sheets and positioning sleeves, The conversion block is located at the receiving space of the control handle, so that the wall-mounted faucet control module can be used for water control bases of different sizes to increase the practicability of the faucet handle and panel set, and increase the convenience in assembly process.

Owner:ALEXANDER YEH IND

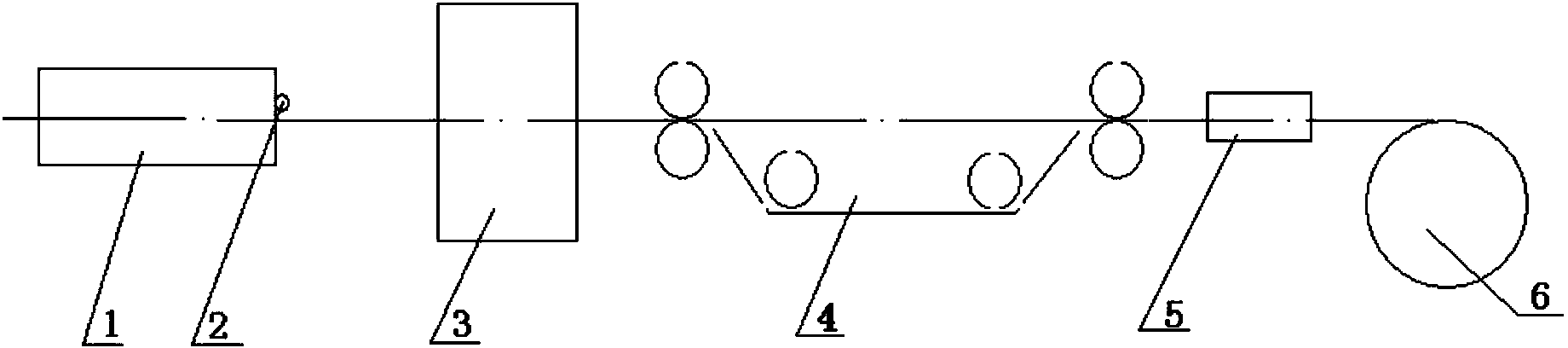

Pickling process and device utilizing residual heat of hot rolled silicon steel strip

The invention discloses pickling process and device utilizing residual heat of a hot rolled silicon steel strip. According to the pickling process, a 120-500 DEG C steel strip which is taken out from a cooling section of a normalizing furnace enters a shot blasting machine to carry out shot blasting and then directly enters the bottom of a pickling tank to carry out pickling, and the steel strip after pickling enters a reeling machine to carry out reeling to obtain a steel strip to be rolled, wherein an oxide scale of the steel strip to be rolled is removed. With the adoption of the pickling process and device, as the residual heat of the silicon steel strip after normalizing is utilized to carry out pickling, the reaction speed of the oxide scale and acid at high temperature is increased, the effect is better, the concentration and the temperature of the acid can be lowered, the warming is not needed, and the energy is saved; in addition, as the high-temperature steel strip is arranged at the bottom of the pickling tank after entering the pickling tank, the heated acid liquor is difficult to volatilize, and the environment pollution is avoided. Compared with the existing descaling process, according to the pickling process, the adopted equipment is less, a flame heating device can not be needed, the energy, the equipment cost and the production cost are saved, and the pickling process is economic and feasible.

Owner:武汉钢铁有限公司

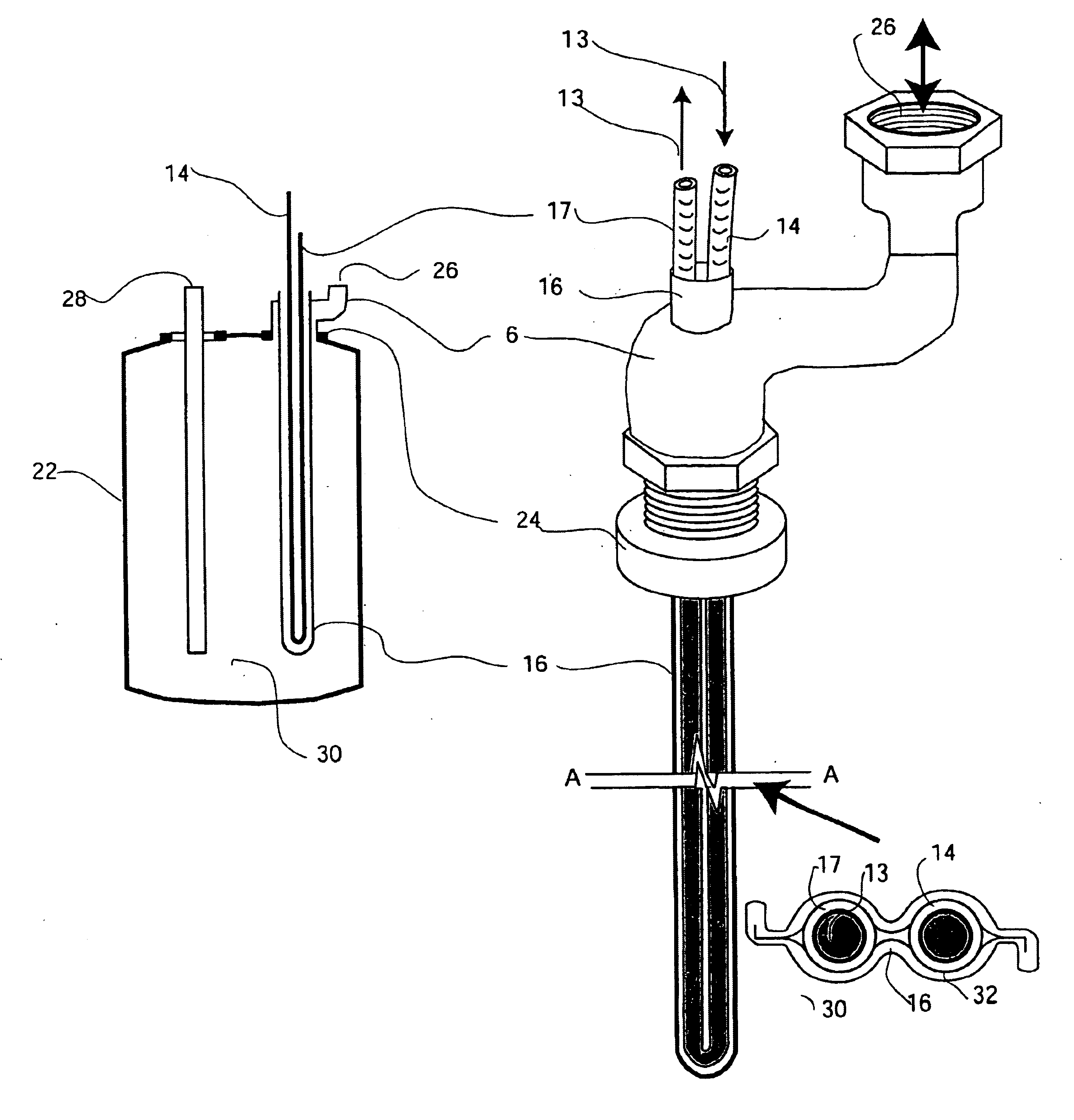

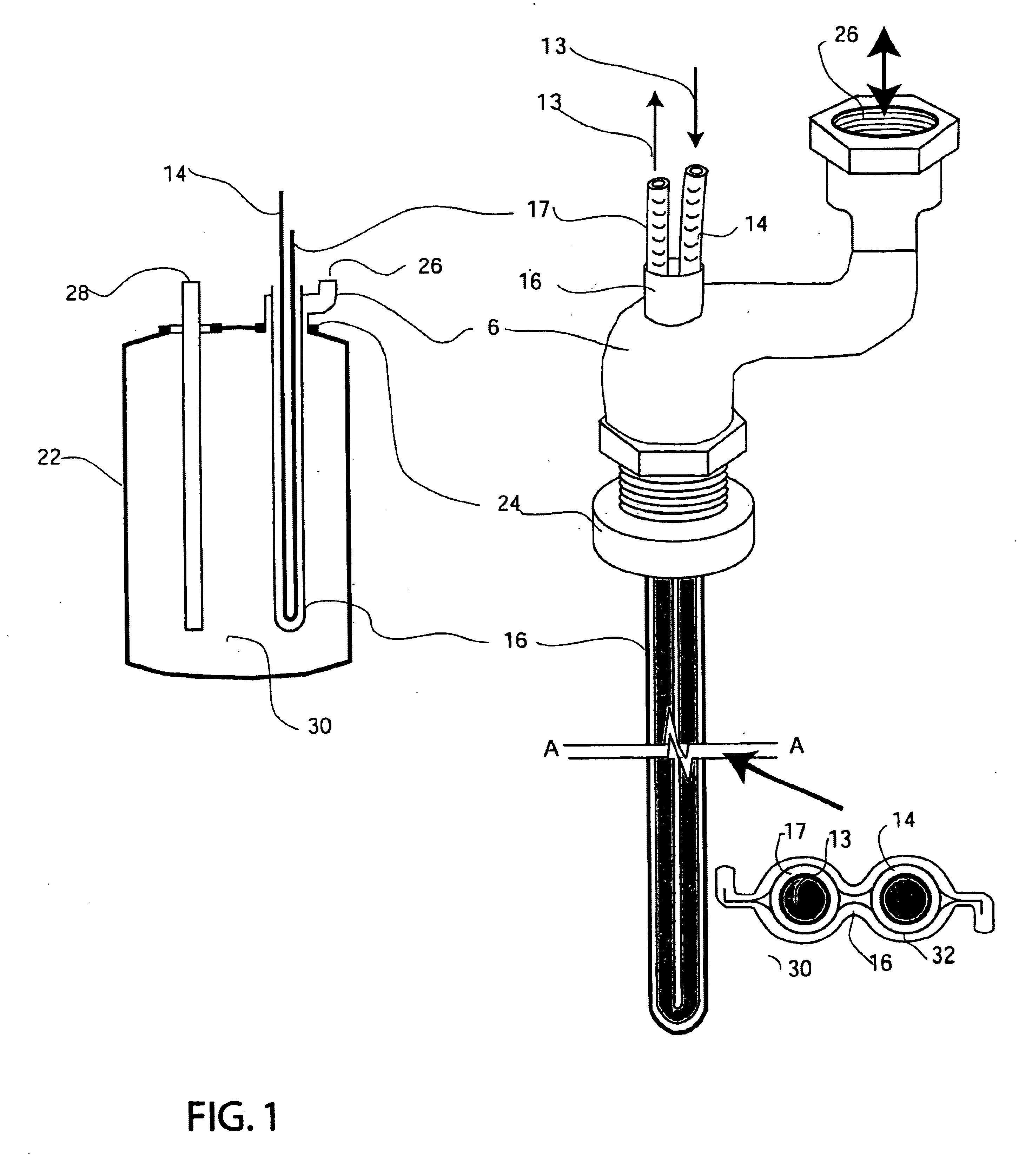

Internal water tank solar heat exchanger

InactiveUS6837303B2Reduce plumbing water flowReduce water consumptionSolar heat devicesHeat storage plantsEngineeringDouble walled

A heat exchanger which is adapted to an existing water tank to allow it to be heated or cooled using a hot or cold toxic or non-toxic liquid. Solar collectors and heat pumps can provide hot or cold liquids. To transfer this heat cheaply and economically to an existing hot or cold, water tank requires a simple efficient heat exchange, which can be easily adapted to the existing tank. The invention recited fills this need by simply screwing into the existing hot or cold, water tank and allow heat or cold to be added or extracted via a simple fluid loop, which is single wall isolated for non-toxic heat exchange fluids and double wall isolated for toxic heat exchange fluids.

Owner:BUTLER BARRY LYNN

Method for reducing vessels stern semi-balance suspension rudder blade surface cavitation

The invention relates to a method reducing cavitation on the surface of a half-balanced suspension rudder leaf at the tail of the ship. The method adopts the measures in the area of the half-balanced suspension rudder leaf which is easy to be cavitated: (1) the right angle at the riverside position at the lower edge of the rudder leaf is changed into fillet; (2) a guide fin is additionally added at the vertical rudder from the lower edge of the rudder leaf to the midpoint of the central line of the oar shaft; (3) a guide bar is additionally added nearby the frontage of the connection between the rubber supporting and the rudder leaf. After adopting the method of the invention, the change of the linetype of the tangential plane of the rear rudder is flat, and the vortex cavitation of a prop can still keep vortex cavitation when floats to the lower edge of the rudder leaf and does not cavitate the rudder leaf at the position; when the rudder angle turns to a certain angle, the prop vortex cavitation floated to the position does not change the performance owning to the demulcent change of pressure field; meanwhile, with the wake flow continuing to drift to the rear of the ship, the added guide bar can reduce the water flux flowing to the clearance and leads the water flow to stably slide by; meanwhile, the unavoidable cavitation is guided out of the surface of the rudder surface, thus relieving the cavitation phenomenon at the position.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

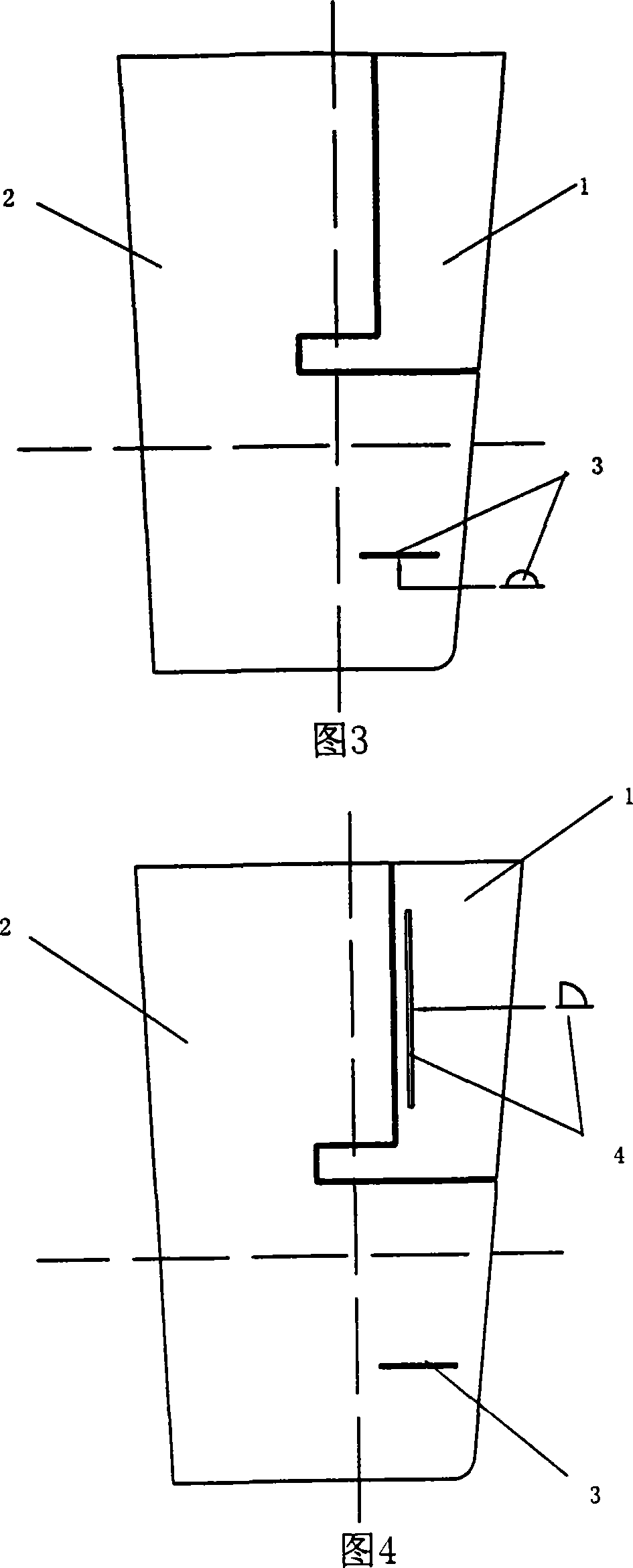

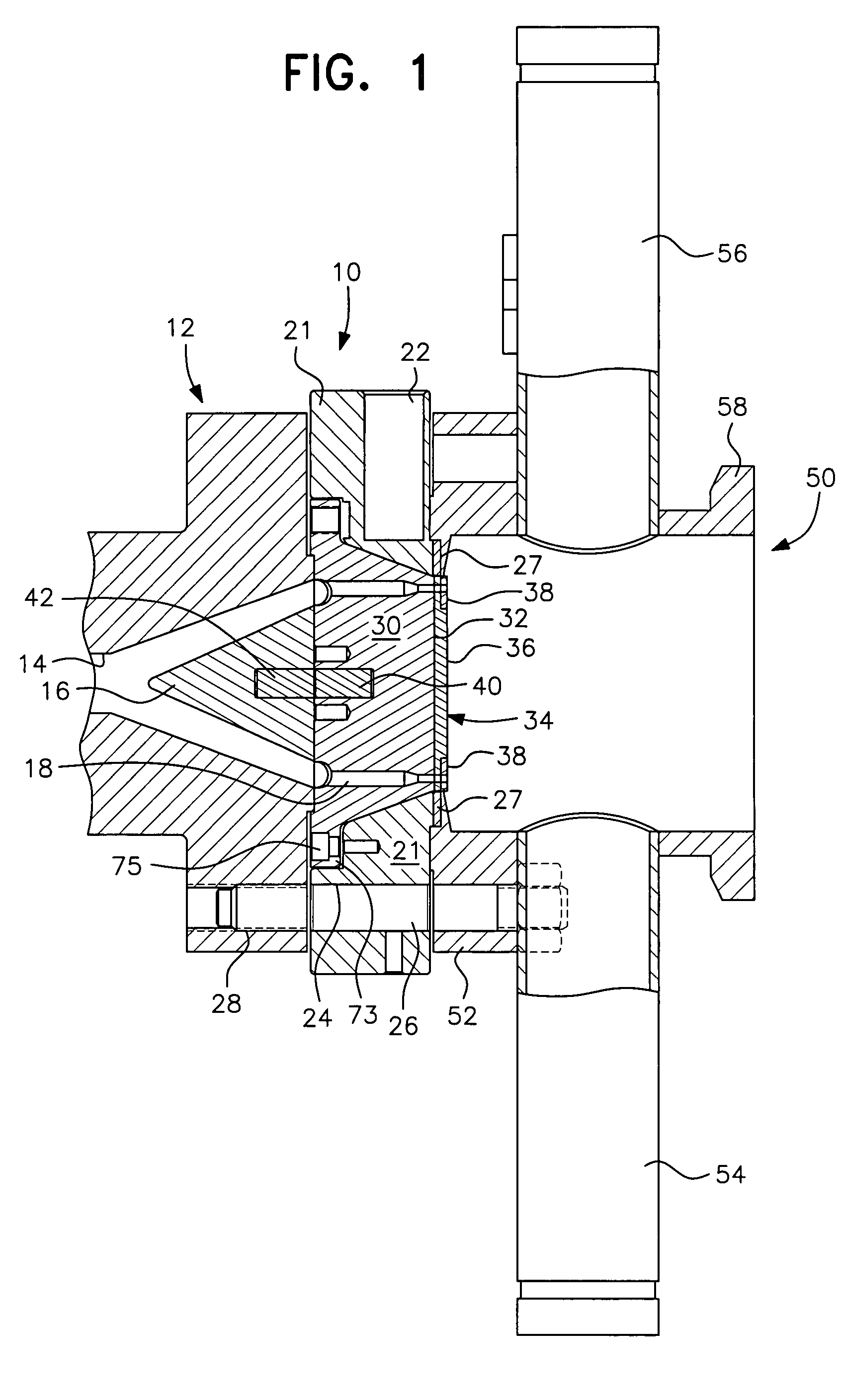

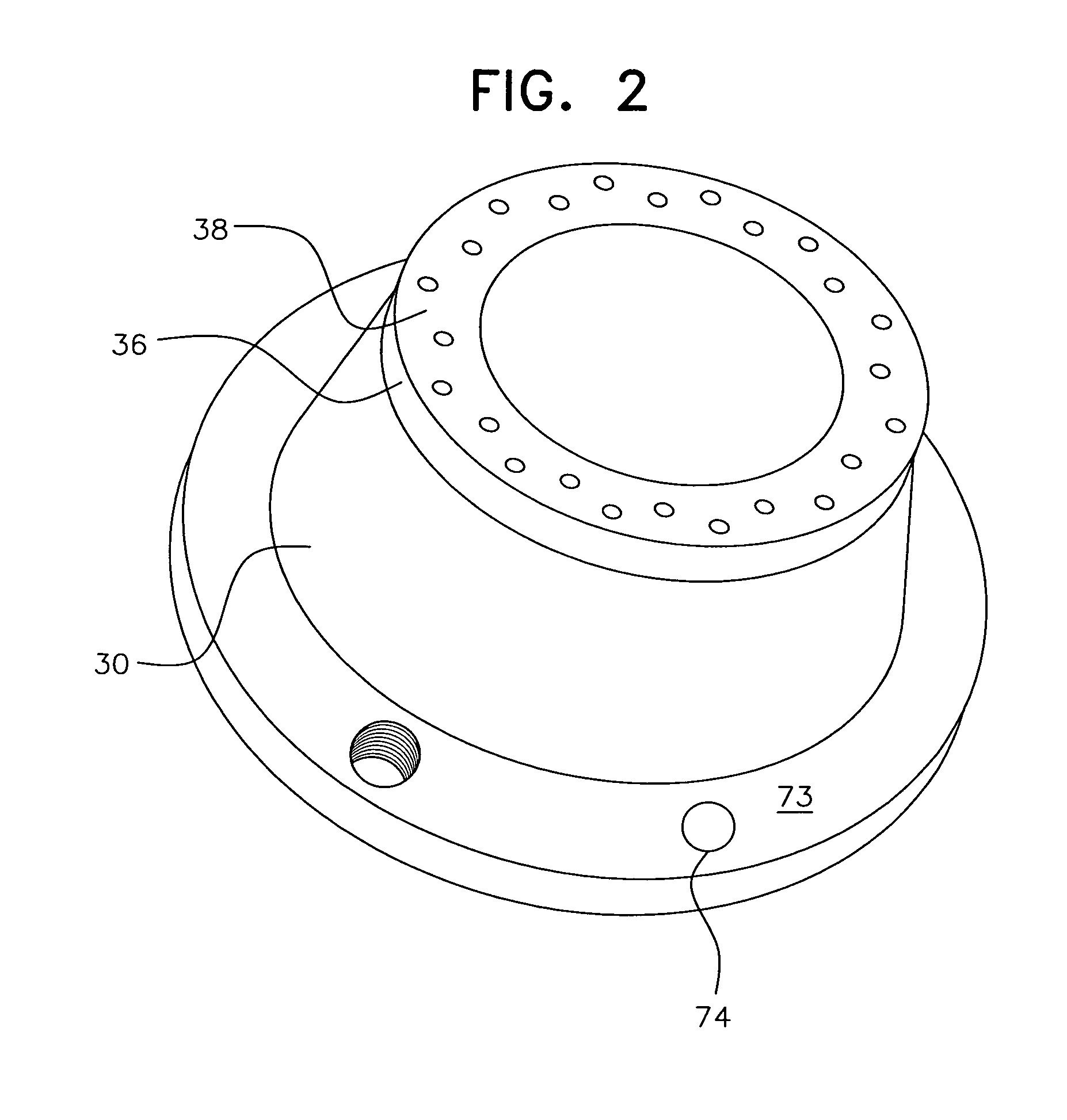

Solid face die plate

A solid face die plate for an underwater pelletizer includes a carrier or holding plate having a circular slot for holding a hard anti-wear element of highly wear-resistant material through which the extrusion orifices open for extruding polymer. The solid face die plate eliminates the need for insulation or plugging material in the center of the die plate and, by embedding the hard anti-wear element within the carrier, protects the edges of the hard anti-wear element for longer wear life.

Owner:GALA INDUSTRIES INC

Air conditioner system energy saving method and device

InactiveCN101865507AReduce energy consumptionImprove efficiencySpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlWater flow

The invention discloses a method of reducing water pump energy consumption and improving host machine efficiency through installing a water flow regulating valve with constant inlet and outlet water temperature difference at the water inlet or the water outlet of an air conditioner system heat exchange coil, and the water flow regulating valve with constant inlet and outlet water temperature difference used for realizing the method. The water flow regulating valve with constant inlet and outlet water temperature difference is formed by a water inlet temperature sensor, a water outlet temperature sensor, a controller, a water flow regulating valve and a regulating valve driver. When the flow and the temperature of air on the air side of the heat exchange coil are varied, after the controller makes a comparison between internal preset corresponding temperature difference and actual inlet and outlet water temperature difference according to the different inlet water temperatures detected by the sensor, the controller outputs a signal to the regulating valve driver to vary water flow to keep the inlet and outlet water temperature difference to be unchanged and to prevent the situation of large flow and small temperature difference from occurring in the system. The controller is connected with the indoor temperature controller of the heat exchange coil. After a closing signal output by the indoor temperature controller of the heat exchange coil is received, the water flow regulating valve is fully closed.

Owner:陈建平

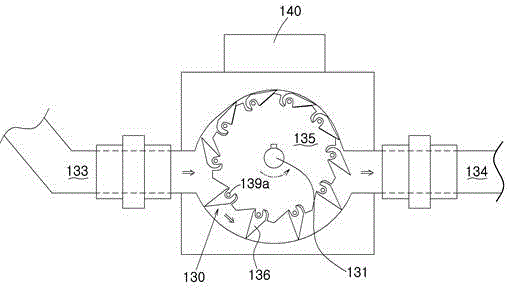

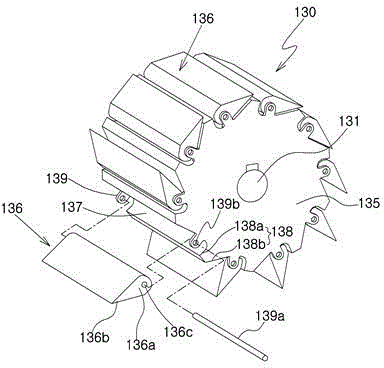

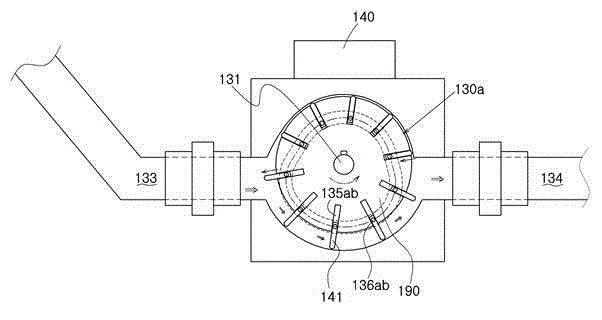

Simple hydraulic power unit

InactiveCN104100450AReduce flow rateReduce water flowWind motor controlEngine componentsTelescopic cylinderElectric energy

The present invention relates to a simple hydraulic power unit which comprises a foldable-wing type waterwheel generating device arranged between pipes and rotates under inflow water pressure. The generating device comprises a cam-type water wheel, a rotating shaft arranged in the center of the cam-type water wheel, and a generating mechanism arranged at one end of the rotating shaft and converting kinetic energy into electricity. The cam-type water wheel comprises a cylindrical body having a rotating shaft inserted in the center and rotating with the rotating shaft, two telescopic blades spacedly arranged on the periphery of the cylindrical body and making the cylindrical body to rotate under inflow water pressure, and cam type slot covers arranged at two side surfaces of the cylindrical body and allowing the telescopic blades to withdraw or protrude along the inner side surface as rotation of the cylindrical body. The simple hydraulic power unit enables the generation of a substantial amount of electricity with a low flow rate and speed.

Owner:CHEONG JUNG TECH

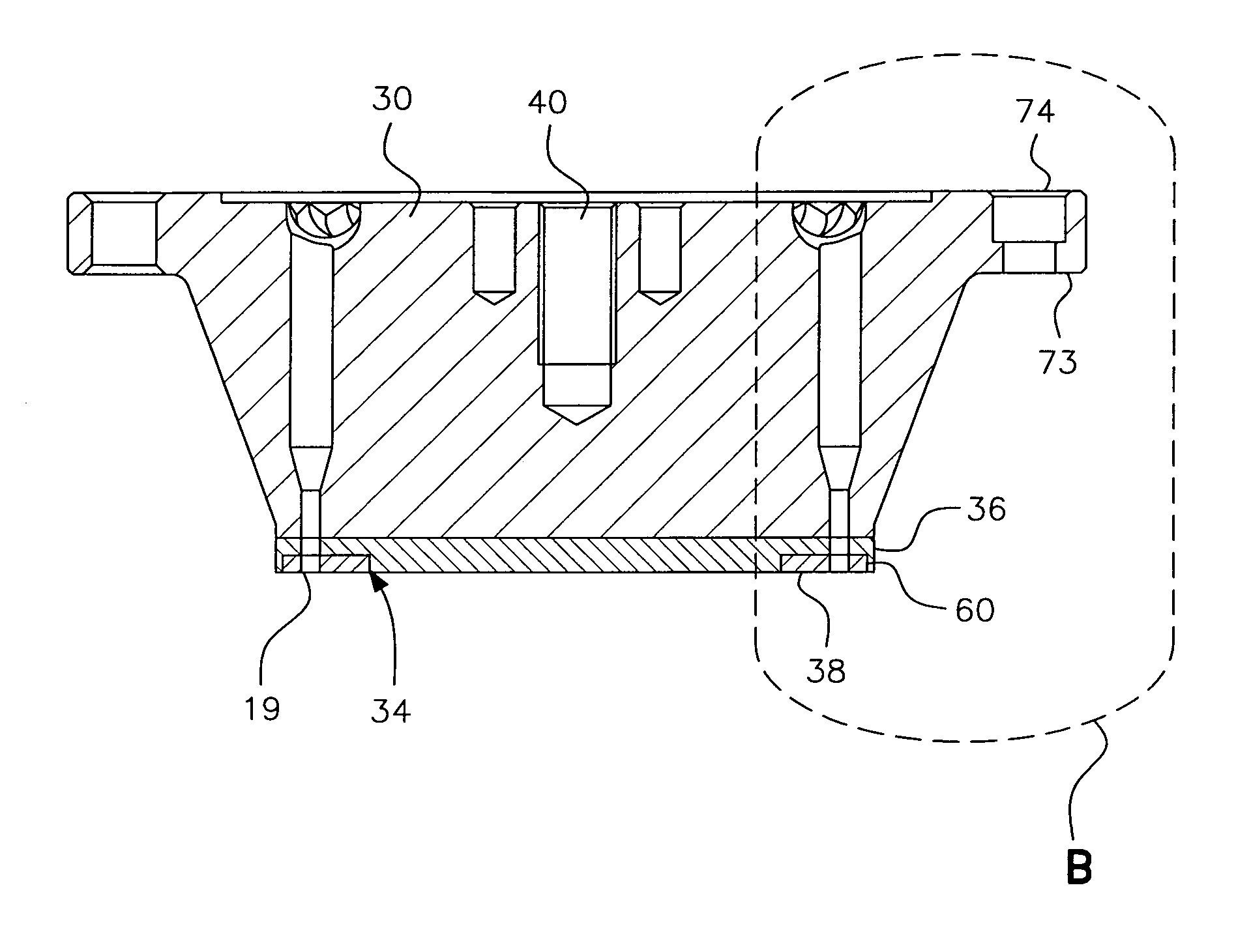

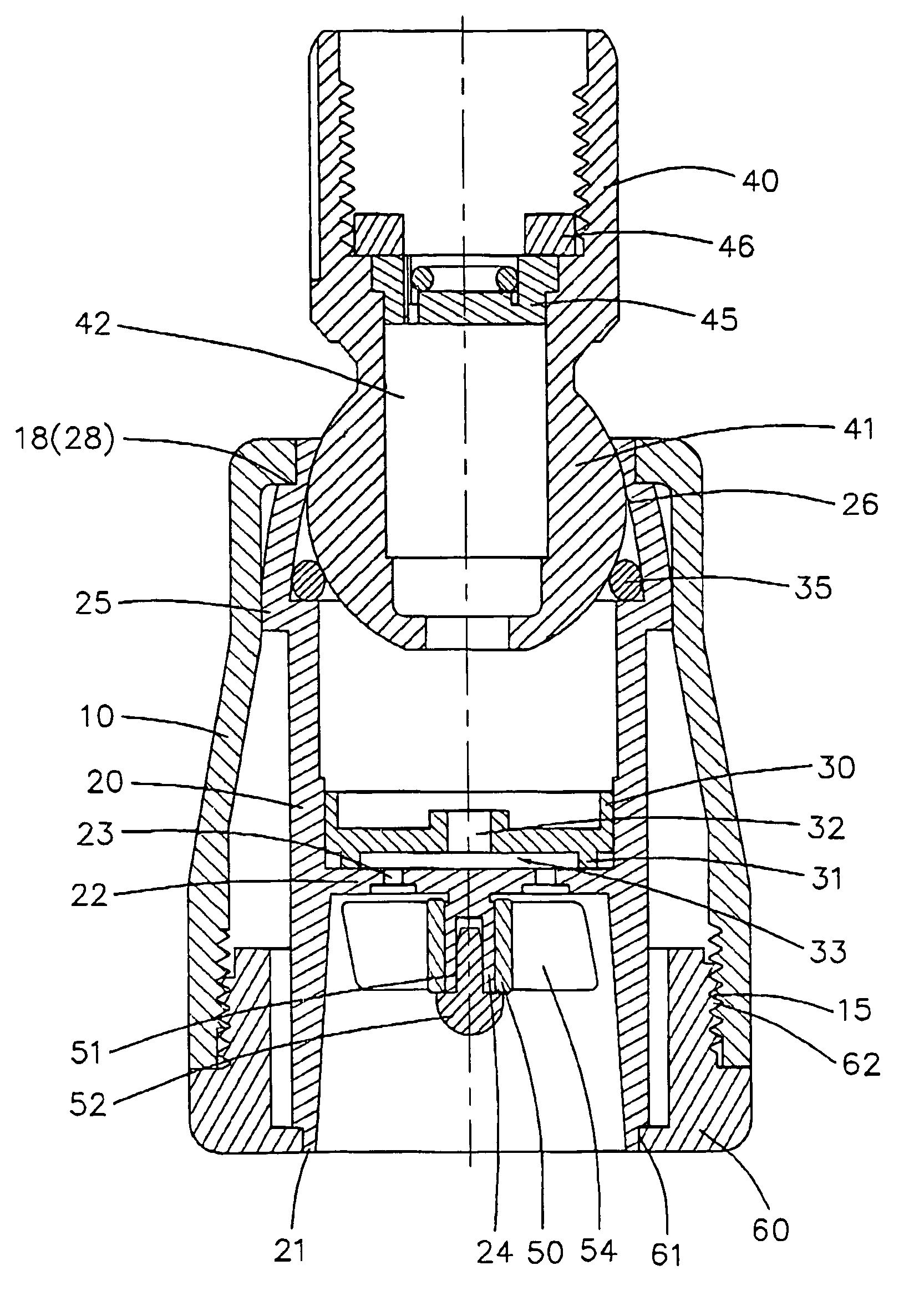

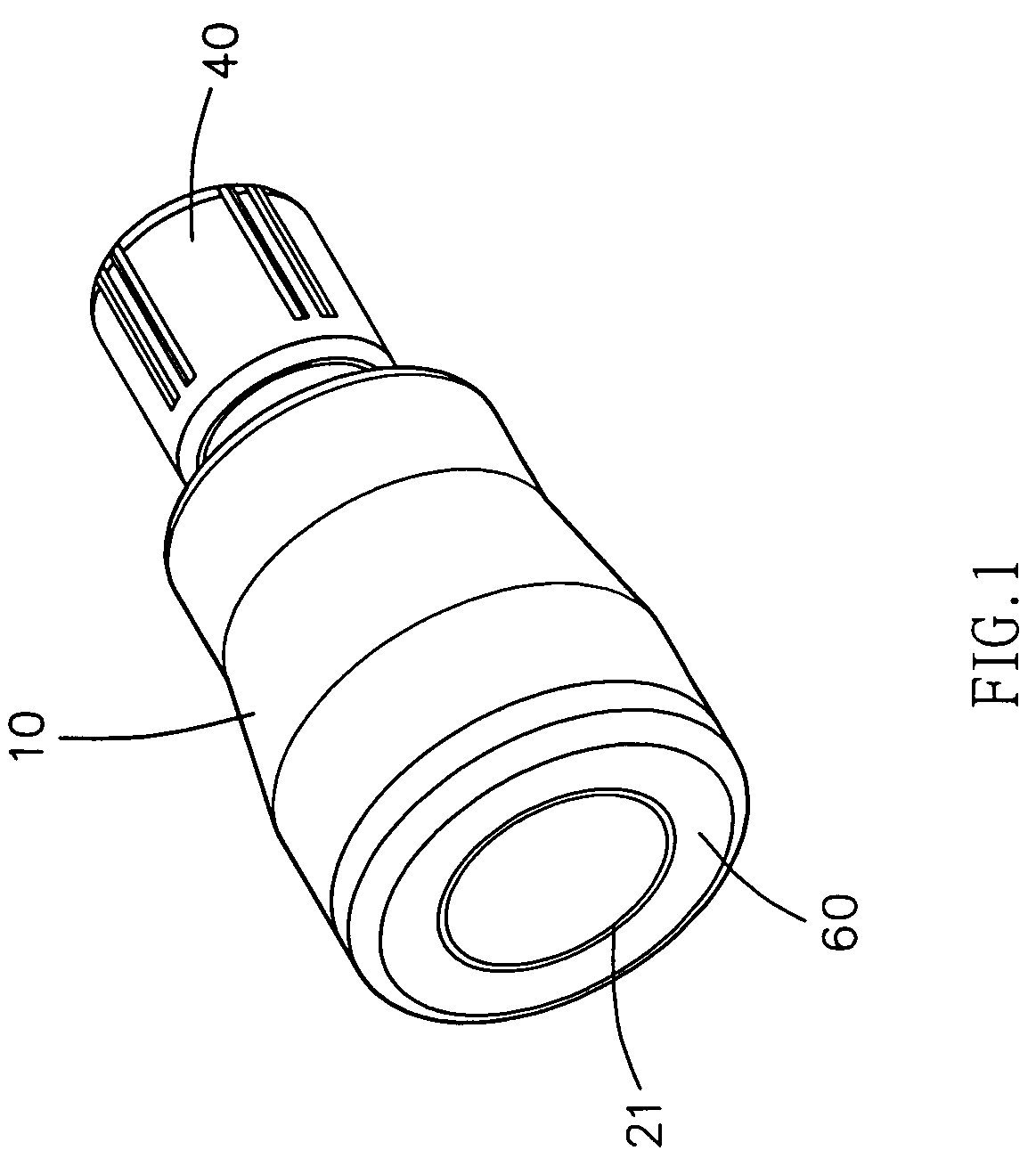

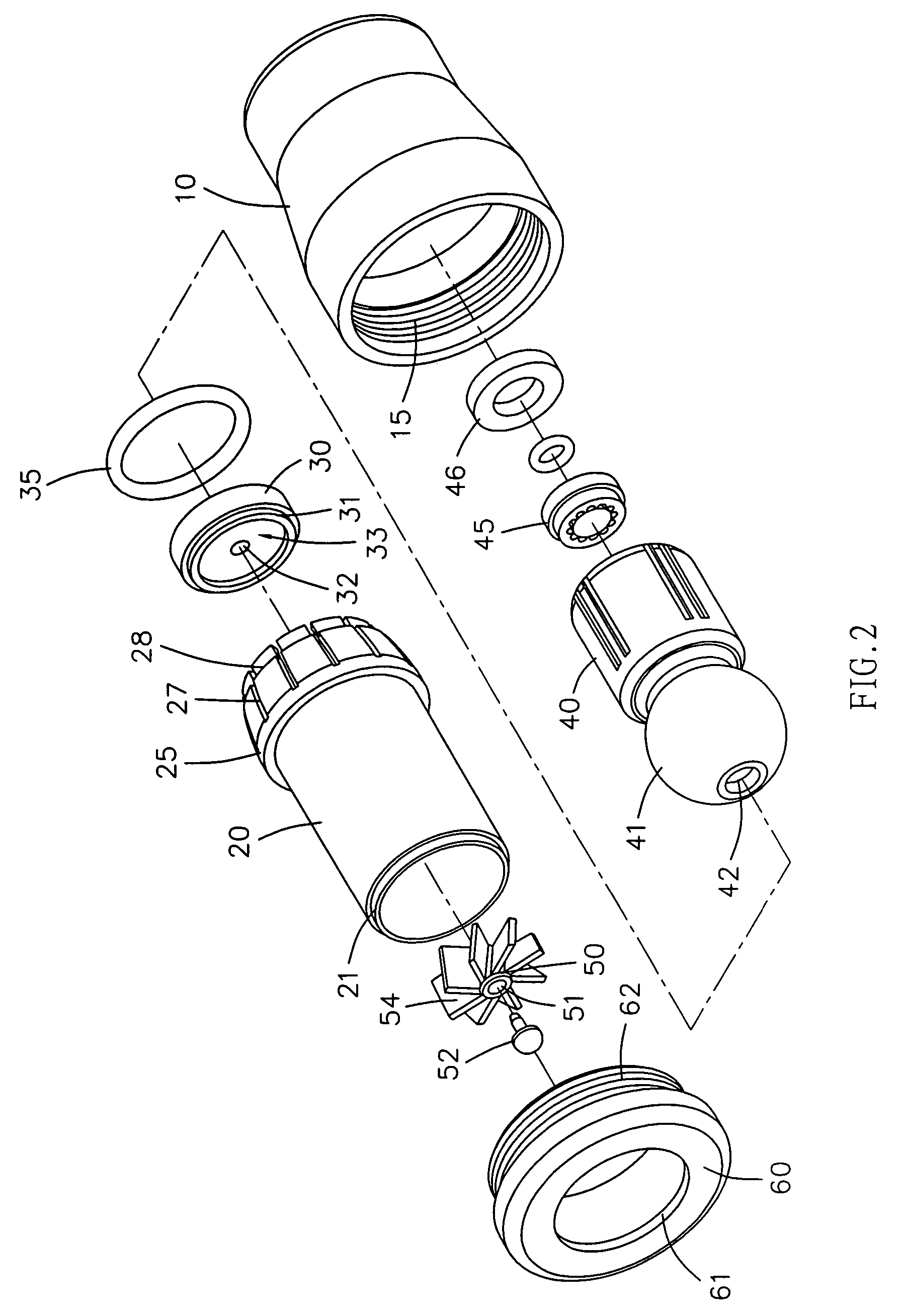

Shower head assembly

InactiveUS7066407B2Reduce water flowConserve waterMovable spraying apparatusSpray nozzlesImpellerWater flow

A shower head assembly includes an outer housing, an inner housing, a catch cap, and an impeller. Thus, the catch cap catches the water flow and introduces the water flow through the water inlet hole into the air chamber so as to reduce the water flow rate, thereby achieving the purpose of saving water. In addition, the water flow is ejected outward in a radiating manner by rotation of the impeller, thereby providing a massaging effect to the user.

Owner:LU TUNG HSIEN

Demand flow pumping

ActiveUS8275483B2Easy to operateSignificant energy savingMechanical apparatusTemperatue controlAir handlerChilled water

Demand Flow operates chilled water plants at substantially improved efficiency, regardless of plant load conditions. In general, Demand Flow utilizes an operating strategy which controls chilled and condenser water pumping according to a constant Delta T line, which is typically near or at design Delta T. This reduces or eliminates Low Delta T Syndrome and reduces energy usage by chilled and condenser water pumps for given load conditions. Operation of chilled water pumps in this manner creates a synergy which generally balances flow rates throughout the plant, reducing undesirable bypass mixing and energy usage at air handler fans and other components of the chilled water plant. At plant chillers, application of Demand Flow increases the refrigeration effect through refrigerant sub-cooling and superheating, while preventing stacking. Demand Flow includes a critical zone reset feature which allows the constant Delta T line to be reset to adjust to changing load conditions.

Owner:SIEMENS IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com