Pickling process and device utilizing residual heat of hot rolled silicon steel strip

A technology of pickling device and silicon steel belt, which is applied in the field of steel processing and manufacturing, can solve the problems of environmental pollution, high energy consumption, and high cost, and achieve good results, energy saving, and lower concentration and temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

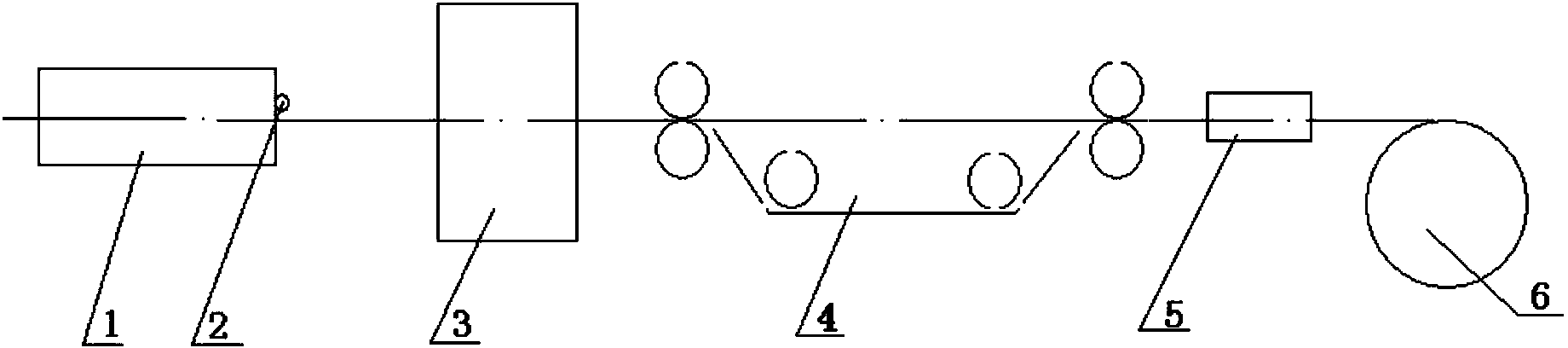

[0022] Such as figure 1 As shown, the residual temperature of the hot-rolled silicon steel strip uses the pickling process, and the special device for realizing the process includes the cooling section 1 of the normalizing furnace, the thermometer 2, the shot blasting machine 3, the pickling tank 4, the hot air dryer 5, Coiler 6.

[0023] The process steps are as follows:

[0024] 1) The 120-500°C steel strip coming out of the cooling section 1 of the normalizing furnace directly enters the shot blasting machine 3 for shot blasting. A thermometer 2 is installed in front of the shot blasting machine 3 to detect the temperature of the steel strip coming out of the furnace. Whether it is within the specified range, according to the temperature requirements of the steel strip, reduce the flow rate of the cooling water pipe in the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com