Automated inlet steam supply valve controls for a steam turbine powered chiller unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

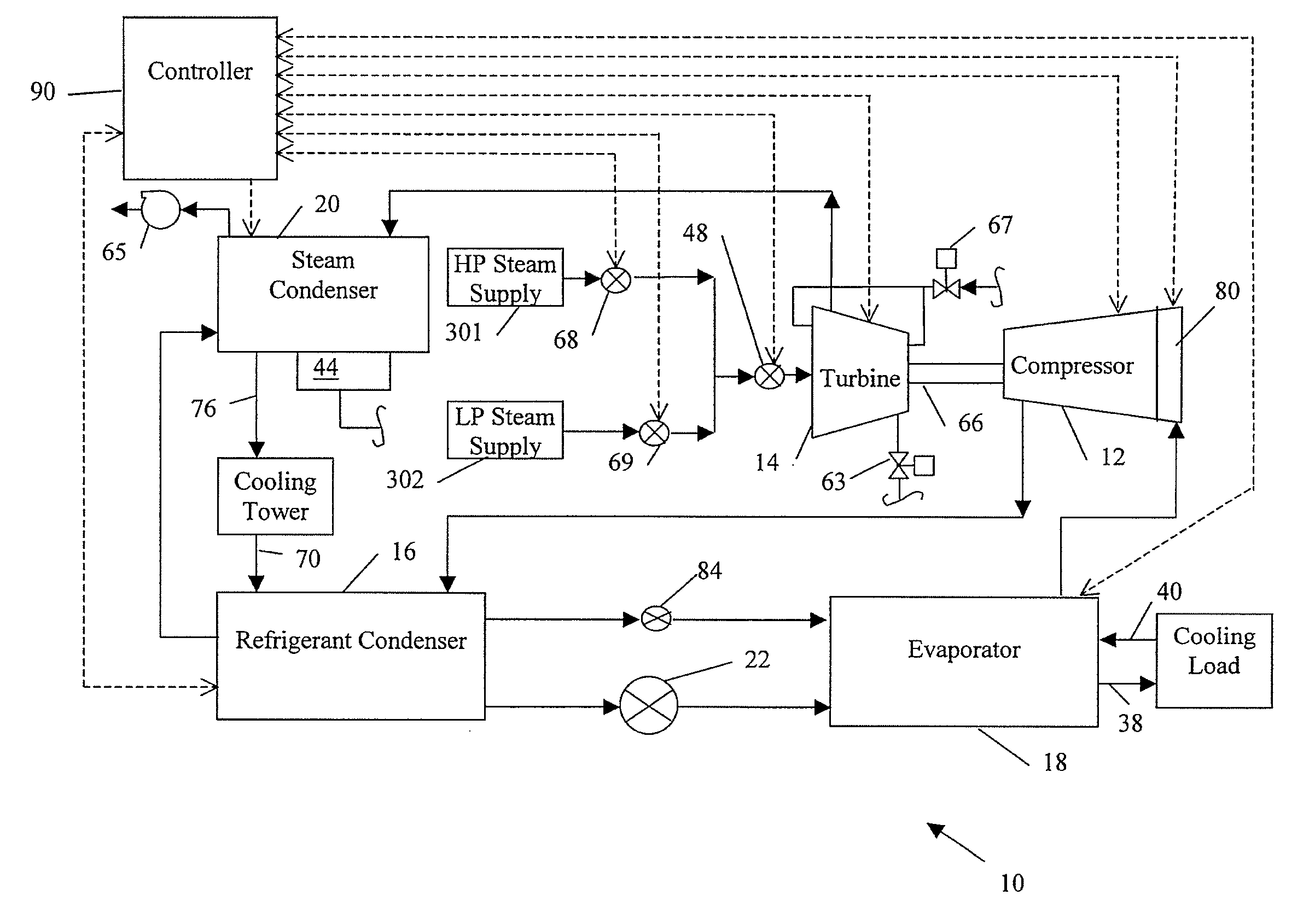

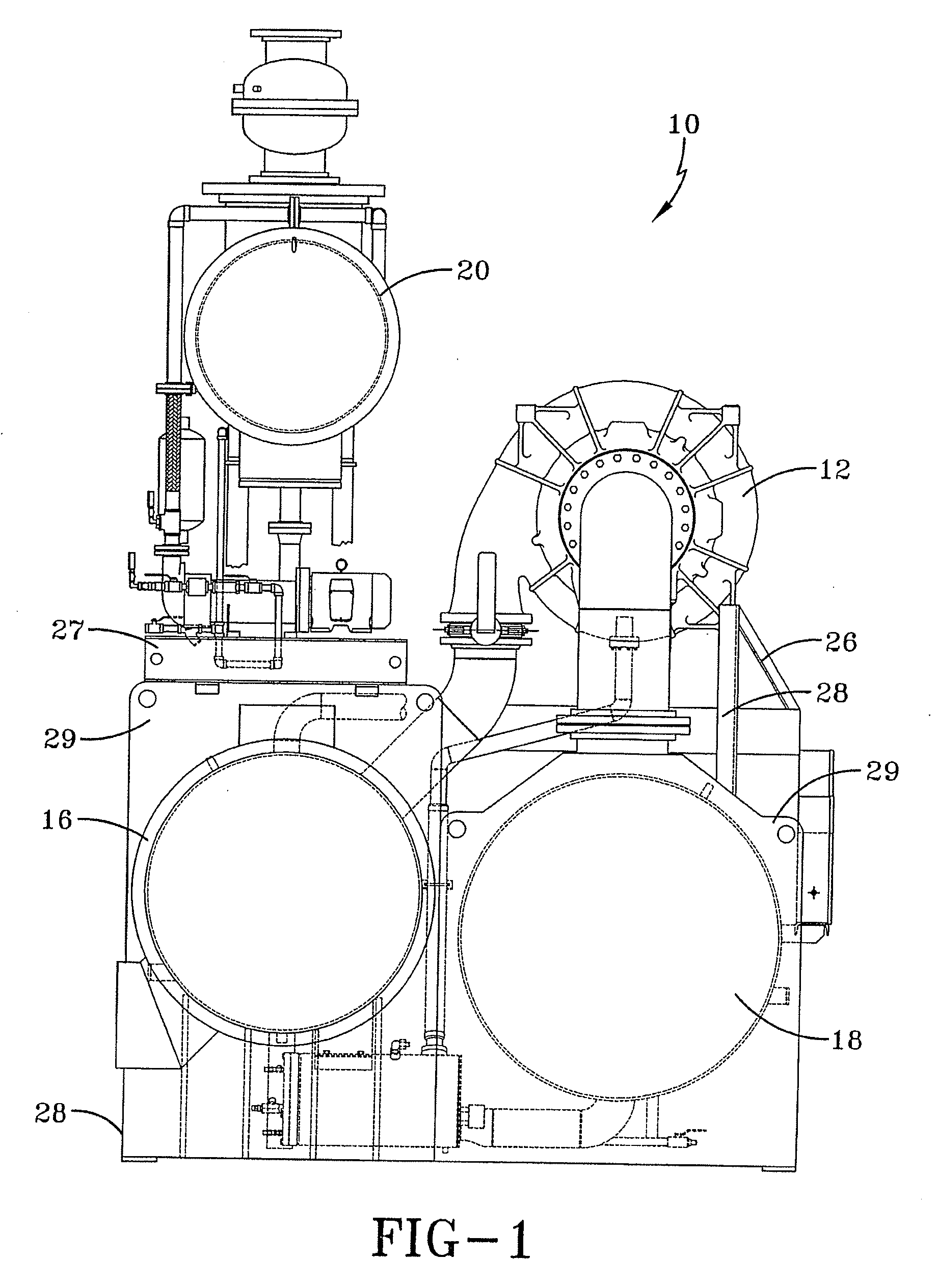

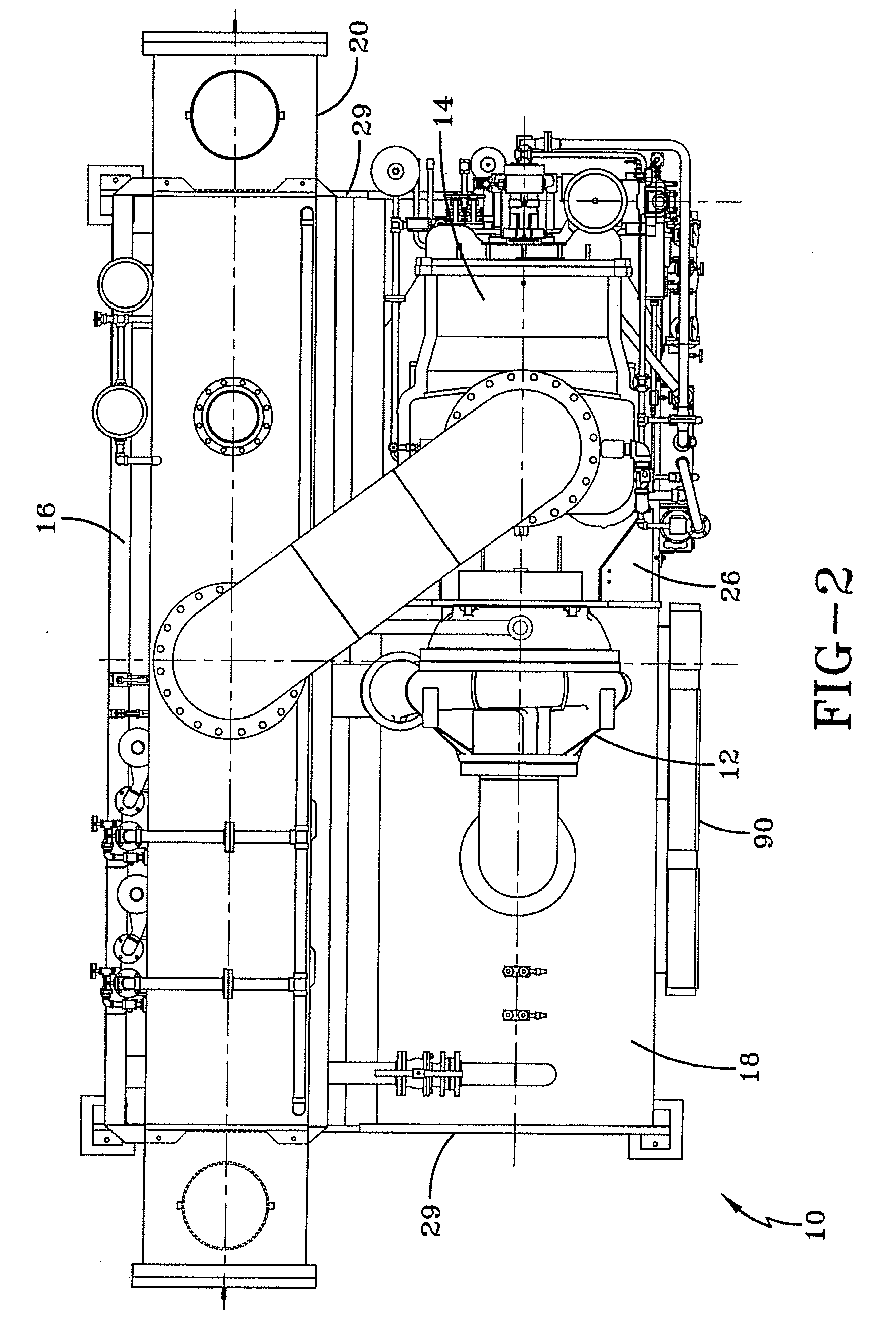

[0019]A general system to which the invention is applied is illustrated, by means of example, in FIGS. 1-3. As shown, the HVAC, refrigeration, or chiller system 10 includes a compressor 12, a steam turbine 14, a refrigerant condenser 16, a water chiller or evaporator 18, a steam condenser 20, an expansion device 22 and a control panel or controller 90. The operation of the control panel 90 will be discussed in greater detail below. The chiller system 10 further includes a compressor lubrication system (not shown) and a turbine lubrication system (not shown). The conventional liquid chiller system 10 includes many other features that are not shown in FIGS. 1-3. These features have been purposely omitted to simplify the drawing for ease of illustration.

[0020]In one embodiment, a “structural frame” permits the stacking or vertical arrangement of major components of the chiller system 10 to provide a prepackaged unit that occupies less floor space with a smaller footprint than a field f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com