A high temperature reaction kettle

A high-temperature reactor and cooling channel technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult mass production, burning, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

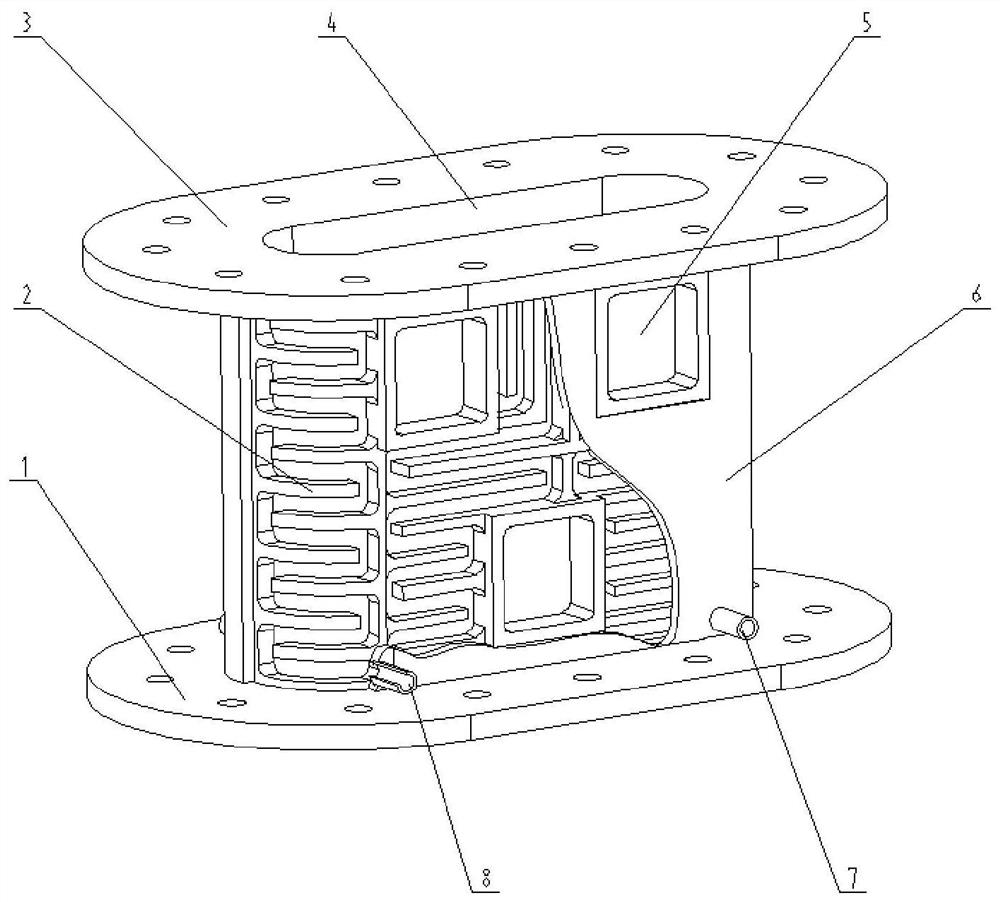

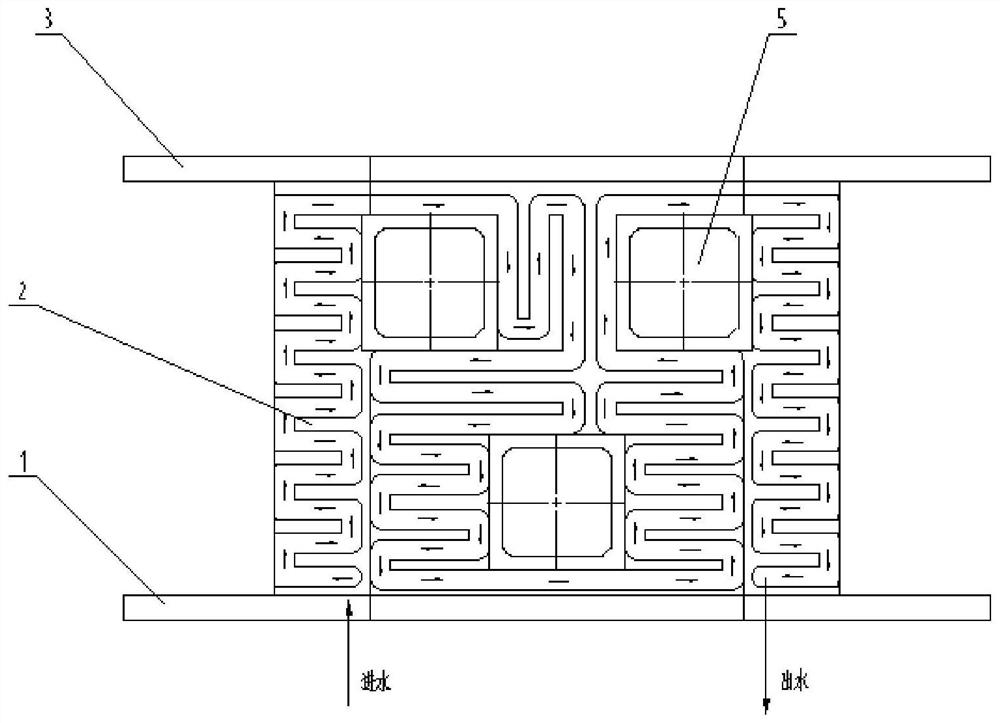

[0021] A high temperature reactor, such as figure 1 , 2 , the outer shell 6 is fixedly connected with the inner shell 4, and a water-proof rib 2 is arranged between the outer shell 6 and the inner shell 4, and a cooling passage for cooling water circulation is formed between the outer shell 6 and the inner shell 4; the outer shell 6 The water inlet pipe 8 and the water outlet pipe 7 are arranged on the top, and the water outlet pipe 7 and the water inlet pipe 8 are connected with the external water source. After the cooling water is injected from the water inlet pipe 8, the cooling water flows through the cooling channel, and the outer shell 6 and the A cooling water passage is formed between the inner shells 4, and then flows out through the outlet pipe 7; the outer shell 6 and the inner shell 4 are provided with through holes 5 for installing heat source equipment. Both the inner shell 4 and the outer shell 6 include arc segments on both sides and a plane segment in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com