Hot water supply and heating system

a technology for hot water supply and heating system, which is applied in the direction of fluid heaters, heating types, lighting and heating apparatus, etc., can solve the problems of shortening the heating amount of the heat source machine, and the temperature of hot water supplied to the hot water outlet tap may be lower than the desired hot water temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

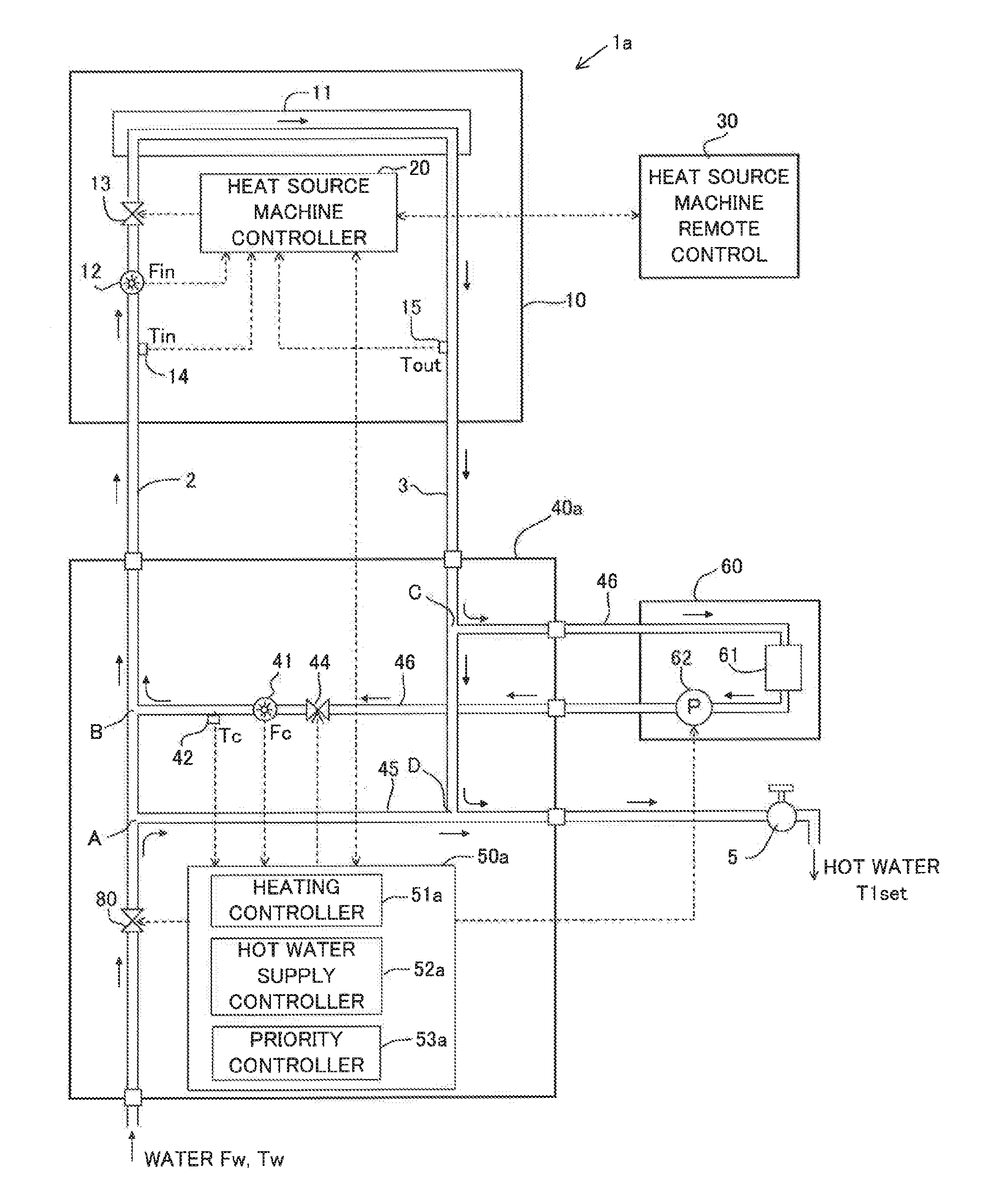

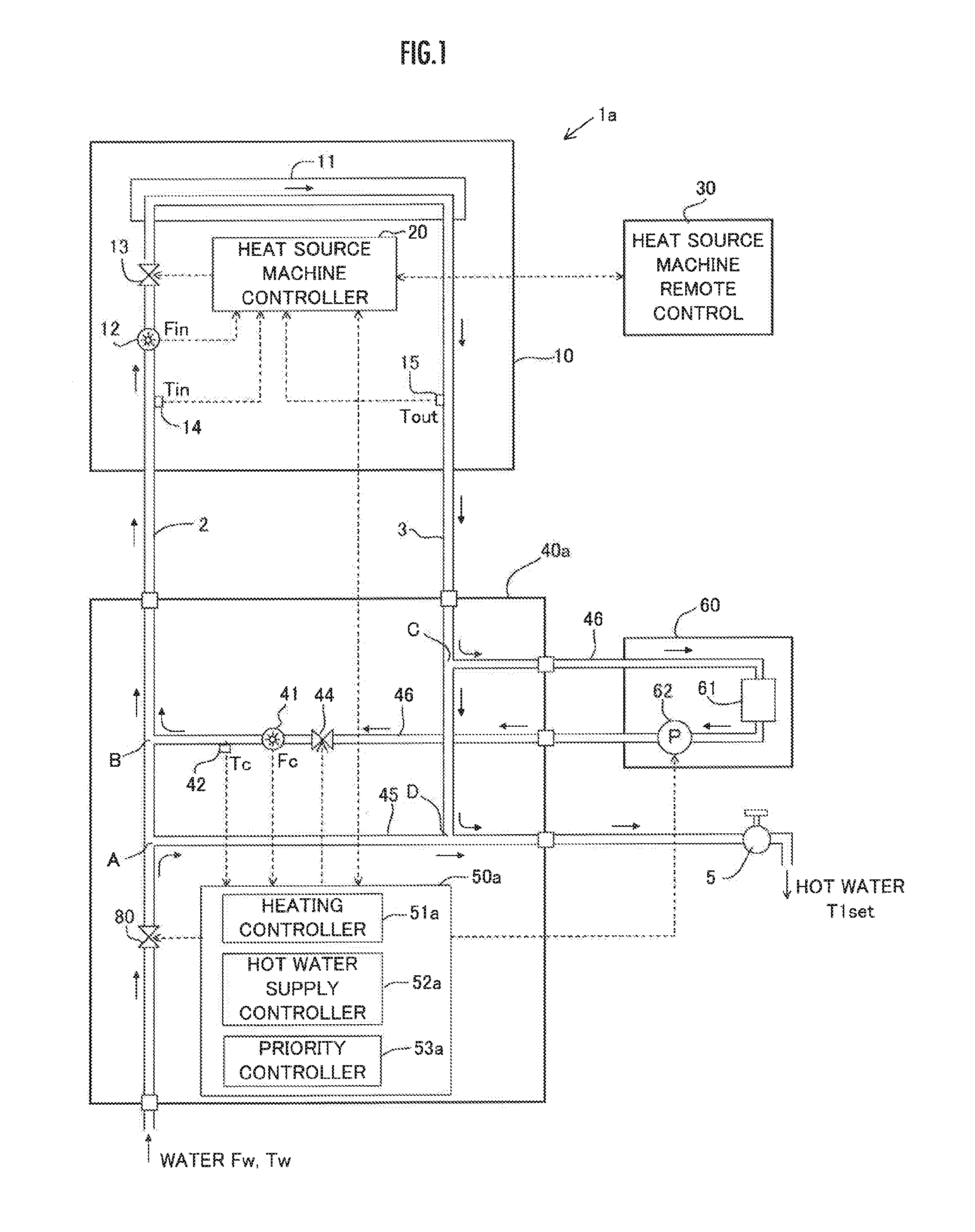

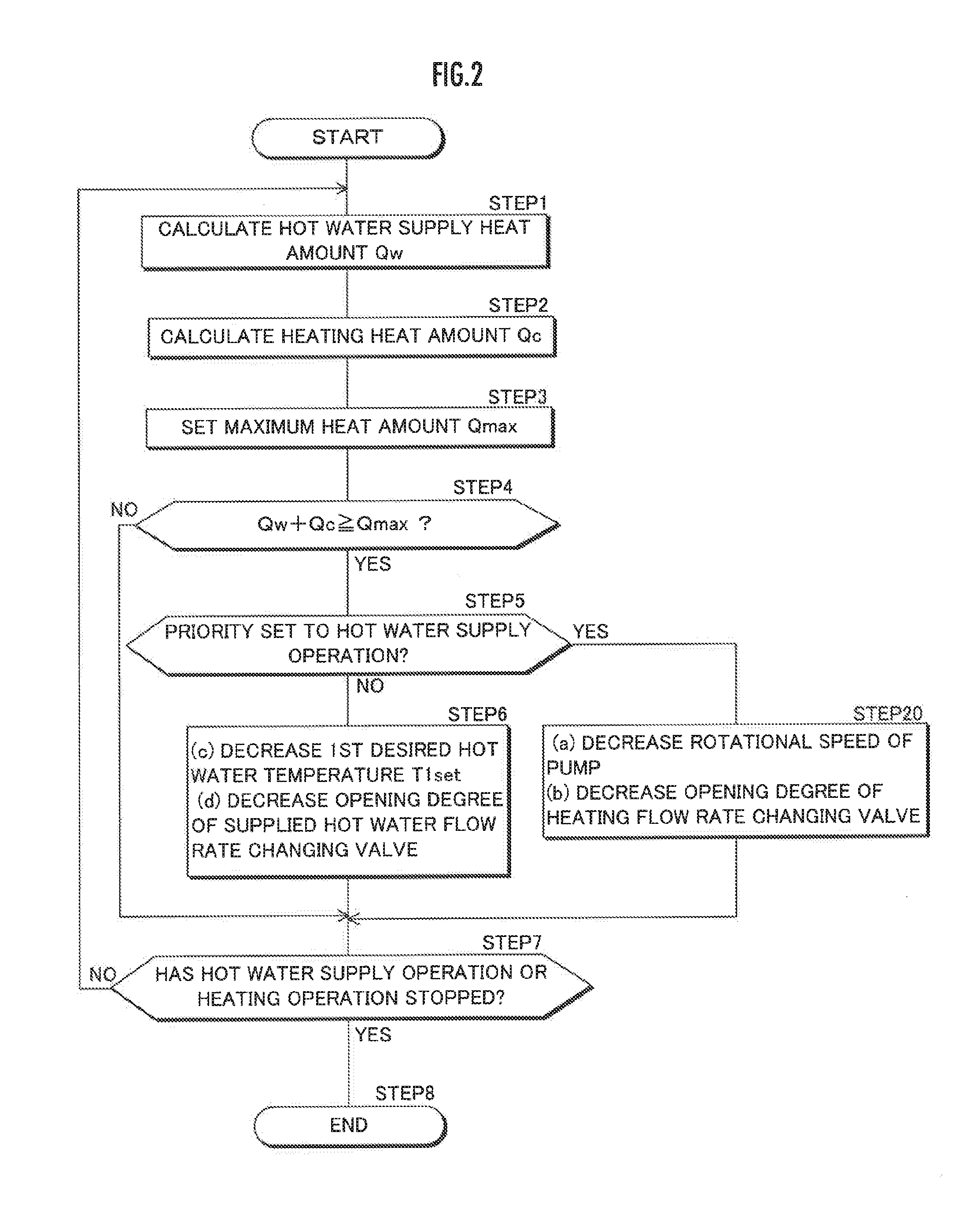

[0041]Referring to FIG. 1, the hot water supply and heating system 1a of the first embodiment is constructed by connecting a heat source machine 10 and a heating connection unit 40a through the intermediary of a water supply pipe 2 and a hot water supply pipe 3. Waterworks (not illustrated) is connected to the water supply pipe 2, and water is supplied to the water supply pipe 2 from the waterworks when a faucet 5 (corresponding to the hot water outlet tap in the present invention), which is connected to a downstream end of the hot water supply pipe 3, is turned on.

[0042]The heat source machine 10 has the water supply pipe 2 connected to the inlet end thereof and the outlet end thereof connected to the hot water supply pipe 3. The heat source machine 10 includes a heat exchanger 11 connected to the water supply pipe 2 and the hot water supply pipe 3 to heat water flowing from the water supply pipe 2 into the hot water supply pipe 3, a heat source machine flow rate sensor 12 which de...

second embodiment

[0092]Referring now to FIG. 3, a hot water supply and heating system 1b of a second embodiment will be described. The same components as those of the hot water supply and heating system 1a of the first embodiment will be assigned the same reference numerals, and the description thereof will be omitted. The configurations of a heat source machine 10 and a heater 60 of the hot water supply and heating system 1b are the same as those of the hot water supply and heating system 1a of the first embodiment.

[0093]The hot water supply and heating system 1b differs from the hot water supply and heating system 1a of the first embodiment in that the heating connection unit 40b does not have the function to communicate with the heat source machine 10. Further, in order to perform the hot water supply operation without communication with the heat source machine 10, the heating connection unit 40b is provided with a output hot water temperature sensor 43 that detects a temperature Tout of the hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com