Construction method of tunnel portal water stopping structure for shield excavation and shield arrival

A construction method and receiving hole technology, applied in earthwork drilling, shaft lining, tunnel lining, etc., can solve problems such as poor water-stop effect and single water-stop barrier, achieve enhanced water-stop effect, simple construction, and convenient implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

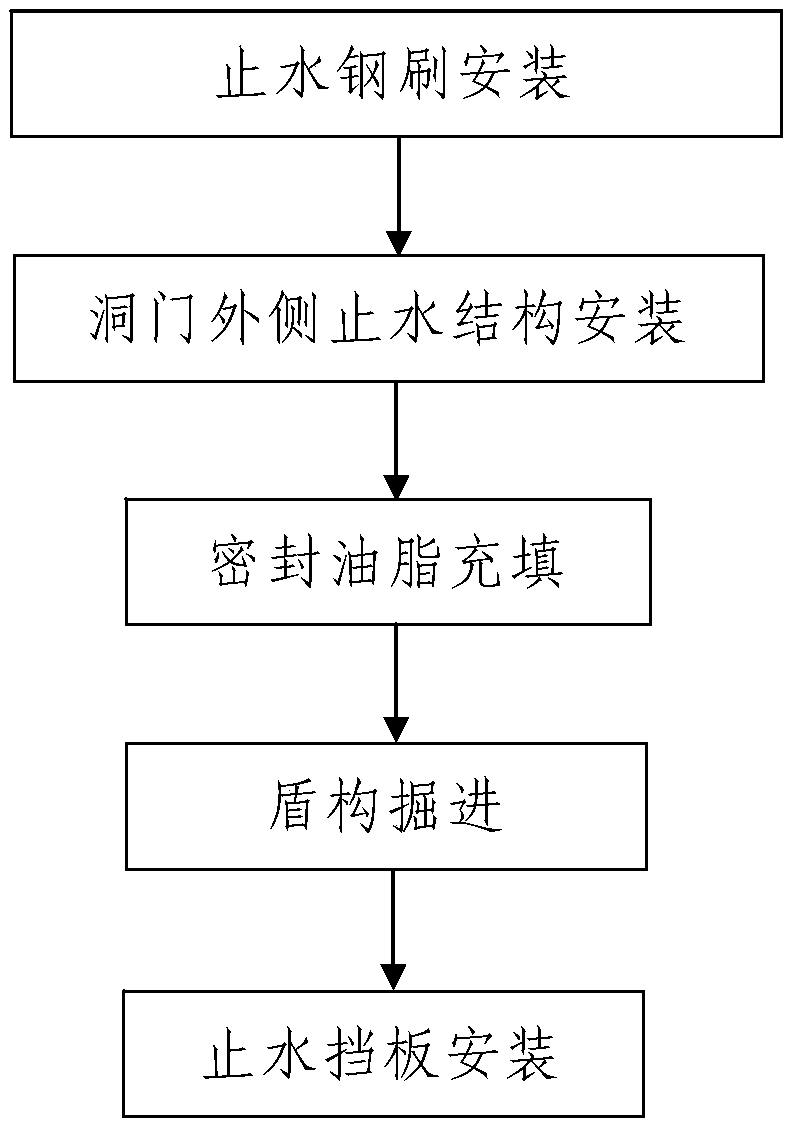

[0065] Such as figure 1 A construction method for the opening and receiving of the shield tunnel water-stop structure shown includes the following steps:

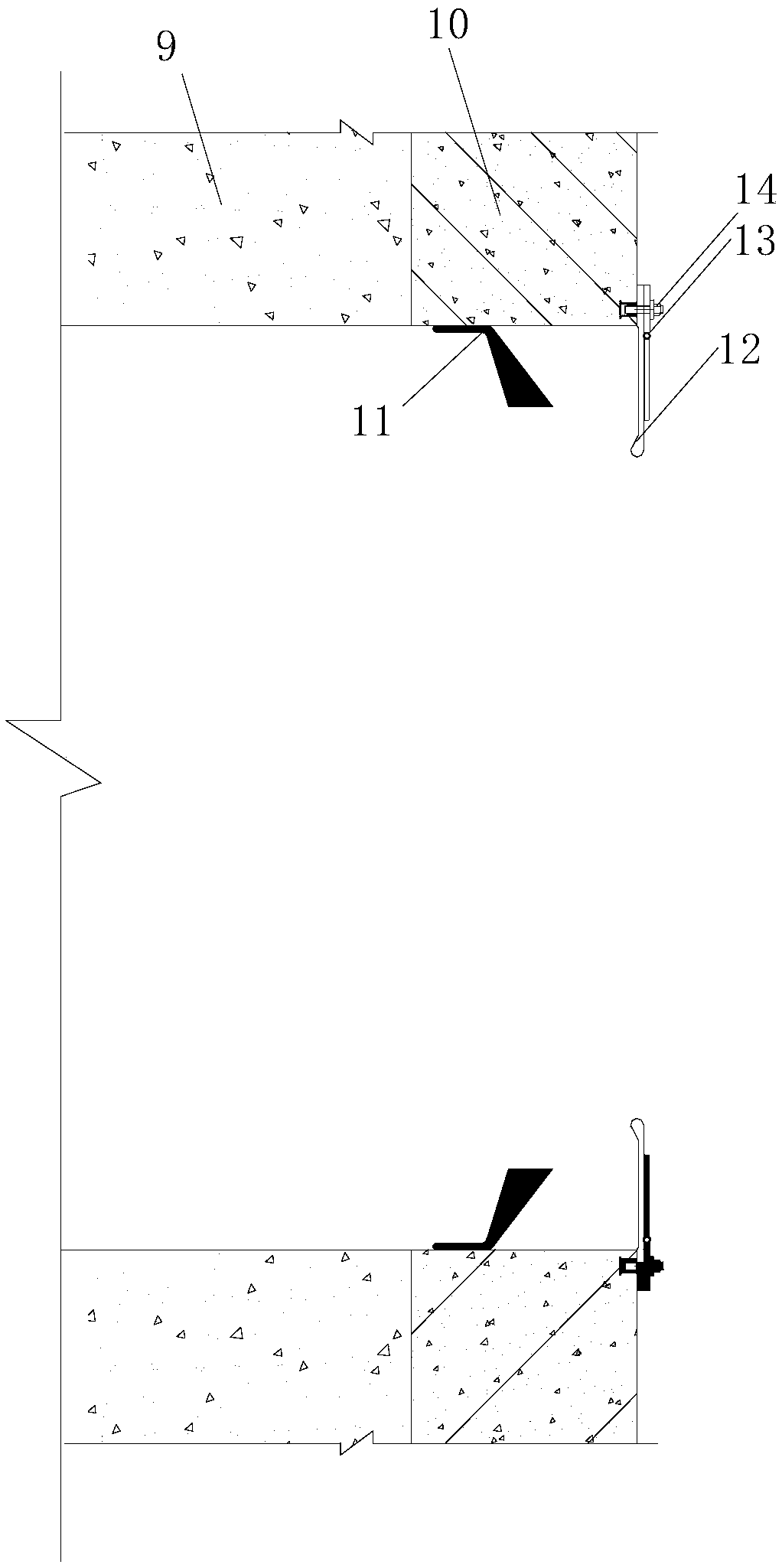

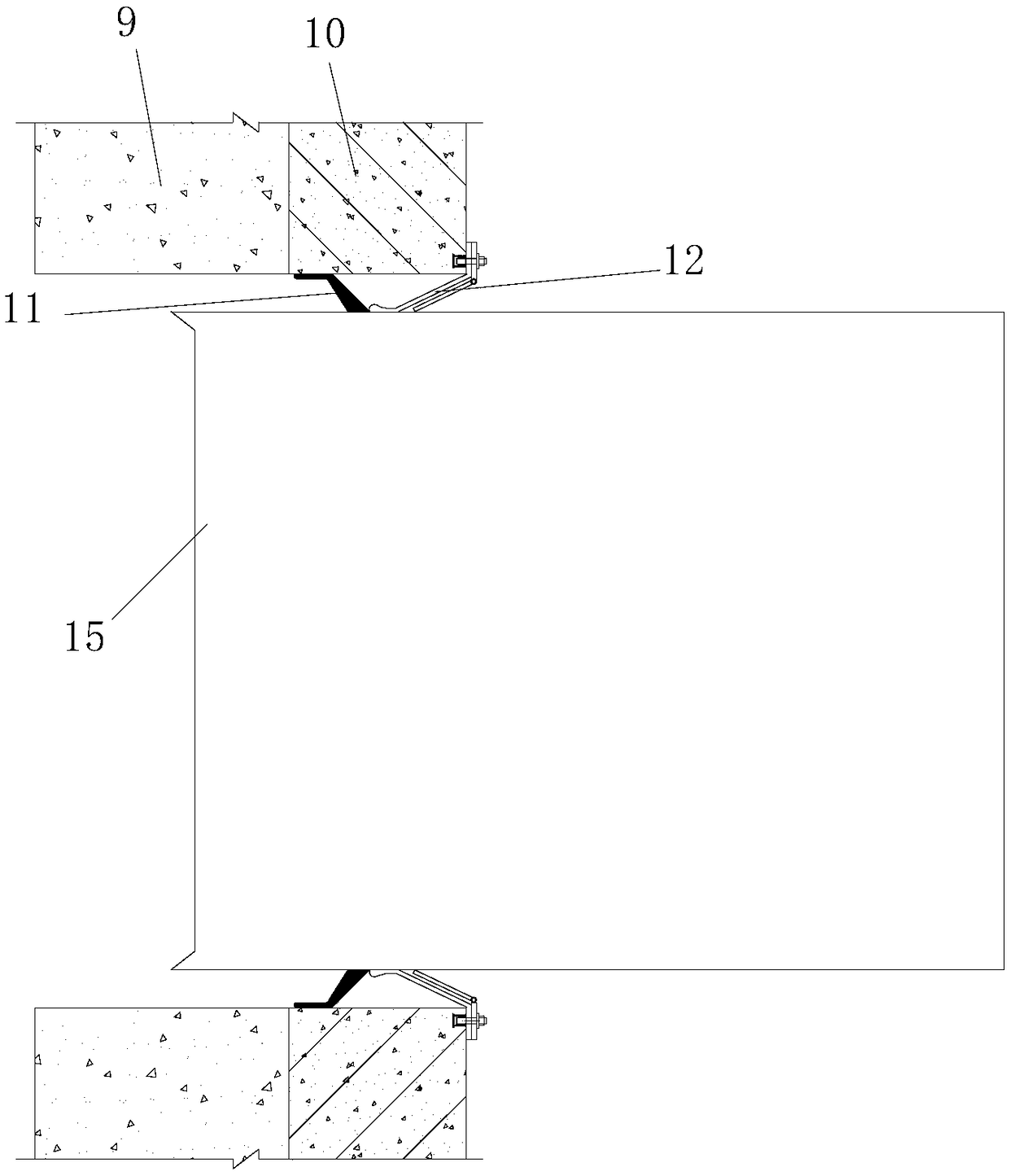

[0066] Step 1. Installation of water-stop steel brush at the door: before the shield tunneling construction of the shield tunnel 1 under construction, install a ring of water-stop on the inside of the starting portal 2 and the receiving portal of the shield tunnel 1 under construction. Steel brush 11, see figure 2 with image 3 ;

[0067] Both the originating portal 2 and the receiving portal are provided with a portal steel ring 10, and each circle of the water-stop steel brush 11 includes a plurality of water-stop steel brushes arranged on the inner wall of the portal steel ring 10 along the circumferential direction. Brush 11, a plurality of said water-stop steel brushes 11 are arranged on the same cross-section of the door steel ring 1 with the same structure and size, and each circle of said water-stop steel brushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com