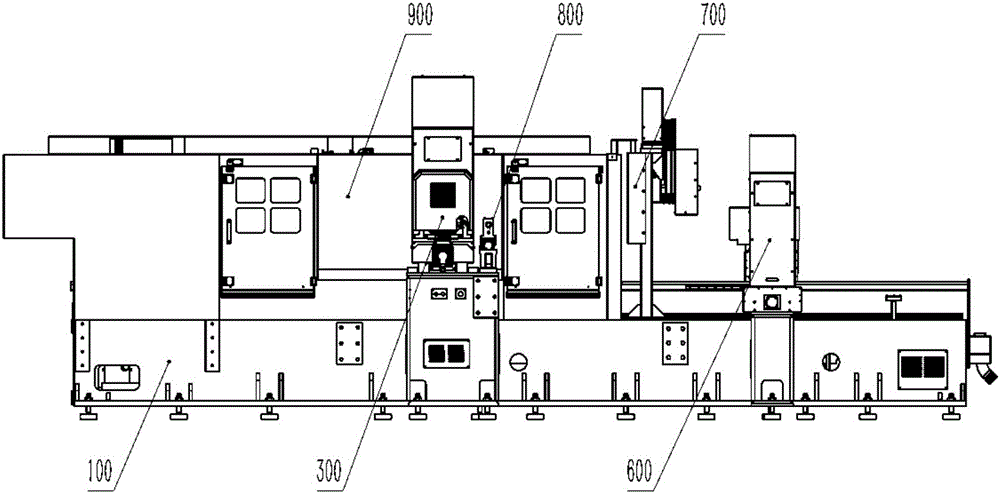

Full-automatic silicon single-crystal rod rolling and grinding integrated equipment

A fully automatic technology for single crystal silicon rods, applied in grinding/polishing equipment, metal processing equipment, grinders, etc. Silicon ingot processing size is limited, and the degree of automation of the roller mill is low, so as to save manpower and logistics costs, reduce processing pollution and noise on the workshop environment, and speed up the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples can make those skilled in the technical field understand the present invention more comprehensively, but do not limit the present invention in any way.

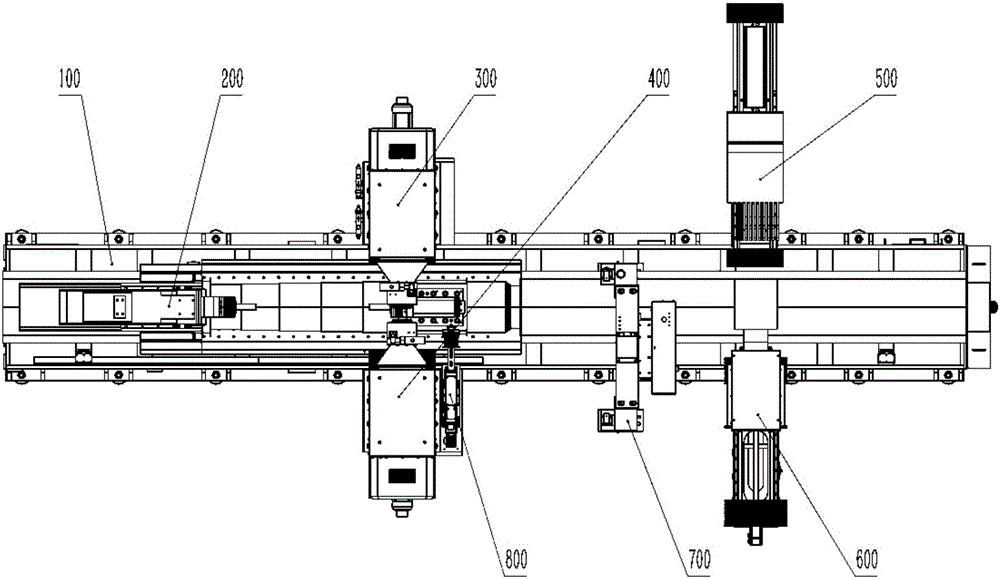

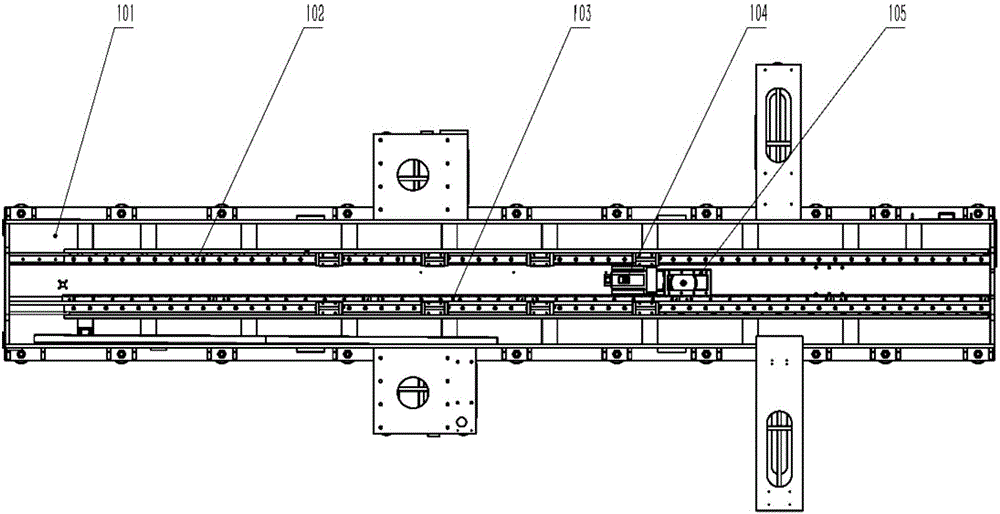

[0037] The fully automatic monocrystalline silicon rod rolling and grinding integrated equipment of the present invention includes a large chassis 100 for carrying; the large chassis 100 is in the shape of a long strip, and two parallel main rails 102 are arranged on its surface along the length direction The grinding table assembly 200 is movably installed on the two main rails 102, and the main drive motor 104 realizes the movement along the main rails 102 through the driving connection mechanism; platform: two platforms are located in the middle of the large chassis 100 and are arranged oppositely, one of which carries the coarse grinding power head assembly 300, and the other carries the fine grinding power head assembly 400; the other two platforms are located at one end of the large chassis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com