Cutter handle with shock absorption function

A tool handle and cutting tool technology, which is applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of severe vibration of coated tools and coating shedding, etc., achieve smooth processing surface, improve processing precision, and reduce defects effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the coated ball-end milling cutter works in the milling range of stone: the spindle speed is 2000-8000r / min; the feed rate is 500-3000mm / min; the cutting depth is 0.5-2mm;

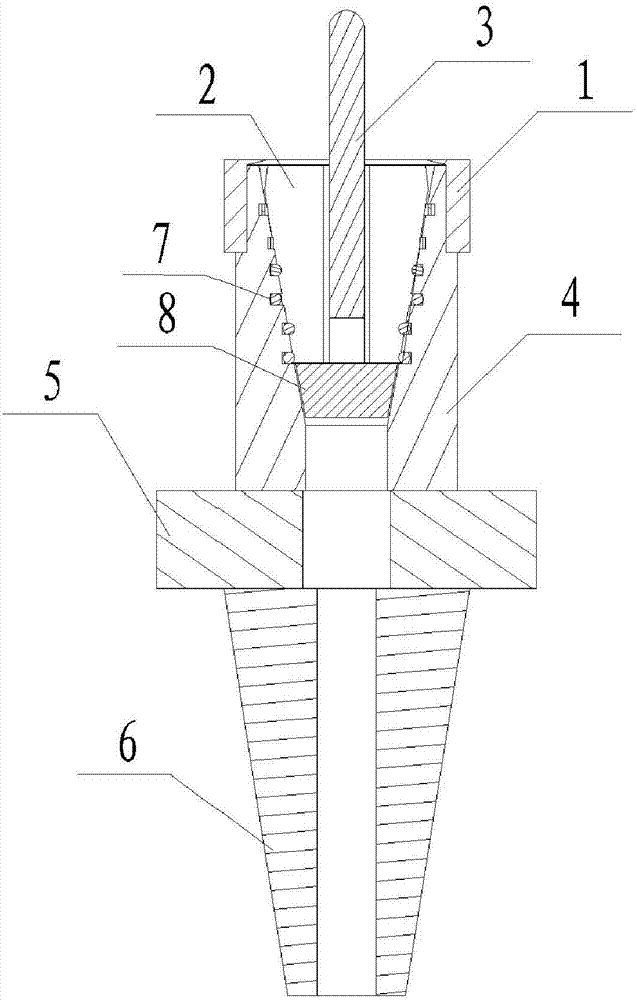

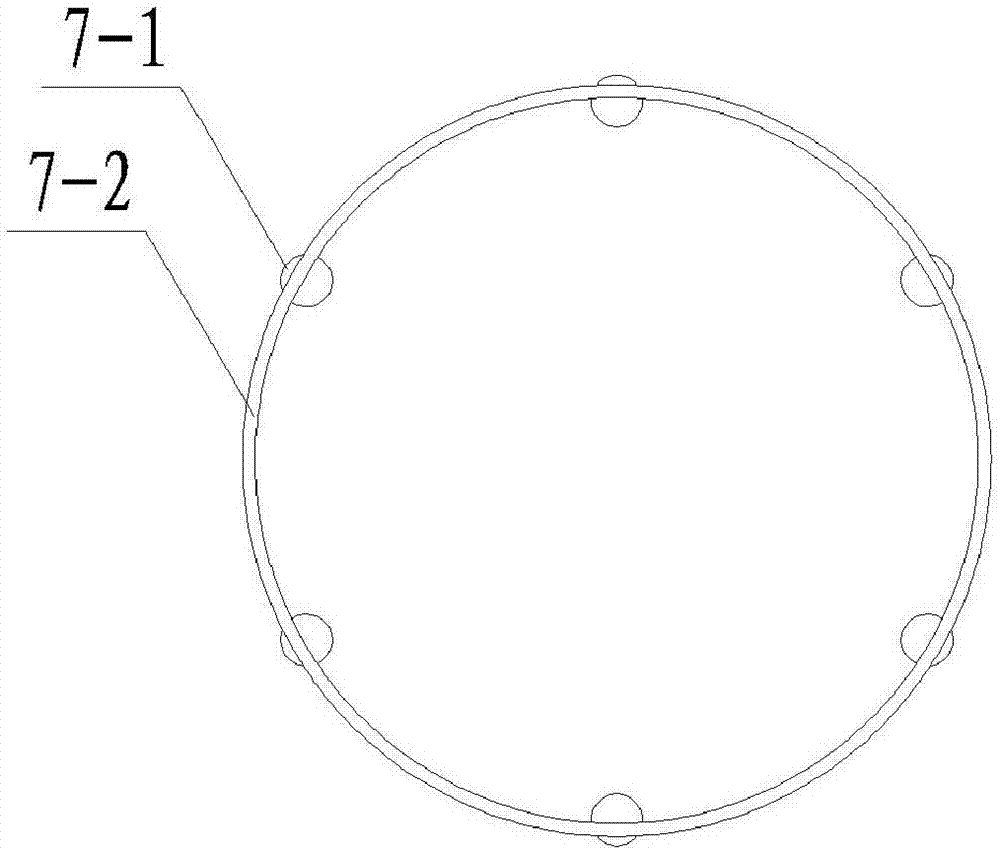

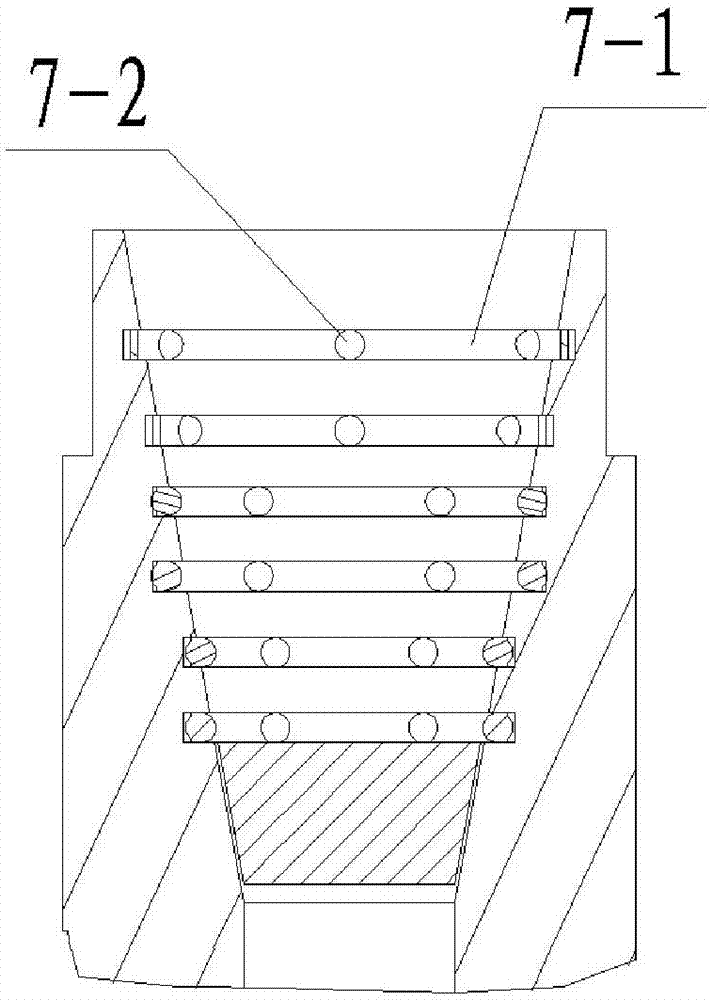

[0038] A coated ball end milling cutter holder with vibration damping function, its cross-sectional view is as follows figure 1 As shown, the structural diagram of the shock absorbing device of the tool holder is shown in figure 2 As shown, the local schematic diagram of the shock absorber is shown in image 3 As shown, it includes a handle body 4, a damping block 8 and a collet 2. The lower part of the handle body 4 is provided with a handle seat 5 and a handle portion 6 in sequence. The collet 2 is a carbon steel spring collet, and the coating The length-to-diameter ratio (L / D) of the ball end milling cutter is 4 to 6, L is the length of the milling cutter, D is the diameter of the milling cutter, where:

[0039] The handle body 4 is provided with an inner hole, and the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com