Copper clad aluminum flat wire welding device

A welding device, copper-clad aluminum technology, applied in the direction of electric heating devices, auxiliary devices, welding equipment, etc., can solve the problem that the length of the flat wire does not meet the requirements, and achieve the effects of light weight, reducing wasted time, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

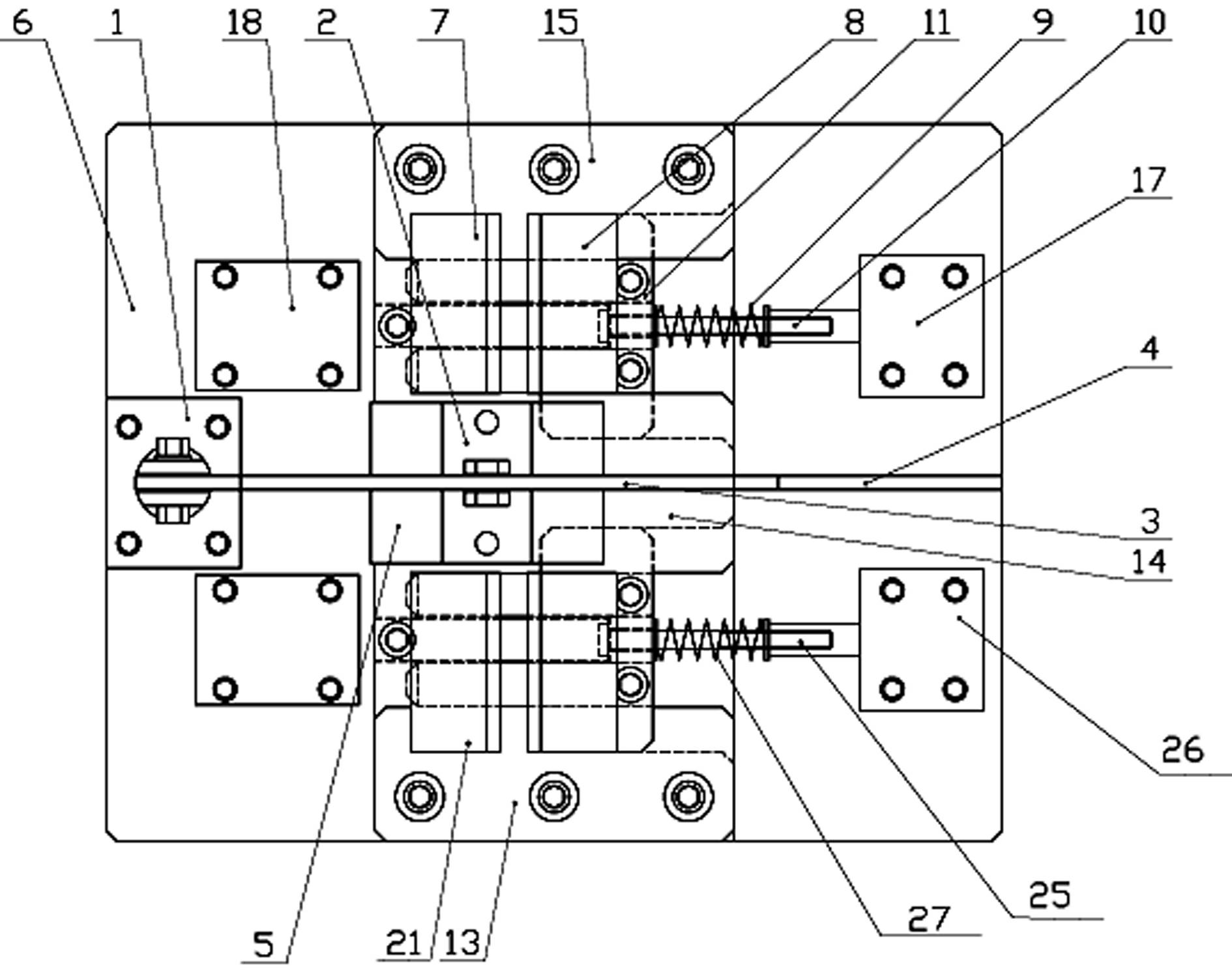

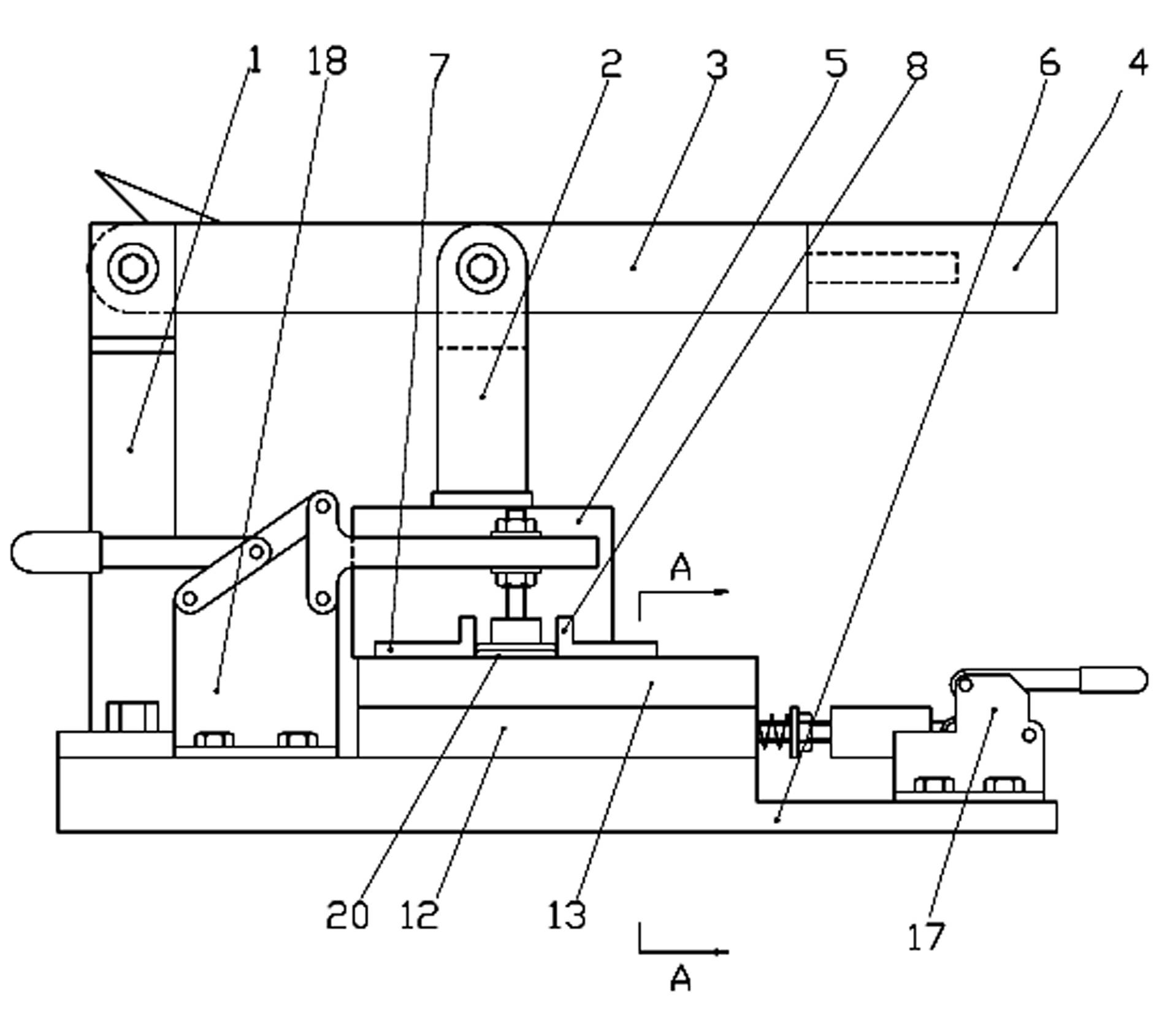

[0015] Such as figure 1 As shown, the copper-clad aluminum flat wire welding device of the present invention includes a bracket 1, a hanger 2, a lifting rod 3, a nylon handle 4, a heating block 5, a bottom plate 6, a clamping block left 7, a clamping block right 8, a spring 9, and a screw rod 10. Pushing block 11, E-shaped plate 12, pressing block left 13, pressing block middle 14, pressing block right 15, pushing bar 16, quick clamp 17, quick pressing tool 18, fixed pushing bar 19, flat wire clamping groove 20 ,in:

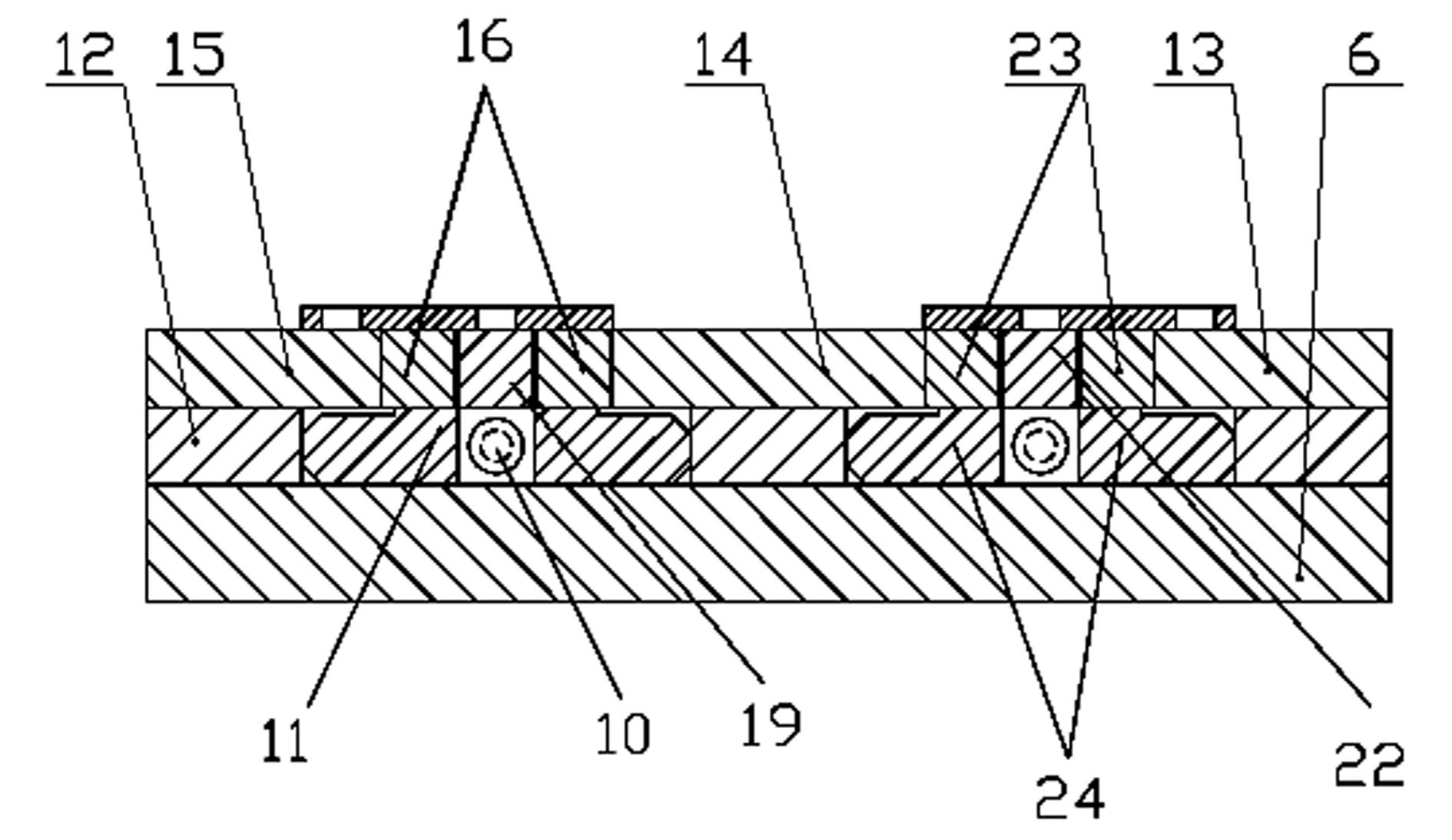

[0016] Such as figure 2 , 3 As shown, an E-shaped plate 12 is fixedly installed on the base plate 6, and the two gaps of the E-shaped plate 12 and the base plate 6 form two chutes, and each chute can allow a push block to slide freely. The top of the push block 11 is connected with two push bars 16 with bolts, and the top of the push block 24 is connected with two push bars 23 with bolts. The top of the push bar 16 is connected with the clamp block right 8 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com