Double toggle rod self-locking clamping device

A technology of self-locking clips and double toggle levers, used in positioning devices, clamping and supporting, can solve the problems of low quality of hydraulic components, high labor intensity, unstable pressure, etc. zoom-in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

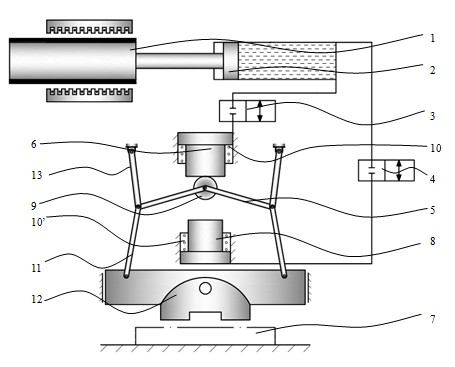

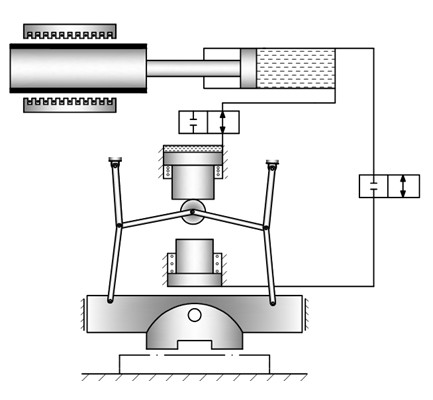

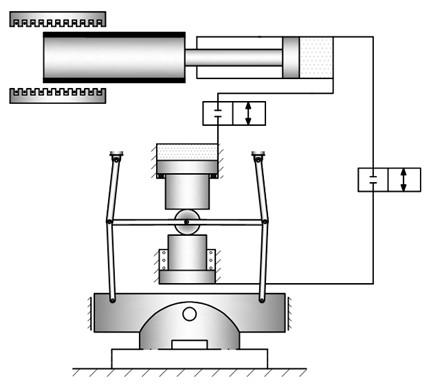

[0041] Embodiment one: see Figure 1~Figure 5 As shown, a double toggle self-locking clamping device includes a driving mechanism and a hinge rod boosting self-locking clamping mechanism. The driving mechanism is composed of a linear motor 1, an active piston 2, and the active piston 2 is inside It is composed of a reciprocating hydraulic cylinder, one end of the active piston 2 is fixedly connected to the output end of the linear motor 1, and the other side is provided with a liquid medium.

[0042] The driving mechanism respectively drives the output mechanism and the reset mechanism through the pipeline, and the controllable on-off valve 3 and the controllable on-off valve 4 are respectively arranged on the pipeline.

[0043] The output mechanism includes an output hydraulic cylinder and an output piston 6 slidingly arranged in the output hydraulic cylinder. A first return spring 10 is arranged between the output end of the output piston 6 and the output hydraulic cylinder....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com