A Friction Stir Welding Method for Suppressing Weld Thinning and Thickening Weld

A friction stir welding and stirring head technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of effective thickness reduction, stress concentration, flash, etc., to avoid cracks, high production efficiency, and achieve two secondary reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

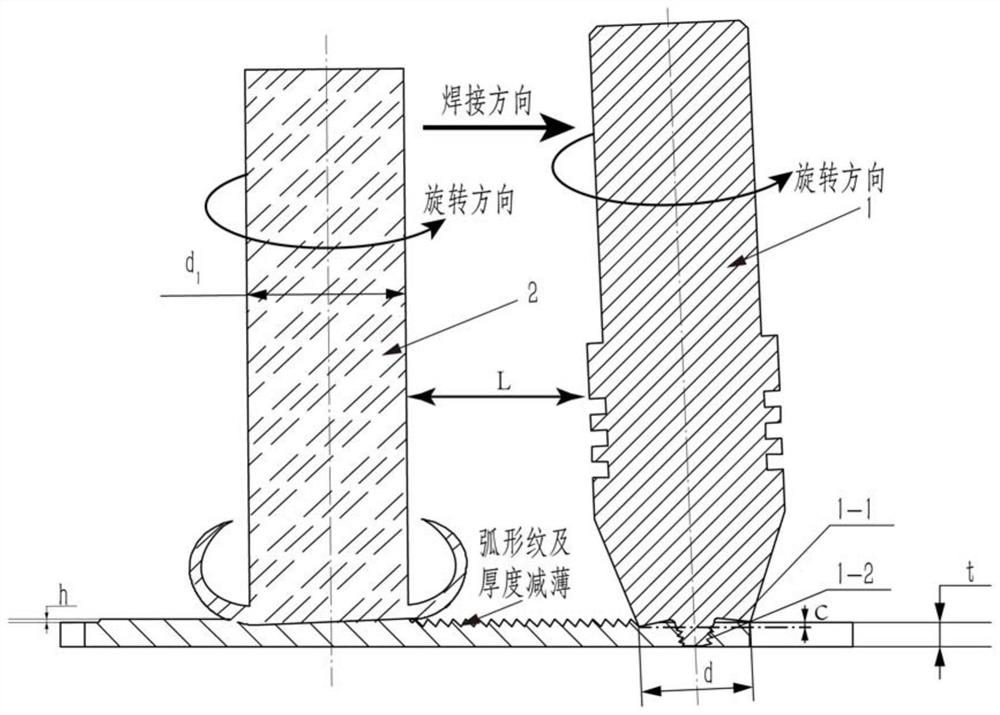

[0032] Such as figure 1 As shown, a friction stir welding method that suppresses weld seam thinning and thickens the weld seam is achieved through the following steps:

[0033] Step 1: Cleaning before welding, first remove the oxide film on the surface of the plate to be welded by mechanical grinding, and then use an organic solvent or cleaning agent to wipe the surface of the plate to be welded to remove oil and metal dust and other sundries. The organic solvent is alcohol or acetone, etc.;

[0034] Step 2: Selection of the material and shape of the stirring head 1 and the consumable friction head 2. The material of the stirring head 1 depends on the properties and thickness of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com