Preparation method of amorphous alloy coating on surface of magnesium alloy

A technology of amorphous alloy and magnesium alloy, which is applied in the field of surface modification and coating of magnesium alloy materials, and can solve problems such as thermal damage on the surface of magnesium alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

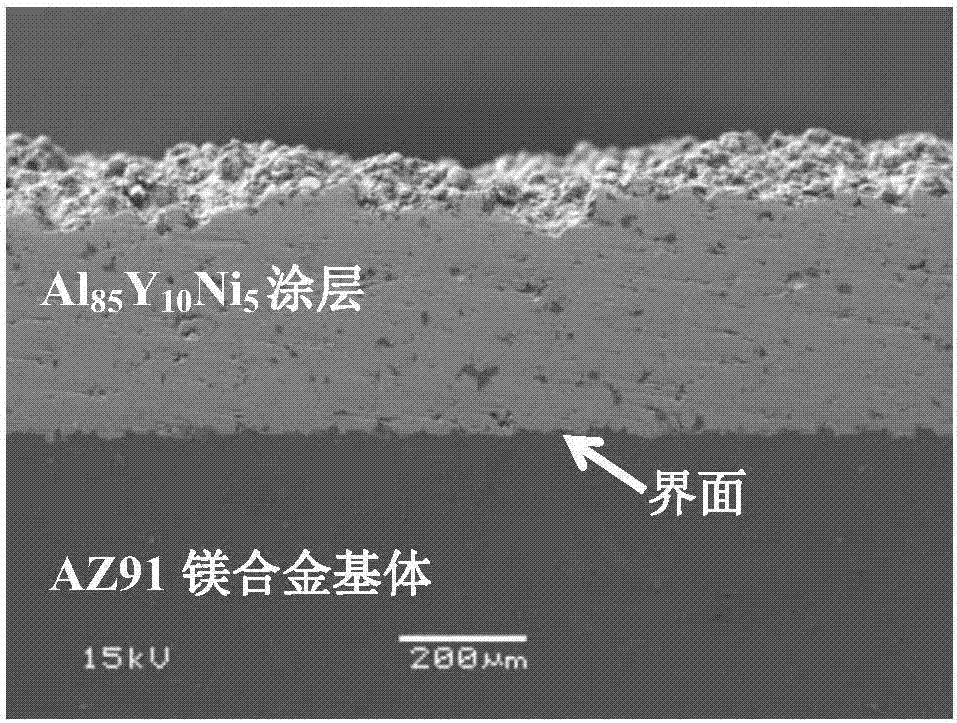

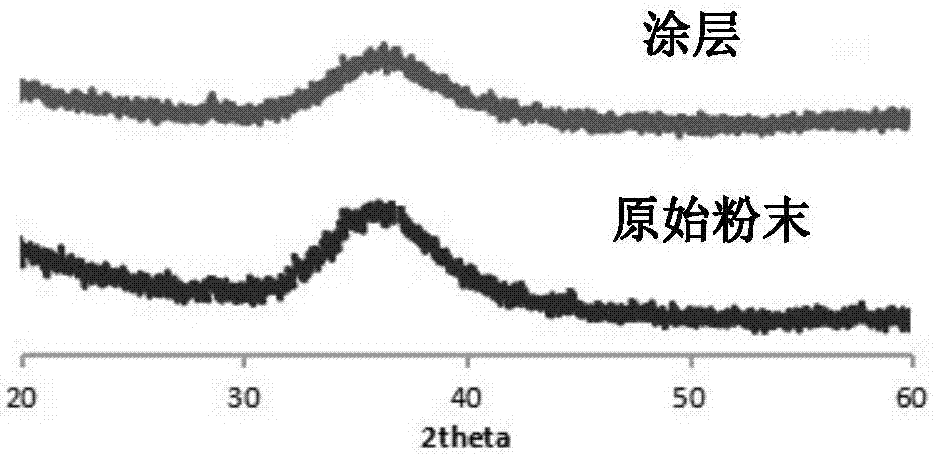

[0023] The invention discloses a method for preparing a low-temperature cold spray coating of an amorphous alloy coating on the surface of a magnesium alloy, which comprises the following steps:

[0024] (1) Raw powder material of amorphous alloy: Al with powder particle size 85 Y 10 Ni 5 Aluminum-based amorphous alloy powder is used as raw material. The powder is sieved, and the powder with a particle size distribution of 5-25 μm is selected as the original powder material for cold spraying.

[0025] (2) Magnesium alloy substrate surface treatment: Use 400-1200 No. metallographic sandpaper to polish the magnesium alloy surface, and then clean the workpiece surface with acetone or alcohol to remove oil stains and surface oxide scales to improve the bonding between the coating and the substrate strength.

[0026] (3) Preparation of amorphous alloy coating:

[0027] The first step is to use an electronic balance to weigh the original Al with a particle size of 5-25 μm 85 Y ...

Embodiment example 1

[0031] (1) The magnesium alloy is pre-polished with No. 400 metallographic sandpaper to achieve a smooth surface and remove surface oxide skin. Then use No. 600 and No. 1200 metallographic sandpaper for grinding treatment in turn, and finally use alcohol to ultrasonically clean the matrix sample for 5 minutes, take it out and dry it.

[0032] (2) Use an electronic balance to weigh Al with a particle size distribution of 5-25 μm 85 Y 10 Ni 5 2 kg of aluminum-based amorphous alloy powder. Put the powder into a vacuum drying oven and vacuumize to 0.5×10 -3 Pa, the drying temperature is set at 80° C., and the drying time is 10 hours.

[0033] (3) Pour the dried powder into the powder feeder, and use an 80-mesh filter screen at the lower end of the drain. The powder feeder is connected to a high-pressure gas tank, the gas is helium with a purity >99.9%, the gas pressure is 2MPa, and the temperature of the gas heater is set at 300°C. The distance between the outlet of the spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com