Preparation method of silver tin oxide contact material for improving sintering property of ingot blank

A silver tin oxide, sintering technology, used in contacts, electrical components, electrical switches, etc., can solve the problems of hindering the contact and diffusion of Ag between powders, complex chemical co-precipitation process, poor processing performance, etc., to enhance mutual Sintering diffusion, superior sintering performance, and the effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

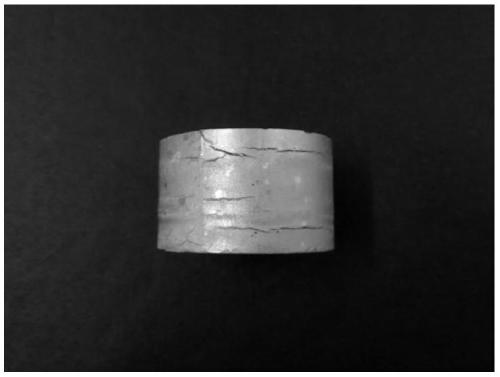

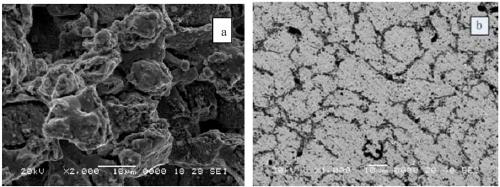

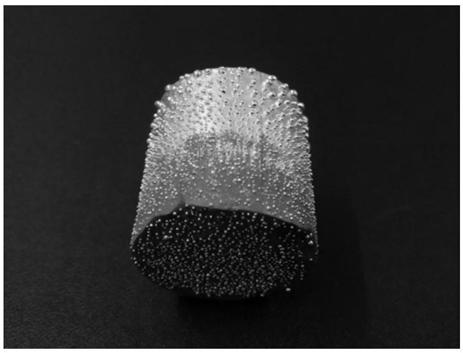

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh each component according to the following mass percentages, place it in an intermediate frequency induction melting furnace and smelt into a uniform alloy melt, then atomize by high-pressure water atomization equipment, and dry the obtained powder slurry for a temperature of over 200 Mesh sieve, very silver-tin alloy powder;

[0035] Sn: 9.5%;

[0036] Additive: Bi 0.1%;

[0037] The remainder is Ag;

[0038] 2) placing the silver-tin alloy powder in a high-pressure oxidation furnace, oxidizing it for 6 hours under the conditions of an oxygen partial pressure of 1 MPa and a temperature of 700° C., taking out, crushing, and passing through a 100-mesh sieve to obtain a silver-tin oxide composite powder;

[0039] 3) The silver tin oxide composite powder is placed in a high-energy ball mill, and wet grinding is carried out under the protection of atmosphere (Ar) until the particle size of the obtained powder is 1 to 2 μm, and the wet-milled powder is placed in an...

Embodiment 2

[0051] 1) Weigh each component according to the following mass percentages, place it in an intermediate frequency induction melting furnace and smelt into a uniform alloy melt, then atomize by high-pressure water atomization equipment, and dry the obtained powder slurry for a temperature of over 200 Mesh sieve, very silver-tin alloy powder;

[0052] Sn: 8%;

[0053] Additives: In 1%, Cu 1%, Ni 1%;

[0054] The remainder is Ag;

[0055] 2) placing the silver-tin alloy powder in a high-pressure oxidation furnace, oxidizing it for 4 hours under the conditions of an oxygen partial pressure of 2 MPa and a temperature of 800° C., taking it out, crushing it, and passing it through a 100-mesh sieve to obtain a silver-tin oxide composite powder;

[0056] 3) The silver tin oxide composite powder is placed in a high-energy ball mill, and wet-milling is carried out under the protection of atmosphere (Ar) until the particle size of the obtained powder is 2-4 μm, and the wet-milled powder...

Embodiment 3

[0061] 1) Weigh each component according to the following mass percentages, place it in an intermediate frequency induction melting furnace and smelt into a uniform alloy melt, then atomize by high-pressure water atomization equipment, and dry the obtained powder slurry for a temperature of over 200 Mesh sieve, very silver-tin alloy powder;

[0062] Sn: 10%;

[0063] Additives: Zn2%;

[0064] The remainder is Ag;

[0065] 2) placing the silver-tin alloy powder in a high-pressure oxidation furnace, oxidizing it for 8 hours under the conditions of an oxygen partial pressure of 0.5 MPa and a temperature of 800° C., taking it out, crushing it, and passing it through a 100-mesh sieve to obtain a silver-tin oxide composite powder;

[0066] 3) The silver tin oxide composite powder is placed in a high-energy ball mill, and wet grinding is carried out under the protection of atmosphere (Ar) until the particle size of the obtained powder is 3 to 5 μm, and the wet-milled powder is plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com