Composite pnenolic aldehyde foam heat-insulating board for building and forming method thereof

A phenolic foam, thermal insulation board technology, applied in thermal insulation, building components, chemical instruments and methods, etc., can solve problems such as poor toughness and easy powdering, and achieve the effect of improving fire resistance, no melting, and ensuring construction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

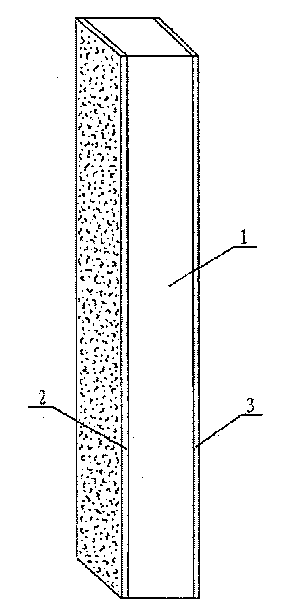

[0052] Examples see figure 1 As shown, the composite phenolic foam insulation board for construction has an upper coating 2 on the upper surface of the phenolic foam insulation board 1 and a lower coating 3 on the lower surface of the phenolic foam insulation board.

[0053] There are raw materials according to the following mass ratio in the composite phenolic foam insulation board:

[0054] [1] 100 parts of foamable phenolic resin.

[0055] [2] Any value between 10 and 25 parts of polyurethane.

[0056] [3] Any value between 0.5 and 5 parts of epoxy resin; the above-mentioned epoxy resin is any one of GEBR-440A80, GEBR-450A80 or GEBR-500A80 special resin for copper foil laminates.

[0057][4] Any value between 10 and 20 parts of the flame retardant; the above-mentioned flame retardant is one or more of tetrabromobisphenol A, chlorinated paraffin, antimony trioxide and flame retardant HT-102 in a mixture.

[0058] [5] Any value between 0.5 and 2 parts of surfactant; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com