Nitride fiber thermal cross-linking assisted atmosphere non-melting method

A nitride and thermal crosslinking technology, which is applied in the fields of fiber chemical characteristics, rayon chemical post-treatment, textiles and papermaking, etc., can solve the problems of unsatisfactory non-melting effect, high cost, and low cost, so as to improve the non-melting effect , Low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

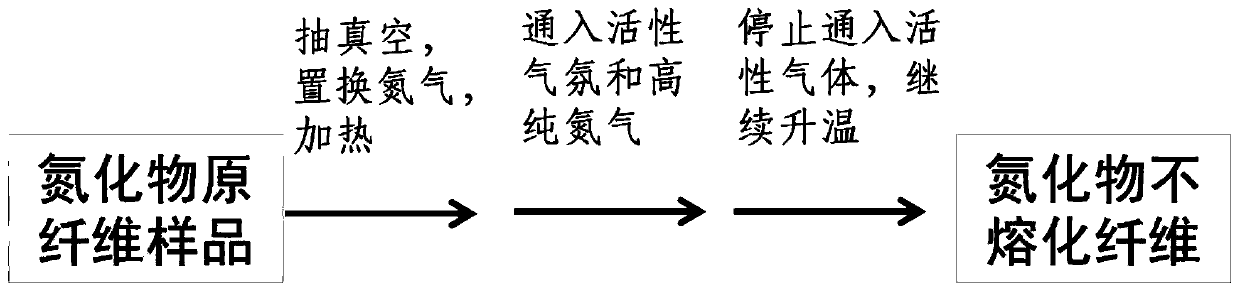

[0036] The present invention provides a kind of atmosphere non-melting method assisted by thermal crosslinking of nitride fiber, comprising the following steps:

[0037] (1) Place 100g polyborosilazane fiber sample in a non-melting atmosphere furnace, vacuumize and replace with high-purity nitrogen, and repeat the operation three times;

[0038] (2) In a high-purity nitrogen atmosphere, the temperature is raised from room temperature to 50 °C at a rate of 1 °C / min, and then trichlorosilane active gas is introduced. The flow ratio of trichlorosilane to high-purity nitrogen is 1:5, and high-purity The flow rate of nitrogen is 1L / min;

[0039] (3) Raise the temperature from 50°C to 120°C at a rate of 0.25°C / min, and keep it at 120°C for 1 hour, then stop feeding the active gas;

[0040] (4) The temperature was raised from 120°C to 350°C at a rate of 1.0°C / min, and kept at 350°C for 2 hours, then heating was stopped and cooled to obtain infusible fibers.

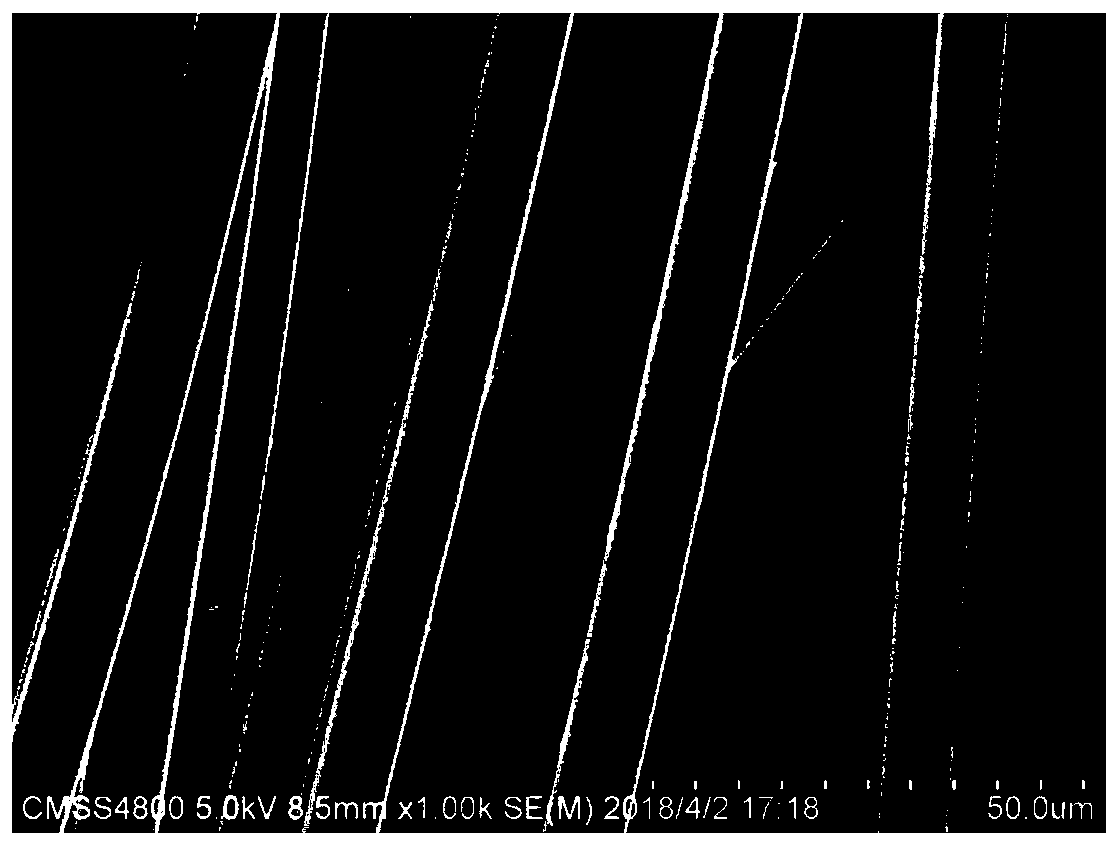

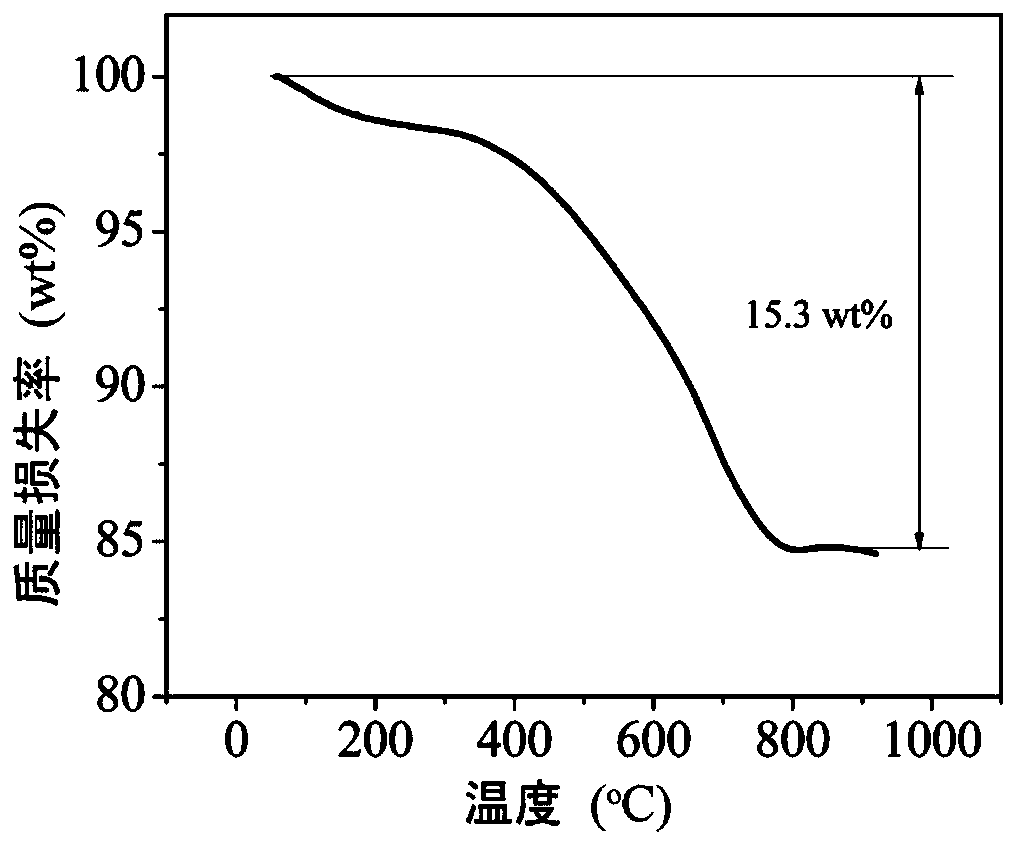

[0041] The infusible f...

Embodiment 2

[0043] The present invention provides a kind of atmosphere non-melting method assisted by thermal crosslinking of nitride fiber, comprising the following steps:

[0044] (1) Place 100g polyborosilazane fiber sample in a non-melting atmosphere furnace, vacuumize and replace high-purity nitrogen, and repeat the operation three times;

[0045] (2) In a high-purity nitrogen atmosphere, the temperature is raised from room temperature to 50 °C at a rate of 10 °C / min, and then boron trichloride active gas is introduced. The flow ratio of boron trichloride and high-purity nitrogen is 1:10, The flow rate of high-purity nitrogen is 0.5L / min;

[0046] (3) Raise the temperature from 50°C to 100°C at a rate of 0.5°C / min, and keep it at 100°C for 1 hour, then stop feeding the active gas;

[0047] (4) Raise the temperature from 100°C to 300°C at a rate of 0.5°C / min, and keep it at 300°C for 2 hours, then stop heating and cool down to obtain infusible fibers.

[0048] The surface of the non...

Embodiment 3

[0050] The present invention provides a kind of atmosphere non-melting method assisted by thermal crosslinking of nitride fiber, comprising the following steps:

[0051] (1) 100g polysilazane fiber sample is placed in a non-melting atmosphere furnace, vacuumized and replaced with high-purity nitrogen, and repeat the operation four times;

[0052] (2) In a high-purity nitrogen atmosphere, the temperature is raised from room temperature to 60 °C at a rate of 5 °C / min, and then trichlorosilane active gas is introduced. The flow ratio of trichlorosilane to high-purity nitrogen is 1:1, and high-purity The flow rate of nitrogen is 2L / min;

[0053] (3) Raise the temperature from 50°C to 150°C at a rate of 1.0°C / min, and keep it at 150°C for 2 hours, then stop feeding the active gas;

[0054] (4) The temperature was raised from 150°C to 350°C at a rate of 2.0°C / min, and kept at 350°C for 1.5h, then the heating was stopped and cooled to obtain infusible fibers.

[0055] The surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com