Motor with braking and decelerating mechanism and for actuating device

A deceleration mechanism and actuating device technology, applied in the field of motors, can solve the problems of small effective contact area, shortened service life, loss of coil springs, etc., achieve low cost, improve user comfort, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The detailed description and technical content of the present invention are described below with accompanying drawings. However, the attached drawings are provided for reference and illustration only, and are not intended to limit the present invention.

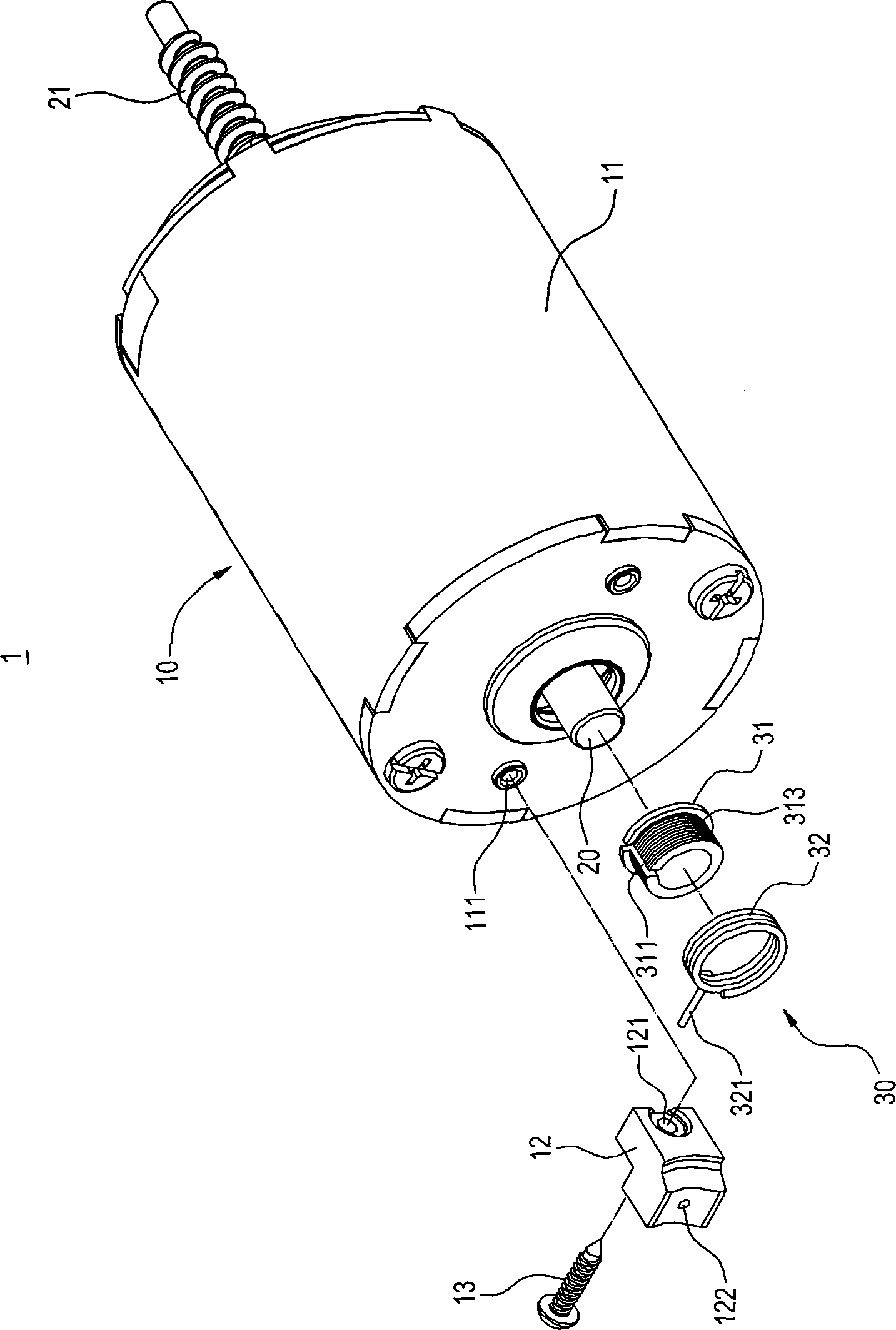

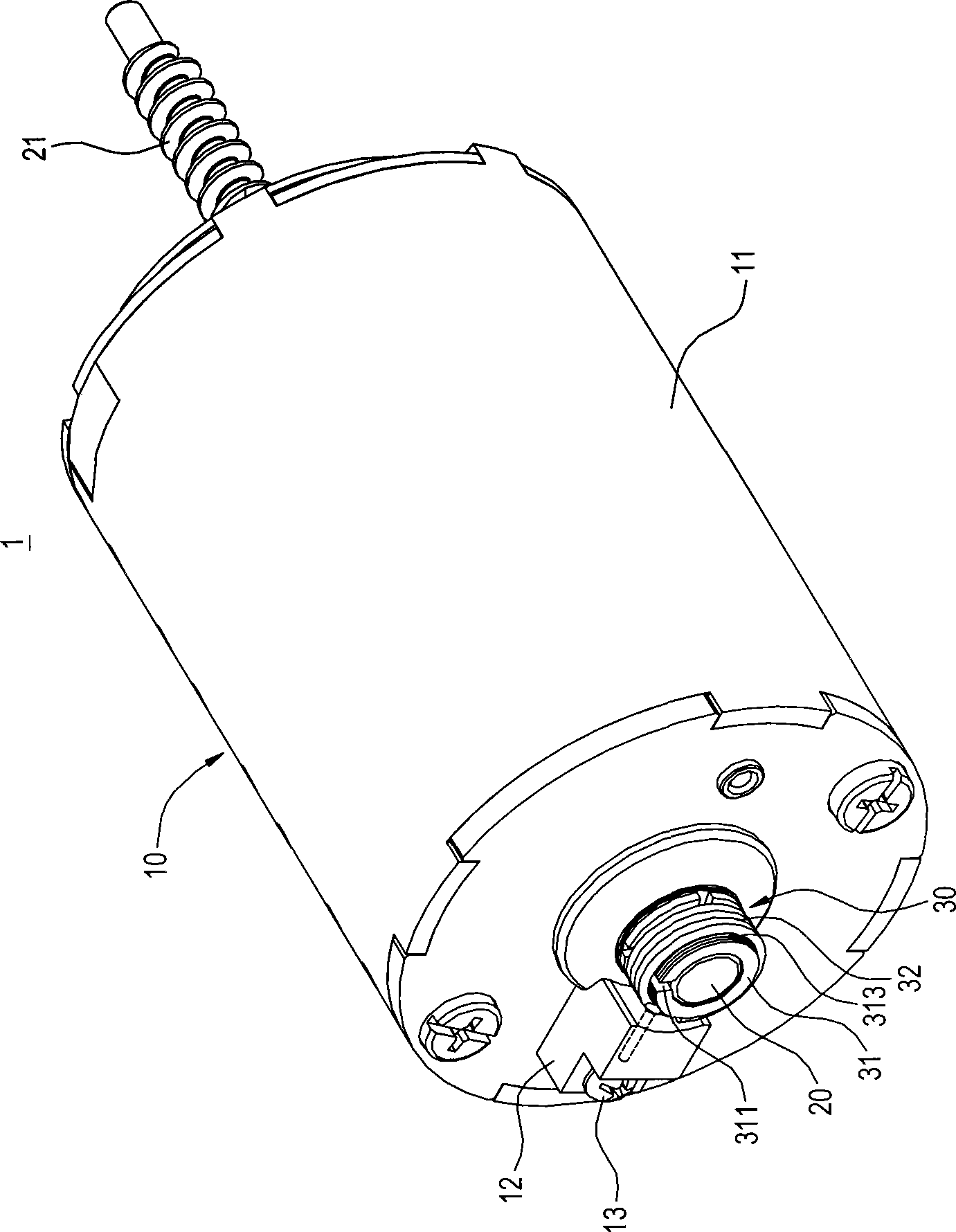

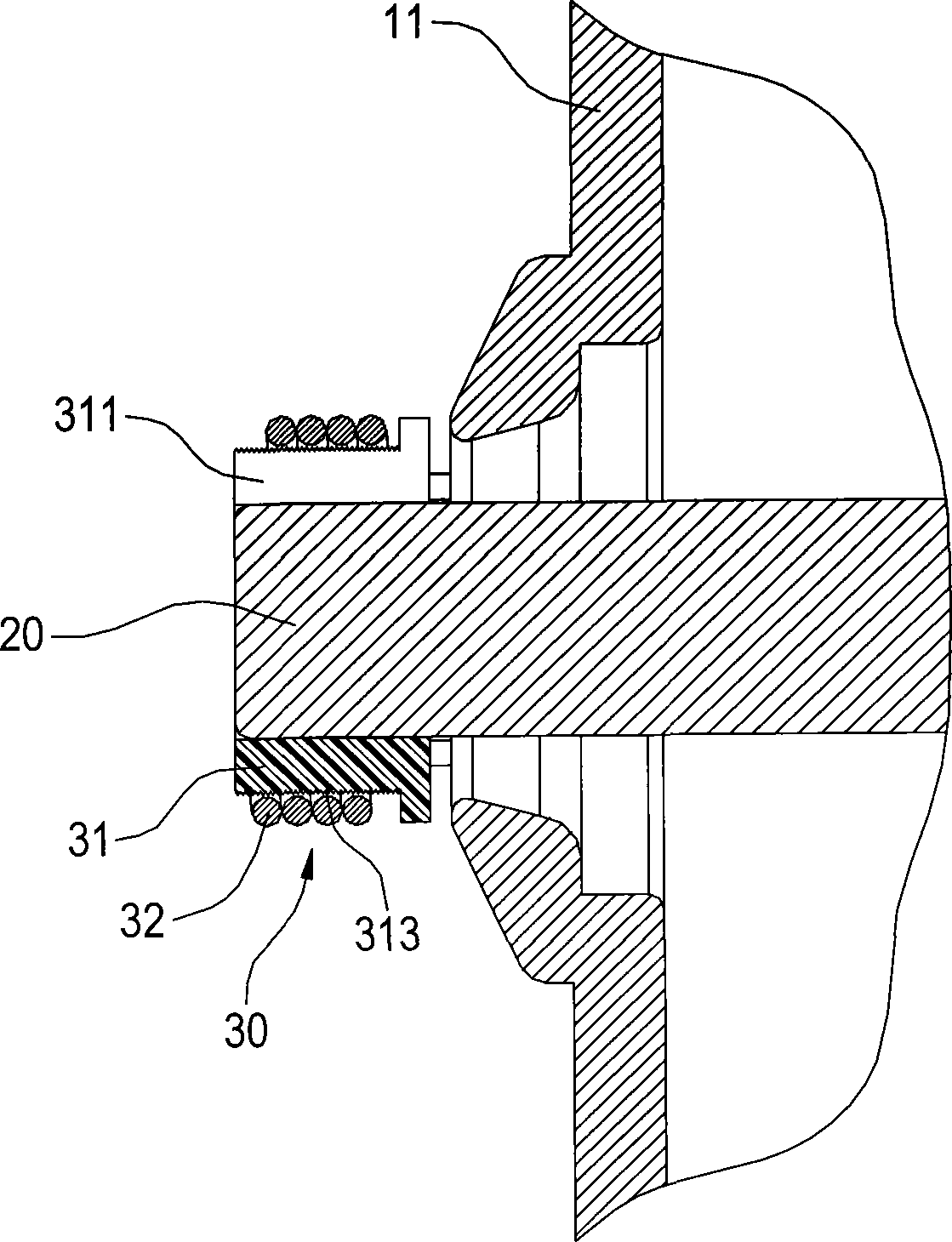

[0052] see Figure 1 to Figure 3 As shown, the present invention provides a motor with a braking deceleration mechanism for an actuator. The motor 1 mainly includes a body 10 , a rotating shaft 20 and a braking deceleration mechanism 30 .

[0053] The main body 10 is mainly composed of a cylindrical shell 11 , a rotor, a stator and a coil set (not shown) accommodated inside the shell 11 , and a plurality of screw holes 111 are provided on the rear end of the shell 11 . The body 10 of this embodiment also includes a fixing piece 12, which is roughly in the shape of a ladder, and has a through hole 121 and an insertion hole 122 on it, and the through hole 121 is used for a screw fixing component 13 to pass through and S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com