Green organic fertilizer fermentation process

A fermentation process and organic fertilizer technology, applied in the direction of organic fertilizer, organic fertilizer equipment, organic fertilizer preparation, etc., can solve the problems of low mass production efficiency, unhealthy health, high fermentation cost, etc., to increase labor costs and shorten fermentation time , The effect of simple feeding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment one: green organic fertilizer fermentation process, comprises the following steps:

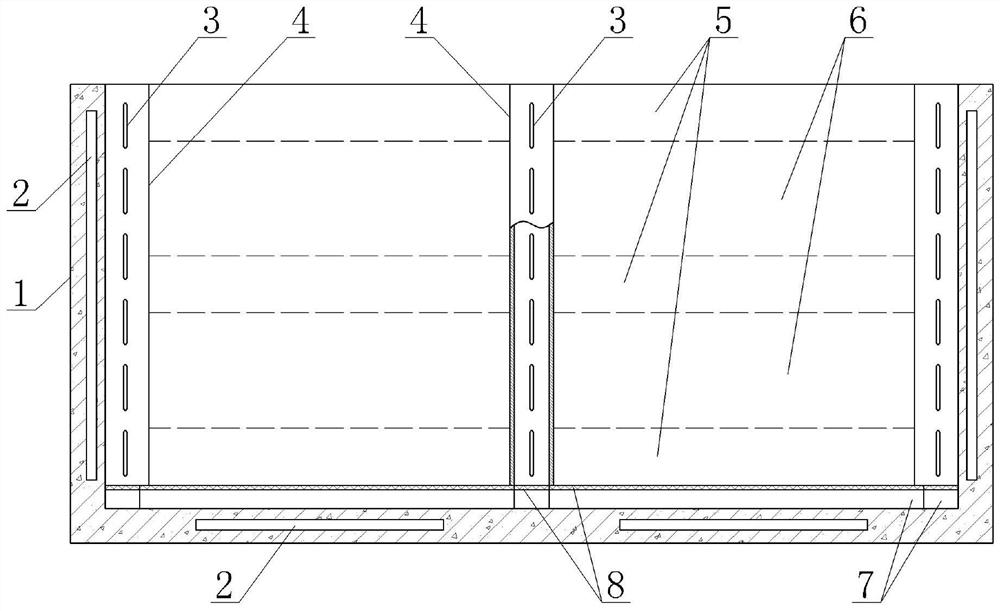

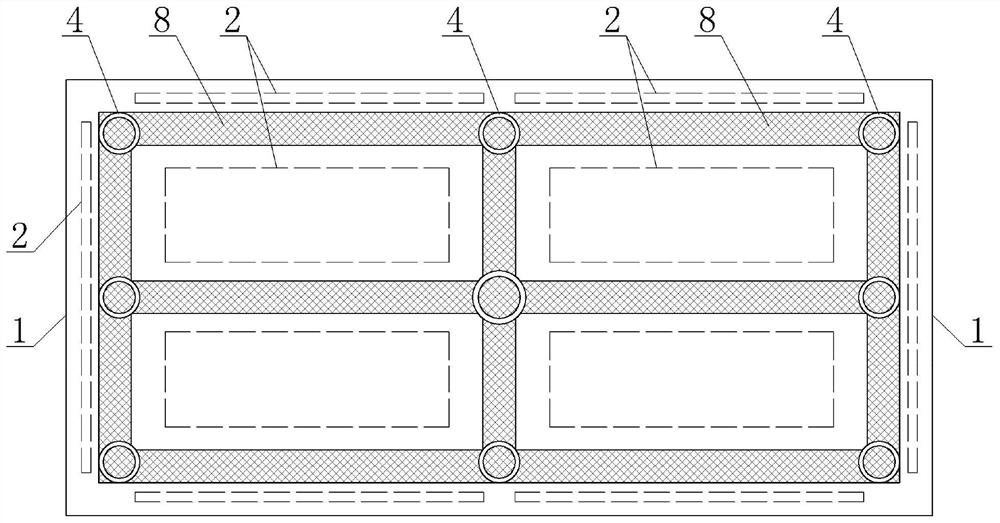

[0039] 1) Build the pool: dig a square pit in the open space, and build the fermentation tank 1 with concrete masonry in the pit. The length of the fermentation tank is 4 meters, the width is 2 meters, and the depth is 2 meters. The thickness of the wall of the fermentation tank is 0.4 meters. , the pool mouth of the fermentation tank is 0.5 meters away from the ground. During the construction of the fermentation tank, an electric heating plate 2 is embedded in the side wall of the fermentation tank. Under the premise of ensuring the surface strength of the side wall of the fermentation tank, the electric heating plate As close as possible to the inner surface of the tank on the side wall of the fermentation tank, it is conducive to heat conduction. The wires of the electric heating plate are thrown out of the tank through the threading pipe to connect with the nearby power su...

Embodiment 2

[0046] Embodiment two: green organic fertilizer fermentation process, comprises the following steps:

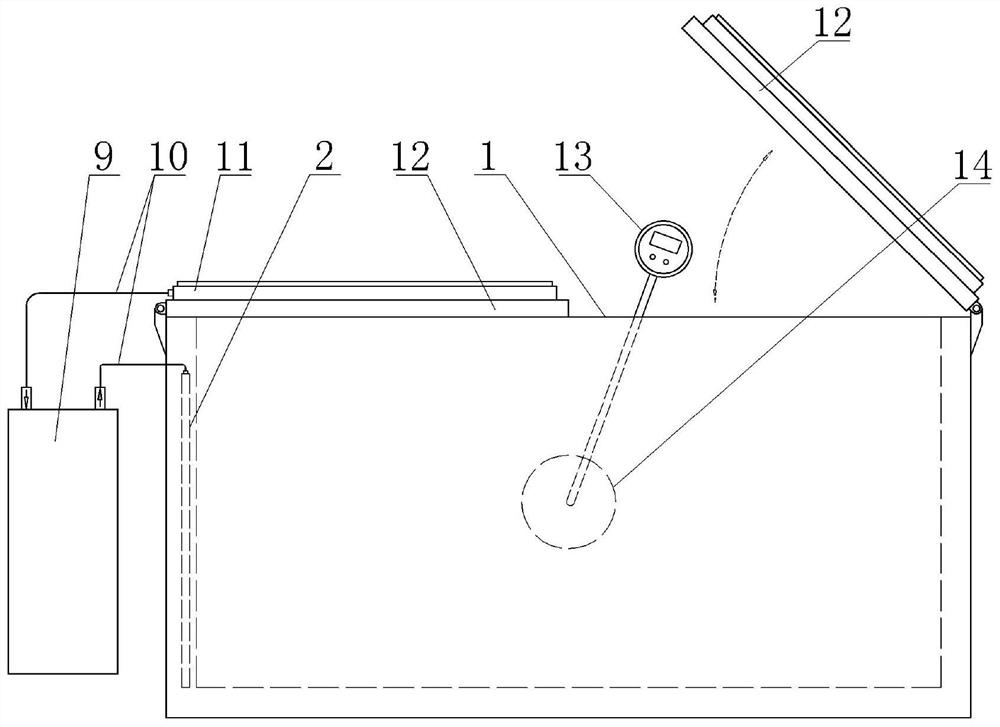

[0047] 1) Building ponds: Dig multiple square pits in a row in the greenhouse, and use reinforced concrete materials to build fermentation ponds in each pit. The length of each fermentation pond is 5 meters, the width is 3 meters, and the depth is 2 meters. The wall thickness of the fermentation tank is 0.5 meters, and the pool mouth of the fermentation tank is equipped with a split pool cover 12, and the pool mouth of the fermentation tank is flush with the ground, and an electric heating plate is embedded in the side wall of the fermentation tank according to the method of embodiment one. , the ground outside the greenhouse is paved with rows of solar cell assemblies 11, and a plurality of storage battery packs 9 are installed in the greenhouse. It is electrically connected with the electric input end of each electric heating plate, and the electric output end of the batter...

Embodiment 3

[0054] Embodiment three: green organic fertilizer fermentation process, comprises the following steps:

[0055] 1) Pool construction: A trough-shaped fermentation tank is constructed by welding stainless steel metal plates in the factory building. The length of the fermentation tank is 4 meters, the width is 2 meters, and the depth is 2 meters. The fermentation tank is fixed on the ground of the factory building through feet , prefabricated a plurality of criss-cross grooves with stainless steel plates on the bottom of the fermentation tank, the depth of the grooves is 12 centimeters, 13 centimeters in width, and each groove is connected to each other, adopting the mode of embodiment one to set the mesh plate and In this structure, the outer surface of each metal plate constituting the fermentation tank is provided with an insulating layer, and the electric heating plate is embedded in the insulating layer, and the heating surface of the electric heating plate is bonded to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com