Putty powder stirring device for building field

A stirring device and putty powder technology, applied in mixers with rotating stirring devices, transportation, packaging, dissolution, etc., can solve the problems of reducing the progress of painting, small volume of mixing tank, inconvenient moving and placement, etc., to ensure uniform mixing, The device has a compact structure and is easy to move and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

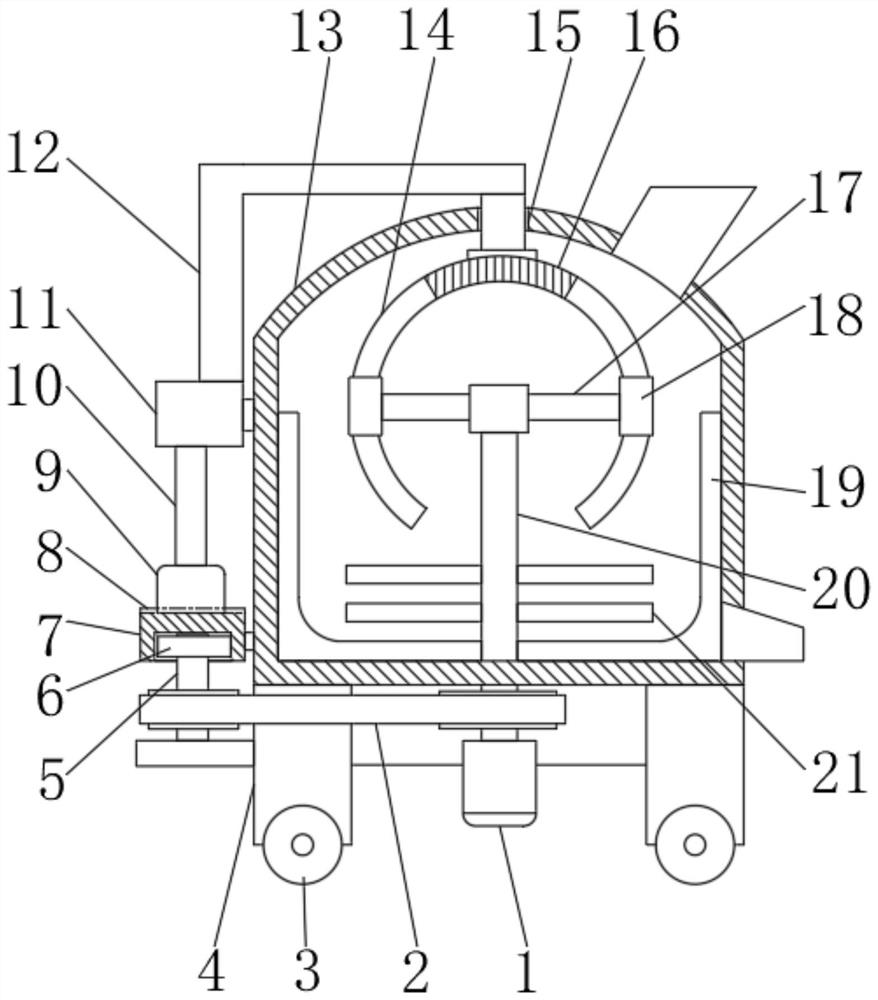

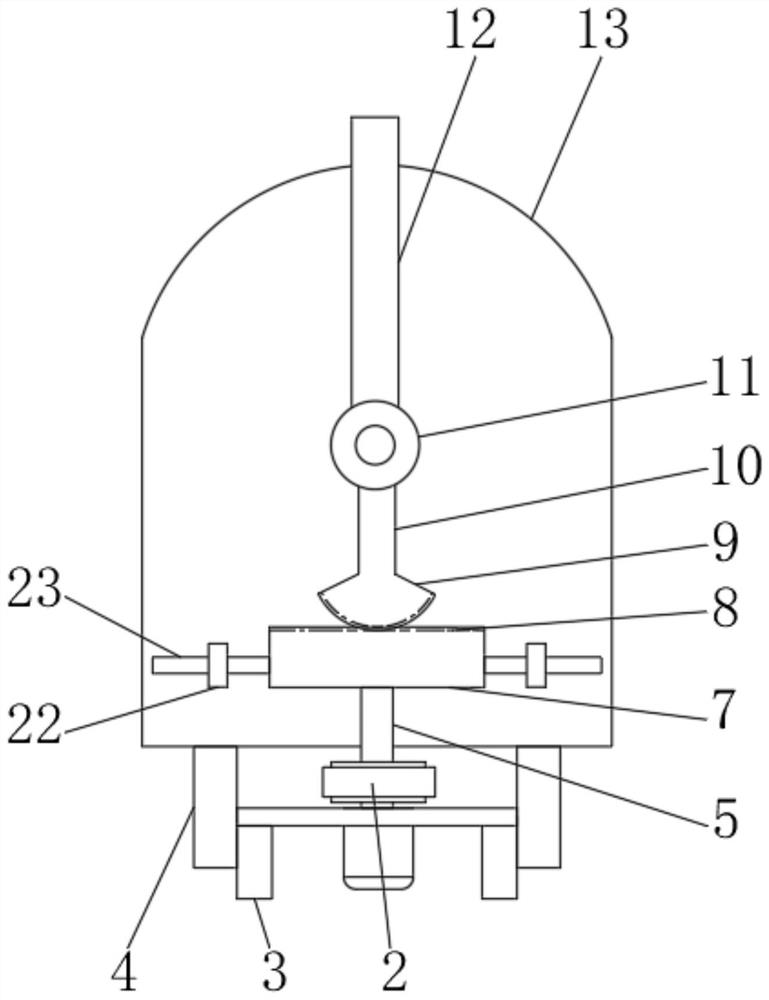

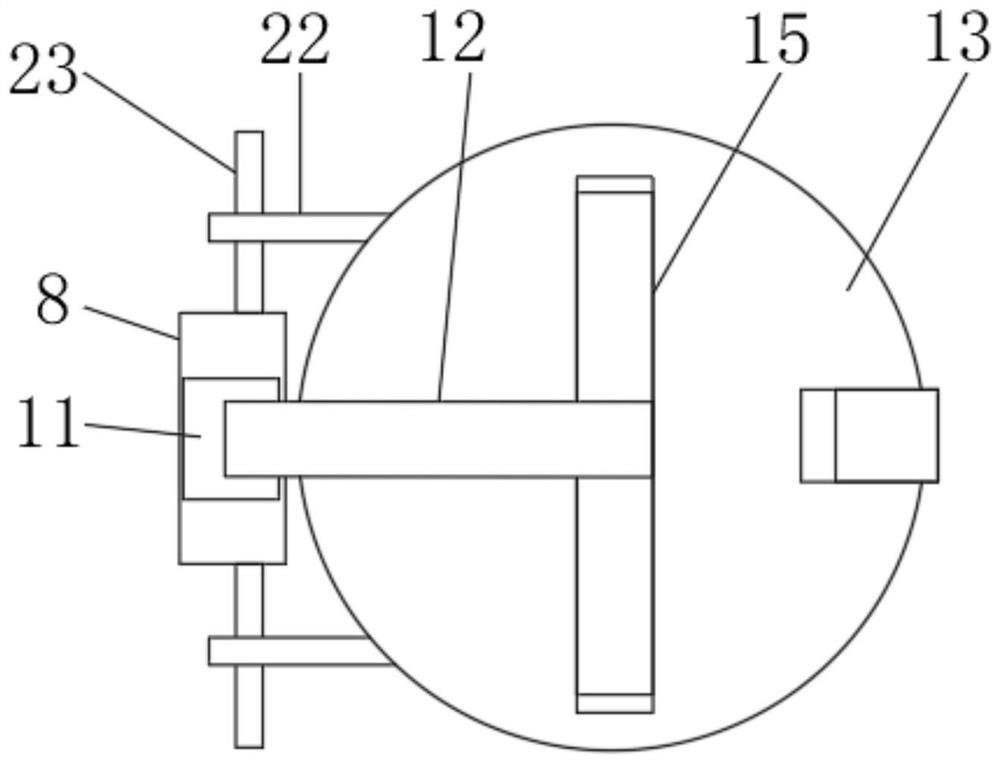

[0026] Embodiment one: refer to Figure 1~4 , in an embodiment of the present invention, a putty powder stirring device for the construction field, including a box body 13, a motor 1 is provided at the outer lower end of the box body 13 to provide a power source, and the output end of the motor 1 is connected to a stirring shaft 20, and the stirring shaft 20 runs through the One end of the box body 13 is evenly provided with a plurality of stirring blades 21 to fully stir and mix the raw materials below the inside of the box body 13. The uppermost end of the stirring shaft 20 is fixedly connected with a bracket 17, and the two ends of the bracket 17 are symmetrically fixedly connected with limited The position block 18, the limit block 18 is moved and connected in the limit groove 14 opened inside the stirring rod 16, so as to realize the movement constraint of the stirring rod 16, and the stirring shaft 20 close to the motor 1 is driven by the belt drive group 2 Connected wit...

Embodiment 2

[0035]Embodiment 2: The invention also provides another embodiment, which is improved on the basis of the above embodiment, and a scraper 19 is fixedly connected to the stirring shaft 20 near the bottom end of the inner wall of the box body 13, The scraper 19 is attached to the inner wall of the box body 13 to clean the inner wall of the box body 13 and prevent the raw materials from adhering to the inner wall of the box body 13 during the stirring process, which wastes materials and is inconvenient for later cleaning.

[0036] In summary, when the invention is working, the raw materials required for the mixing of putty powder and water can be put into the box body 13 through the feed port, the motor 1 is turned on, and under the transmission of the stirring shaft 20, the mixing of the mixing blade 21 to the box body 13 is realized. The raw materials at the bottom of the interior are stirred and mixed, and at the same time through the linkage transmission, the belt drive group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com