Rapid synthesis method of AgGaGenSe2(n+1) series compounds

A synthesis method and compound technology, which can be applied to selenium/tellurium compounds, elemental compounds other than selenium/tellurium, chemical instruments and methods, etc. Long cycle and other problems, to achieve the effect of large single synthesis amount, easy control of components, and fast synthesis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

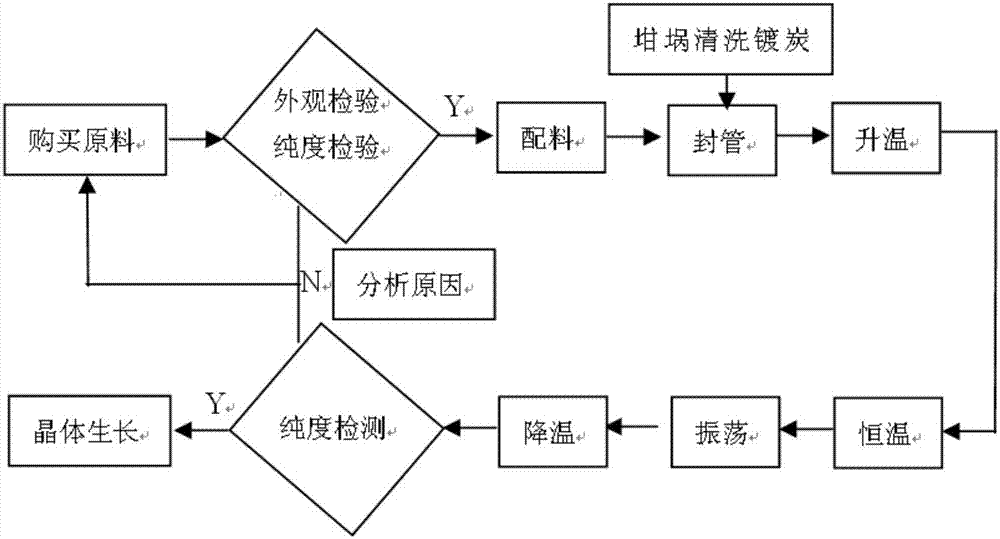

Method used

Image

Examples

Embodiment 1

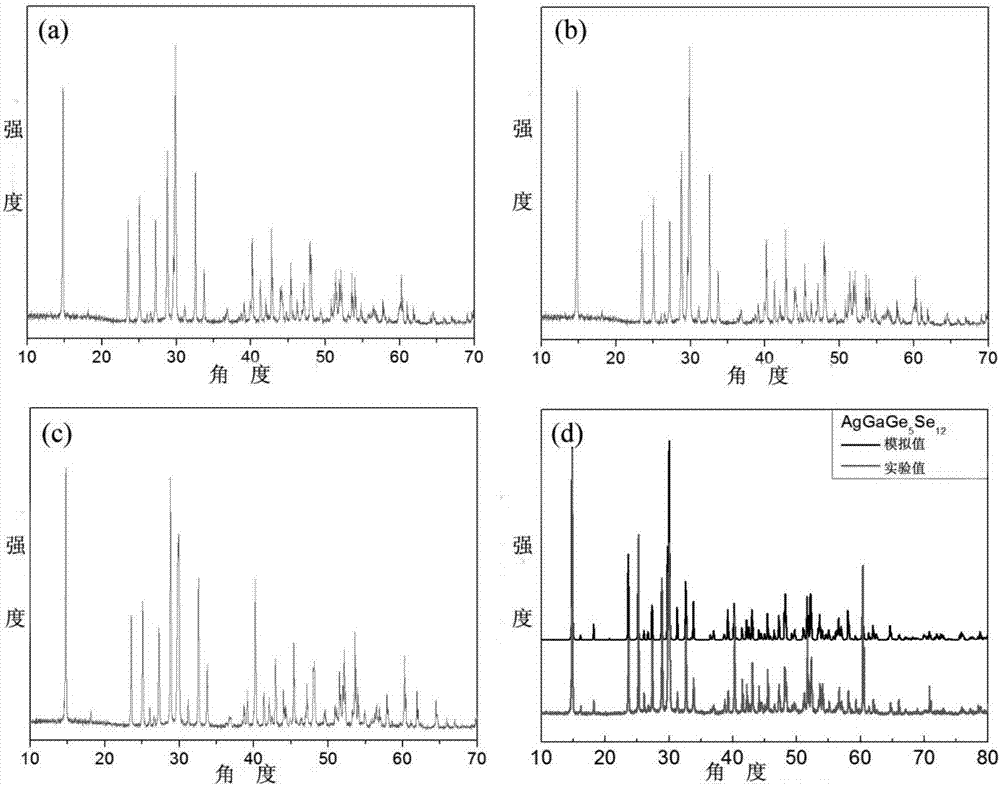

[0028] Example 1: AgGaGe 5 Se 12 Rapid Synthesis of Compounds

[0029] ①Clean and dry the synthetic crucible made of quartz with deionized water, and coat the surface of the crucible with a carbon film;

[0030] ② Use 99.995% pure AgGaSe 2 and GeSe 2 As the initial raw material, according to the amount ratio of 1:5 substance, the total is 400g, the reaction raw material is put into the quartz crucible, and the vacuum is evacuated to 10 -2 Pa sealed;

[0031] ③Put the sealed quartz crucible into a horizontal resistance synthesis furnace, and plug the furnace mouth with high-temperature refractory cotton. 200°C / h to raise the temperature of the resistance synthesis furnace to 900°C. After 4 hours of constant temperature, use manual oscillation to shake the resistance synthesis furnace at a constant speed of 10° / min. The shaking amplitude maintains an angle of 10° with the horizontal ground for 5 minutes;

[0032] ④ After shaking, lower the furnace temperature to 750°C at a...

Embodiment 2

[0033] Example 2: AgGaGe 3 Se 8 Rapid Synthesis of Compounds

[0034] ①Clean and dry the synthetic crucible made of quartz with deionized water, and coat the surface of the crucible with a carbon film;

[0035] ② Use 99.995% purity Ag 2 Se, Ga 2 Se 3 and GeSe 2 As the initial raw material, according to the amount ratio of 1:1:6 substances, the total is 300g, the reaction raw material is put into the quartz crucible, and the vacuum is evacuated to 10 -3 Pa sealed;

[0036] ③ Put the sealed quartz crucible into the vertical resistance synthesis furnace, and plug the furnace mouth with high-temperature refractory cotton. 100°C / h to raise the temperature of the resistance synthesis furnace to 950°C, and after constant temperature for 3 hours, use mechanical oscillation to shake the resistance synthesis furnace at a constant speed of 8° / min. The shaking amplitude maintains an angle of 30° with the horizontal ground for 10 minutes;

[0037] ④ After shaking, lower the furnace...

Embodiment 3

[0038] Example 3: AgGaGe 2 Se 6 Rapid Synthesis of Compounds

[0039] ①Clean and dry the synthetic crucible made of quartz with deionized water, and coat the surface of the crucible with a carbon film;

[0040] ② Use 99.995% pure AgGaSe 2 and GeSe 2 As the initial raw material, according to the ratio of 1:2 substance, the total is 350g, the reaction raw material is put into the quartz crucible, and the vacuum is evacuated to 10 -2 Pa sealed;

[0041] ③Put the sealed quartz crucible into a horizontal resistance synthesis furnace, and plug the furnace mouth with high-temperature refractory cotton. 50°C / h to raise the temperature of the resistance synthesis furnace to 920°C. After constant temperature for 2 hours, use manual oscillation to shake the resistance synthesis furnace at a constant speed of 5° / min. The shaking amplitude maintains an angle of 20° with the horizontal ground for 8 minutes;

[0042] ④ After shaking, lower the furnace temperature to 780°C at a rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com