A kind of method for preparing aluminum hydride

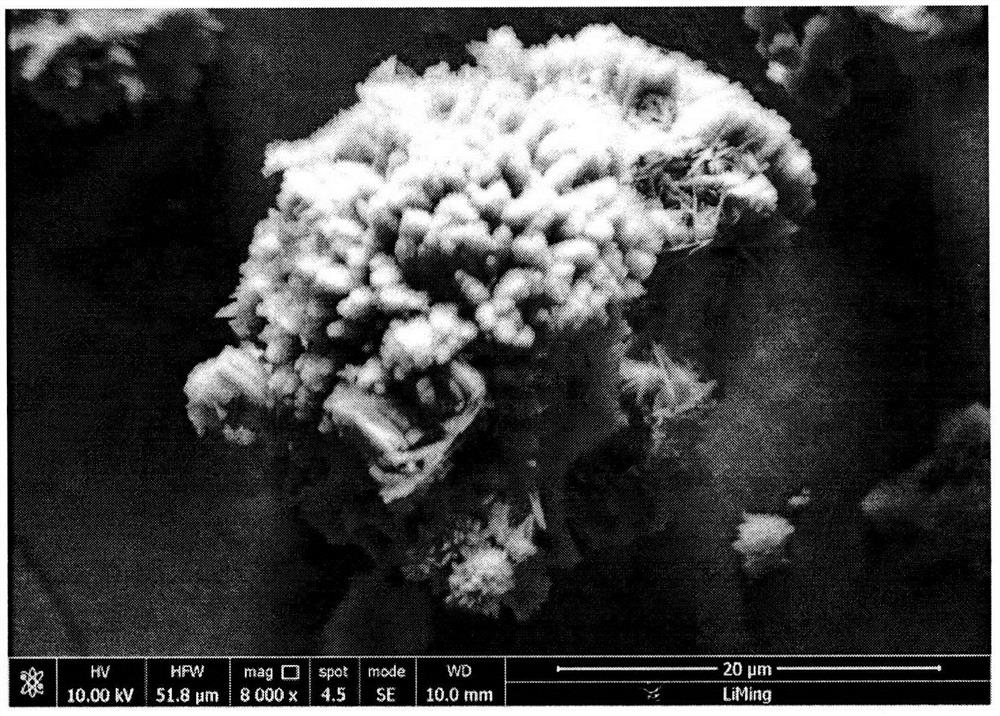

A technology of aluminum hydride and aluminum hydride, applied in chemical instruments and methods, metal hydride, hydrogen, etc., can solve the problems of difficult purification of ammonium aluminum hydride intermediate, low yield of aluminum hydride, and cost of a large amount of ether, etc. Achieve the effects of large product particles, fast synthesis rate, and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

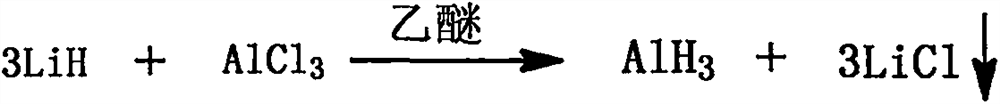

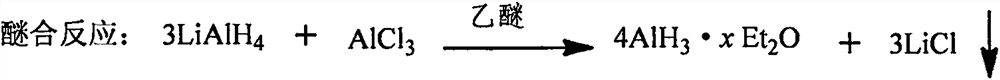

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Under nitrogen protection, weigh 1.56g LiAlH 4 (0.0411mol) in a 500mL three-necked flask, add 150mL of anhydrous toluene, add about 50g of zirconia grinding medium with a particle size of 0.8mm in the three-necked flask, and install a reflux condenser and a constant pressure dropping funnel, and stir vigorously 1h; then weigh 15.95g of purified dioctadecyldimethylammonium chloride (0.0274mol) into a 250mL flask with a branch, add 150mL of anhydrous toluene, heat and stir in an oil bath at 50°C Dissolve; then, transfer the dioctadecyldimethylammonium chloride solution to a constant pressure dropping funnel, and drop it into a three-necked bottle within 30 minutes; after the addition, react at 60°C for 24 hours; the next day, let it stand After cooling, filter through a sand core funnel twice to remove the precipitate and recycle the zirconia grinding medium to obtain a toluene solution of quaternary ammonium aluminum hydride.

[0031] Weigh 0.05gC 60 In the toluene sol...

Embodiment 2

[0033] The crystallization aid is the ground aluminum trihydride seed, and the others are the same as in the examples. The yield is 35%.

Embodiment 3

[0035]It is basically the same as Example 1, except that 1-2 mL of ether is added to the toluene solution of benzyl chloride, and is added dropwise to the toluene solution of quaternary ammonium aluminum hydride along with the benzyl chloride solution, and the reflux state is maintained. Steam out at the end. The yield was 37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com