Method for treating low-grade nickel laterite ore

A laterite nickel ore, low-grade technology, applied in the field of hydrometallurgy, can solve the problems of expensive installation and maintenance, large atmospheric leaching equipment, low nickel and cobalt leaching rate, etc., and achieves low consumption of sulfuric acid and efficient development and utilization. , The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

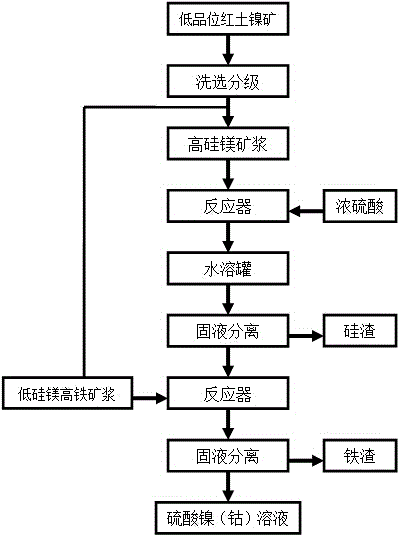

Method used

Image

Examples

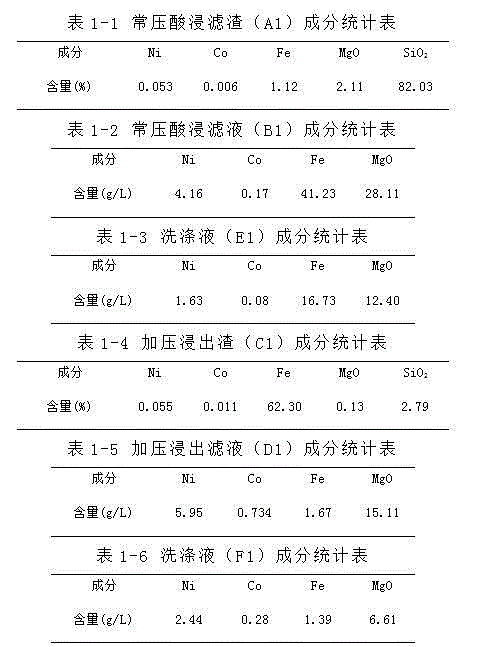

Embodiment 1

[0044] Take 500Kg (dry basis) and grind to -80 mesh 2 # Add 500Kg water to the high-silicon magnesium ore to make high-silicon magnesium slurry, and prepare 500Kg of concentrated sulfuric acid (98%). Use the mortar pump and the concentrated sulfuric acid pump to strictly control the flow rate. The high-silicon magnesium pulp preheated to 100°C and the concentrated sulfuric acid preheated to 180°C are simultaneously added to the feed port of the twin-screw pusher reactor, and the pulp and concentrated sulfuric acid are mixed rapidly. After being flowed into the twin-screw pusher reactor for rapid reaction, it is pushed out of the double-screw pusher reactor. The total reaction time is 10 minutes.

[0045] After cooling down, the reaction material of the crisp and loose honeycomb solid paste is simply broken and poured into a water immersion tank, and 1500Kg of water is added, and stirred for about 30 minutes. Pump the water-soluble slurry into a plate and frame filter press f...

Embodiment 2

[0056] Take 500Kg (dry basis) and grind to -80 mesh 5 # Add 500Kg water to the high-silicon magnesium ore to make high-silicon magnesium slurry, and prepare 500Kg of concentrated sulfuric acid (98%). Use the mortar pump and the concentrated sulfuric acid pump to strictly control the flow rate. The high-silicon magnesium pulp preheated to 80°C and the concentrated sulfuric acid preheated to 160°C are simultaneously added to the feed port of the twin-screw pusher reactor, and the pulp and concentrated sulfuric acid are mixed rapidly. After being flowed into the twin-screw pusher reactor for rapid reaction, it is pushed out of the double-screw pusher reactor. The total reaction time is 10 minutes.

[0057] After cooling down, the reaction material of the crisp and loose honeycomb solid paste is simply broken and poured into a water immersion tank, and 1500Kg of water is added, and stirred for about 30 minutes. Pump the water-soluble slurry into a plate and frame filter press fo...

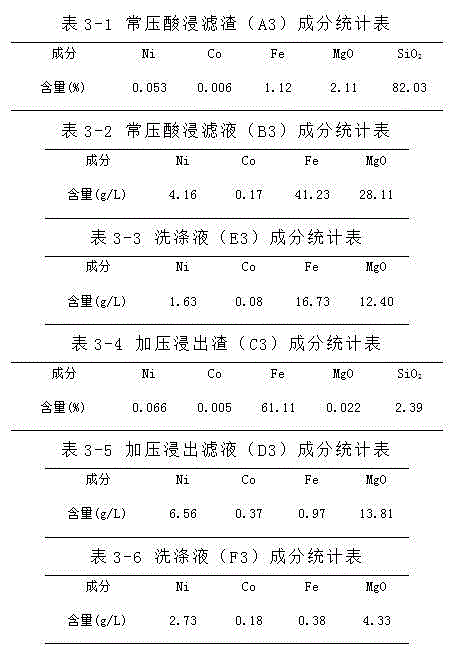

Embodiment 3

[0068] Take 500Kg (dry basis) and grind to -80 mesh 2 # Add 500Kg water to the high-silicon magnesium ore to make high-silicon magnesium slurry, and prepare 500Kg of concentrated sulfuric acid (98%). Use the mortar pump and the concentrated sulfuric acid pump to strictly control the flow rate. The high-silicon magnesium pulp preheated to 100°C and the concentrated sulfuric acid preheated to 180°C are simultaneously added to the feed port of the twin-screw pusher reactor, and the pulp and concentrated sulfuric acid are mixed rapidly. After being flowed into the twin-screw pusher reactor for rapid reaction, it is pushed out of the double-screw pusher reactor. The total reaction time is 10 minutes.

[0069] After cooling down, the reaction material of the crisp and loose honeycomb solid paste is simply broken and poured into a water immersion tank, and 1500Kg of water is added, and stirred for about 30 minutes. Pump the water-soluble slurry into a plate and frame filter press f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com