Method for preparing millimeter-scale polymer composite microsphere

A technology of composite microspheres and polymers, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of increasing the process of solvent collection and processing, increasing production costs and difficulties, and diffusing the atmosphere, and achieves adjustable density, universal Simple sex, avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

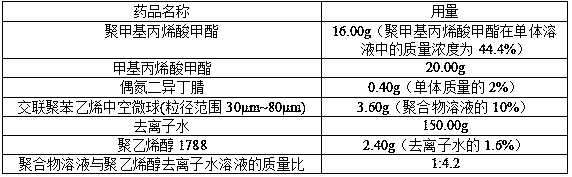

[0022] Example 1: Polystyrene coated carbon black powder to prepare polymer composite microspheres, the specific formula is shown in Table 1:

[0023] Table 1:

[0024]

[0025] Specific steps are as follows:

[0026] (1) Add 20.00g of styrene to a 50mL beaker, then add 1.05g of polystyrene microsphere particles, stir to dissolve completely, then add 0.40g of azobisisobutyronitrile, stir and mix evenly;

[0027] (2) Add 1.06 g of silica particles (particle size range 70-100 μm) to the mixed solution prepared in step (1), stir and mix well;

[0028] (3) Add 100.00g deionized water and 1.00g PVA1788 to a 250mL three-necked reaction flask with a reflux device, a stirrer and a heating device, stir to dissolve it completely, stop stirring, and add the prepared solution in step (2). The mixed solution was heated to 75 °C for 4 hours at a speed of 300 rpm, and then heated to 85 °C for 1 hour. After cooling, filtration, washing and drying, a non-crosslinked polystyrene-coated car...

Embodiment 2

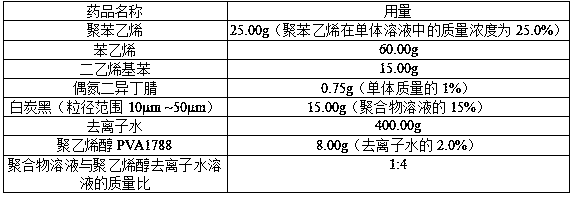

[0030] Example 2: Polystyrene coated silica particles to prepare cross-linked polymer composite microspheres; the specific formula is shown in Table 2.

[0031] Table 2:

[0032]

[0033] Specific steps are as follows:

[0034] (1) Add 60.00g styrene, 15.00g divinylbenzene, 25.00g polystyrene microsphere particles to a 150mL beaker, stir to dissolve completely, then add 0.75g azobisisobutyronitrile, stir to dissolve completely;

[0035] (2) Add 15.00 g of white carbon black (with a particle size range of 10 μm to 50 μm) into the polymer monomer solution prepared in step (1), and fully stir to mix the materials evenly;

[0036](3) Add 400.00g deionized water and 8.00g PVA1788 to a 1L reaction kettle with a reflux device, agitator and heating device, stir to dissolve it completely, stop stirring, add the mixed solution prepared in step (2), Under the rotating speed of 300 rpm and heating up to 70 °C for 4 hours, then heating up to 85 °C and curing for 1 hour, after cooling...

Embodiment 3

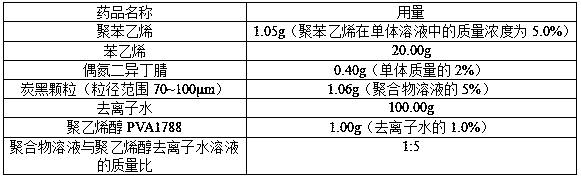

[0038] Example 3: Using waste polystyrene foam board to wrap ferric oxide powder particles to prepare polymer composite microspheres. The specific formula is shown in Table 3;

[0039] table 3:

[0040]

[0041] Specific steps are as follows:

[0042] (1) Take the waste polystyrene foam board, wash it, dry it, crush it into small pieces, add 5.00g vinyl acetate, 30.00g styrene and 35.00g waste polystyrene foam to a 100mL beaker, and stir to make It is completely dissolved, then add 1.05g dibenzoyl peroxide, stir and dissolve completely;

[0043] (2) Add 35.0 g of ferric tetroxide (with a particle size range of 30 μm to 60 μm) into the polymer mixed solution prepared in step (1), and fully stir to mix the materials evenly;

[0044] (3) Add 210.00g of deionized water and 6.3g of PVA1788 to a 1L reactor with a reflux device, a stirrer and a heating device, stir to dissolve it completely, stop stirring, and then add the mixed solution prepared in step (2) , maintained at 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com