Al4SiC4 refractory material and preparation method thereof

A refractory material and premix technology, applied in the field of refractory materials, can solve the problems of high reaction temperature and long holding time, and achieve the effects of low reaction temperature, fast synthesis rate and short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

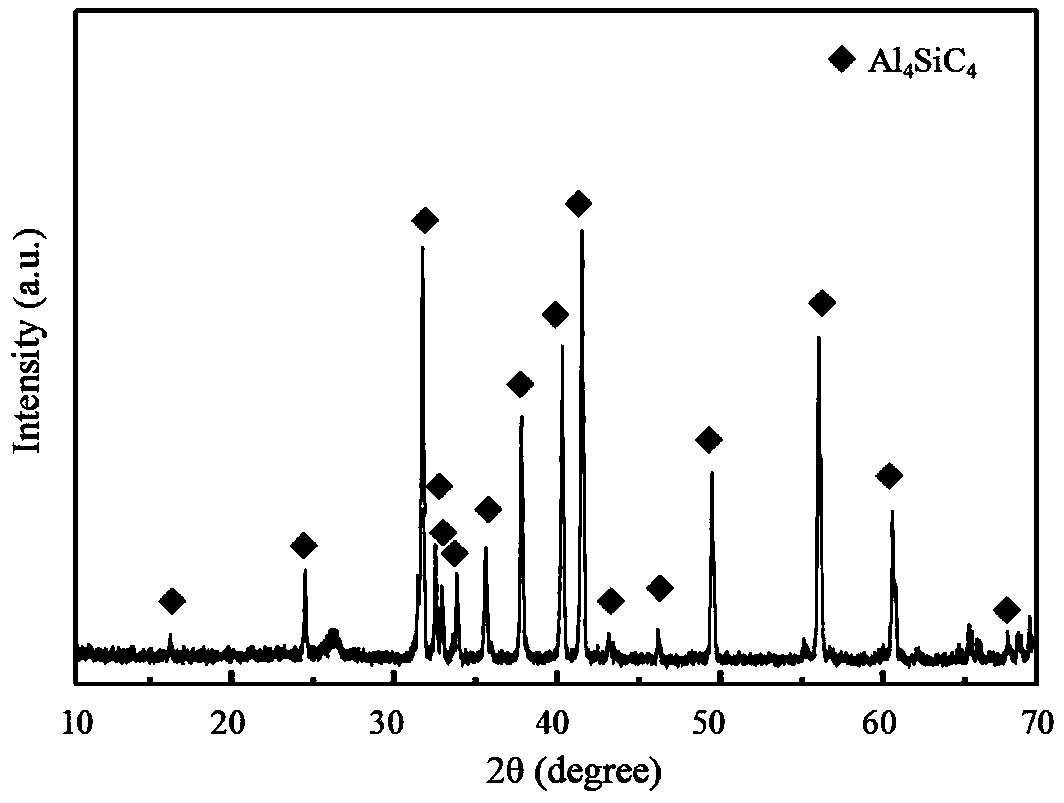

Image

Examples

Embodiment 1

[0024] This embodiment prepares Al 4 SiC 4 The refractory methods are:

[0025] Add metal aluminum, elemental silicon and aluminum-silicon alloy to the thermosetting phenolic resin, control the molar ratio of Al, Si and C to 4:1:4, and stir evenly to obtain the premix; then put the above premix at 200°C Bake for 27 hours, then treat it in an induction furnace, heat it up to 1000°C at a rate of 10°C / min for heating reaction, and then heat it at 1000°C for 0.5 h, that is Al 4 SiC 4 refractory material.

[0026] Al prepared in this example 4 SiC 4 Refractory material, purity ≥ 80%, after 1000°C water vapor corrosion for 100h (water vapor to air volume ratio is 1:4, total pressure is 1 standard atmospheric pressure), the weight gain rate is 3.75%.

Embodiment 2

[0028] This embodiment prepares Al 4 SiC 4 The refractory methods are:

[0029] Add metal aluminum, elemental silicon and aluminum-silicon alloy to the thermosetting phenolic resin, control the molar ratio of Al, Si and C to 4:1:4.2, stir evenly, and obtain the premix; then put the above premix at 200°C Bake for 24 to 30 hours, then go through induction furnace treatment, heat reaction and heat preservation in the induction furnace under a protective atmosphere, in which the rate is raised to 1200°C at a rate of 11°C / min for heating reaction, and after heating reaction at 1200°C Keep it warm for 0.5h to get Al 4 SiC 4 refractory material.

[0030] Al prepared in this example 4 SiC 4 Refractory material, purity ≥ 83%, after 1000°C water vapor corrosion for 100h (water vapor to air volume ratio is 1:4, total pressure is 1 standard atmospheric pressure), the weight gain rate is 3.35%.

Embodiment 3

[0032] This embodiment prepares Al 4 SiC 4 The refractory methods are:

[0033] Add metal aluminum, elemental silicon and aluminum-silicon alloy to the thermosetting phenolic resin, control the molar ratio of Al, Si and C to 4:1:4.4, stir evenly, and obtain the premix; then put the above premix at 200°C Bake for 24 to 30 hours, then pass through the induction furnace, and then heat the reaction and heat preservation in the induction furnace under the protective atmosphere. Keep it warm for 0.5h to get Al 4 SiC 4 refractory material.

[0034] Al prepared in this example 4 SiC 4 Refractory material, purity ≥ 85%, after 1000°C water vapor corrosion for 100h (water vapor to air volume ratio is 1:4, total pressure is 1 standard atmospheric pressure), the weight gain rate is 2.95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com