A kind of manganese series inverse spinel phase high emissivity infrared pigment and preparation method thereof

A technology of inverse spinel and high emissivity, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve the problems of low synthesis rate, unfavorable transition metal doping, high energy consumption, etc., and achieve crystal grain Small and uniform, increase structural defects, and improve infrared performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

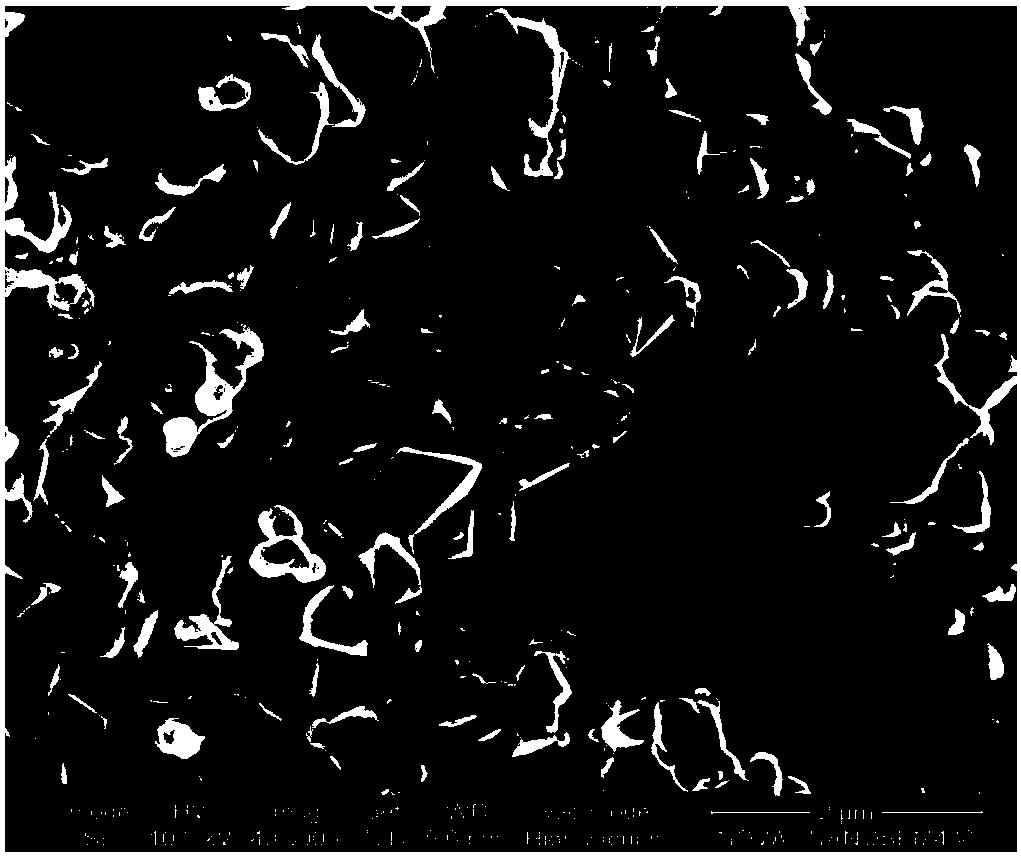

[0044] A preparation method of a spinel phase high emissivity infrared pigment, comprising the following steps:

[0045] (1) Take 32gCo 2 o 3 with 68g electrolytic MnO 2 Mix, add 5ml of sodium polyacrylate and 2ml of glycerin, then add 93ml of water and alcohol mixture mixed at a volume ratio of 1:1, grind for 30min according to the material: ball mill: liquid ratio of 1:1:1, and the speed is 300r / min , take out the material, then pour the material into a tray, put it in an oven at 150°C to dry, and obtain a mixture;

[0046] (2) 30g of the mixture of step (1) is packed into a diameter of 30cm and a height of 80cm in a ceramic crucible, which is placed in a thermal insulation saggar mullite fiber sagger, and is tightly sealed with ceramic wool around the device; The sagger of the material is placed in a microwave sintering furnace, and the microwave with a power of 20kW is used for 2 minutes, and the microwave of 6kW is used for 3 minutes. After the temperature of the mater...

Embodiment 2

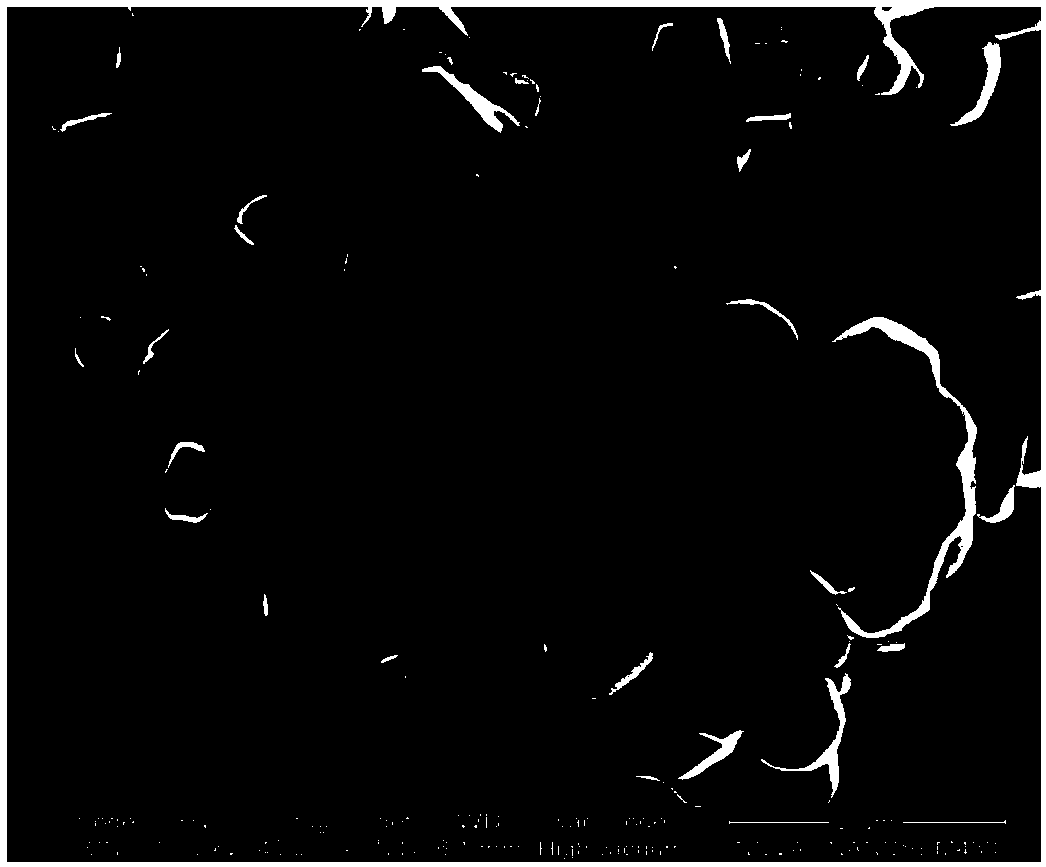

[0051] A preparation method of a spinel phase high emissivity infrared pigment, comprising the following steps:

[0052] (1) 25gCo 2 o 3 with 75g electrolytic MnO 2 Mix, add 5ml of sodium polyacrylate and 2ml of glycerin, then add 93ml of water and alcohol mixture mixed at a volume ratio of 1:1, grind for 30min according to the material: ball mill: liquid ratio of 1:1:1, and the speed is 300r / min , taking out the material, pouring the material into a tray, and drying it in an oven at 150°C to obtain a mixture;

[0053] (2) 30g of the mixture of step (1) is packed into the crucible, the crucible is put into the mullite fiber sagger, and the seal is intact, the sagger of the device material is placed in the microwave sintering furnace, and the microwave with a power of 10kW After acting for 4 minutes and 6kW microwave for 3 minutes, the temperature of the material rose to 900°C, the microwave was stopped, and after 30 minutes, the material was taken out from the sagger to obt...

Embodiment 3

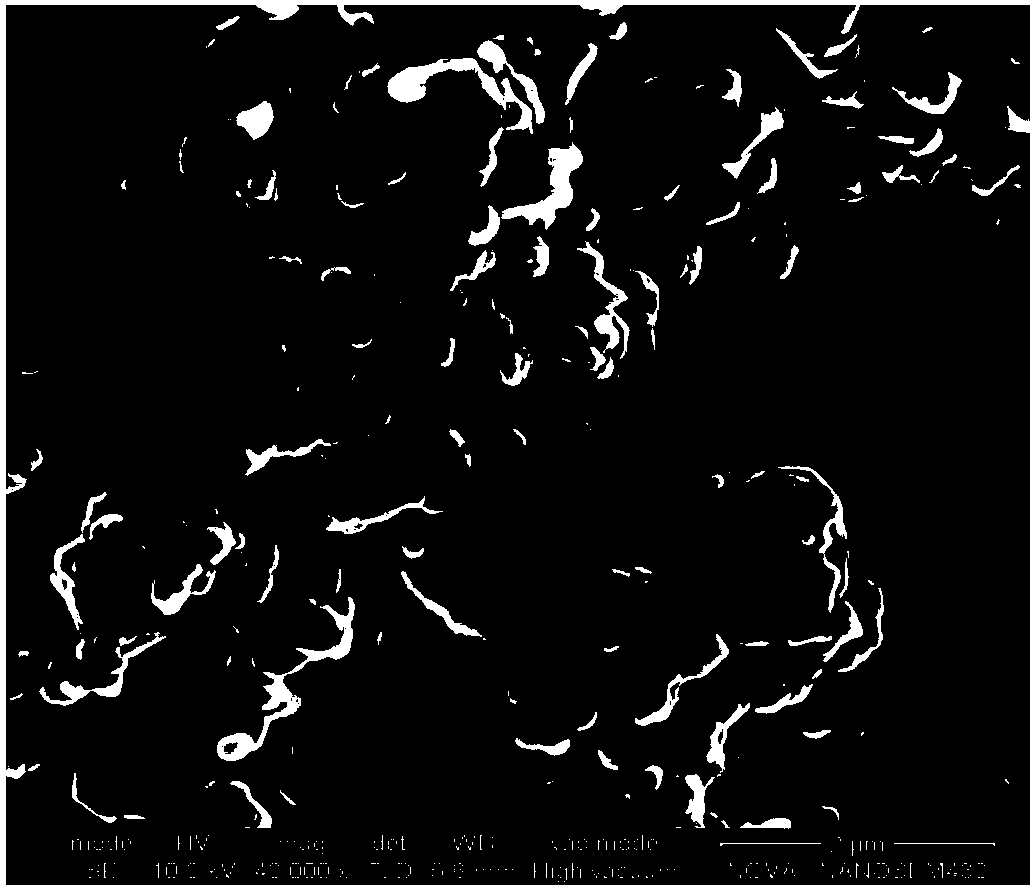

[0058] A preparation method of a spinel phase high emissivity infrared pigment, comprising the following steps:

[0059] (1) 30gCo 2 o 3 with 70g electrolytic MnO 2 Mix, add 5ml of sodium polyacrylate and 2ml of glycerin, then add 93ml of water and alcohol mixture mixed at a volume ratio of 1:1, grind for 30min according to the material: ball mill: liquid ratio of 1:1:1, and the speed is 300r / min , take out the material, then pour the material into a tray, put it in an oven at 150°C to dry, and obtain a mixture;

[0060] (2) Put 30g of the mixture of step (1) into the mullite fiber sagger, and seal it well, place the sagger of the device material in a microwave sintering furnace, and use a microwave with a power of 10kW for 4min, and a microwave with a power of 6kW After 3 minutes, the temperature of the material rises to 900°C, stop the microwave, take out the material from the sagger after 30 minutes, and you can get (CoMn)(CoMn) 2 o 4 crystalline powder;

[0061] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com