A kind of brine impurity removal device and impurity removal process

A brine and process technology, which is applied in the field of brine removal devices and impurities removal processes, can solve the problems of slow filtration, high water content in filter cakes, and inability to form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

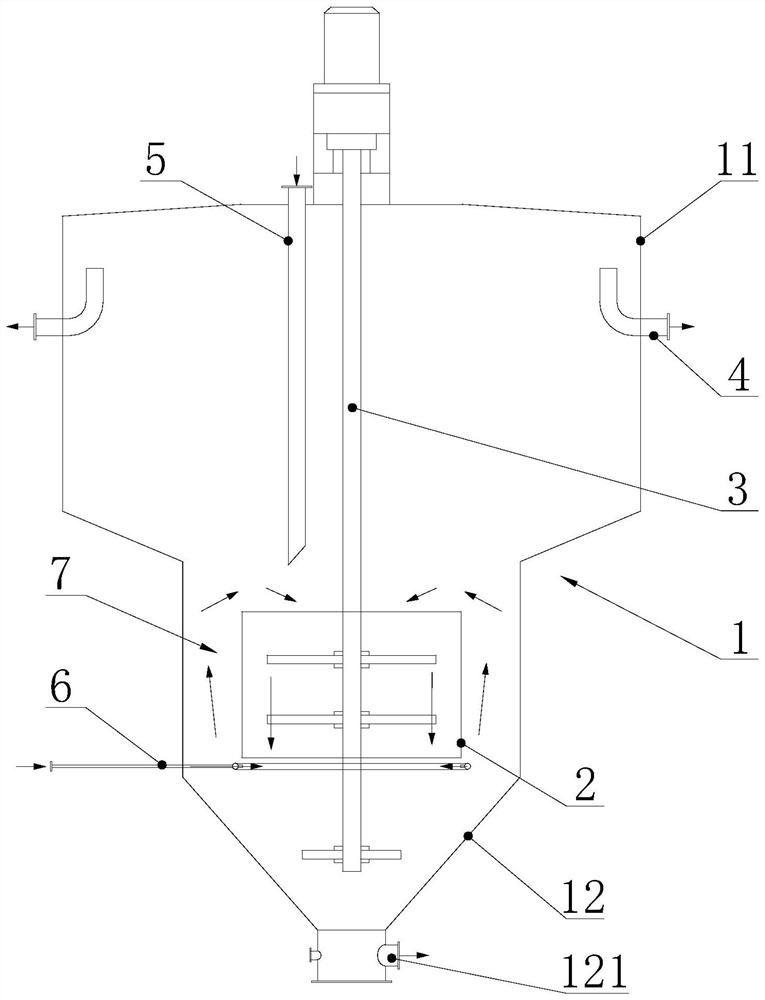

[0032] see figure 1, The brine impurity removal device includes a cylindrical shell 1 , a guide tube 2 , and a stirring device 3 . The cylindrical shell 1 is composed of an upper cylindrical shell 11 and a lower conical shell 12. The bottom of the conical shell 12 is provided with a salt mud outlet 121, which is opened and closed by a valve. Close, in the present embodiment, the inner space of the cylindrical section housing 11 is a stepped shape with the upper part being a large diameter section and the lower part being a small diameter section, and a cone-shaped section passes between the large diameter section and the small diameter section of the cylindrical section housing 11. The shells are connected, the big end of the conical shell faces upwards, the small end of the conical shell faces downwards, the shell of the cylindrical section and the shell of the conical section are made of stainless steel, and the large diameter of the shell of the cylindrical section The upp...

Embodiment 2

[0035] The brine impurity removal device of Example 1 was used to carry out the impurity removal test, and the capacity of the cylindrical shell was 25L.

[0036] In the brine to be removed, the content of sodium chloride is 300g / l, the content of calcium chloride is 2.8g / l, and the content of magnesium chloride is 2.0g / l.

[0037] The removal steps are:

[0038] 1) Add brine to the brine impurity removal device, the added brine overflows the upper opening of the guide tube in the brine impurity removal device, and add 19g of magnesium hydroxide and 40g of calcium carbonate as crystal seeds;

[0039] 2) Turn on the stirring device, stir at a rotating speed of 60rpm, add brine to the upper part of the inner space of the draft cylinder through the brine delivery pipe, and add the impurity remover to the lower part of the inner space of the draft barrel through the impurity removal agent delivery pipe, and control the flow rate of the brine to 80ml / min. The flow rate of impurity...

Embodiment 3

[0043] The brine impurity removal device of Example 1 was used to carry out the impurity removal test, and the capacity of the cylindrical shell was 25L.

[0044] In the brine to be removed, the content of sodium chloride is 300g / l, the content of calcium chloride is 3.4g / l, and the content of magnesium chloride is 1.6g / l.

[0045] The removal steps are:

[0046] 1) Add brine to the brine impurity removal device, the added brine overflows the upper opening of the guide tube in the brine impurity removal device, and add 3 g of magnesium hydroxide and 9 g of calcium carbonate as crystal seeds;

[0047] 2) Turn on the stirring device, stir at a rotating speed of 60rpm, add brine to the upper part of the inner space of the draft cylinder through the brine delivery pipe, and add the impurity remover to the lower part of the inner space of the draft barrel through the impurity removal agent delivery pipe, and control the flow rate of the brine to 80ml / min. The flow rate of impurity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com