Whole grain premixed dumpling flour containing puffed sorghum, and preparation method thereof

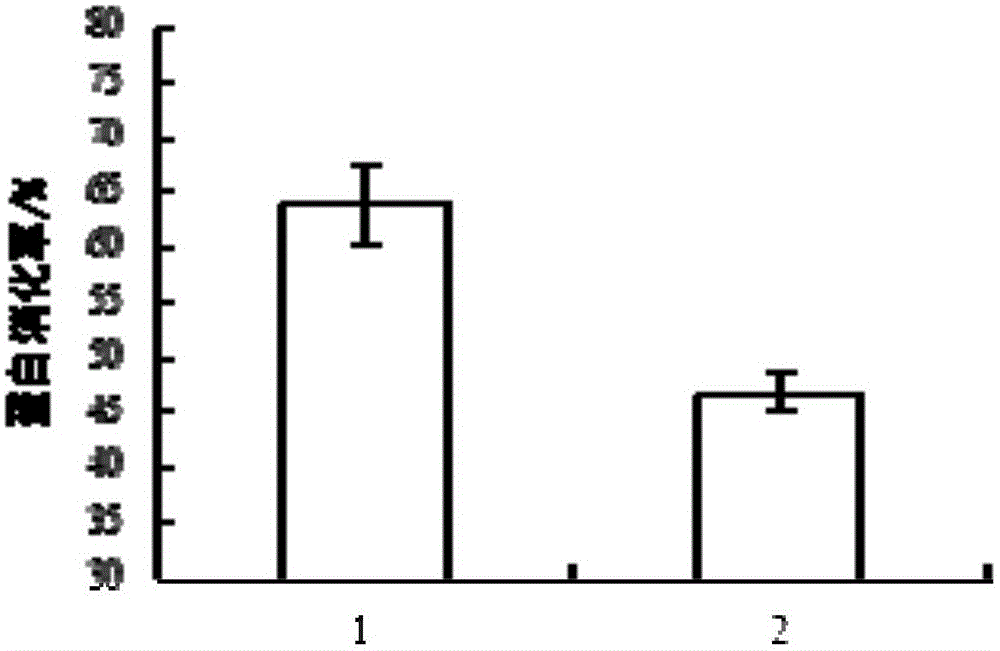

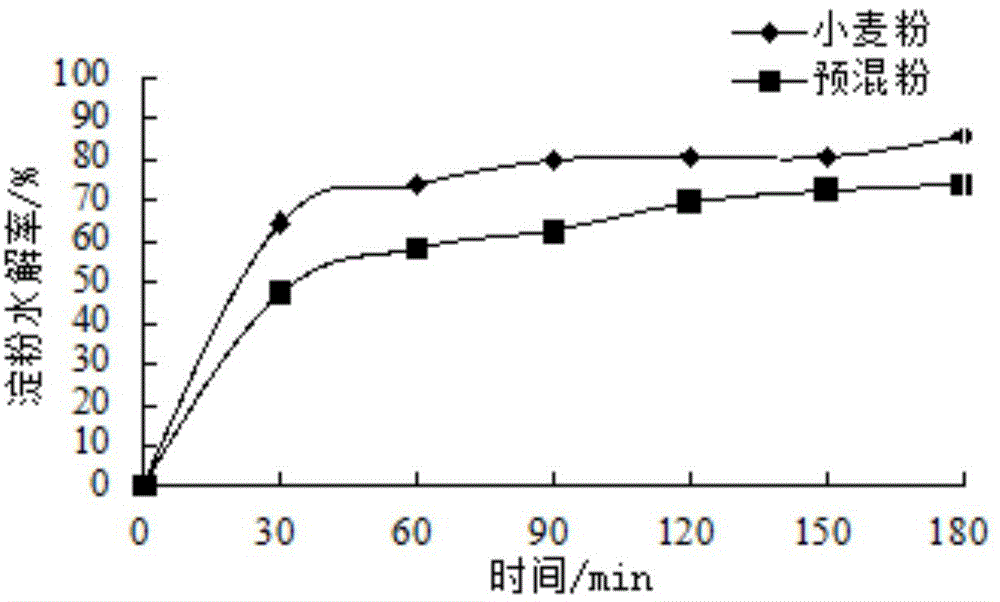

A technology of whole grain and dumpling flour, applied in food preparation, food science, application and other directions, can solve the problems of low protein digestibility of sorghum flour, slow hydrolysis rate of starch substances, etc., and achieve the effect of improving functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1: The preparation method of whole-grain red sorghum puffed powder 1: take red sorghum grains with a peeling rate of 6%, grind them to 60 mesh, and adjust the moisture content of the material to 18%-22% for the obtained whole-grain red sorghum raw powder. After sealing overnight, carry out extrusion puffing. The puffing temperature is set to 100°C in zone I, 120°C in zone II, and 150°C in zone III (manufacturer: Jinan Saixin Machinery Co., Ltd., model: DS32-II). The feed rate is 6kg / h, the screw speed is 240r / min, the puffed product is crushed to 90-100 mesh, and the moisture content of the puffed powder is 10%-12%.

Embodiment 2

[0071] Example 2: The preparation method of whole grain red sorghum puffed powder 2: the sorghum bran powder crushed to 60 mesh is added to the sorghum fine powder at a ratio of 20% (based on the whole grain red sorghum raw powder as 100%) to obtain whole grain For raw red sorghum powder, adjust the moisture content of the material to 18%-22%. After sealing overnight, carry out extrusion and puffing. The feed rate is 5kg / h, the screw speed is 230r / min, the puffed product is crushed to 90-100 mesh, and the moisture content of the puffed powder is 10%-12%.

Embodiment 3

[0072] Example 3: The preparation method of whole grain red sorghum puffed powder 3: the sorghum bran powder crushed to 60 mesh is added to the sorghum fine powder at a ratio of 15% (based on the whole grain red sorghum raw powder as 100%) For grain red sorghum raw powder, adjust the moisture content of the material to 18%-22%. After sealing overnight, carry out extrusion and puffing. The feed rate is 6.5kg / h, the screw speed is 210r / min, the puffed product is crushed to 90-100 mesh, and the moisture content of the puffed powder is 10%-12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com