A method for preparing high-purity sodium fluorotitanate

A technology of pure sodium fluorotitanate and sodium fluorotitanate, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problem of high price of sodium fluorotitanate, different quality of sodium fluorotitanate, and harsh production process and other issues, to achieve the effect of reducing the difficulty of process implementation, good product index stability, and improving the applicability of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

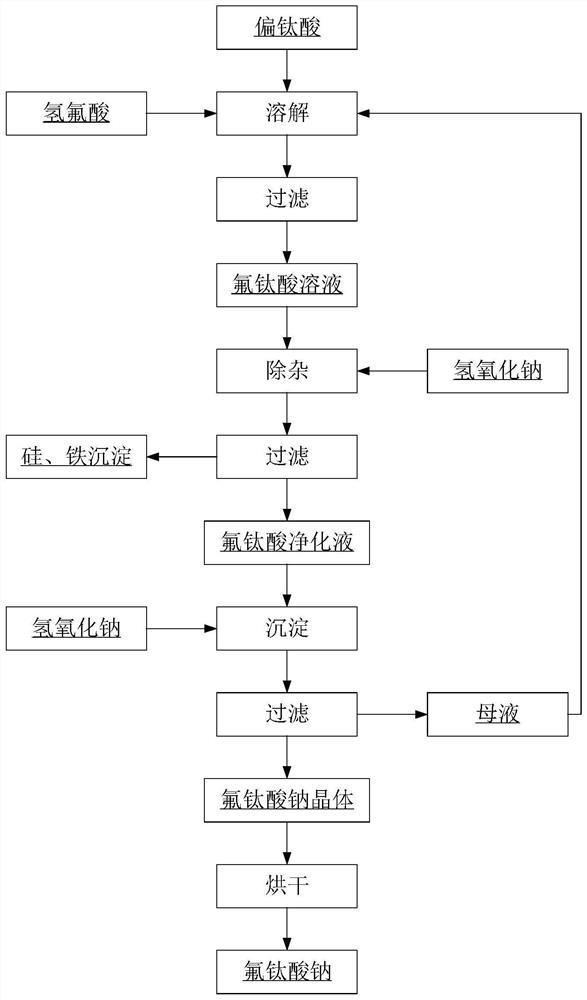

Image

Examples

Embodiment 1

[0036]This embodiment provides a method for preparing high-purity sodium fluorotitanate, the method comprising the following steps:

[0037] (1) Add hydrofluoric acid to metatitanic acid, control the molar ratio of fluorine and titanium to 6:1, stir and react at 30-40°C for 20 minutes, and obtain fluorotitanic acid solution after solid-liquid separation;

[0038] (2) adding concentration to the fluorotitanic acid solution obtained in step (1) is 20wt% NaOH solution, controlling the mol ratio of NaOH and silicon in the solution to be 1.2:1, stirring for 3h, solid-liquid separation after completion of the reaction, Obtain a fluorotitanic acid purification solution with a silicon element concentration of <100mg / L and an iron element concentration of <50mg / L;

[0039] (3) Adding a NaOH solution with a concentration of 20 wt% to the fluorotitanic acid purification solution obtained in step (2), controlling the mol ratio of NaOH and titanium in the mixed solution to be 1.3:1, stirri...

Embodiment 2

[0042] This embodiment provides a method for preparing high-purity sodium fluorotitanate, the method comprising the following steps:

[0043] (1) Add hydrofluoric acid to metatitanic acid, control the molar ratio of fluorine and titanium to 6.5:1, stir and react at 30-40°C for 30 minutes, and obtain fluorotitanic acid solution after solid-liquid separation;

[0044] (2) adding concentration to the fluorotitanic acid solution obtained in step (1) is 30wt% NaOH solution, controlling the mol ratio of NaOH and silicon in the solution to be 1.5:1, stirring for 5h, solid-liquid separation after completion of the reaction, Obtain a fluorotitanic acid purification solution with a silicon element concentration of <100mg / L and an iron element concentration of <50mg / L;

[0045] (3) Adding a NaOH solution with a concentration of 30wt% to the fluorotitanic acid purification solution obtained in step (2), controlling the mol ratio of NaOH and titanium in the mixed solution to be 1.8:1, stir...

Embodiment 3

[0048] This embodiment provides a method for preparing high-purity sodium fluorotitanate, the method comprising the following steps:

[0049] (1) Add a NaOH solution with a concentration of 10wt% to the fluorotitanic acid solution, control the molar ratio of NaOH and silicon in the solution to 1.1:1, stir and react for 6 hours, and separate the solid and liquid after the reaction is completed to obtain a silicon element concentration < 100mg / L, fluorotitanic acid purification solution with iron concentration <50mg / L;

[0050] (2) Adding a NaOH solution with a concentration of 15wt% to the fluorotitanic acid purification solution obtained in step (1), controlling the mol ratio of NaOH and titanium in the mixed solution to be 1.6:1, stirring the mixed solution for 4 hours, and the reaction is completed After solid-liquid separation, sodium fluorotitanate crystals are obtained, and the obtained sodium fluorotitanate crystals are dried at 110° C. for more than 2 hours to obtain s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com